Sam Deller may have thrown his toys out after missing out on scoring the car of his dreams, but once he calmed down, he set about building his own

Words: Todd Wylie Photos: Richard Wood

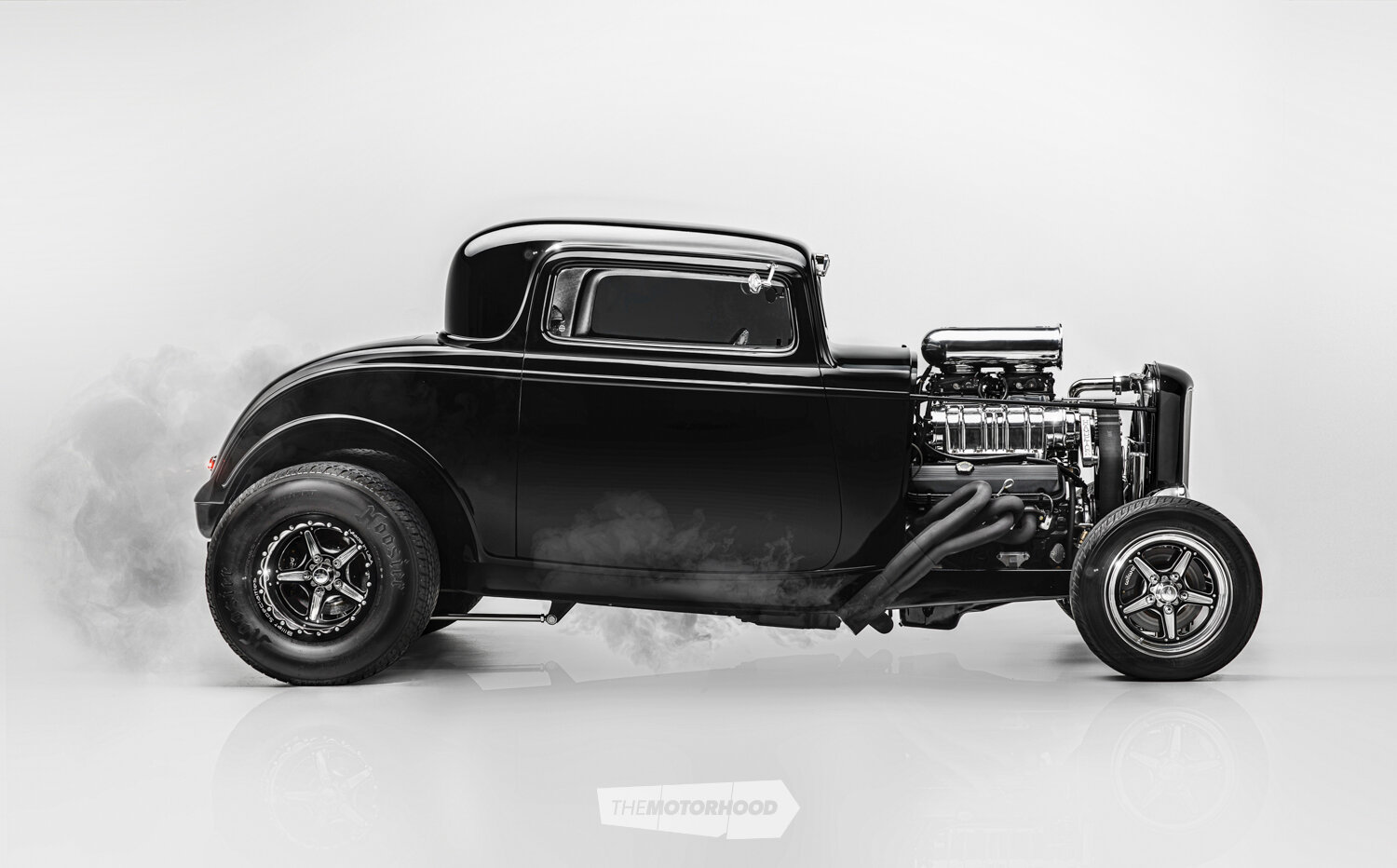

Once upon a time, in a land not so far away, a guy found a blown big block–powered ’32 coupe he wanted, paid the money for it, and lived happily ever after, frying tyres wherever he went … This is not that story. This is a story about a guy called Sam Deller, who found a blown big block–powered ’32 coupe for sale, but messed around too long and missed out on it instead. Don’t think we’re being harsh on him here, as Sam’s the first to admit that he shouldn’t have procrastinated on paying the seller — Russ McIntyre — the money and being done with it. We’re glad he didn’t, though, as the result of the tantrum he threw when he found out he’d missed it, was him deciding that he’d just need to build his own version instead. The photos that he took of the car would simply serve as blueprints for his own build, and, to this very day, they’re still stuck on the shed wall, partly as inspiration, and partly to remind him to take the chances in life when they present themselves.

Sam’s love of ’32s goes back long before Russ entered his life, though. His misspent youth included rebuilding a T-bucket and hanging out with plenty of bad influences. A fellow hot rod club member, Chris Harris, should need no introduction to many, having long built and owned various hot rods, drag cars, and land-speed racing vehicles, and Sam vividly recalls his ’32 coupe.

“That thing was, and is still, way cool,” he states, and, as much as he would have loved to own it half a lifetime ago, he did the sensible thing of packing his bags, moving overseas, and living the life before settling back home in New Zealand. It was only after a spur-of-the-moment trip to Repco Beach Hop 17 that the ’32 inspiration raised its head again, and did so in a major way. If Sam was to get a ’32, it needed to tick all his boxes, meaning it needed to be all the Bs: black, blown, big block, and badass.

“I assumed this combination was common because I found one on Trade Me that same afternoon,” he says of Russ’s car.

Being in the laundry business, and creating a replica — or counterfeit, if you like — the car that Sam would build over the next few years would cleverly be called ‘Dirty Laundry’.

Calling it a knock-off, though, isn’t really doing the finished product justice, as, while it may have been based on Russ’s car, it’s equally as impressive and deserves its own recognition. Right from the Kiwi Konnection chassis upwards, the car has been built well.

Part of that was due to Sam working with Duane Jones at Kiwi Konnection to deck the chassis out with all the bits required to turn it into a roller before it was shipped. This meant that welding the boxing plates into the rails, along with adding a central K-member and front and rear crossmembers, was performed in house. Duane’s team also grafted in a custom four-link and mounts for Aldan coilovers, along with a Heidts SuperRide front end. With the suspension fitted, a nine-inch diff built around a Currie housing, and packed with a Truetrac head and 31-spline axles, was fitted under the rear. Just like the front end, the diff was adorned with a pair of Wilwood discs and calipers.

While Russ’s car had mix-matched wheels, Sam sourced 15×6-inch and 15×12-inch Billet Specialties Street Lite wheels to be fitted before the chassis was strapped into a container and sent down under.

While the puzzle was coming together stateside, Sam was finalizing a deal to get a fibreglass ’32 three-window coupe body from Pete Osborne locally. With Pete’s factory being in Napier, the finished body wouldn’t need to go far before it could be mounted to the chassis, as that task was entrusted to Maurice Leonard Restorations in Hastings. It was here that the majority of the build would take place. Sam explains, laughing, that he was, “That guy who came in all the time to watch the build come together, but in hindsight probably didn’t do myself many favours” — with all the years of experience that Maurice and Dennis have, that supervision probably wasn’t really necessary. However, in contrast, Sam can’t speak highly enough of the guidance and input he received from LVV Certifier Marty Jones along the way.

“I engaged Marty to get involved as early as possible with regard to scratch-built certification,” Sam says. “I was really worried about all this red tape, but in hindsight found that the best thing I could have done was to involve him right from the beginning. Every step of the way, we had things checked, right through to the complete mock assembly. I must say this process was a breeze. I didn’t think I’d ever end up thanking a certifier, or the process, but it is there for good reason and very straightforward to get through if you simply ride the wave instead of trying to swim against it.”

Trying to fit a big block into a ’32 without extending the hood profile, or losing access to the distributor is no small task, so before the firewall could be created, the engine needed to land and be fitted. Like the rest of the parts for the build, Kiwi Shipping was responsible for ensuring safe delivery from the land of stars and stripes to Hawke’s Bay.

Sam states, “Kiwi Shipping is awesome! They handled the numerous orders from the US and have an online portal where you can deliver and aggregate all your separate orders to their address in LA. Then, when you’re ready, you hit go and they’ll load it all into a shared container. Every time one of these containers arrived it was like Christmas, of which I must’ve had about five in one year.”

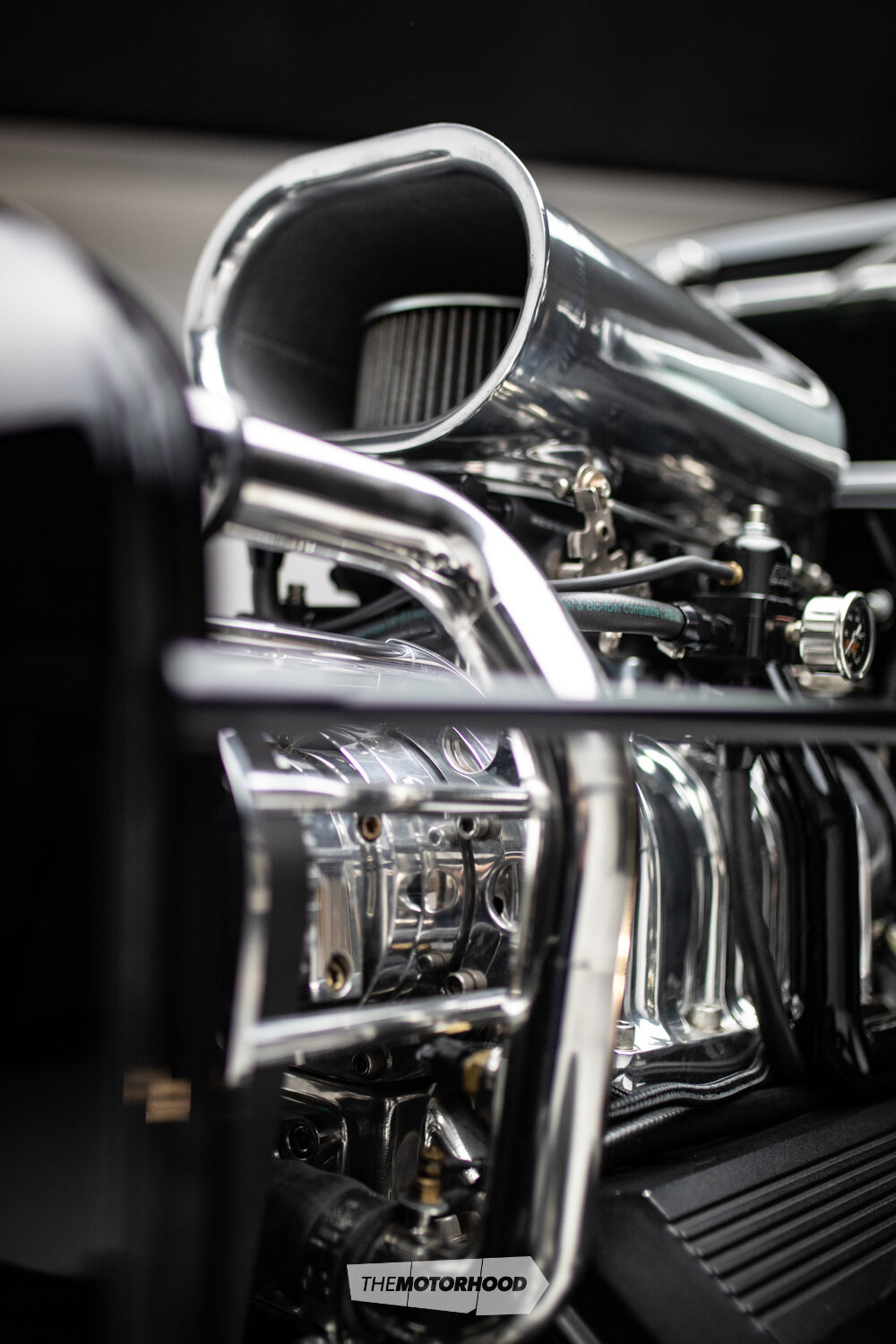

The engine itself wasn’t just any old blown big block, but a fresh 502 from well-known engine builder John Nijssen at Stroker Engine in the US. Interestingly, the block is a low compression HT502 truck variant, which, despite it’s seemingly simple make-up, now delivers the stump-pulling torque figure of 750lb·ft at 1800rpm and still creates 780hp at 5500rpm. This is all done with cast iron heads and a five-per-cent underdriven BDS 8-71 supercharger. It’s not all dinosaur technology under the hood though, as Sam’s a technology fan at heart, so he took it upon himself to wire up a FAST XFI fuel-injection system. The coloured spaghetti links the XFI Sportsman dual-quad throttle bodies to a FAST in-tank fuel pump along with an MSD 6AL ignition and Inferno coil.

When asked if doing this himself was a tricky task, Sam says, “It was pretty much plug ’n’ play. All those people who said aftermarket EFI was temperamental at best are full of it. This is the best thing since sliced bread. No more screwdrivers, jets, and timing lights to carry around. I can remotely login to this through my laptop if need be. But I don’t need to because it just works — first start, every start.” While that’s high praise, it’s not the only part of the engine package he loves, as the ‘loudener kit’ upgrade to the supercharger — that sees a big, wide, dirty-old square-tooth belt drive fitted — is also on his list. This apparently “emits music better than any audio system could”. That noise is competing with the muffled exhaust notes exiting the rear through a combination of 2.5-inch pipes, Flowmaster mufflers, and Coby resonators. If the need ever arises, the caps on those beautiful custom headers, built by Maurice and Barry, can be removed, and the engine’s sound can be truly set free.

Although Sam may have been kicking himself initially at missing out on Russ’s car, now that he’s behind the wheel of his own version, that tantrum is a thing of the past. “The car is easy to drive, reliable with streetable raw horsepower, and no nasty powerband,” he says. It does love a good drink, however, with Sam laughing that, “it can pass everything but the servo”. That minor issue aside, it’s his own creation, and that’s something that the purchased car would never have been!

This article originally appeared in NZV8 issue No. 185