Words: Turnkey Industries Photos: Rod Dunn

The irony is not lost on Gary Morton that despite being regarded as the foremost wire wheel maker in the world, his own car does not run wire wheels. But while it may not have the wheels, his world-renowned attention to detail and fabrication abilities are present throughout the build. Mind you, he’s owned the 1941 Chrysler Businessman’s Coupe for 28 years, so you’d also hope it was pretty damn good. That’s not to say the car took that long to build, but it was spread out over that time period due to various other aspects of life getting in the way. Gary thinks in reality it took about four years of actual work and, given that almost all of it was performed at home, even that’s not bad going.

Purchased off eBay back before buying cars off the internet from abroad was really a thing, Gary took a big punt, but it was well worth it, as even though it was rare then, it’s even rarer now. Mind you, even if they were common, chances are there still wouldn’t be any others customised the same as this. Being a self-described old school hot rodder, he had a plan for the build right from the outset — to use some traditional rodding components, but with a bit of a twist. While many rodders use Jaguar suspension from 1970s or 1980s models, Gary ended up using the components from a 2001 Jag XK8. This all came about in 2002 after he was commissioned to buy the XK8 out of Japan as a damaged vehicle to put the running gear into a Jag MKII. While doing this, he realised the wheel track would be right for the Chrysler, and as the parts weren’t needed for the customer car, they were up for grabs. With the donor car having travelled just 6000km from new, it was as good as using brand new parts, making the swap even more appealing.

Understandably, the Frankenstein project of grafting in the Jag gear required custom box section chassis rails to be fabricated and a cross brace added, for which Gary used 50x100mm box. As we know, the key feature of the Jaguar suspension assemblies is how they are self-contained beside the front shock mounts, so mounting the Jag front, complete with steering rack and brake assembly, was fairly straight forward. It did come with one catch, and that was that the donor was right-hand drive, so rather than change this to suit the left-hand drive configuration of the body, he decided to convert the car to suit instead. Before he could get into that side of things, the chassis needed completing though, including mounting the Jag’s rear end, which like the front was all inclusive including diff, axles, brakes, and suspension.

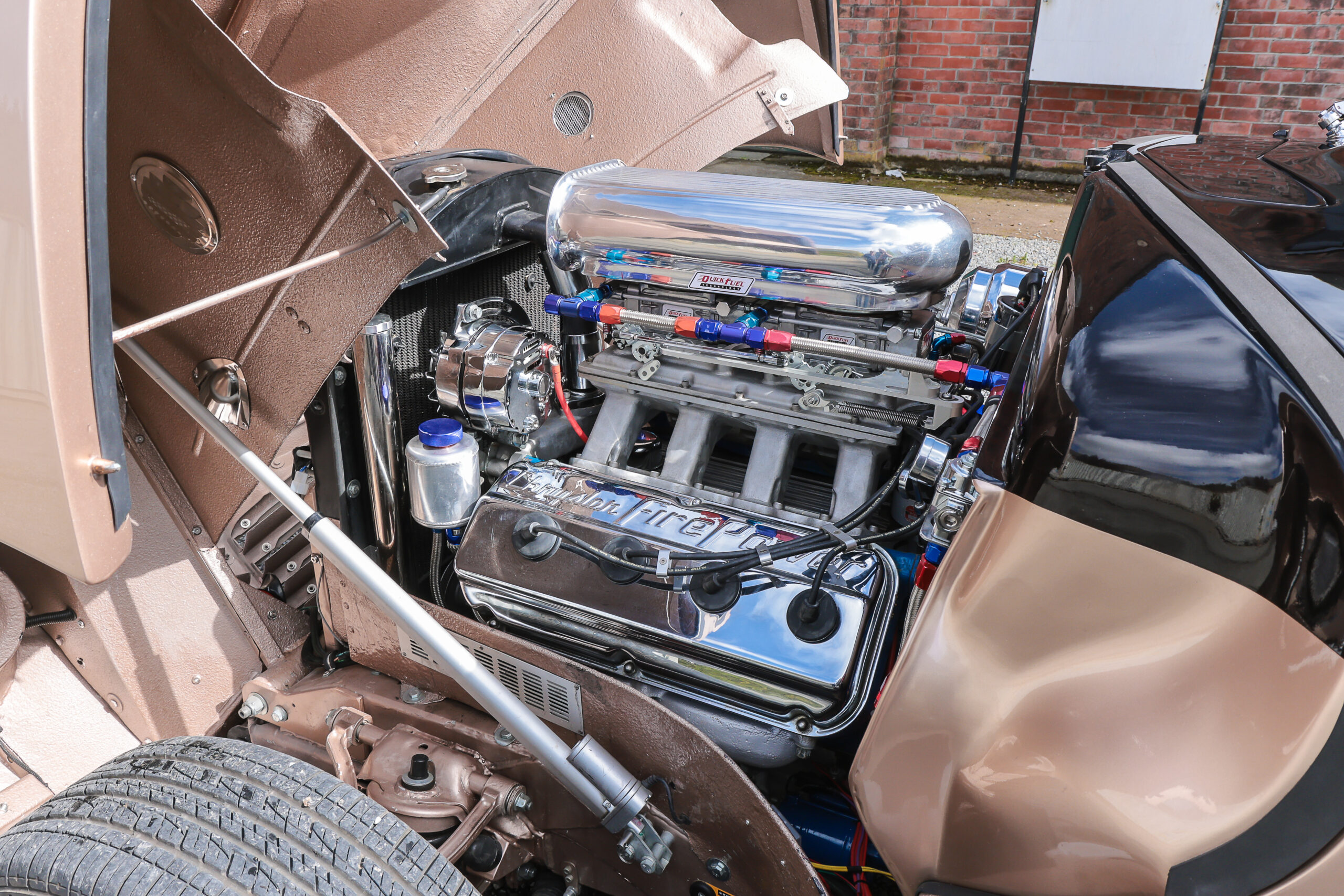

Before the body could come near the chassis again, Gary wisely decided to mount the new engine and drivetrain. While the factory fitted straight six may have been okay back in 1941, he knew a real hot rod needed a Hemi. The one he managed to get his hands on was a 354ci version from a 1956 Chrysler New Yorker. Rather than using the Chrysler transmission, he decided to fabricate an adaptor to attach something a bit more suitable. Some people may ask why bother, but the Powerflite transmission of these early Hemis aren’t known for their longevity, nor ease of repair, so the change to a tried and tested TH400 was a very wise one. With these components in place, Gary shifted his attention to all the finishing touches, like building a 2¼-inch exhaust system, running the new brake lines, and building a 3-inch driveshaft.

With the chassis back rolling again, the body could be remounted to it. While that may sound like a couple of bolts, sadly that wasn’t quite the case. The floor of the car was rusty, and the firewall no better, so Gary set about fabricating replacements. During this process he mounted an 8.5-inch dual diaphragm brake booster and Wilwood master cylinder and mounting points for the fuel system the components required. The reason for these components is that the Hemi is not left stock, as Gary stripped it down and rebuilt it for greater power with Ross 10:1 forged pistons. Externally, he ditched the restrictive original carb and manifold in favour of a custom tunnel ram and a pair of 450cfm Quick Fuel carbs. While it’s never been on a dyno, it’s easy to establish that it makes much more power than it did in factory form. His fabrication work under the hood didn’t end there as he next turned his attention to building his own radiator, a job not for the faint hearted.

Clearly not being shy of undertaking his own fabrication work, it should come as no surprise that he was happy to build his own right-hand-drive dashboard. Utilising the Jag’s donated steering column and central air vents, he built everything around them before adding a swag of VDO gauges and a touch screen head unit. Will Sales was called upon for the upholstery work which included recovering the Jaguar-sourced seats as well as every other surface. What couldn’t be covered was painted by Rob Duff, who also took care of painting the exterior. The top colour of the two-tone hue that Gary chose may look black, but when the right light hits it’s very clearly a dark chocolate brown with a gold pearl.

The exact blend was custom mixed for the car, as was the main colour that now adorns the car’s body. With the cars being so rare, it takes a true trainspotter to pick out all the modifications that have been made before any colour was sprayed. Take the lights for example — both front and rear sets have been frenched into the body and the bumpers have been removed along with creating custom exhaust outlets. The grille is also a custom piece, fabricated by Gary to look almost factory, while the tilt front it attaches to is most definitely not stock. As part of the process of building the tilt front, Gary adapted a remote control system, something he thought of while lying in a hospital bed that utilised a similar system. You can imagine the surprise on people’s faces when he operates it from as far as 50 metres away.

After various life changes along the way, Gary got stuck in and has spent the past few years determined to get the car completed. It was finally on the road and legal just before the 2023 Kaikoura Hop, and the hard work was rewarded when the car was selected as one of the Top 10 cars at the event. From there on it’s been trouble-free motoring — Gary and partner Fiona are getting the car out every chance they get. Afterall, he’s got over 20 years of missed cruising to catch up on!

_______________________________________________________________________________________________________

This article originally appeared in NZV8 issue 219

SPEC LIST

Vehicle: 1941 Chrysler Royal Business Coupe

Engine: 354ci Chrysler Hemi, Ross 10:1 forged pistons, custom tunnel ram, 2x450cfm Quick Fuel carbs, 2¼-inch exhaust, custom made radiator

Drivetrain: TH400 transmission, shift kit, custom adaptor plate, Jaguar XK8 diff, custom driveshaft, 2001 Jaguar XK8 front end, Koni shocks, Jaguar rear end

Brakes: 8.5-inch dual diaphragm booster, 1-inch Wilwood master cylinder, Jag discs and callipers

Wheels: 17×6-inch and 17×10-inch Ridler wheels

Exterior: Welded rear fenders, custom roll pan, recessed number plate, recessed tail lights, tilt front, frenched headlights, custom grille, custom paint

Chassis: Custom front clip, custom crossmembers

Interior: Jaguar X300 seats, aftermarket steering wheel, VDO gauges, custom fibreglass dashboard, touch screen head unit

Performance: Untested

Driver: Gary Morton

Car Club: East Coast Rodders

Age: 69…. 70 now 28 Oct

Occupation: Wheelwright

Previously owned cars: Lots

Dream car: Got it

Why the Chrysler: It is so rare, I had to have it

Build time: 28 years (4-years full time)

Length of ownership: 28 years

Gary thanks: Will Sales, Rob Duff