Mike Pearce never set out to create New Zealand’s ultimate Mustang … he just wanted a good one, then the bar moved

Words: Mike Pearce / NZV8 Photos: Strong style Photo

Specs

1965 Mustang fastback

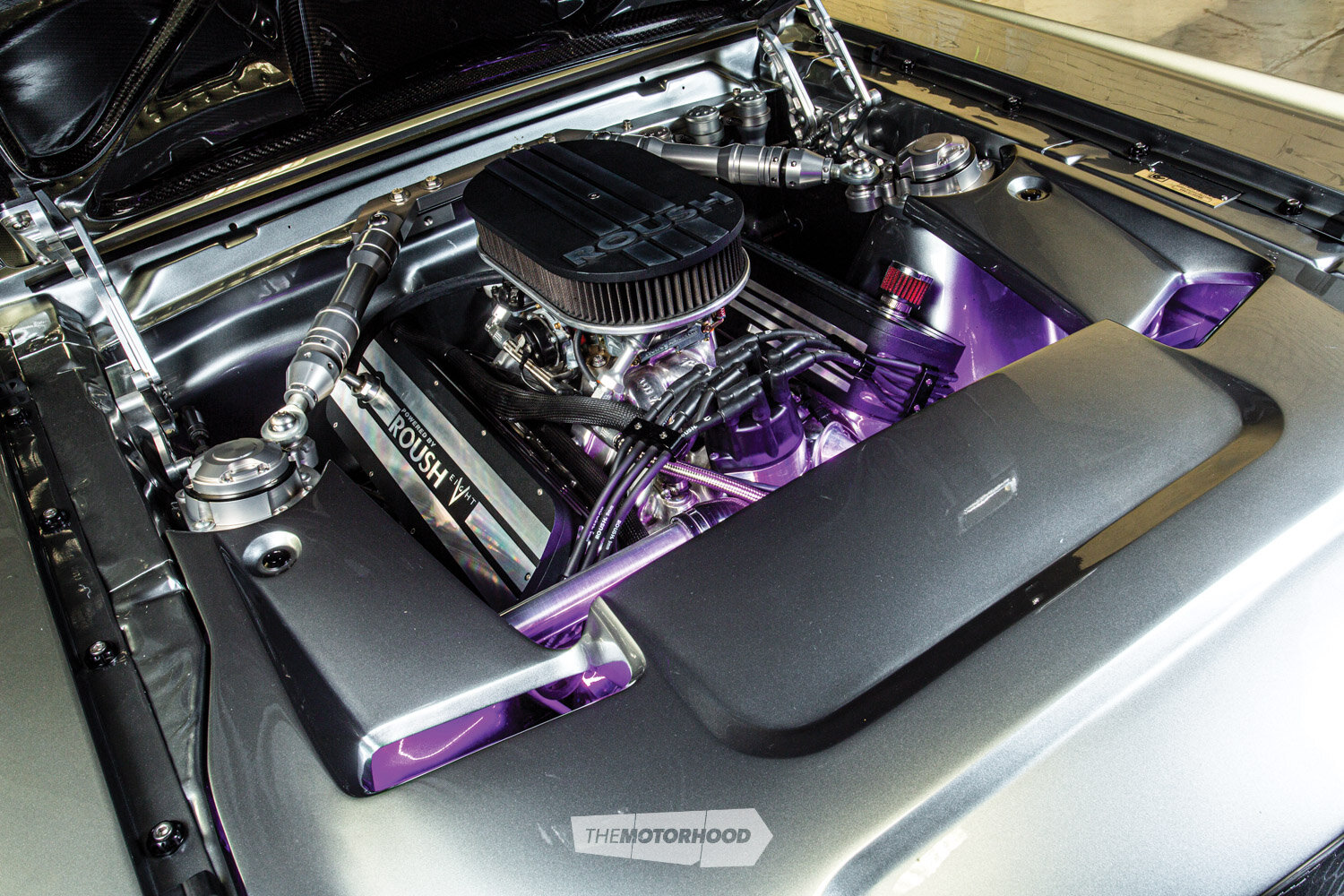

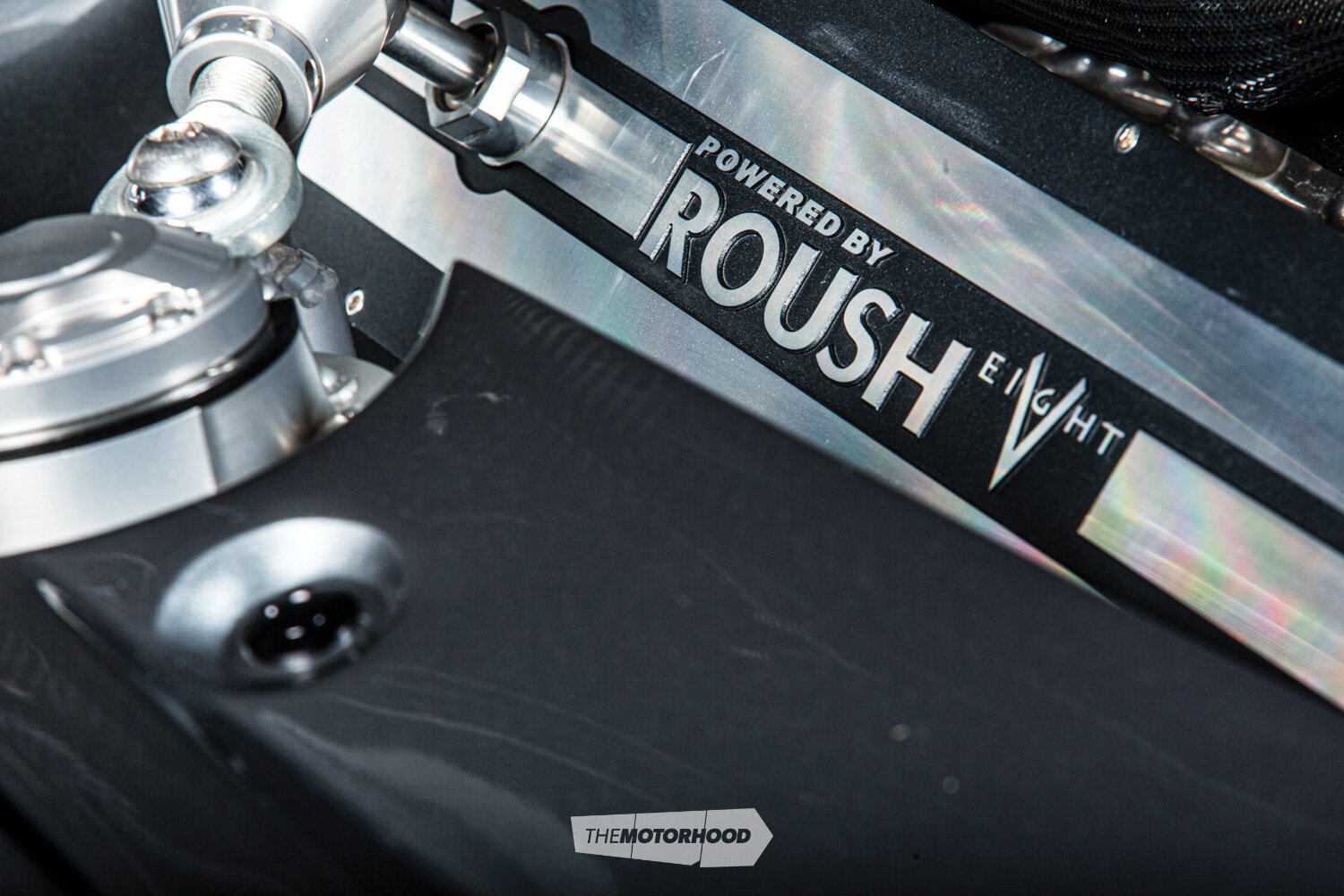

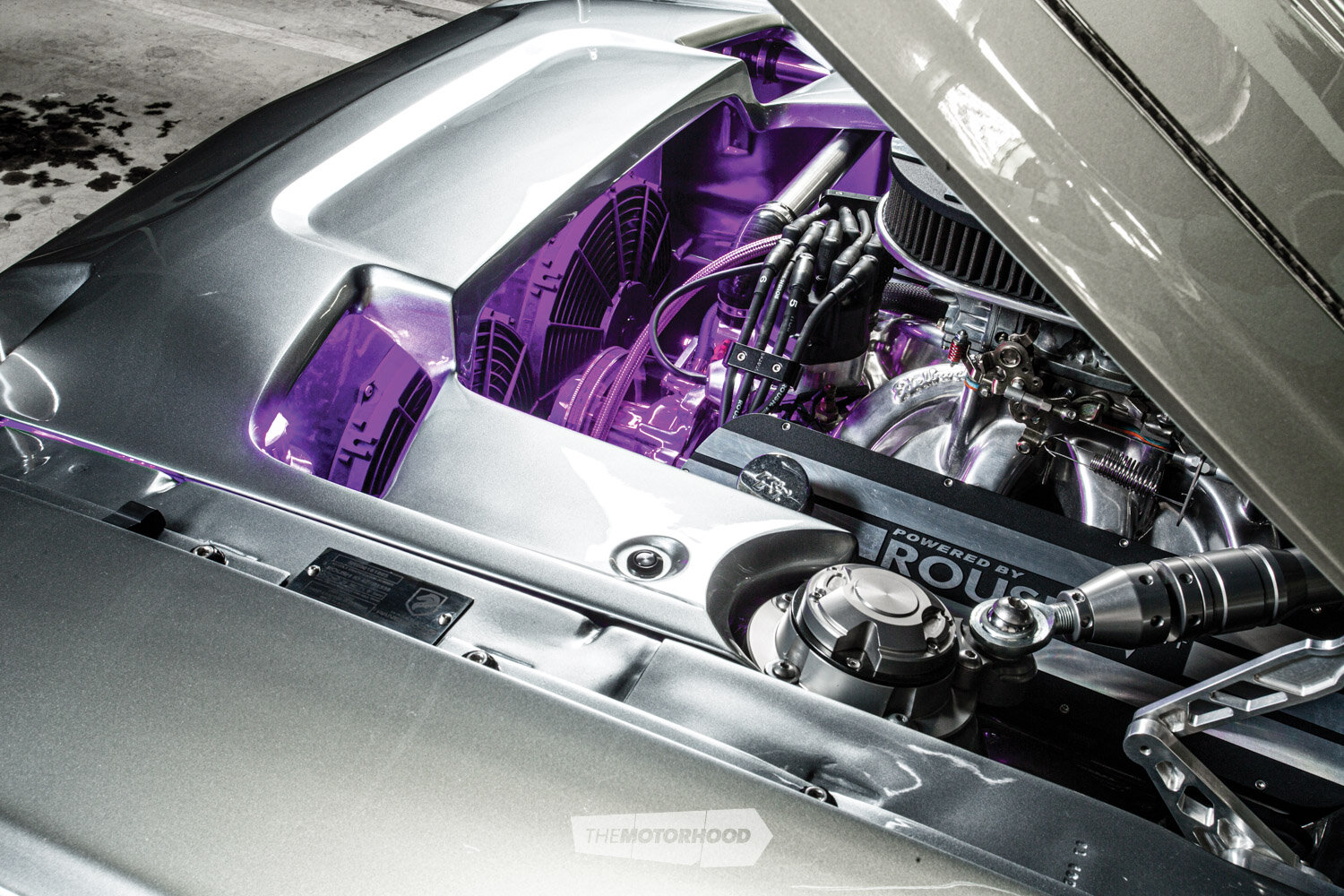

Engine: Roush 427R 427ci small block Ford, cast-iron four-bolt block, steel four-inch crank, H-beam rods, forged pistons, aluminium CNC-ported heads, roller cam, single-plane intake, Holley 850cfm four-barrel carb, custom twin 2.5-inch exhaust, Flowmaster mufflers, custom aluminium radiator, twin electric fans, MSD ignition

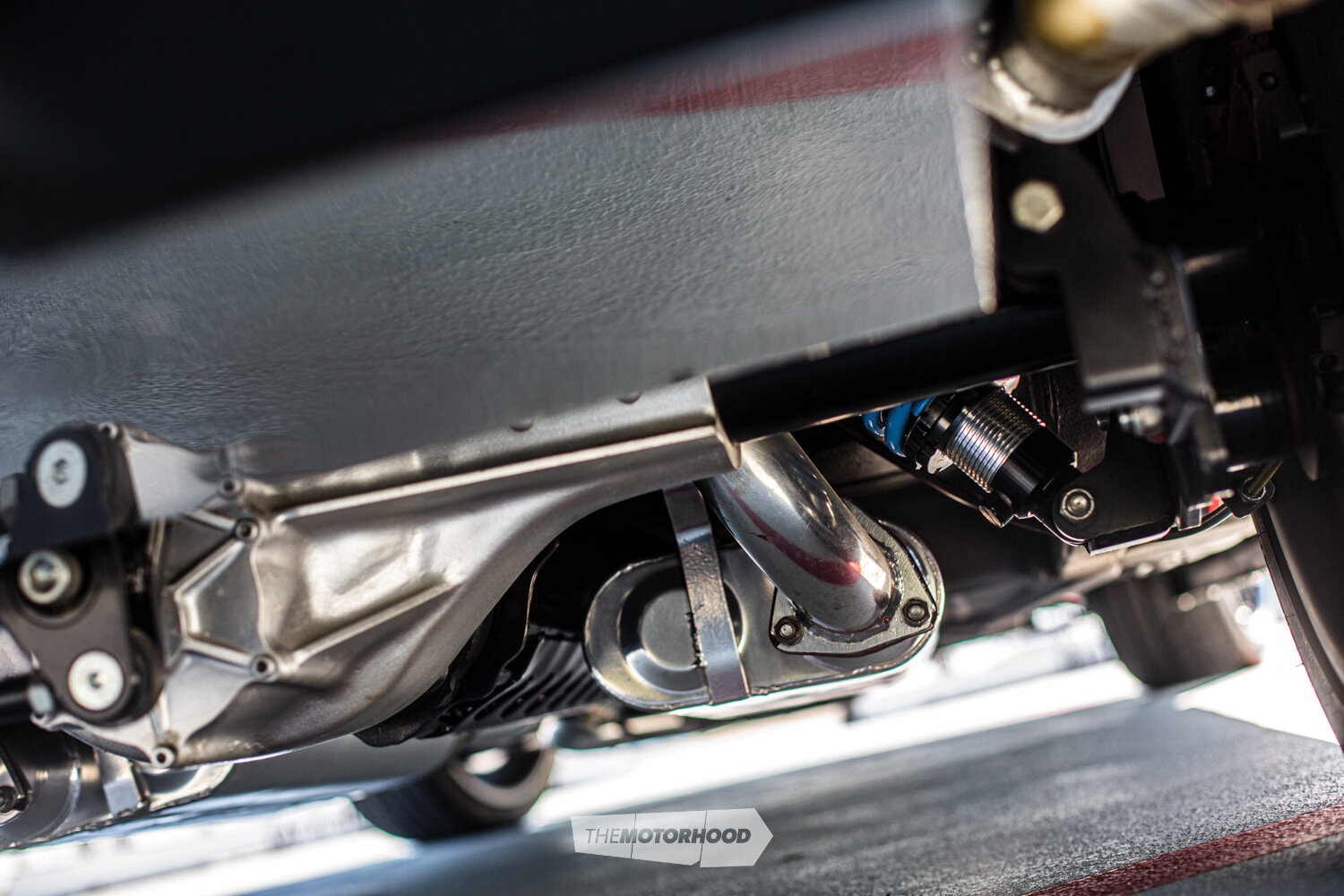

Driveline: Tremec TKO 600 gearbox, McLeod RST twin-plate clutch, custom Ford nine-inch diff, 3.55:1 gears, LSD head

Suspension: RRS coilover front struts, RRS lower control arms, RRS three-link rear, QA1 coilover shocks, RRS rack-and-pinion steering

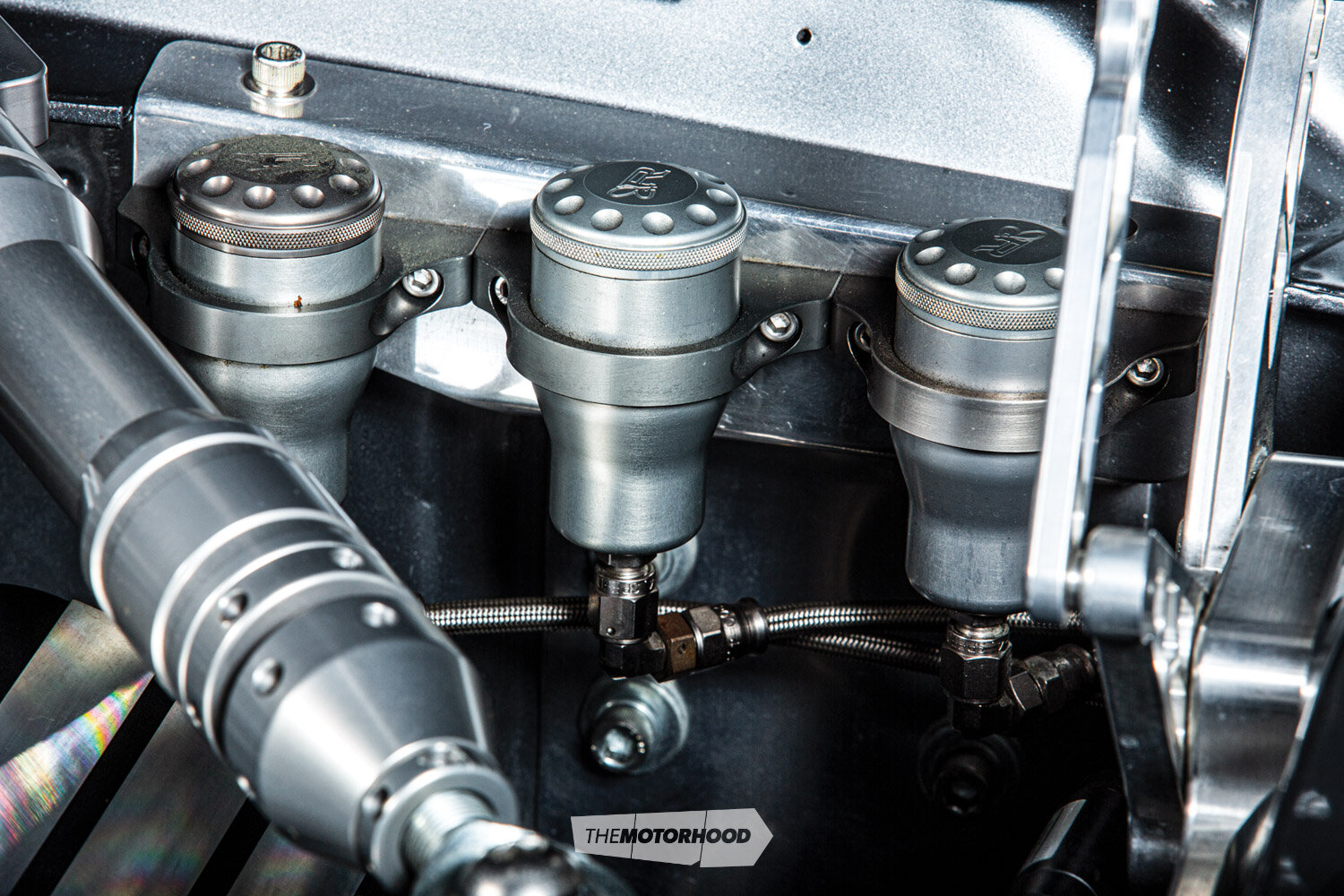

Brakes: RRS Phase Four brake package, 345mm two-piece front rotors, six-piston front calipers, 315mm rear rotors, four-piston calipers, RRS under-dash brake booster

Wheels/Tyres: 18×8.5-inch and 18×9.5-inch Forgeline DE3S titanium-finish wheels, 235/40R18 and 285/35R18 Nitto NTO5 tyres

Exterior: Ringbrothers carbon-fibre bonnet, flush-mount Autoworks smoked windscreens, Ringbrothers gas strut hinges, Ringbrothers bonnet pins, Ringbrothers door handles, Ringbrothers LED billet lights, Hella front driving lights, custom billet gas cap, custom bumpers, custom side skirts, de-chromed, de-badged, PPG Liquid Silver metallic paint

Chassis: Strengthened sills, strengthened front, strengthened rear end

Interior: Sparco R333 seats, Billet Specialties steering wheel, Ringbrothers shifter, electric windows, AutoMeter gauges, Sony reversing camera, custom dashboard, custom centre console, custom overhead console, LED interior and engine-bay lighting, electric start-stop system, Dynamat insulation, Alpine iLX-702D head unit

Performance: 560hp, 546lb·ft

Some time ago, well, really since I was 16 years old, I always had the idea to take a classic Mustang fastback and turn it into a restomod — one that would handle and stop like a modern car but must have that V8 soundtrack. Some years down the track, add a little seven-litre small block Roush 427R engine, and let the fun begin! If you think the name’s familiar, you’d be right, as the ’65 has graced these pages once before — but it never looked as good as this.

You simply cannot just throw a Roush engine into a car that was built 55 years ago and hope to get down the road without undertaking a massive amount of work, or you will end up in a ditch!

The planning and discussions with business owner Malcolm Sankey from Matamata Panelworks was a long and enjoyable process. These guys really know what it takes to craft such cars, and I put together initial renderings [Mike’s day job is as a graphic designer], and a long parts wish list to guide the guys on what the beast should look like. After plenty of meetings and coffees, the car started to evolve and take shape. A Mustang restomod with massive power that sounded amazing and handled as good as it looked was the goal.

Renders on paper are great, but functionality is best. It needed to withstand the hammering I was going to throw at it, so the car was stripped naked, and a massive amount of body strengthening was carried out. Looking at the finished product now, you’re be very hard pressed to see what lies beneath. It simply looks factory and is a credit to the way these guys work.

There isn’t a panel on this car that has not had the Panelworks treatment, from flush mounting the windows, the very tricky custom dash, the centre console — with two coffee-cup holders (thanks, guys!) — as well as the overhead, roof-mounted console, which houses a number of switches for the lighting and extra fans, etc. Then there’s the rear valance / air-diffuser sections, and, of course, the impressive front splitters / valance sections. Not to mention the hexagon-pattern water-cut front grilles, which were a first for the boys. Malcolm has a great bunch of passionate guys and gals who work with you to achieve your dream car.

One such guy is Jhune, who is simply a master craftsman when it comes to creating one-off metal fabrication — I simply cannot believe the way metal can be hammered and massaged into such detailed panels. The inside bonnet panels are a great example of this, as they had to fit the contours of the carbon-fibre bonnet above. The dash area is another. I would receive numerous texts from him saying, “Is this what you like, Mike?” And what would come through would be astonishing.

I set about designing the front of the car and based the design inspiration off the current Shelby Mustang look, but it also needed to look right on a much older body shape. Many drawings later, and after numerous discussions with both Malcolm and Jhune, we settled on a steel top section, housing Hella spotlights with integrated turn signals and a lower alloy-constructed splitter. We needed to keep the weight down on the car so we could put the Roush engine’s 560hp to good use. I didn’t want a powerful engine in a heavy car; that didn’t seem to make much sense to me.

This meant construction had to be not only lightweight but also functional, as the airflow needed to be directed correctly to keep the front of the car down once at speed and keep the engine cool.

The rear of the car was also rendered up, as we faced a few design and construction challenges here as well. How do you get the side-exiting exhausts out the rear quarters, as well as fitting a larger gas tank and the adjustable suspension, and keep the lower stance of the vehicle? After further sketches and a mock-up or two via WhatsApp from Jhune and Malcolm, the problem was sorted.

With the addition of flush-mounted windows, custom front cowl panel, and the Autoworks smoked glass, the body shape simply blends back into itself and makes the car look even more integrated. All chrome was removed from the bumpers before they were cut, then tucked into the body panels and painted in the car’s custom PPG Liquid Silver metallic body colour. Blair from Matamata Paintworks worked his magic here, but not without having to spray five varying silver-coloured panels until we landed on the final colour, which we named ‘Liquid Silver’ — sorry, buddy, but it was worth all the effort. On the underside of the bonnet, Blair had to apply six coats of clear coat as the Ringbrothers carbon-fibre bonnet simply kept on absorbing coat after coat.

I chose Forgeline DE3C forged concave wheels, which are a three-piece design, not only for their lightweight construction but also for their performance, and they look great on this body shape. They also had to be wide enough to handle the power, so the rear was mini-tubbed to fit the meaty Toyo rubber, which keeps the car firmly planted on the tarmac.

I had seen many cars on the internet and in magazines with side-exiting exhaust, but I wanted the Muzzy to have something a little different, so challenged the Panelworks boys to make mine exit out the rear quarters — not such an easy task, as it turned out, but well worth it. It’s a detail that people pick up after looking at the car for a bit. You get, “Oh, see what you’ve done there. That’s not normal, right?”

The interior has been treated to diamond-stitched black leather throughout, including the padded overhead headliner. I purchased a set of front Sparco R333 seats, which Matamata Motor Trimmers refined and added additional foam to provide an even more comfortable fit. The rear side panels, door cards, and dash were also given the same treatment with double stitched grey thread, which highlights the pattern. The Sparco seat inserts were given a carbon treatment, and also the insert on the dash proudly displays the painted 427R badge, which ties nicely into the Ringbrothers bonnet.

I must declare I’m a bit of a fan of the guys at Ringbrothers in the US and the billet alloy parts they manufacture for early Mustangs, and my vehicle displays many of their parts. The strut brace is one such impressive item, functionally stiffening up the front of the car, but it’s also a very nice piece of kit to look at, all engineered from billet alloy. The interior and exterior door handles, door pulls, front and rear boot strut, and shifter are also Ringbrothers items. Even the fasteners used for attaching the body panels have been replaced with custom items, a detail that is not missed by judges when the car gets displayed at shows.

LED lighting was also added to the wish list, and Panelworks added this treatment to the engine bay, under the dash, and boot areas. The system allows you a number of different-coloured light effects controlled by a remote. So, once under spotlights at shows, you can adjust these for maximum visual effect. Another item on the list was the push-button start-stop ignition system, electric handbrake, and additional override cooling fans, which operate via a flick of a switch located in the overhead console panel.

I remember when Malcolm first handed me the ‘keys’ — OK, since we don’t have any keys, it’s a fob instead. Anyway, the Mustang was certainly a handful, and I found out very quickly that you had to be pretty sure you had your wits about you once you hit the gas pedal. This car will bite you. Maximum power is best applied in a straight line otherwise you end up having to make some serious corrections. But, hey, that’s the fun of a Roush engine. These things are built with a lumpy cam and like to rev and run hot.

Roush itself describes them as “putting the ‘hot’ into hot rods”. There’s nothing better than ripping through the Tremec TKO 600 gearbox and really winding the car out on a twisting back road. She handles nice and flat, with very little body roll, something the original Santa Barbara car wasn’t very good at when it was first exposed to New Zealand roads.

I think one of the nicest things about building a car like this is the people you meet along the way, the craftsmen and women out there, and the joy you get from others seeing the car for the first time, who understand and acknowledge the effort that goes into building a one-off. The first time the completed car was displayed to the public was at the National Mustang Convention and Car Show, where hundreds of Mustang owners come together to enjoy each other’s company and their creations. ‘65 Fast’ didn’t disappoint, either, picking up Best Restomod (all years category) — no easy task — and it since continued its winning formula. But 2020 is it for the awards; it’s now back to the tarmac and I’m hoping to get the car on the race track to really test the set-up.

I get asked by a lot of people if this car is finally finished, but the problem I have is, as a designer, you are continually relooking at the thing, thinking maybe this or that needs to change or be added to, so the simple answer is, it’s a work in progress.

Driver

Mike Pearce

Car Club: Waikato Mustang Owners Club

Age: Untested

Occupation: Graphic-design company owner

Previously owned cars: 1967 Mustang notchback, Subaru WRX STi and GTB wagon, custom VW Beetle

Dream car: Depends on the usage really

Why the Mustang? Always wanted a first-generation Mustang (fastback) since I was 16 years old

Build time: Two years

Length of ownership: 10 years

Mike thanks: Matamata Panelworks (Malcolm ‘the Boss’, Jhune ‘Metal Magician’); Blair ‘Painting Artist’ at Matamata Paintworks; Ted from Matamata Auto Trimmers; James from Mag & Turbo Ponsonby; finally, thanks to Lara, Evie, and Imy for putting up with my obsession these last few years

This article originally appeared in NZV8 issue No. 185