The big man grew up surrounded by slammed HQs, so it’s only natural he has built his ultimate version of one — although this one is packing a monster 496-cube blown big block, an engine combination that cuts an intimidating stature to match his own

Words: Marcus Gibson Photos: Adam P Photography

Long before he donned the black jersey, was named World Rugby Player of the Year in 2014, and was instrumental in winning the Rugby World Cup in 2015, a much younger — although probably not much shorter — Brodie Retallick called the streets of Amberley, Canterbury home. If you know anything of car culture in this particular region you’ll know that four-door sedans of Australian descent slammed on the likes of Tridents or Hotwires by way of cut springs are a very common sight. Of these, it was the HQ Holdens that caught the big man’s attention.

“They were always loaded up with older teenagers rolling around, so that was always the car I wanted to have. No one that age had Monaros, so they were never on my radar,” Brodie recalls.

Spec

1971 Holden Belmont

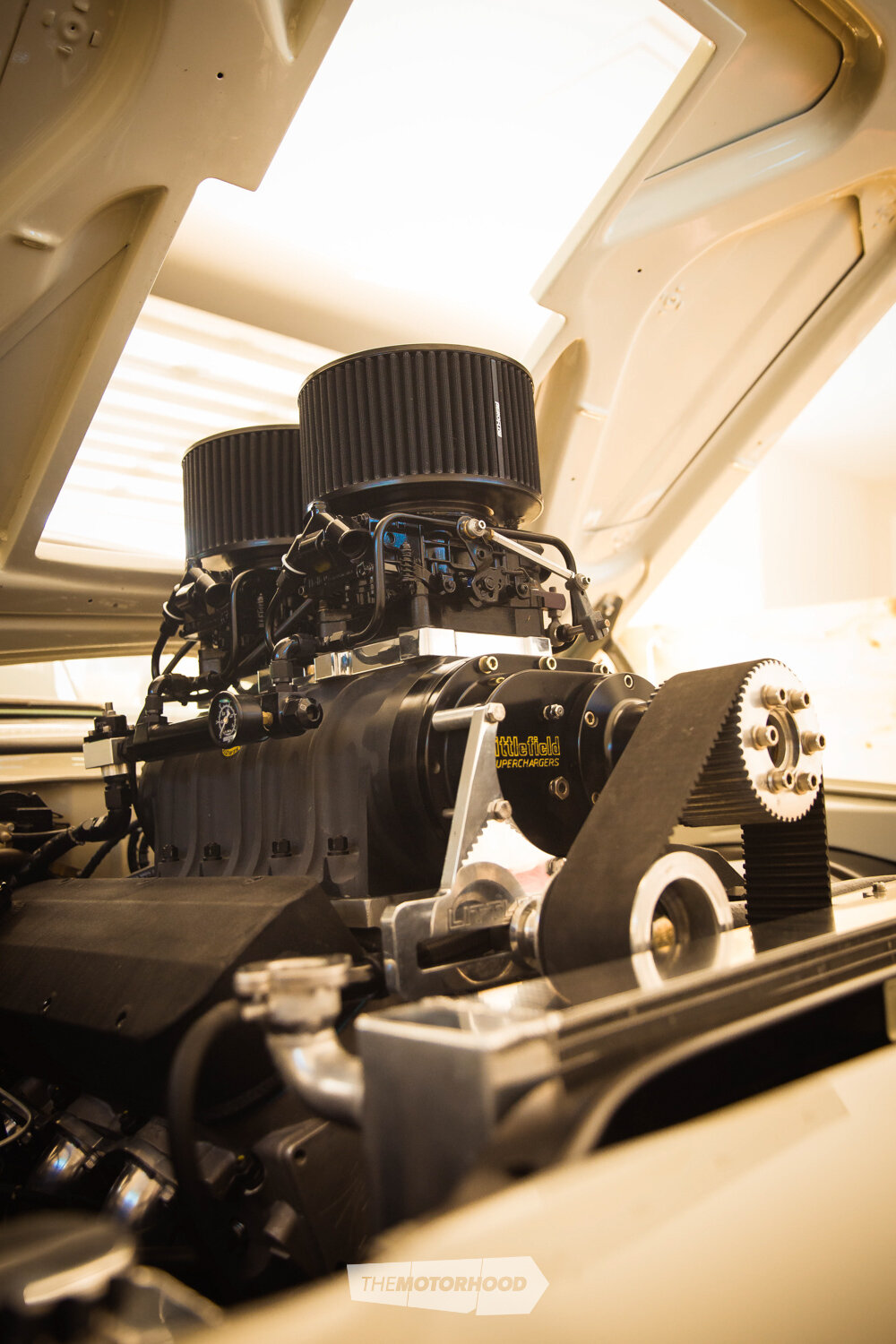

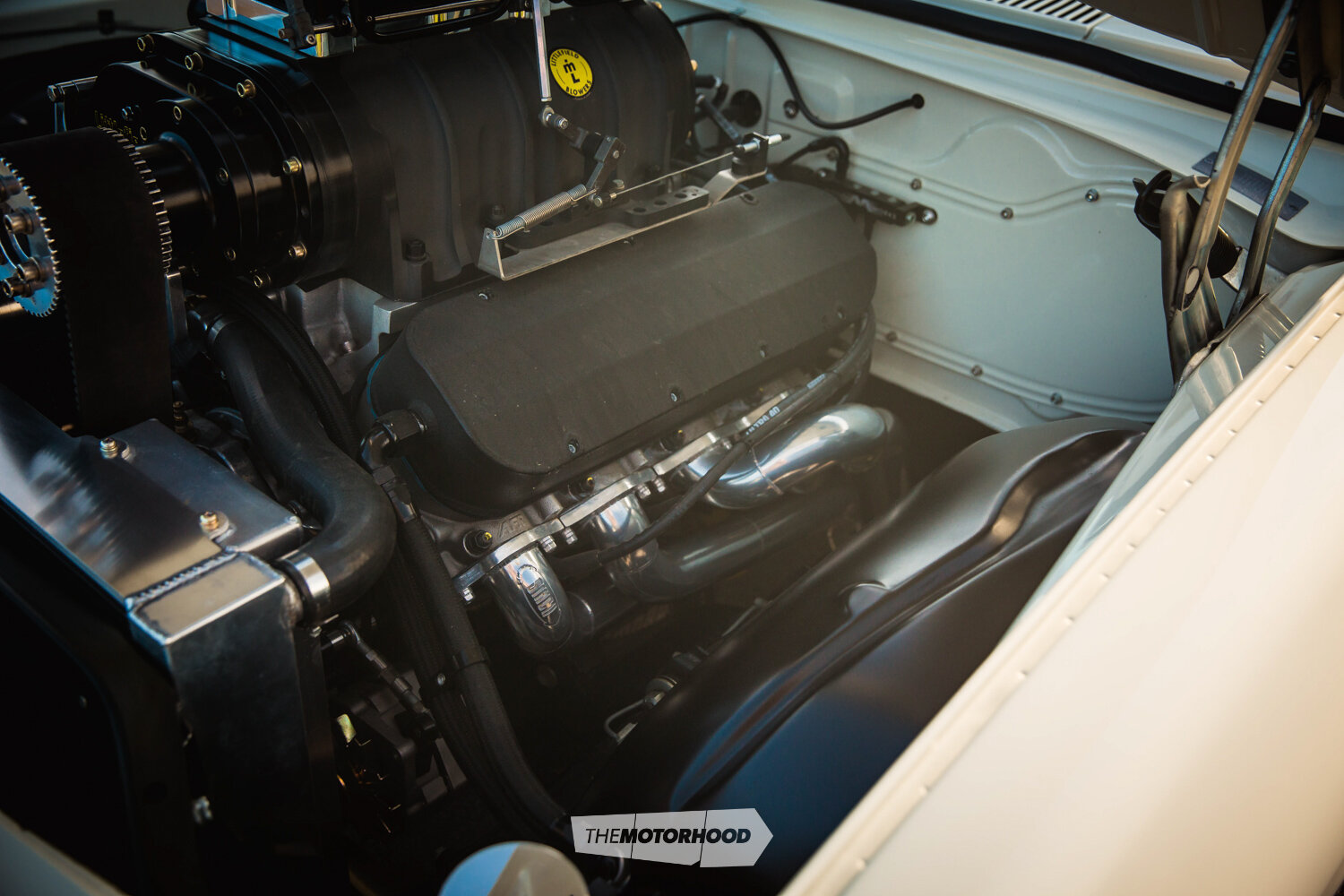

Engine: Craig Hammond (HPE)–built 496ci big block Chev, GM 10.200 truck block, clearanced for 4.250 stroke, Eagle 4.250 4340-steel-centre counterweighted crank, Eagle 6.800 H-beam rod, CP billet flat-top pistons, ARP L19 bolts, ATI damper, Moroso oil pan, Moroso oil pump, Moroso oil pickup, ARP main studs, Marsh Motorsport ported AFR 305cc Magnum heads, Comp Cams roller camshaft, REV 2.250-inch stainless intake valves, REV 1.880-inch Inconel exhaust valves, PAC valve springs, Comp Cams tool-steel retainers, T&D 1.75 shaft rockers, Littlefield 8-71 competition blower, Littlefield manifold, dual Quick Fuel 850cfm boost ref carbs, Aeroflow air cleaners, Custom 110-litre fuel tank, Moroso fuel pump, Aeroflow regulator, MSD Digital-7 CDI, MSD crank trigger, Moroso leads, Sinco custom 2.25-inch headers, Sinco 3.5-inch exhaust, twin Adrenalin R mufflers, Aussie Desert Cooler radiator, custom oil cooler, braided lines throughout

Driveline: Chuck Mann–built TH400, manual reverse valve body, ATI 300M input shaft, roller thrust bearing, HD 36-element sprag billet converter, anti-balloon plate, B&M quicksilver shifter, Aeroflow trans cooler, nine-inch diff, 31-spline axles, Tremec LSD, 1000hp rated driveshaft

Suspension: (F) Two-inch drop spindles, Bilstein shocks, Camaro springs, 32mm Whiteline sway bar; (R) Monroe shocks, VY Commodore springs, Nolathane bushes throughout

Brakes: Eight-inch booster, Wilwood master cylinder; (F) Wilwood four-pot calipers, Wilwood rotors; (R) Ford Explorer calipers and rotors

Wheels/Tyres: (F) 17×8-inch RC component billet, Mickey Thompson S/S sportsman 26/6/17; (R) 15×8-inch RC component billet, Mickey Thompson E/T Street 255/60/15

Exterior: PPG Rover colour painted by Mark Holstein Refinishers, all nuts and bolts re-zinced or chromed

Interior: VY SS front seats, custom rear seat, Billet Works column and wheel, Fusion head unit, Fusion 6x9s

Performance: Untested

A few years later, he’d be living that dream with his own slammed HQ on Tridents and Eagers, but it was far from the perfect example. After meeting fellow Holden lover and Aussie expat Andrew Clatworthy of Streetneat in 2012, Brodie was impressed with his work and started to plan a new HQ build. It would still be on Tridents and Eagars, but this time around with a blower sticking out of the hood and with the body done right — the kind of car Brodie planned never to sell.

The duo kept in touch, and, in 2015, a Belmont shell was purchased. Brodie wanted Andrew on the job, although it took some smooth-talking for him to take on the project, as Brodie explains: “I started to pester Andrew a bit, as he wasn’t working on cars at the time. I tried to convince him to do it on the weekends, but he was never keen. It wasn’t until after four or five months that he messaged and said he’d take it on and it would be the first car he’d build in New Zealand since relocating from Aussie.”

Wasting no time, Brodie dropped the body off at Kiwi Metal Polishers where it was dipped bare. It was not a happy pickup, though, as more was left in the tank than loaded onto the trailer. There were rust holes everywhere. Although Brodie was expecting some of it, the extent had him on the hunt for another shell. He went as far as viewing a few before coming to the realization that he’d probably end up no better off. The search wasn’t in vain, however, as he’d unearthed plenty of spares fit for sacrifice.

While trying to buy one body I was told he didn’t want to sell the car as it was his wife’s but he knew of a shed full of HQ parts if I wanted to have a look,” Brodie tells us. “A couple of calls later, and we were out there with two utes and two trailers loading up as many body panels, parts, and trim as we could carry.”

The restoration began with the removal of the outer skin — or what was left of it — before it was strapped to Andrew’s rotisserie, where it would spend the better part of the next couple of years as Andrew put his metal-crafting skills to the test repairing or completely rebuilding 99 per cent of the body, with only the floor not requiring any work. Many of the spare panels he’d pick up from the barn were donated to the cause, and others, such as the rear quarters, were fabricated from scratch along with many other pieces. Finally, it was ready for colour. Andrew Holstein at Mark Holstein Refinishers laid down the white, which, although it looks like it could be a factory hue, is actually a Rover colour.

However, the work was far from over and the car returned to Streetneat to have the engine combination fitted as planned — a blown 350/400 combination poking skywards, while, out back, a built nine-inch was slotted in, along with some simple yet effective suspension to nail the stance. Brodie then took over and dropped it off to Scotty at Waikato Motor Trimmer for a full retrim in a shade of brown closely resembling what it would have left the factory with. The only thing missing was the front bench seat, which was replaced with a set of VY SS buckets, also in brown leather and modified to make sure that Brodie’s two-metre-tall frame could fit behind the wheel.

You’d think, having just completed his dream build, Brodie would be smiling from ear to ear after the first drive, right? That was far from the case. Despite the fact that the HQ looked as tough as nails on a set of 15-inch Draglites, the blown and blueprinted 350 was underwhelming.

“It was a real let down,” he explains, “and not at all what I had hoped for. A couple of weeks later, I was talking to a friend, Justin Williamson, and he mentioned he knew of a big block with an 8-71 in an Impala that was coming up for sale. We went round there that weekend and went for a ride and I was hooked. The owner, Dave, was going bigger, so I struck up a deal between him and the engine builder Craig Hammond so the motor would be stripped down and freshened up before going into the HQ.”

The combination would also come with a bulletproof Chuck Mann TH400 — for good reason, as the big block would be anything but underwhelming. Based on a tall-deck GM truck block, it had received the works at HPE, where it was clearanced for the 4.250-stroke, 4340-steel-centre, counterweighted Eagle crank. The rods are 6.8-inch stroke H-beam Eagles with ARP L19 hardware, and the pistons are custom-order billet flat-top CP items, a combination that creates 496 cubes. The heads — which came with the package — are 305cc Air Flow Research (AFR) Magnums and spent a ton of time at Marsh Motorsport, where they received extensive port work. A Comp Cams roller cam, 2.20-inch stainless intake, and 1.88-inch Inconel exhaust valves from Racing Engine Valves (REV) were fitted. The heads were also modified to suit shaft-mounted rockers, which are 1.75-ratio T&D items.

It’s a serious package, and when you see the black blower from Littlefield on top, you know why it’s an 8-71 competition unit complete with a pair of 850cfm Quick Fuel carbs on top. Running an MSD CDI unit and avgas on the dyno at Marsh, the combination made just shy of 1000hp, and, although it’s yet to be strapped back on, now that it’s been rebuilt and switched to E85, it will make plenty more than the old ‘bling motor’ could ever have dreamed of.

With such a demanding day job, getting time to spend in the shed is a rare occurrence for Brodie, especially with his current overseas commitments, although some downtime with injury did mean he had some time to get the new combination bolted in, or at least supervise and feed the boys while they did the heavy lifting — it was a serious shoulder injury he was nursing.

It was then back to Sinco, which had handled the first exhaust, to build the set of custom headers that the tall-deck block dictated. This is backed by a 3.5-inch stainless exhaust to let the big engine breathe. Another weekend with the boys — this time, an 80-hour ‘let’s get it done’–type affair — finally had the new combination ready for its maiden voyage, complete with a new look and stance by way of a reverse-staggered set of RC Components wheels inspired by the builds coming out across the ditch.

A silver lining to certain global issues in the world that would not allow Brodie to return to Japan was that the maiden voyage was quickly followed by an open track with very loose rules for a weekend at Chrome Expression Session to really blow the cobwebs out and ensure that that grin was here to stay. The next big hurdle will be getting it legal, but, with work calling, that can wait — oh, and there is another build to shift focus onto; you can see it on page 80.

Driver

Brodie Retallick

Age: 29

Occupation: Grass cutter

Previously owned cars: ’64 Impala, couple of HQs, Studebaker

Dream car: This

Build time: 5½ years

Length of ownership: 6½ years

Brodie thanks: Andrew Clatworthy (Streetneat); Scott Stinson, for all his help; Jake Hakaraia (for eating all the pizzas); Waikato Motor Trimmer; Mark at Mark Holstein Refinishers; Dave Mills (PPG); Eddie Apps; and anyone who has ever helped get the car together, big or small

This article originally appeared in NZV8 issue No. 187