data-animation-override>

“Blowin’ Dart-fuelled smoke in your face, this is one LH that should carry a government warning for others!”

In this world, there are those who think a burnout is as simple as selecting a gear and standing on the gas. For some that is true … but how about building a vehicle that is capable of doing burnouts to compete in national and international events whilst retaining street drivability? That is an entirely different story, and this is that story.

The LH Torana featured is owned by Ryan, driven by Liz, and powered by much more than a supercharged, nitrous-breathing iron lung. It is also powered by an enormous amount of pride, reflected by the well-considered components and engineering mastery.

Ryan has owned the LH for 11 years and counting [at the time of writing], having purchased it off his uncle. It rolled off the production line powered by a Starfire 1.9-litre engine. The LH Torana was a vehicle with much potential, as proven by the SLR5000. History has shown that, while there was nothing wrong with the Starfire engine, there was so much potential that this engine may as well have been cast with the words ‘candidate for transplant’. Like many of its kind, this LH received new breathing capability in the form of eight cylinders in a beautiful V shape.

This is a car that has evolved over time, progressing from a single carburettor set-up, to a twin carburettor tunnel-ram set-up, to the mechanical and chemical supercharged wonder we see today. A trusty 350ci small block Chev and five-speed manual transmission soon found its way into the LH, and Ryan started tinkering — as you do. A 600cfm Holley carburettor and Mr Gasket scoop were installed, along with the obligatory, and necessary, larger rims and tyres. This combination would satisfy most people, but not Ryan. The next phase in the evolutionary process was an Edelbrock tunnel ram with twin 450cfm Holleys, to satisfy his desire for an engine protruding out the bonnet. And then came the story of the 406 and supercharger …

The LH would soon have some serious muscle in the form of horsepower. Having already sent numerous gearboxes, clutches, differentials, and axles to the automotive graveyard, Ryan and Liz came to the conclusion that the LH deserved a strip-down and rebuild with a view to strengthening the major structural components. Holden had never imagined that the skeleton of their original car would have to cope being transformed into something bionic!

As the strip-down progressed, with each component carefully cleaned and weld-strengthened, it became rather obvious the strengthening route was the correct way to go … the poor LH had a stress fracture (read: tearing apart) of the firewall! Holden had manufactured a well-designed chassis for the Torana and the factory concepts were extended by Eel (with Ryan is assistance) to form an immensely strong and aesthetically impressive boxed-frame extension.

The decision was then made to step up to the world of the 400ci small block. Unfortunately, the first engine purchased was not quite up to standard for what was planned. The crankshaft bearings were showing signs of stress, a crack was discovered in the block, and there were no engine mounts — they had been removed as a result of a previous custom installation. It would have taken a wad of cash to resolve these. Instead, a Dart ‘Little M’ 406 block complete with supercharger was available, and research showed this was indeed a realistic option from a financial (and owner stress) perspective. The Dart features include priority mains oiling, four-bolt splayed mains caps, and extra thick cylinder walls — and the deal was done.

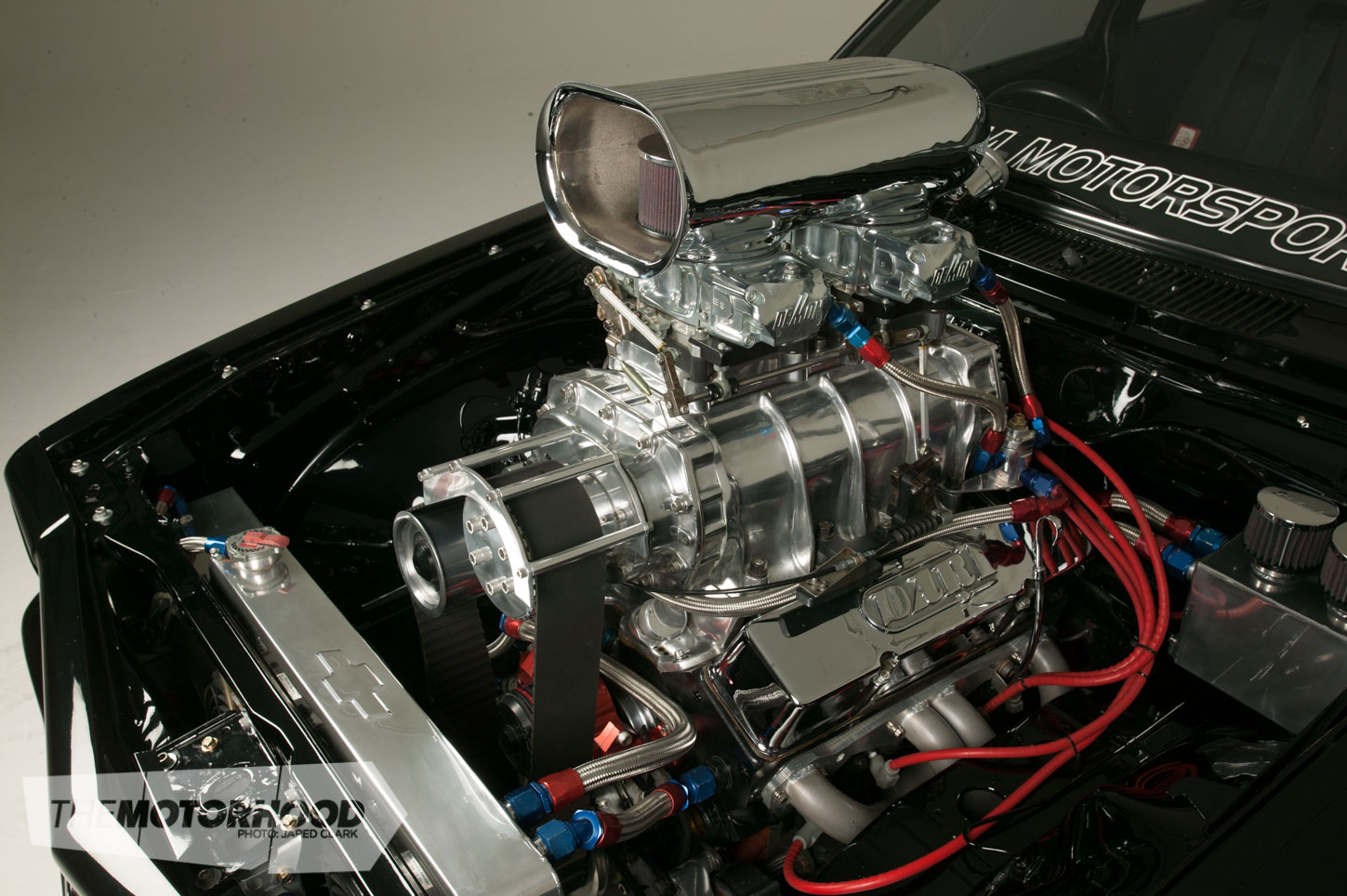

Sitting on top of the Dart block, making sure the LH does not run out of puff, is a glorious 6-71 supercharger by Garry Peterson that was expertly rebuilt by Al from Al’s Blower Drives. This set-up runs nine per cent underdriven — with the street exhaust it provides 10psi of boost, while in competition, or any other time the cravings take over, it provides 13psi.

Not so obvious at first glance are the custom-fabricated plates that allow sideways mounting of the twin Barry Grant Mighty Demon carbs — done to allow improved linkage operation and removing the need to machine grooves into blower casing. There are also custom-fabricated plates for optimum throttle operation and a very impressive plate on the front of the engine that features a bearing assembly to compensate for pulley vibration. Also fabricated was a custom scatter-shield that fixes to the enlarged transmission tunnel – a very sensible investment from an occupant-safety perspective.

The internal components purchased to go with the Dart block are of the highest standard. An Eagle stroker crankshaft spins Eagle rods and JE forged pistons, an Isky roller camshaft lifts Competition Cams pushrods that pivot Crane Gold roller rockers and Ferrea severe duty stainless-steel valves in the Pro Topline 242 Iron Lightning cylinder heads.

A phenomenal amount of time was spent on research to identify components. The services provided by Rob Penman and Eel in this respect were invaluable, and the knowledge and skill of these men should be considered close to that of specialised surgeons — one turning spanners, the other turning steel.

A Tremec T56 six-speed manual transmission mates to the engine with a Ford nine-inch LSD differential out back that was built by Diffs R Us whose sponsorship, support, and continued involvement in this LH is invaluable. Now that this car had plenty of get-up-and-go, consideration was given to reining in the power. The brakes were upgraded at the front with DBA cross-drilled and vented rotors, while the rear received HQ drum brakes, and a Wilwood brake bias was thrown in for good measure.

The detailed engine, complete with braided hosing and anodized fittings, is the most obvious feature of the LH. Looking beyond the obvious, you note the panels on this car are straight and clean; the Panther Mica paint applied by Cam at Diamond Autofinish has incredible depth, although there is now an array of scratches in the paint at the rear of the car — these scratches can be considered trophies from the many steel-belted tyres that have been defeated by the LH. The graphics are expertly applied and there is just the right amount of chrome to glisten through the “occasional” smoke screen.

This vehicle was built to break traction, not gain it. I was lucky enough to join Liz as she put the LH through its paces. What I observed was an education, what I experienced was like nothing before, and what I left with was complete admiration. It all started rather passively, with a sideways smile from Liz and undetected pressure on the gas … then the immense iron lung began to sing its song and Liz’s workplace became rather busy. She became less concerned with the comfort of her passenger, focusing upon the myriad gauges, flicking her left wrist from first through second, third, and into fourth, while her bare feet controlled the pedal movements with the precision of a concert pianist on acid. Her right wrist was flicking the car through graceful arcs as the billowing smoke enveloped the LH. From my vantage point, the smoke seemed surreal — it was like time was in slow motion, and the smoke was rolling ever so slowly around, almost embracing us. Looking further out the window I realized that what I could see, essentially in the eye of the storm, was multiplied many times as you gazed further and further from the LH. By the time Liz had finished, it is entirely accurate to say she had more tread on her feet than what was remaining on the tortured rear tyres!

There is an artistry to a burnout and the quality is dependent on many factors including driver skill, vehicle, and choice of tyre. One of the initial goals was to build a car to flame the tyres … yep the LH went there and did that! In the competition world of burnouts, you need to consider things such as elapsed time — i.e. you must perform within an ideal window of two-and-a-half to three minutes [yeah, maybe back in those days!]. You must also produce quality smoke which is dependent upon your choice of tyre, as each brand has its own burn characteristics. You have to consider and measure the rpm to pull in each gear, in order to reach optimal burn temperature, and you also have to consider vehicle movements as the swinging arcs of vehicle aid in presenting a consistent, and consistently growing, display. We hit 8,200rpm during the performance — to put that in perspective, at 7,400rpm in fourth gear, the rear wheels are doing 140mph!

On one hand, this LH is a competition bruiser. On the other hand, it is a street cruiser. A lazy Sunday was recently spent cruising around central and suburban Auckland. The motorway of Auckland opened my eyes to the sheer power of the LH, which displayed massive straight-line power when demanded. In suburban traffic it behaved very well, and I just love the idle of supercharged cars! The ride was extremely comfortable thanks to the upgraded suspension featuring KYB gas shock absorbers and SLR5000 springs. The interior of this car is very tastefully done; the front seats are AutoSport items and the rear is factory that has been custom upholstered to match the front. Liz had the cheek to say “but it doesn’t have an interior” a short while ago … well I tempted to say “Bollocks to Liz” on that one, but I won’t, because this car does not have power steering and Liz might hit me!

Ryan and Liz set more than just rubber on fire with this LH — they have almost burnt out their opposition. With Liz as pilot in over 20 burnout competitions, the LH has only twice not finished in the top three, and has also won ‘Best Presented’. Ryan won that, and he has a prized vacuum cleaner for his efforts! Ryan and Liz have the won the Skidfest competitions season 2000–’03, placed second in the Skidfest Nationals in Christchurch in 2002, and won the Hamilton National burnout championship in 2003. 2004 and 2005 saw Ryan and Liz focus on international competitions, and have shipped the LH twice to Summernats in Canberra. On both occasions, they have placed in the Top 10 of the World Burnout Masters and were also picked to participate in the hallowed Super Cruise.

Proof of the streetability of the LH is the fact that, at the time of writing, it has just driven back from Tokoroa where Ryan and Liz put on a display as part of a promotion to encourage safe driving practises.

Please do not view this article as glamorizing smoking — we all know how dangerous that habit is, it simply seemed a suitable theme for a vehicle that smokes ’em up regularly. It is fair to say that this is probably the only vehicle that I will write about for NZV8 that I would feel comfortable smoking inside, for obvious reasons. It would be incredibly funny to have the LH officially declared a smoke-free workplace environment … I wonder what OSH and ASH would have to say. I know what Liz would say, and I can guess they would not be three letter words. What we can say — and print — is that Ryan and Liz have a car, and a great many achievements that they can be immensely proud of. And, just for the record, the nitrous oxide system has yet to be turned on!

Specs

Engine: 406 ci small block Chev, Dart Little M cast-iron block, splayed four-bolt mains, Eagle 4130 stroker crankshaft, Eagle H-beam rods, JE forged pistons, 8.2:1 compression ratio, Isky roller camshaft, Pro Topline heads, Crane Gold 1.6:1 roller rockers, Crane stud girdle, Ferrea stainless-steel valves, 2.125-inch intake valves, 1.6-inch exhaust valves, Edelbrock B10 custom intake manifold, GMC 6-71 supercharger, custom rear bearing plate, two 750cfm Barry Grant Mighty Demon boost-referenced carburettors, Nascar mechanical fuel pump, Jaz fuel cell, two Mallory fuel-pressure regulators, NOS Cheater twin-plate jettable nitrous system, Tommy T racing headers, three-inch collectors, 2½-inch exhaust (street), Flowmaster mufflers (street), three-inch exhaust (burnout), Forza mufflers (burnout), Aussie Desert Cooler radiator, Davies Craig electric fans, CSI electric water pump, Mocal oil cooler, modified sump

Driveline: Tremec T56 six-speed manual, Pro 5.0 shifter, YellaTerra explosion-proof flywheel, McLeod variable clamp pressure plate, Wilwood hydraulic release bearing, Ford nine-inch diff, LSD centre, 3.7:1 ratio, Currie axles

Suspension: SLR5000 springs and sway bars, KYB gas shocks

Brakes: Holden HQ front brakes, hubs, and stub axles, DBA cross-drilled and vented rotors, Holden HQ rear drums, Wilwood brake bias

Wheels/Tyres: 17×9-inch Momo Arrow, 255/40R17 Bridgestone Grid III

Interior: Momo steering wheel, Autosport fixed-back bucket seats, Auto Meter gauges, Sony headunit

Performance: 557hp and 550lb·ft at the wheels

Driver: Liz and Ryan

Age: Yeah nah

Occupation: Builder / operations manager

Build time: This LH continues to evolve.

Length of ownership: 11 years and counting

Thanks: Rob at RPM Motorsports; Lee aka Eel; Mike at Mullins Tyres for supplying countless rear tyres; Cam at Diamond Autofinish; Lee at Diffs R Us; Jaydene at Mag and Turbo North Shore and Takapuna; Bob Dayal at Alter Electroplaters; Cannon at Cannon Signage Concepts