Wheels are wheels are wheels, right? Well, not quite — we take a look at the facts and fictions you might not know, with help from several industry experts

Where the styling of your car is concerned, wheel choice is the make-or-break decider. However, it’s not just styling — wheel choice can have a notable effect on ride and handling. But, how hard could it be? Get the size and stud pattern right, and you’re all good to bolt those new rims on, right? Not quite. You see, while those are arguably the two most important factors when it comes to replacing the wheels on your car, they are far from the only ones worth considering.

With regard to wheel sizing, it’s also important to note the ‘offset’ — sometimes referred to as ‘backspace’ — and centre bore size to ensure a safe fit. Depending on the application of the wheel, its construction is also well worth considering.

Measurements

Width is easy to understand, denoting the breadth of the wheel. However, when it comes to taking measurement, it’s easy to fall into the trap of assuming it’s the width from outer to outer, which is incorrect. The correct way to measure wheel width is with no tyre mounted, measuring between the beads, which will yield the advertised width of the wheel. Measuring total width between external edges will add up to an extra inch in width, which does need to be factored in when calculating what wheels will fit — however, this is not the measurement to be used when purchasing or specifying a new set of wheels.

Diameter simply measures the diameter of a wheel — the straight-line distance passing through the centre of the circular face of the wheel. However, as simple a concept as that is to understand and measure, a number of factors regarding wheel diameter must be considered. If you have installed larger-than-factory brakes, it is vital to ensure that the chosen wheel will clear them — the factory-style 15-inch steel wheels on your sleeper project will be unlikely to clear your Wilwood six-piston calipers and 13-inch discs.

Similarly, it is important to keep tabs on ‘rolling diameter’ — the total diameter of the wheel and tyre combination. As diameter directly affects the ‘circumference’ of a circle — the distance covered in one rotation — it is easy to unwittingly have an impact on overall gearing, affecting both speedometer accuracy and performance characteristics.

Expert opinion: Lance Bell from Arrow Wheels

“I have been custom-making two-piece and three-piece wheels for 36 years, and have made more than 4500 wheels in that time. There are a number of benefits to running a two- or three-piece wheel, as opposed to a solid-cast, fixed-offset wheel. If you’re building a high-performance track or road car, you’ve got to look at weight. Reducing unsprung weight is crucial. The average cast wheel weighs 12–14kg; the average weight of Arrow Wheels spun three-piece wheels is 6–8kg. That’s a huge weight saving, with the added bonus of the wheels being custom-made to suit your size and offset requirements.”

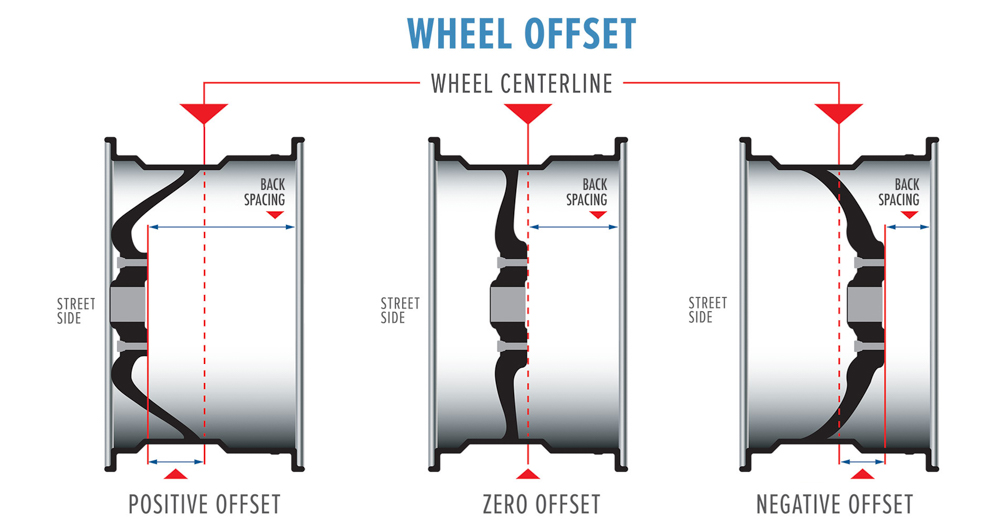

Offset is a measurement of the distance, in millimetres, between the wheel’s hub mounting face and the centre line of the wheel width. A zero-offset wheel has the hub mounting face at the width centre line. Most wheels leave the factory with positive offset — that is, a hub mounting face closer to the outer edge of the wheel than the width centre line.

Backspacing is an alternative measurement of offset, measuring the distance between the hub mounting face relative to the inner edge of the wheel. Backspace and offset share a positive correlation — that is, a larger backspace inherently implies a higher offset, while a smaller backspace implies a lower offset. In addition to overall width, it is the most important factor to consider for correct wheel fitment.

Expert opinion: Lance Bell from Arrow Wheels

“Over the many years [I have been in the business], I have designed some custom machines to suit our manufacturing and repair business. Our safety-bead machine puts a groove in the rim section, which holds the tyre on the outer faces of the wheel. We also use this machine to roll out some bends in spun rims.

“We can also custom-cast wheel centres. We first pull the wheel apart and measure the centre to ensure it will work with our Arrow Wheels spun shells. Factoring in for shrinkage — when wheel centres are cast, they shrink by four to five per cent — we will add material to the centre to build it up and out.

“A mould is made of this centre, and, once we have cast as many as the customer requires, the filler material is taken off the original centre, returning it to its original condition.”

PCD is the abbreviation of ‘pitch circle diameter’ — essentially, the wheel’s stud pattern. PCD is a key factor in whether a wheel will be able to be mounted to a vehicle’s hub. The first digit always refers to the number of studs — generally four, five, or six. The second number refers to the diameter of the circle in which the studs are arranged. The common Ford stud pattern of 5×114.3 implies five studs arranged in a circle with a 114.3mm diameter.

Centre bore measures the diameter of the hole in the centre of the wheel. This is an important consideration, because the ‘spigot’ — the lipped protrusion at the centre of a hub or brake drum — is usually what locates the wheel on the hub. It is therefore important that the wheel’s centre bore matches the hub size to ensure correct load bearing. Wheels with a larger bore size may be located on the hub with hub-centric rings to take up the empty space, while wheels with a centre bore too small may be able to be bored out to fit. However, due to the potential for structural compromise, a wheel-repair specialist should be consulted about this option.

Expert opinion: Melody from SSA Wheels and Tyres

“One of the most common mistakes people make is buying wheels that don’t fit their car. That’s why we’ve made it easier with our online wheel-selection tools at ssawheels.co.nz. Just select your car model, and you’ll be able to see which wheels would fit your car. If you already know what size and offset you need, you can also select the specifications that you want. However, despite the online tools, we always recommend a trial fit before purchase.”

Centre bore measures the diameter of the hole in the centre of the wheel. This is an important consideration, because the ‘spigot’ — the lipped protrusion at the centre of a hub or brake drum — is usually what locates the wheel on the hub. It is therefore important that the wheel’s centre bore matches the hub size to ensure correct load bearing. Wheels with a larger bore size may be located on the hub with hub-centric rings to take up the empty space, while wheels with a centre bore too small may be able to be bored out to fit. However, due to the potential for structural compromise, a wheel-repair specialist should be consulted about this option.

Expert opinion: Melody from SSA Wheels and Tyres

“Buying a wheel and tyre package is always going to work out cheaper than buying them separately, and the tyres are guaranteed to fit the wheels!”

Cast: Casting is the most common type of construction for mass-produced aftermarket alloy wheels. The casting process uses gravitational force to draw molten alloy into a mould, which is cast by allowing it to set, forming a wheel when complete.

Forged: The forging process begins with a solid billet of alloy, which, via a forging die, is forced into the approximate cylindrical shape of a wheel — a blank, in effect. The high pressure results in a dense material with no chance of porosity, rendering it incredibly strong. The blank is then spun out, forming the rim section, before being machined down to specification. The end result is a wheel that provides an exceptional strength-to-weight ratio.

Expert opinion: Lance Bell from Arrow Wheels

“Most people don’t realize that about 90 per cent of damaged wheels can be repaired,” Lance told us. “Gouged edges are the most common damage, and are easily fixed. Around $200 will get you a fully painted wheel on the car — sorted.

“Cracked rims, broken sections from cast wheel edges, and bends in rims can all be inspected and repaired, if they are not too far gone.

“First, we’ll hand-spin a damaged wheel to check what we’re dealing with, looking for things like hairline cracks. If it’s repairable, we can weld it up and straighten it with a specialist machine. We then send it for a crack test, if that needs to be done. We’ll weld up the edges, file it back, undercoat the wheel — some of it will get burnt off by the welding — hand-sand it, paint it, and clear-coat it. The wheel comes out looking brand new.”

Billet: A decade ago, billet wheels were the preserve of the rich and famous, but technological advancements have greatly expanded the realm of CNC-machined billet wheels to a more mainstream audience. They still aren’t cheap, but the upshot is that there is almost infinite customization available — from wheel design through to sizing. CNC technology means that a billet wheel of just about any style can be produced in just about any size and offset to fit virtually any vehicle.

Two-piece: As the name implies, two-piece wheels are constructed of two separate pieces. In most cases, it will be a cast, forged, or billet centre section fastened to a rim barrel. The advantage of this wheel design is retention of the strength characteristics of a one-piece design, with built-in serviceability should the rim or centre become damaged.

Expert opinion: Fred Morgan from Herb Morgan Tyres and Wheels

“Just because a wheel fits, doesn’t mean it will work for your application. Take offsets, for example. These days, the Ford Falcon takes a range of offsets; if you don’t select the correct one for your car, you can end up running into problems with clearance and balance, etc. It’s not just a case of bolting a wheel on and it’s good to go.

“As we’ve been around for more than 50 years, we sell only quality brands — TSW, Enkei, and Niche, for example — and our team have the experience to know what will be best for your particular requirements.”

Three-piece: Three-piece wheels can be broken down into three separate sections — the centre section, the inner barrel, and the outer barrel. Due to the serviceability of this design, it is possible to curate inner and outer barrel widths to fit your vehicle perfectly. This is also beneficial in that individual parts can be replaced should they be damaged, unlike a one-piece wheel.

However, there are disadvantages. Due to the three-piece construction, off-the-shelf aftermarket three-piece wheels may lack the stiffness of purpose-manufactured one-piece designs, although this is unlikely to be of concern for street-driven applications. The individual parts also mean that three-piece wheels are costly to produce, often commanding premium prices.

Expert opinion: Melody from SSA Wheels and Tyres

“There is a legal requirement regarding how much you can stretch your tyres, as well as how far your wheels can protrude from the guard — refer to the rim-size compatibility LVVTA information sheet. Usually, the tyre tread is not permitted to pass the wheel arch. Most of the time, I would recommend using common sense.”

Expert opinion: Jamie Philipp from Flush Fitment

“You’d be surprised by what some of our customers don’t know, so we always try to provide useful information,” says Jamie from Flush Fitment, distributor of Touchdown and Revo wheels.

“While we always aim to measure our customers’ wheels correctly for them, sometimes customers are unable to come to us. If you are unable to make it to a store, we recommend using the online guide on the willtheyfit.com website. You just need to input the size of your existing tyre, the width and offset of your existing wheel, and the details of the new wheels and tyres, and it will provide you with a range of relevant information, including the change in poke, wheel arch gap, and speedo error.”