What is it, how do you work it out, and what does it mean?

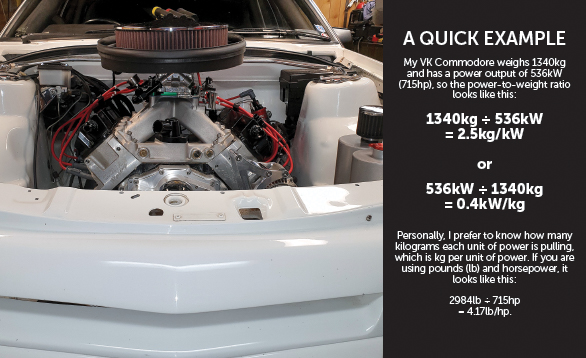

Some people say that there are two ways to go fast: with plenty of power, or with as little weight as possible. The reality is, no matter how much weight you’re packing, power-to-weight ratio is an insurmountable equation. The ‘power-to-weight ratio’ is simply working out how many kilograms (kg) each unit of power (kilowatt — kW) has to pull. Or it can be the reverse of this: how many units of engine power are available for each unit of weight (also known as ‘mass’)? The latter is the most common form used by the automotive industry. The units can be in kilograms and kilowatts or pounds and horsepower, it’s your choice, but the answer in any unit (metric or imperial) is a very good way of comparing different cars and how you might expect them to accelerate. Clearly, if you’re using weight divided by power output, it will be the car with the lower number that’s better off, and if you’re using power output divided by weight, it will be the higher number which is better.

Now we know how to work this out, but what does it actually mean? In simple terms, it means that the car that has the lower weight-per-horsepower ratio will accelerate faster than the car that has the higher weight-to-horsepower ratio, if you’re using the weight-divided-by-power ratio, or it means the opposite, if you’re using the power-divided-by-weight ratio.

Unfortunately, the world isn’t quite that simple, and as some of you will have already picked up, this calculation is worked out at peak power, and we all know that engines make different amounts of power at different points. Some are designed to accelerate from lower rpm, others at higher rpm, while some have better gearing that takes advantage of where the torque curve kicks in. However, it is still a good guide, as weight doesn’t just affect a vehicle’s acceleration but also how well it stops and how well it corners.

An interesting real-life example of power-to-weight ratio is the Holden 308 V8 versus the Chev 350 small block V8 transplant that was popular before the LS series of engines arrived. The Chev weighed about 61kg more than Holden’s plastic fantastic. If you do the calculations on the engine alone, using my own VK as a benchmark, the Holden would be 200kg (engine weight) divided by 536kW (719hp) (power output), which equals 0.37kg/kW. The Chev would be 261kg divided by 536kW and this equals 0.49kg/kW. We are clearly not comparing standard engines here, but the Chev is going to have to make about 705kW (945hp), an increase of 169kW (227hp), to break even with the power-to-weight ratio of the Holden. Obviously, this may be too expensive to attain or simply not possible. Of course, an all-alloy LS would turn this around, which is part of the reason why they are so popular for conversions.

Handling factors may be less influenced by power-to-weight factors and more by where the weight is, and this begins to alter how a car handles, which brings about more significant challenges, especially for competition cars. The worst place to have weight in a vehicle for handling is over the front wheels, and the first-generation Chev — or any heavy engine for that matter — does not help in this instance. Weight up front can overload the front tyres under cornering and this in turn induces understeer, and, while I hear the loud pedal brigade giving the age-old advice, “You just stand on it”, we’re talking handling here, not drifting. I experienced this first-hand at Pukekohe raceway, coming over the hill onto the front straight in the previously mentioned 308-powered VK. I was closely followed by a VH Commodore powered by a 350 Chev which was keen to get past me, as I had out-braked it into the hairpin (I had less weight to pull up). As I accelerated hard on full throttle out of the corner, I checked my mirror and saw the Chev-powered VH in a serious oversteer as the driver stood on it. This ended in a red flag by the time I got to the end of the front straight. The Chev-powered VH had gone into a wild series of fish tails, ending up in the Armco backwards. What’s my point? Front–rear balance is probably more important that power-to-weight ratio, and excessive torque at full throttle doesn’t necessarily solve your understeering problem — or corner exit speed, for that matter.

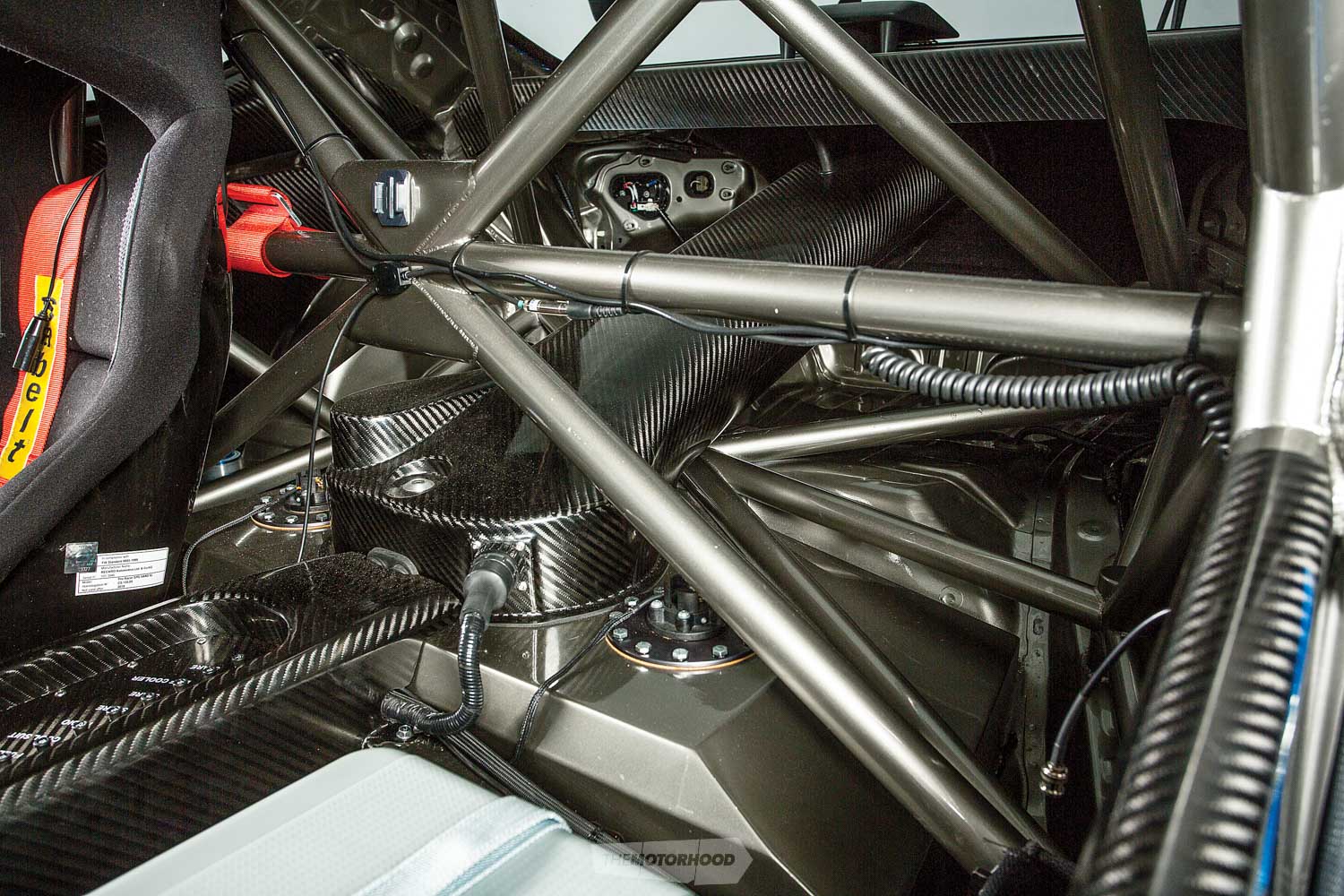

On the topic of balance, I was at Pukekohe back in the day when the Trans-Am class cars were racing. These and Formula 5000s (F5000s) are among my favourite race cars. The Trans-Ams run mostly Chevs and Ford V8s, as do the F5000s, with the odd Repco Holden 308 thrown in the F5000s. While they run stock block V8s, they are all space-framed. The F5000 weighs around 670kg and produces 395kW (530hp), which gives it a power-to-weight ratio of about 1.7kg/kW. These stock block V8s can reach up to 300kph (186mph) on the right track.

I had a look under one of the Trans-Am cars that was jacked up, and it took a little while to figure out what was hanging off the driveshaft just ahead of the diff. I soon recognized that it was the alternator. While power-to-weight ratio is one thing, shifting weight around is the answer. I was once asked by another racer why I had made my drop tank out of stainless steel and not aluminium, and I got a very strange look when I answered, “Because it’s heavier”. We never did get into it, but I had removed around 38kg from the engine in the VK, and I could afford to stick a bit more weight in the boot, including the battery. Why? Because I get better front–rear weight distribution.

To sum this up: power-to-weight ratio is important for acceleration, as well as braking, and the weight of any engine transplant that you use in a car can worsen the power-to-weight ratio and/or front–rear balance and also reduce handling and performance, even if the new engine has a bigger displacement and more power. Equally important as power-to-weight ratio is front–rear balance, and these two factors together can create a very, very quick and responsive vehicle.