Words: Todd Wylie Photos: Glen McNamara

Most of us have dream cars, right, even if they don’t instantly come to mind. Chances are if you’re pressed you’ll be able to think of at least one car that you’d really love to own. For Auckland’s Kevin Watkins, that was always a ’69 Dodge Charger. As any Mopar fan will tell you though, Chargers aren’t exactly thick on the ground. That scarcity is somewhat directly linked to what made them so popular to begin with — The Dukes of Hazzard, and Fast & Furious. According to the internet, which we know never lies, 26 Chargers were wrecked in the first Dukes movie, 325 in the TV series, and who knows how many were destroyed through the Fast & Furious franchise? Maybe it was due to this that while Kevin had always wanted to own a ’69, he’d essentially given up on that dream, thinking it was now all but impossible. That didn’t stop him from owning and building some nice cars, such as his ’53 Chev pick-up that we featured in our last issue, but none of those cars were Chargers, or Mopars of any variety.

Despite not really needing another car at the time, when he received a phone call from a friend asking him if he’d be interested in buying a ’70 Charger off him, Kevin didn’t stop to think for too long before saying yes. Unlike the countless Chargers that had been jumped, destroyed for big screen action, or generally abused, the car was a dead stock survivor. While the seller probably assumed it would stay that way, complete with faded light blue paint work and 383ci engine, Kevin had more than a few different ideas.

It took six months for those ideas to really formulate and gain momentum. Part of that time was spent finding the right people who could help with the vision he had. Being busy in his own job, he needed someone who was on the same page as him, someone he could give an overview of what he needed but not need to be on hand each and every day to answer all the small questions. That someone was Glen Jennett at Engine Specialties Ltd. Glen’s well known for his engine builds, with his name having graced these pages countless times related to everything from tough streeters to circuit cars, drag cars, and a handful of the country’s top burnout cars. But there’s more to the man and his business than just engine building, as he’s more than capable of project managing a full build, or parts thereof.

In this case, Kevin had him take care of the whole mechanical package — fitting, as it was the lack of performance from the original engine that was the key driver for the overhaul.

Rather than go for a completely new engine, Glen and Kevin discussed using the original numbers matching block, and throwing a bunch of modern know-how at it.

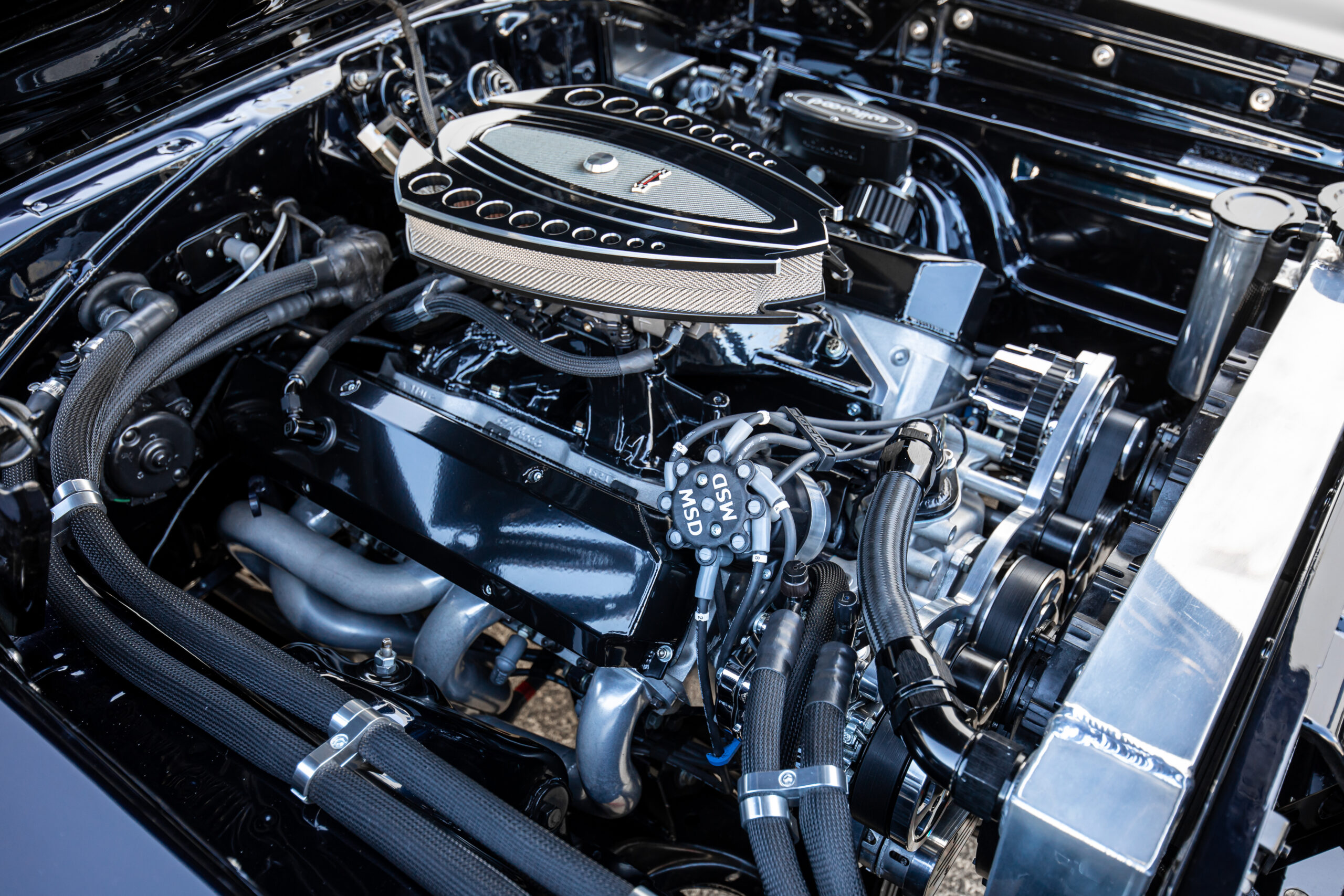

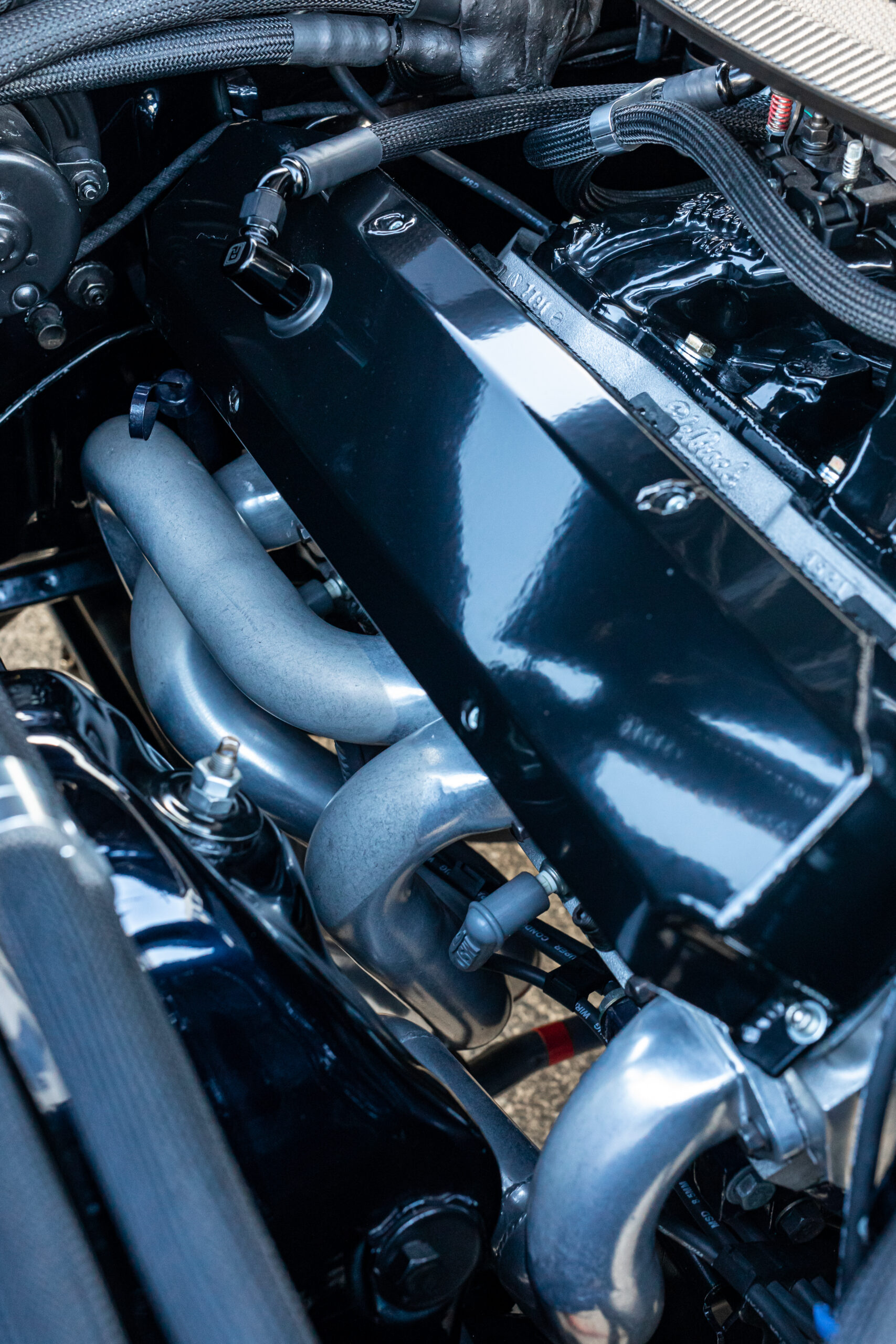

The first step was to replace the entire rotating assembly with a Scat forged crank, Scat H-beam rods, and JE forged pistons. The outcome of the new parts was a set-up that displaces an impressive 494ci, and with so much capacity to move air, the stock top end was never going to be refitted. The cast iron heads were donated for scrap and a set of new aluminium items sent in for surgery. Once ported and polished, Glen and his team filled them with stainless valves along with Comp Cams valve springs, Comp Cams retainers and keepers. A hydraulic roller cam and Morel lifters were selected to give the firing orders, while an Edelbrock single plane manifold, and 850cfm vacuum secondaries Quick Fuel carb were selected to control the airflow.

For the other side of the combustion equation, things were kept simple with the installation of a Bosch 044 fuel pump and a swathe of AN-8 lines and fittings, and an Aeroflow regulator from the good folk at Greenlane Speed Shop.

The team didn’t hold back on making the engine look good too, although the MSD ignition components they selected add both looks and functionality. The same can be said for the CVF Billet serpentine belt system that was installed to the front of the motor before it was dropped in the hole. As well as looking after the power steering pump, the pulley kit also includes an air conditioning pump for the aftermarket AC system.

Unlike some other brands that need transmission changes to handle an increase in power, the Chrysler TorqueFlite 727s, such as the one that the car came with from the factory, can be rebuilt to handle some serious power. Of course to get the strength needed, you need a transmission guru who knows their shit, and there is none more knowledgeable than Chuck Mann. Sadly for Kevin — and his bank balance — the same factory-toughness can’t be said for the rear end. Rather than mess around with finding a 9-inch diff from the Dark Ages, Glen pointed Kevin in the direction of a brand-new Currie Enterprises 9-inch, complete with 3.25:1 ratio and 31-spline axles. While installing the new bits under the car, the Engine Specialties team found time to handcraft a new 3-inch exhaust system, even going as far as building their own custom stainless mufflers for it.

Mind you, with the Hotchkis torsion bars and Hotchkis rear springs they installed, you’ve got to get yourself down pretty low these days if you want to check it out.

Before the car rolled out of the Engine Specialties workshop, a set of new, but factory-style, front callipers and discs were added to the front to replace the sub-optimal stock drum set-up. Although most cars end up with big front brakes and small rears, this one is a bit different, with 4-pot Wilwood callipers and 11-inch rotors adapted up to the rear diff. The reason for those is in part because they came with the diff, but in part to try to fill up those massive 22×10.5-inch Asanti wheels. Mind you, the front set isn’t exactly small either, coming in at 22×9-inches.

In some ways it would have been cool to leave the car like this, with all the gear hidden under the — well and truly weathered — hood, but Kevin’s not exactly one to settle for anything less than perfection. Having dealt with Grant and the team at Shields Bros Panel & Paint previously, he knew they could do his vision justice. That vision was for the car to be coated in the deepest shade of black possible, but with a slight twist in the form of a whole bunch of blue pearl added to the mix. The team delivered on that vision, and created a custom paint mix that looks black 99 per cent of the time, but catch it in the right light and you’d almost swear it was blue.

What you can’t see is the hard work that went into getting the panels straight, including the work to the rear arches to accommodate the 305/30R22 sized rear rubber. To ensure a finish that would last, both the floor and the engine bay were blasted right back to bare steel and epoxy primed before any colour could be applied.

Unlike the blue/black exterior, the interior is pure black, and pure class thanks to plenty of hard work by Darren Orton to cover most of the soft surfaces in perforated leather. The big exception to that was the dashboard that was recovered thanks to the experts at Dashboard Restorations. If you’ve not seen their magic before, it’s impressive how they can take a full-size dash like the Charger’s and throw it into their special vacuum system to stick new vinyl to it. The result is a brand-new looking crack and imperfection-free dash. They used the same technique to bring the door panels and rear side panels back to as-new condition — that is, without being the factory shade of blue. Besides the soft trimmings, the remainder of the interior is fairly stock, bar a Forever Sharp steering wheel and decent JVC audio system.

While the guy who sold him the car may have his own views on it, having preferred that the car stayed original, Kevin’s achieved his goal of building the car his way, and that’s something that can never be argued about. Having gone from thinking he’d never own a Charger, to being behind the wheel of his custom-built masterpiece just two years later, it’s easy to see why Kevin is now a very happy man!

_______________________________________________________________________________________________________

This article originally appeared in NZV8 issue 212