Words: Connal Grace Photos: Rixsta Sammons

The depths of Trade Me and Facebook Marketplace often present a deal for the diligent hunter. At times it’s like a minefield of projects where there has been one setback too many — someone’s pride and joy reduced to hopes and dreams — then just deadweight needing to be rid of. It’s something most of us will be familiar with. If you haven’t been through it, you’ll know someone who has. The thought never crossed Craig Taylor’s mind, even though he probably has had more reason than most to throw in the towel during the build of his epic HSV Clubsport R8.

It started not long after he got his dream car — this one, in fact. Once he’d done the mandatory wheel swap and over-the-radiator intake, he got bored and wanted more power. That’s how it always starts.

As Craig’s first son was due, he bit the bullet and squeezed in a cam, gilmer drive, and exhaust while he still had fun tickets to spare. Not long after, the clutch began to play up, so he moved to a Mantic twin-plate item. Then the gilmers started giving him grief. Seemingly getting this sorted would mean he could enjoy his dream car once again, but boys will be boys, and he eventually rooted the clutch after doing a New Year’s burnout.

Then he went on a holiday to Summernats. Since he intended to give the fuel system a once-over to future-proof it, he already had thoughts of mini-tubbing the rear end while he was at it, and seeing how the cars in Aussie are done set a chain of events in motion.

On the way back home, he stopped in at Rocket Industries where he picked up the fuel pumps and surge tanks, then came the hunt for a suitably tough rear end.

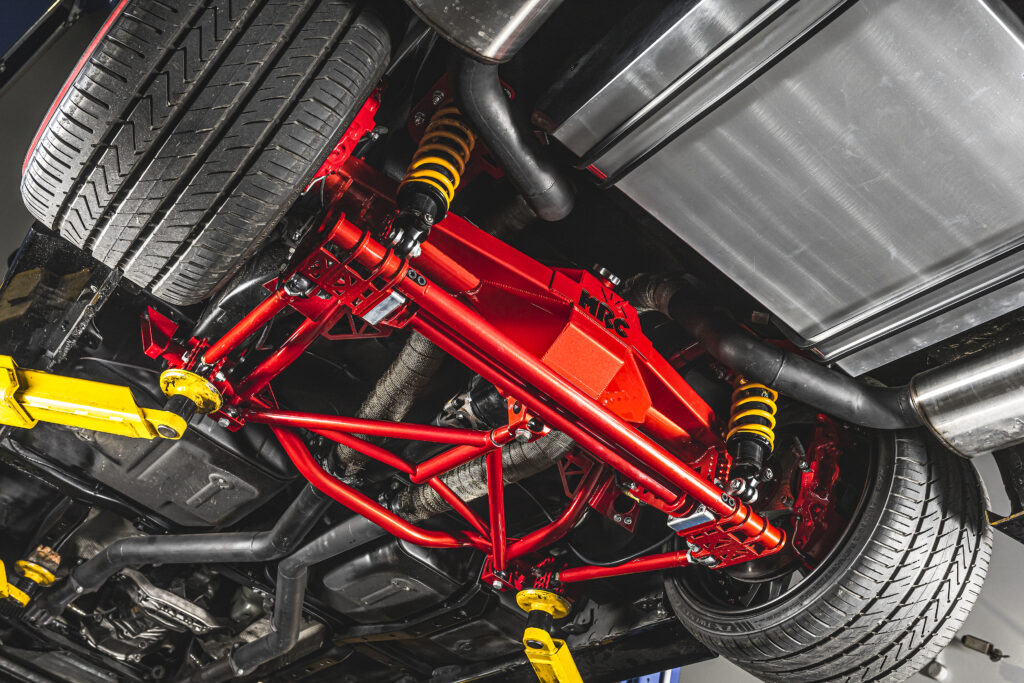

We’re talking nine-inch diff, four-link, and a whole lot of fabrication. The VZ passenger cars were only manufactured with an independent rear, so whatever he went with had to be able to be LVV certified, and that’s how Craig eventually got in touch with John at Monro Racecars in Australia, who offered a four-linked rear clip with full-floater nine-inch that Craig’s certifier was happy with.

“As I wanted to be different with this build, I had come across some VF GTS rear brakes for sale in Australia, which I bought and had sent to John,” Craig says. “However, Race Products had not fitted these brakes to their floater hubs at the time, but still made light work of making up what was needed for them to work.”

Things seemed to be going well, then the country went into lockdown. Luckily for Craig, he found Snedden Global Logistics, which managed to pick his gear up, ship it over, and deliver it to his workplace — “I couldn’t thank them enough!”

Then came the hard part. He had to find someone who could install this major piece of the puzzle and work alongside the LVVTA’s requirements for a complete redesign of the rear end.

He found a place, then his certifier stopped answering the phone. Eventually, he found someone happy to help with the many different aspects required to complete the work to a street-legal standard, and the cutting and welding began. “A couple of weeks in, I could finally start to see what my dream was going to look like,” he recalls.

The ride height was set, tubs completed, and a new boot floor made up to suit the fuel cell. This rendered the factory filler obsolete, so it was shaved. As the imperative was for it to remain street legal, it couldn’t just be a ‘weld it all in and go’ type of deal. Finer details like the factory ABS still had to work, and that’s a lot easier said than done.

“At this stage, I couldn’t find anyone to help make the ABS work with the floater hubs, let alone anyone actually committing to it,” Craig despairs — one of a handful of major issues needing to be resolved.

He had heard of Jase at Performance Industry in Palmerston North, and after attending Aussie Assault at Taupo and learning that a few of his mates at the track had had work done by him, and all had positive things to say, Craig got in touch. “At this stage, based on my previous experiences, I had major trust issues with who worked on my car,” Craig explains. “Safe to say, it was a ruthless conversation, but Jase fully understood.”

Loading up the transporter trailer for the five-hour drive to Palmy, the Clubby was straight onto the hoist and the cards laid on the table.

“We had a game plan. The deal was that if I was happy with the first bit of work and the major problems that needed to be sorted, he was to continue and finish the whole car.”

The services of Dion from Prometheus Prototyping were promptly engaged, and a week later Craig was sent photos of the new ABS rings and brackets, which would now hold the rear calipers, ABS sensors, and relocated handbrake calipers — a set-up necessitated by the room required to run an ABS ring on each floater hub.

“I was blown away. Going from past experiences of people who didn’t want to help, or saying it may or may not work, to having a template to check whether everything would fit and work,” Craig says. Having the brackets CNC machined and LVVTA approved took a big piece out of the remaining to-do list

Addressing Craig’s age-old idler pulley issue, Jase found the tensioner wasn’t even lined up, and that was soon put to bed. Then came all-new fuel lines, and the Summernats-special surge tank and fuel pumps. “What a feeling it was to hear it fired up!” Things were finally beginning to go to plan.

Even though it was on a base tune, everything worked perfectly, and Craig finally got a taste of why he’d endured the myriad disappointments of the build.

At this stage, Jase and the Performance Industry team had more than fulfilled the terms of the initial deal, and Craig gave them free rein to bring it to the finish line. Jase’s go-to panelbeater, Callum Orr, quickly uncovered some sins from previous work. The front guards were munted from a half-pie roll job, and the rear quarter was warped from too much heat used in shaving the old filler cap. Two steps forward, one back.

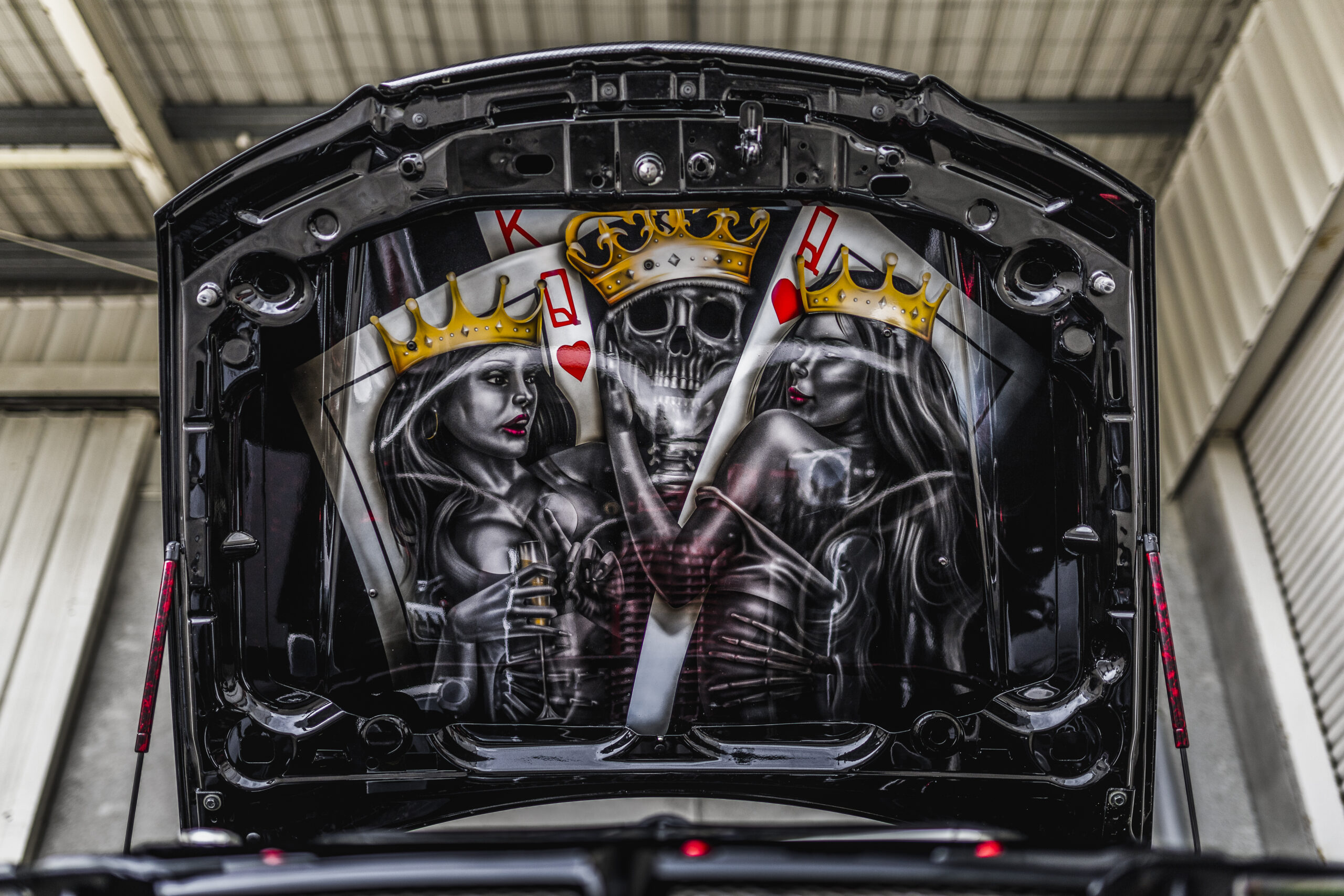

As the build had already gone too far — the decision to install new guards and a new rear quarter — when Craig next made a visit, the HSV was closer than ever to being complete. By the time it was ready for paint, he had a few ideas in mind. “Unfortunately, fixing mistakes from others had left my bank account rather empty, but I was pretty happy to stay with the factory black paint.”

They say a project is never finished, but by the time Precision Auto Painters had laid down the sleek Glasurit paint, it felt pretty damn close. Craig and Jase both agreed there had to be a goalpost, and settled on AutoFest in September.

Two weeks out, it was at full throttle on the finishing details, and a holy-shit moment when Craig finally got to drive it … and reunite with the LS engine’s old belt problem. “With just a week to spare, I was wondering if we would actually make it,” Craig recounts. “Jase worked his magic, talked with Harrop, and a bunch of new parts arrived to finally resolve the problem.

“Rolling through the gates was an awesome feeling, knowing this was the day everyone got to see my dream. When it came time to rip the covers off after a few hectic days and very little sleep, it was a priceless experience to have shared with my Dad, son, and the Performance Industry family.”

The best part — if it can get better than that — was driving away to the thumbs up and appreciation of onlookers, just in time to tick off a summer with friends and family. A monster build has finally ended, giving him a monster in the garage — just the way it should be.

_______________________________________________________________________________________________________

This article originally appeared in NZV8 issue 211