Words: Todd Wylie Photos: Glen McNamara

You could fill an entire book with the colourful language used during the build of this gorgeous ‘66 GTO. While there are builds that seem to constantly fight their owner – and this was certainly one – there are also builds that make their owner in the process. Despite how it may seem to those of us who have followed the build of the car for the last nine years, its owner Darryl Ingham assures us he’s not actually a fan of recreational Russian Roulette and that he does in fact like money, despite the amount he has poured into the GTO. But he’s certainly run the gauntlet to get the car through to where it is now. As he says, “I probably let this car go into such an extensive re-birth because of what I had been through with the car: weddings, divorce, deaths, births .. It was more than just a car. And it wasn’t your typical type of car you see at every car event anyway, so I almost felt like I owed it to it … Fucking thing.”

He’s actually owned the car for 14 years now, and we even featured it way back in Issue No. 86, although the only things remaining of the car since then are really one sill, the boot lid and grille panel. The rest has all since been replaced, although that wasn’t quite the plan from the outset.

Having almost lost the car as part of a divorce settlement, which brought plenty of mental health issues with it, Darryl was determined that both he and the car would bounce back better than ever – and they certainly have! He takes over the story: “I was always keen on the car being a weekend warrior at the drag strip, but I knew for the car to be competitive, it would need a few minor upgrades.”

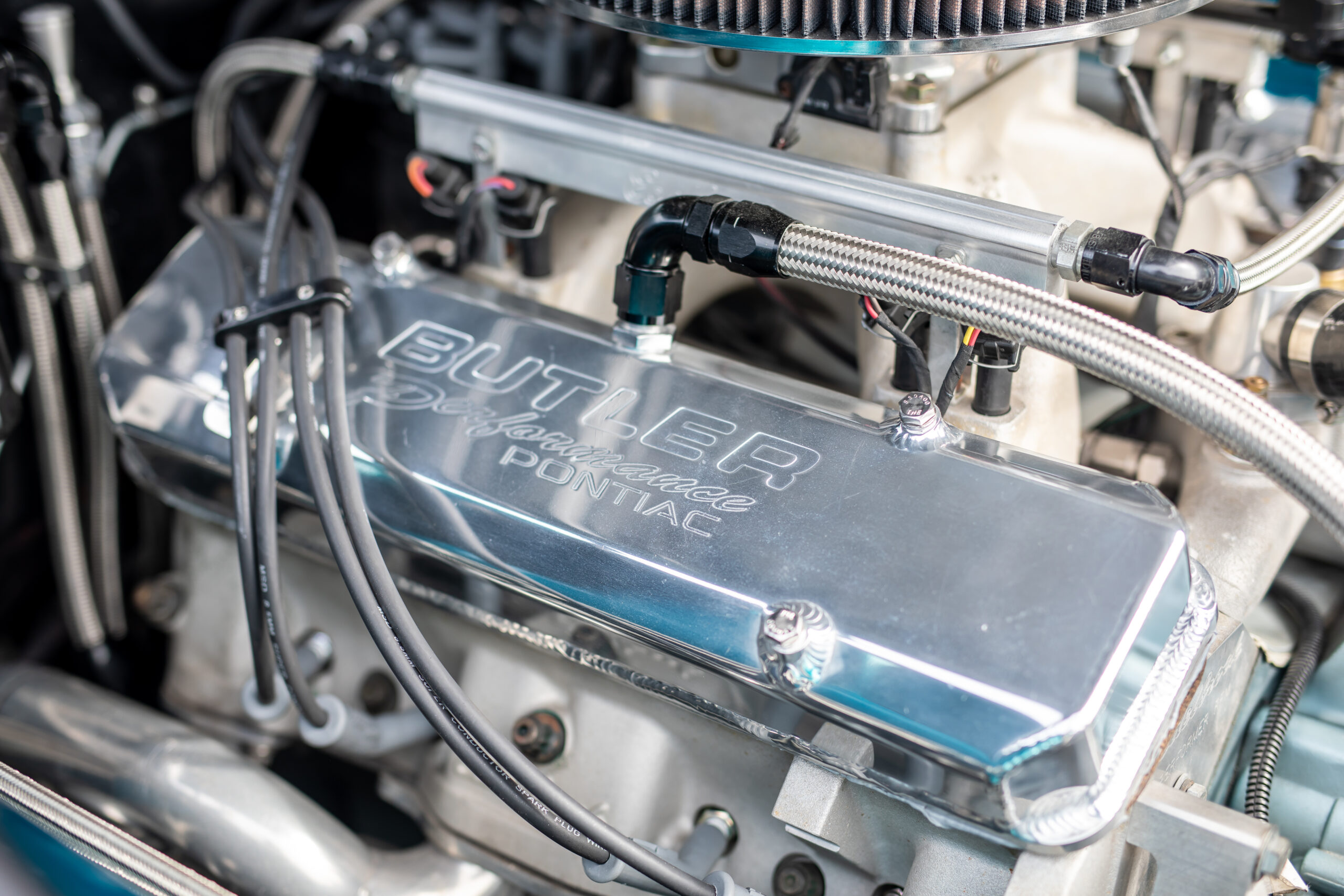

Those first upgrades were largely focused on the engine department, but rather than mess about with the car’s original numbers-matching motor he had different ideas. “.. they are becoming harder to find in their original condition and I would never have forgiven myself if I had wrecked it, so a custom Pontiac engine was chosen.” Never one to shy away from having a laugh at himself (and anyone who knows Darryl is well aware of just how unique that laugh can be), he’s well aware that normal people with commonsense would have picked a much more cost-effective and readily available big block Chev engine option. Darryl, though, is neither a normal nor sensible person, well, when it comes to this car at least. “I wanted to keep it Pontiac to show they can be competitive, keeping in with the branding and as a point of difference.”

Having spoken with several engine builders overseas, he found Butler Performance to be the most approachable and helpful so he started doing a few reference checks. “Everything you read about Butler’s engines has considerable respect and holds them in the highest regard. In my opinion, they are the ultimate Pontiac engine builder. When you ring them, Jim Butler talks to you about what it was like drag racing in the ’60s and all the famous people he rubbed shoulders with in the industry. His sons Rodney and David run the company now.”

Having spoken to Butlers about what he was looking for, he settled on a 535ci package based on an Indian Adventures II (IA 2) block. For those not fluent in Pontiac, which, let’s face it, is all of us, Darryl tells us that’s the equivalent of a Dart block, but of course being obscure, it was a whole lot more expensive. That description sets the scene for the whole engine: think high end, but oddball, and you soon start to see why an off-the-shelf big block Chev would have been the smart man’s choice.

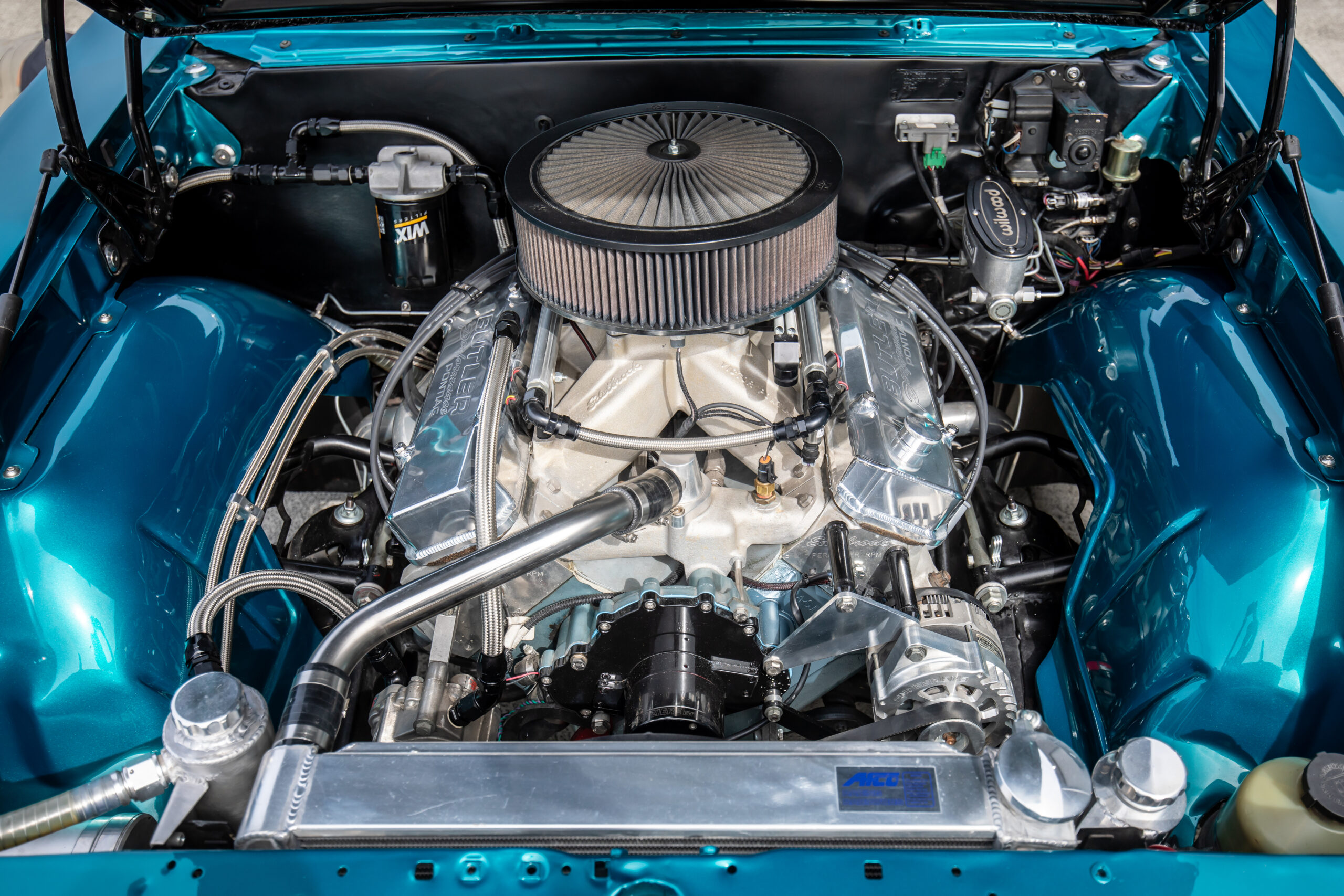

That big price tag bought a block with splayed billet 4-bolt caps that support an Eagle forged crank along with Eagle rods and Ross forged pistons. ARP fasteners have also been used top to bottom, including to secure the CNC ported Edelbrock Performer RPM Wideport 87cc heads. Wanting the engine to be tough but (debatably) streetable, the setup runs a Butler Performance custom solid roller cam with specs that read .742 / .706 lift at 0.50 and 284/292 duration. Taking instructions from the bumpstick are 2.25-inch intake and 1.74-inch exhaust valves operating in conjunction with T&D offset shaft roller rockers. As you’d expect, the fuel, ignition and cooling systems are all just as impressive, even if Darryl does curse himself for doing multiple parts of the build multiple times, fuel system included. Now that the car is finished, the high octane pump gas is stored in a custom fuel cell that hides a Holley 450 in-tank fuel pump. The ignition system was taken care of by Butler Performance and includes MSD everything; Pro Billet distributor, leads and ignition box. With an engine as performance oriented as this, the cooling is always important, and is why he opted for a Meziere electric water pump, Affco twin-pass radiator and a big-arse fan. That’s all walk in the park stuff though compared to the intake and EFI system. It all starts with an Edelbrock Victor EFI manifold fitted with a billet 4150 throttle body and eight 60lb/hr injectors. The whole lot is controlled by a FAST XFI ECU tuned to produce an impressive 815hp at 6500rpm and 686ft/Ib at 5800rpm, more than enough to meet Darryl’s goal of having a tough streeter, with the ability to fry the rear hides in any gear whenever he feels like it.

To back up that engine combo, Darryl had Chuck Mann work his magic on a TH400 transmission fitting it with a carbon fibre scatter shield, manual valve body along with race-spec clutches and bands. He even went as far as fitting a low reverse roller clutch, heavy duty bearing set and paired it with a Coan 9-inch custom stall converter for good measure.

A good mate and fellow Pontiac owner, Larry Kerridge, took care of dropping the engine in the hole and getting it running, but once it was drivable it was moved on to Mike Bari at NXT LVL Automotive. “Like Larry, Mike’s another clever bastard,” states Darryl, and he’s right. Like Darryl, Mike’s fussy beyond belief, so his role of getting the car properly sorted soon expanded to a much larger task than anyone expected. While under the car to sort out the custom headers and exhaust system, Mike started to inspect the previously back-halved chassis. What he found wasn’t good. In fact, it was ungood and there was no way it was going to be capable of handling the power from the big cube Ponti motor. While a plan was being formulated on how to address that rather large issue, Mike carried on with all the other jobs on his list of stuff to do. That included changing out the power steering to an electric pump along with setting up the braking system, but more on that later.

The more the rear end was looked at, the bigger the job got, as not only did the suspension need changing, but the rear chassis rails also needed replacing. With Mike needing to focus on other customer projects, Darryl was introduced to Chopper from Chopper’s Body Shop. Chopper is one of those guys who can’t be spoken highly enough of. Don’t let the body shop name fool you, as Chopper’s is much much more than that. After looking at what it would take to create new chassis rails, discussions led to importing a set that were already mandrel bent.

Darryl tells us, “Speaking to the usual overseas aftermarket chassis suppliers was proving difficult as they weren’t being helpful, especially in the post covid climate. They were actually bordering on arrogance .. Chopper’s infinite list of contacts led us to MacDonald Brothers Racing in Australia, who happen to fabricate mandrel-formed chassis rails, sheet metal 9-inch diffs, wishbones, chromoly link bars and brackets – and it was right across the ditch. Right product, the right price, quick freight. They are too easy and great people to deal with.”

Knowing the rear quarters on the car could also do with a bit of work, Darryl suggested to Chopper to give them a tidy up while grafting the new rear clip in. A quick look, and that was never going to work. Although Chopper and his team have the skills required, looking at the time it would take to fabricate them, replacing them with completely new sheet metal was a more cost effective option. Except… well, true to form for this build, even that wasn’t going to be quite that straightforward. As Darryl recounts, “The problem is that the complete ‘66 rear quarter panels are no longer available anywhere. The only way around it is to use ‘67 quarters and modify the ends to match the different shape of a ‘66. I did plenty of homework and found articles from various sheet metal workers and panel beaters who had done the same modification. Chopper’s body language was saying, ‘I don’t want to f**king do this…’ so he thought about it while dealing with the chassis. But when he did it, the result was nothing short of outstanding.”

One thing soon led to another, as the car was clearly going to need a repaint, so it seemed the right time to peel off the factory vinyl roof and cross your fingers that everything underneath was okay. Of course it’s not hard to guess what that led to, and soon enough the car needed a new roof skin too. Working their way forward, stripping back the paint soon revealed the doors and front guards were equally as pitted underneath. Long story short, there aren’t many panels or exterior parts that haven’t been replaced.

Darryl’s view on the whole ordeal is quite philosophical. “When you go through a process as intensive as this, communication and rapport with the fabricator are essential when throwing ideas around. Trust their knowledge and expertise.” That’s a good summary of where things are at and a credit to the way that Chopper works.

With the new rear chassis rails came a braced 9-inch sheet metal diff housing along with custom 4-link suspension arms, which Chopper soon had assembled and installed. The exquisitely made piece truly is a work of art. If you ever see the car in the flesh, have a peek under its skirt; the underneath is just as good as the outside.

Later on in the piece these would be matched with QA1 coilovers to bring the ride height down, so far down in fact, that even if the car just looked at a blemish on the road it would scrape at the thought of it, so a new two-piece driveshaft was required, and the already ceramic-coated exhaust system needed to be cut and modified once more. But at least the car has the right amount of low now. Up front the ride height was balanced out with UMI control arms and similar QA1 coilovers.

Once the car was rolling and the body had been metal finished, it was dropped down the road to Charlie’s Custom Paint & Pinstriping, where Chaz and team would perform the finishing work before paint. “This guy is just as pedantic as Chopper .. To anyone who hasn’t seen Charlie’s work, I highly recommend you go on social media and check out his mirror-like finishes – and the GTO is no exception. The colour is so deep in the sun that the whole car looks like a precious gem.” While leading up to this point, there had been endless banter with mates about what colour to paint it, and plenty of pressure to go with a funky shade of brown. Darryl was adamant it would look like shit, and well, he was kinda right (but don’t tell him that). Instead what he wanted was a teal look, and with a bit of playing around with custom formulas, that’s what Chaz created. There are countless hours in the paintwork, including giving the engine bay and interior a satin finish. The unenviable part of getting all the trim back on without scratching it was up to Chopper and his crew, which, of course, they did with ease. Helping with that aspect is that plenty of the trim was brand new too, including the custom made rear quarter badges that give the game away that there’s something a little bit special lurking under the hood.

Throughout the paint and bodywork stage, Darryl was tossing around ideas for wheels, again receiving plenty of unhelpful suggestions from those who shall remain nameless. Clearly they had to suit the modern pro-street look, but choosing the right set was an agonising decision. In the end he opted for 17 x 4.5-inch and 15×14-inch Custom RC Components wheels – little did he know that getting tyres to fit those narrow fronts wasn’t going to be a simple task. Thankfully the 31×16.5×15 Hoosier Pro Street rears were a touch easier to source. Behind these is the braking setup taken care of by Mike at NXT LVL Automotive, which consists of Wilwood 4-pot calipers on each end operated by a Wilwood master cylinder.

To say that Darryl has been to hell and back with the build is akin to saying a boxing match is a professional cuddling event. It’s somewhat fitting that the Pontiac brand was named after American Indians, and the car has been christened Cochise after one of the greatest Indian warriors. Just like the real Cochise, the car has battled over adversity and stands out amongst its peers for its muscular build, power and bravery – and it too will go down in the history books for being fierce and undefeated. The build has been a battle, but the battle is over, and it’s been a lesson in how to fail spectacularly!

_______________________________________________________________________________________________________

This article originally appeared in NZV8 issue 221

SPEC LIST

Vehicle: 1966 Pontiac GTO

Engine: 535ci Pontiac, Indian Adventures II (IA 2) block, splayed billet 4-bolt caps, aluminium o’ring screw in frost plugs, Eagle H-beam rods, Ross forged pistons, Eagle forged crank, ARP fasteners, Crower custom high-seat offset solid roller lifters, Iwis Pro Billet double roller timing chain, Canton oil pan and pick up, Cometic gaskets, Powerbond damper, BPI Sportsman billet vacuum pump, MSD ignition, MSD Pro Billet distributor, MSD leads, Meziere electric water pump, Accusump, Butler Performance custom solid roller cam – .742 / .706 lift @0.50 284/292, CNC ported Edelbrock Performer RPM Wideport 87cc heads, 2.25-inch and 1.74-inch stainless steel Ferrera valves, Comp Cams springs, Comp Cams locks and titanium retainers, T&D offset shaft roller rockers, Edelbrock Victor EFI, billet 4150 throttle body, BP FAST XFI sequential EFI, 60lb/hr injectors, custom stainless fuel cell, Holley 450 fuel pump, custom headers, 3-inch exhaust, Glasspak mufflers, custom Afco twin-pass radiator

Driveline: TH400 transmission, carbon fibre scatter shield, manual valve body, race clutches and bands, low reverse roller clutch, heavy duty bearing set, Coan 9-inch Maximum Performance custom stall converter, CNC machined billet aluminium stator, super sprag, Pontiac ATI SFI flexplate, Yukon Grizzly Aluminium through-bolt 9-inch diff centre, MacDonald Brothers 9-inch sheet metal diff housing with a back brace, Motive Performance 4.3:1 gears, 35 spline Moser axles, custom two-piece driveshaft

Suspension: UMI control arms, electric power steering pump, MacDonald Brothers custom 4-link, QA1 coilovers, Competition Engineering sway bar, custom panhard bar

Brakes: Wilwood master cylinder, Wilwood 4 pot calipers, Wilwood discs

Wheels/Tyres: 17 x 4.5-inch and 15×14-inch Custom RC Components wheels,

26x6R17 Mickey Thompson Sr front tyres, 31×16.5×15 Hoosier Pro Street radials

Exterior: Modified ‘67 rear quarters, custom tubs, custom rear floor, custom 3D printed fender badges, custom Debeer products GM teal paint, satin clear interior

Chassis: MacDonald Brothers Racing mandrel-formed rear chassis rails

Interior: Sparco Evo seats, custom roll cage with swingout door bars, Pontiac Sportswood steering wheel, TCI Outlaw shifter, FAST digital display

Performance: 815 hp at 6500rpm, 686ft/Ib at 5800rpm

Driver: Darryl Ingham

Age: Really bloody old

Occupation: Company Director

Previously owned cars: XY Fairmont, XA GT Falcon, ‘70 RT Dodge Charger, ‘69 Mach 1 Mustang, ‘70 Ranchero GT, ‘91 Buick Roadmaster Estate Wagon, C5 Corvette, ‘70 Buick GSX

Dream car: Don’t have a single dream car. I’d have a fleet of dream cars

Why the GTO?: It was unique/different to everything else while still being a sexy shape.

NZV8 mag had a significant influence on me and a lot of other people. The Pro Street scene was coming out of the closet, and Todd opened the door

Build time: 9 years this time around

Length of ownership: 14 years

Darryl thanks: Mike Bari at NXT LVL Automotive, Chopper at Chopper’s Auto Body Shop, Charlie’s Custom Paint and Pinstriping, Larry, Paul, Steve, Todd, Shane, Matt, the bloke at Glen Eden Auto Electrical, the blokes at Lincoln Tyres, Andy at Musclecars Universe