Words: Todd Wylie Photos: Deven Solanki

If you were into cars and growing up in Auckland in the ‘90s, there’s a good chance you would have spent some time down at Eastern Beach. The area was a well-known cruise destination for cars of all types, be they tubbed and blown V8s, ported rotaries, turbo fours, or anything in between. Some of the big names of the drag racing scene spent their early years down there, and that’s where Roger Talbot first became obsessed. At the time he was driving imports such as the now collectable Mazda DOHC turbos, but the exposure to the V8s that he saw down on The Parade soon had him yearning for a Holden.

Having grown up in a Holden family, he knew what he wanted, and ended up with a VH wearing VK front sheet metal and packing a decent 308 under the hood. Being young and carefree, he spent all he had on the car over the next few years sorting out the engine as well as looking after the body work. When the car was later stolen and found burnt out, he didn’t replace it, but the desire to own something else never left.

He tells us, “Years later after having supported a family member through cancer and my mum being ill with dementia, I realised that life is too short, and you have to make the most of the time we have. Live with no regrets and build the most epic car now because you can’t take it with you.” By this time he was living in the Far North and running a successful company, so the days of blowing every cent he had were over.

This time he could buy something and go all out on it straight away. What he found looked like an HG Holden, except, it wasn’t, it was a South African SS Kommando. He soon had it in with Steve and the team at Mike’s Engines for a cammed 383, 5-speed Tremec and 9-inch rear, but before the build was even finished, he was already thinking of the next one.

“Every now and then I would call in and see Steve and throw some thoughts around.

One day on such a visit I mentioned that I was thinking about a twin turbo LS but that was about as far as it had gone. About 6 months later Steve called and said he had such a LS1 motor that he had already started on to build as a turbo, and things had changed and did I want first option on it? That wasn’t a hard decision to make. Now I had to find a body to put it in.”

Obviously the Kommando was then sold on [and later appeared in NZV8 Issue 200 in the hands of Charlie Bailey]. Roger knew he wanted a truck, preferably a fleetside and with that thought a rough plan began to evolve into a well planned-out concept.

It wasn’t all smooth sailing finding the right starting point though, having paid a deposit on a long bed C10 before getting stuffed around by the seller. While this was going on, a patina-finished Apache popped up, and he couldn’t get down to Auckland quick enough to check it out. Although it may have had a bit of rust, it more than made up for it with character, and Roger knew it was the perfect base to build the ultimate pickup from.

A couple of weeks later he and his daughter Danielle, along with Steve from Mike’s Engines, were dragging it back north straight to Steve’s workshop to start the build. The brief to Mike’s Engines was clear: it needed to be slammed on bags, retain the patina look, and, of course, end up with that LS engine in it complete with a couple of turbos. Oh, and it must produce 1000hp for good measure.

Right as Steve and the team started getting into the build, lockdown kicked in, which significantly hampered progress. Once free from the madness though, the chassis was started on, as there was plenty of work that needed to be done. With all the original suspension components removed, the crew mounted the bare rails to a frame and began fabricating a Z-notched front end and C-notched rear. A Heidts clip was grafted in to take care of front suspension and steering duties and the rails boxed from front to rear. With the boxing in place, a triangulated 4-link was added and set up with Ridetech ShockWaves. The front end was treated to a similar ShockWave set-up, which required a modification to the lower arms as well as custom fabricated top arms.

In preparation for the 1000hp motor package, Roger went all out on both the brakes and the diff. The former being looked after by Wilwood 13-inch front rotors and 6 piston calipers up front along with 11-inch rotors and matching 4 piston calipers on the rear. That rear set-up is fitted to a Krysler Shop 9-inch diff housing filled with a Strange head, Truetrac centre and Dutchman 31 spline axles.

With the fab work done, the body was sent to Greg at Greg Smith Engineering and Western Blasters to be fully sandblasted, then painted gloss black. Once coated and before the body could be put back on all the plumbing was completed for the AccuAir eLevel system along with the brakes and fuel system.

Simultaneously, the body was sent to Jordan at Whangarei Autobody to tidy up the rust work. Sadly, one of the doors was a bit too far gone to be saved, and to make matters worse the replacement arrived from the States with a dent in the top of it. Given that he was after a beater look though, the decision was made to leave the dent in place, as it added to the character. Of course, matching patina is never easy, but the team at Compas Kustoms are used to working on out-of-the-box jobs, so set about matching the natural aged look perfectly.

While the outside of the cab is well aged, there’s plenty of sheet metal work that has gone into the underbonnet side of things, such as custom inner guards and a recessed firewall. Of course, there’s no shortage of fab work that has gone into the engine set-up itself either. Being engine builders and reconditioners first and foremost, the team at Mike’s Engines have built the LS1 with new components throughout to ensure it would be happy with the desired power figures. The block itself has been half grouted for strength before being filled with forged pistons, H-beam rods and a prepped crank.

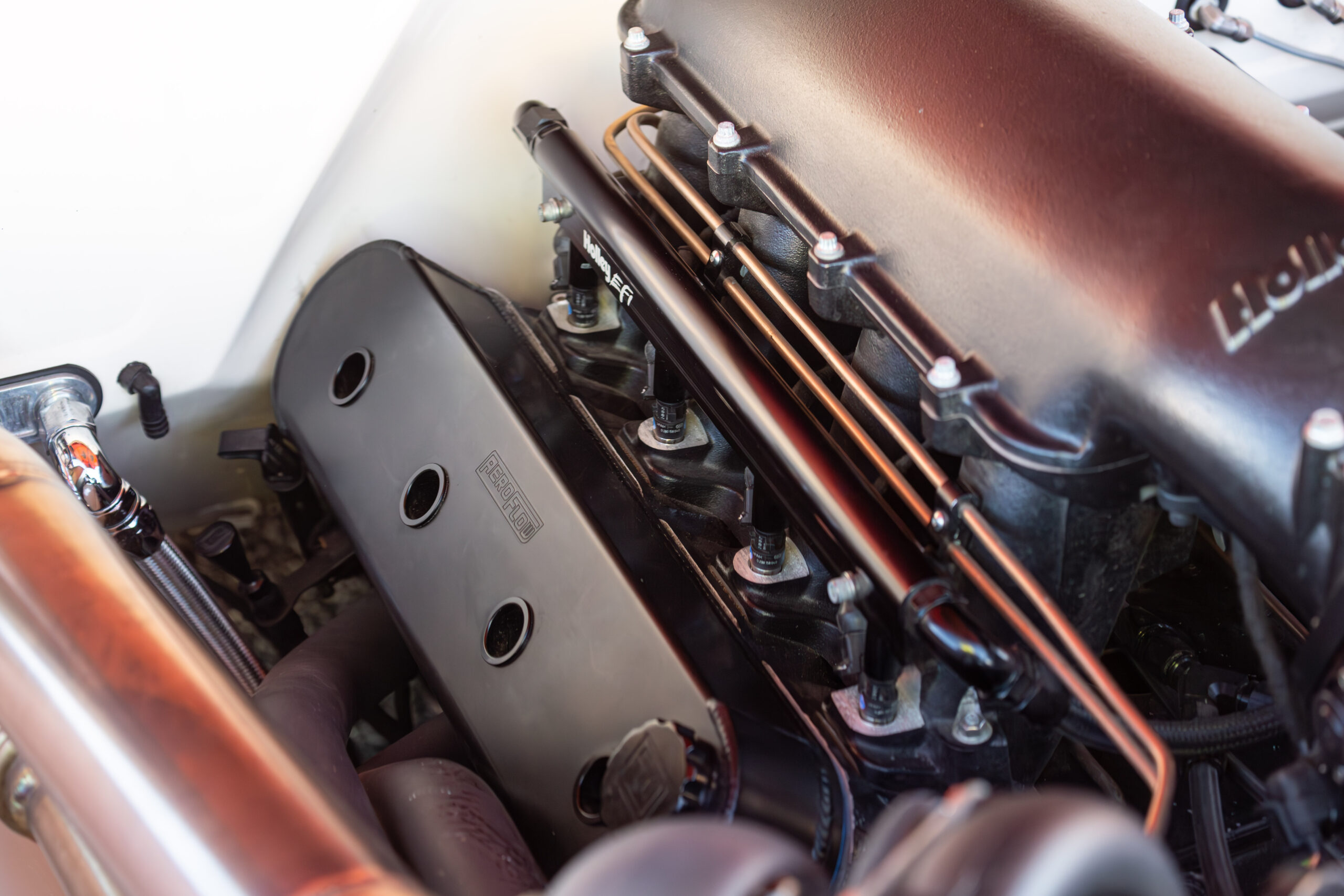

LS engines respond well to simple mods, and Mike’s know all the tricks, like adding LS7 lifters along with a turbo-friendly camshaft from the team at Kelford Cams. ARP fasteners have been used throughout, including for the head studs, which clamp MSLR steel head gaskets. While that stuff is all well and good for reliability, the fun stuff is on the outside, like the pair of mirror image Aeroflow Boosted 6662 turbos. A Link Thunder ECU calls the shots while twin 44mm external wastegates manage how much boost makes it into the Holley Hi-Ram intake manifold. The transmission that backs up this tough combo is a 4l80E built by Advanced Automatics with a custom converter controlled by a Quick 4 controller. Looking at the perfect finish under the hood, it’s almost hard to comprehend it’s all hiding within a patina-covered body. Of course there are a few hints from the outside though, that the truck has had some serious hours spent on it.

Like the engine bay, the interior is also in strong contrast with the exterior. Everything within the cab is custom right down to the picnic blanket that has been created from the same retro-inspired material that the seats have been trimmed in. Snowden Custom Seats in Fort Worth Texas supplied the unique seats as a nod to Roger’s wife’s Scottish heritage. The seats helped set the scene for the rest of the interior, which now also wear gauges from Dakota Digital along with switches from So-Cal switches, Ididit tilt column and a steering wheel from Forever Sharp.

Brian Clancey at Precision Interiors also had a large part to play, retrimming the remaining soft bits to match.

While a lot of the custom parts in the interior came from the land of stars and stripes, the wheels came out of Showwheels in Australia. Chris who runs the show over there is a Kiwi and understood Roger’s brief completely. The result is a stunning custom set of 22×8.5-inch and 22×12-inch rollers built to have as much dish as possible and painted in bronze to be as close to the rusty patina colour as possible.

With a ride height that sees the chassis hit the deck, and the giant wheels, there’s not a whole lot of tray depth left, but what the tray may lack in capacity it certainly makes up for with style. After searching everywhere for the right type of timber for the bed, Roger came across a company called NZ Native Riverwood. The company specialises in scuba diving in local rivers to pull up logs that were lost when Northland was being forested hundreds of years ago. They had the perfect timber for the build — river-sourced Totara. Hiding below the Totara-lined bed is a pull-out tray for added storage as well as a locker for the battery and air tank set-up to reside.

Throughout the build Roger would try to call in to check up on progress as often as possible, enabling him to start prepping and purchasing parts for the next step. Finally, in late December 2022, the finished product could be taken home for the very first time. Roger tells us he couldn’t be happier with how it’s turned out, and how the truck drives and handles like a new car on steroids. “I can’t get enough of driving it as it has turned out just like the picture I had at the beginning. I owe a huge thanks to all involved in creating it”. So although his own car journey started with him looking up to the guys with all the cool cars at Eastern Beach, the tables have now well and truly turned, as we’re sure Roger and the truck will be inspiring generations to come wherever he goes.

_______________________________________________________________________________________________________

This article originally appeared in NZV8 issue 218