Words: Marty Burnside Photos: Cam Leggett

This story begins in 1994. The automotive world had its challenges. BMW had just purchased Rover from British Aerospace, Ayrton Senna died at Imola, Italy, during the San Marino Grand Prix, and OJ Simpson did a runner from the cops in a Ford Bronco.

New Zealander Chris Saywell, who was living in Perth, Australia, at the time, had his own challenge. He wanted a project car. He had found a 1970 Ford Mustang fastback being used as a chicken coop, purchased it for the princely sum of $5500 — which was bloody cheap back then — and decided to bring it back to New Zealand.

With the car now safely landed in Taranaki, Chris called upon the expertise of a local panel beater, Barry Cruickshank. Over the next 12 years, Barry and Chris replaced all the required sheet metal. Then it was on to Brendan Landers for the prep and paintwork.

Unfortunately, tragedy struck. Chris was killed in a motorcycle accident in October 2006, just before he started assembling the Mustang.

This is where Vaughan’s story begins. Vaughan was friends with Chris, and after the dust had settled from the funeral, he approached Chris’s parents, Pat and Dorothy, to see what their plans were for the car. Did they want to see it disappear, never to be seen again, or did they want to see it stay local and be completed the way Chris wanted? Vaughan proposed that he take ownership, and, to his surprise, Pat and Dorothy told him that they would love him to have the car and see it through to completion. He was over the moon!

Murphy’s law, Vaughan was in the middle of selling his house at the time of this conversation, so the Muzzy stayed at Pat and Dorothy’s for another 12 months until a shed was built at Vaughan’s new property. Then it was home time.

Vaughan had a long history of working on cars, both for himself and his mates, but he felt he needed some guidance as to where exactly to start on this project. Enter Pete Robinson. Vaughan and Pete go back a bit — Vaughan purchased an XF Falcon off Pete, which he has owned for 18 years. Pete’s suggestion was that they start from the bottom, and work their way up from there, so steering and suspension were the first port of call. An RRS steering rack that Vaughan ordered from Australia was soon installed. Next came the suspension. The call was Koni two-way adjustable shocks all around, with heavy-duty lowered springs in the front and lowering blocks on the standard leaf springs in the rear.

If you want a car to go, then it also needs to stop. Chris had already set up the nine-inch in the rear with XF disc brakes, and collected a ton of parts for the Muzzy, and Vaughan wanted to keep it as close to Chris’s dream as possible, so he opted for a combination of Wilwood four-pot callipers and rotors for the front.

Amongst the collection of parts was an XD Falcon brake booster and master cylinder, so those were sent to get refurbished. Pete and Vaughan also settled in to make all the brake lines and fittings. At the same time, new fuel lines were put in place.

Chris had already purchased and modified a destroked 460-cubed motor out of a 1971 Ford Lincoln to become a 429 — not that he divulged what modifications were done, but his brother Mark told Vaughan, “He spent a shit tonne of money to make it go fast!”

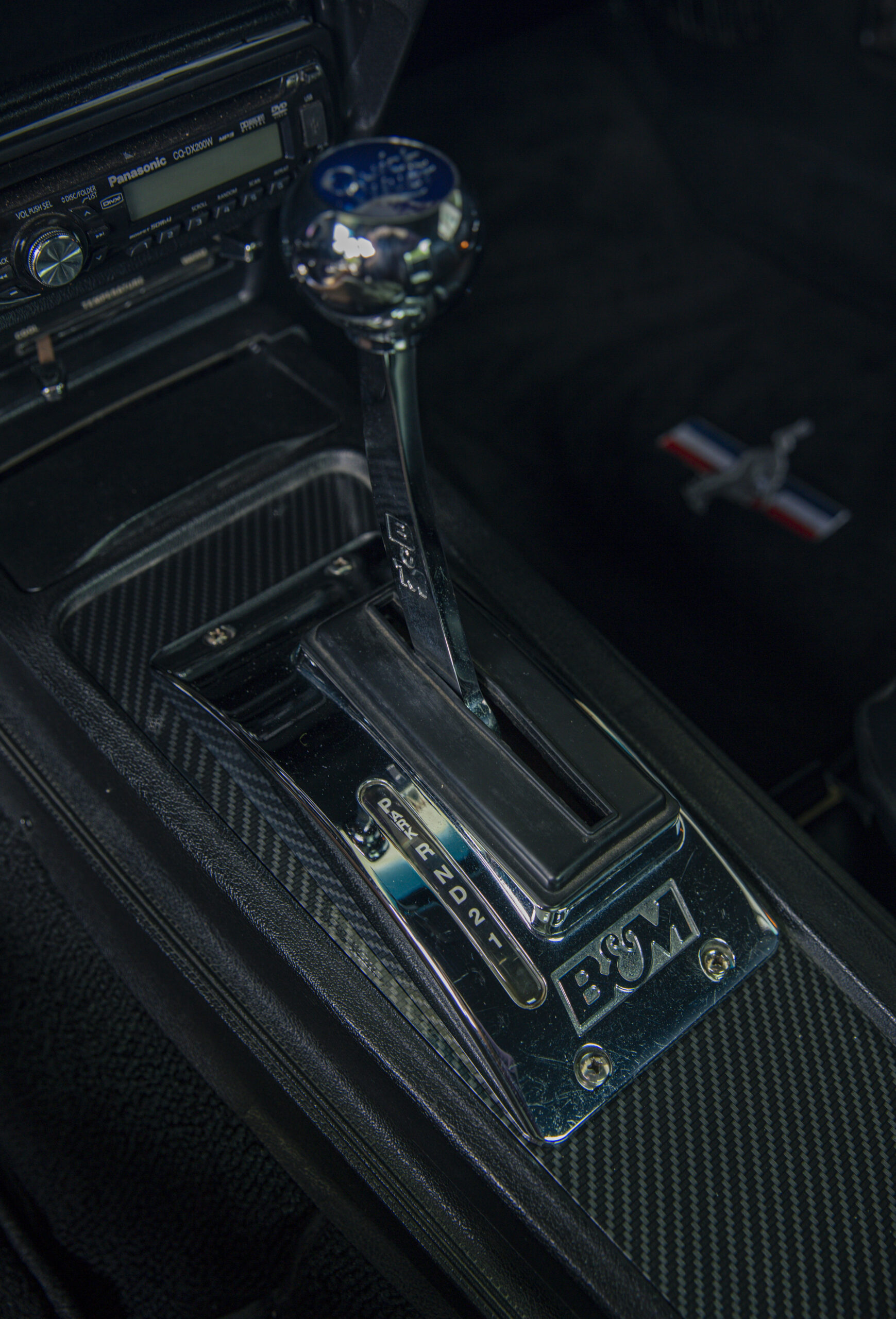

The C6 behind the motor was still original, so it was sent to Skinny Colson to be upgraded with a 2500rpm stall converter and shift kit to suit.

On the return of the transmission from Skinny, both motor and transmission slid into the painter’s booth. Metallic charcoal was the choice here.

Then, on a Wednesday afternoon, both pieces became one with the car, at last. Unfortunately, due to a break up, the project was put on hold for the next five years, with the car sitting under cover at Pete’s workshop.

Upon being able to start working on the car again, Vaughan talked with Geoff Wakeling, a fellow Egmont Rod and Custom Club member and, as Vaughan states, “an engineer extraordinaire”, about the possibility of building a custom exhaust assembly — nothing was available from the shelf for this set-up as the big block takes up so much room in the engine bay. As a result, the car was put on a transporter and sent down to Eltham, where the exhaust was scratch built, so that the serviceability of simple things like spark plugs stayed away from being a challenge. Once the exhaust system was complete, it was sent to HPC for coating.

Geoff then raised a matter that hadn’t yet come to mind with Vaughan: engine bay bracketry. After collecting the materials suggested, Geoff got stuck into designing the alloy power steering and alternator brackets. Once it was milled at Geoff’s workshop, their attention turned back to the exhaust system fitment, complete with stainless tailpipes.

With the exterior ticked off, Vaughan’s mind turned to how to get the interior to look as good. He set about mocking up a custom dashboard. The seats were reworked at Custom-Line Upholstery in Stratford, under the watchful eye of the owner, Chris Foley, with the roof lining going in just prior to glass fitment. What you can’t see, now that it’s completed, is just how much Dynamat sound and heat insulation has been installed underneath — Vaughan tells us it’s everywhere.

Vaughan now turned his attention back to the engine, as he was getting impatient to hear it scream into life. However, he hadn’t thought about the fuel, apart from making the new lines. A ring around fellow Egmont club members started the search for a suitable carb. After a handshake and a few dollars exchanged, Vaughan purchased a Demon 850cfm double pumper from club member Hamish Heistand, who was fitting a Holley Sniper set-up to his Camaro. Bad news for Hamish became good news for Vaughan, as the wrong Holley set-up arrived — yes, Hamish admits he ordered the wrong kit — so Vaughan purchased that, too.

With a change of fuel system style, the lines had to be redone. An in-tank pump was installed, along with baffles in the tank.

The time had arrived to fire the Mustang into life for the first time. That day was 15 September 2019. Chris’s family were on the scene, and all systems were checked and double checked. Vaughan flicked the switch, and it was alive — giving goosebumps to all in attendance.

After a cool-down period for the engine, the team undertook testing of the transmission, brakes, etc. The final touches began over the next few months — fitting the panels, gapping alignment, and final wiring and system checks. It was time for the big road test. Chris’s brother, Paul, was visiting from Australia and it was now February 2020. It was with great pleasure that Vaughan got to take Paul, Pat, and Dorothy for a spin down the street.

The club’s bi-annual rod run was to take place in October 2020, and following 12 hours of Brendan’s skill in detailing the car, the Muzzy was presented to the club, with great applause — and ribbings given for the length of the build.

The next outing was for the wedding of Vaughan and his new bride, Megan. Although the car was still not legal, it just had to be there.

Trying to get it legal became the stuff of legend. Vaughan was trying to get the Mustang VINed. Although he had had a letter from NZTA stating he could lay tyre to tarmac, he was advised that he had to show the car’s provenance. As the car had arrived in Australia with incorrect paperwork, and Vaughan had to prove its registration in its birth country, America. He even managed to track down the dealership from which the Mustang was sold new, but unfortunately its records didn’t go back far enough.

As Vaughan states, “In a sheer act of frustration and desperation”, he posted his story on several Mustang pages on Facebook. After a number of dumb responses, he got a couple of positive responses directing him to a historical VIN recording agency, which confirmed in writing that the car had never been stolen or written off in an accident. This was fantastic help. The second response was from an Australian who did restoration, who gave Vaughan an email address for the Australian customs department, which gave Vaughan the shipping name and date of arrival in Australia. With this information supplied, the VIN tag got attached.

A warrant of fitness and final compliance issues were sorted, and the registration sticker was attached in April 2022. A final touch was the personalised plate. Vaughan explains that Chris’s nickname was ‘Charlie Fast Cars’ so 429CFC sits proudly on the car.

While the process was long, at times bloody painful, and almost baited with a white flag, Vaughan is extremely proud of the finished result, and hopes that, wherever Chris is, he’s smiling