Shaking ground may have delayed the build of this fine Falcon, but, these days, it’s the car that brings the rumble to town!

Whenever the topic of ‘Canterbury’ is uttered on the news, you know that some waxing lyrical about southern resilience is just around the corner. But every cliché is steeped in truth, and it’s definitely no lie that they breed and build them a special kind of tough down the line. If ever a testament to that southern resilience is required, look no further than the masterpiece that is Mike Blackmore’s ’64 Ford Falcon.

You see, despite the car’s outstanding presentation, the build process was a long and tedious one, punctuated by those Christchurch earthquakes that have become a grim topic of general knowledge throughout the country. Despite that, the end result you’re looking at must surely exceed even Mike’s initial expectations of the build.

“I’ve always liked coupes, and thought two-doors were the only way to go,” Mike says, explaining why his ideal car would only ever possess the fewest number of doors possible.

Knowing that he wanted to start a full-scale project, Mike decided to do things right, so shopped around for a reliable go-to guy before committing himself to a build.

“I’d met Mark Stead [owner of Big Shed Customs] at the McLeans Island Swap Meet about 15 years ago, and he’d just finished a ’32 — I chatted to him for quite a while, and I liked the way he rolled,” Mike tells us. “He was an interesting cat to talk to. I did some background work [on him] through mates that grew up in Blenheim, and he checked out to be a straight-up guy, with good skills and a good reputation.”

With his go-to guy all sorted — whether Mark knew it at the time or not — Mike was left looking around for the right car to get stuck into. That popped up while he was on holiday in Brisbane and was leafing through a Trade & Exchange–style publication over there.

“It was a rolling body full of rust, which the owner had been using as a parts car. I had looked at an HQ Monaro LS two weeks earlier and was close to buying that, but the Falcon tickled my fancy just a little more,” he recalls.

It may sound like a bit of a questionable call, but Mike didn’t think so then, and he definitely doesn’t now! Unfortunately, he experienced several delays when it came to extracting the Falcon from Australia; it eventually landed in New Zealand around nine months after he’d purchased it. Mike always knew that he wanted to build the car into something different, and it had to handle properly, like the Escort circuit car he owns. For several years, he juggled the Falcon between various storage spaces as he built up the collection of everything that he’d require to dive into the build, and, just as importantly, complete it. It was while he was searching for an engine that a mate planted the seed in his mind about a stroked Windsor topped with a B&M supercharger — an idea Mike found hard to resist.

It was just as the metaphorical ball had begun rolling and was gathering momentum, that the brakes were applied, with Mike moving to Perth, where he’d be stationed for 13 months. However, that turned out to be a blessing in disguise. While there, he began sorting the handling side of things, thanks to liberal helpings from the RRS Australia catalogue, from which a steering rack, front coilover shocks, a custom three-link set-up for the rear end, an under-dash brake booster, and rear brake calipers were all sourced. All the while, Mike continued sourcing parts locally and from the US, waiting for the time when he could throw everything at the Falcon.

Three months after returning from ‘Straya’, Mike bought a house and launched head first into the project. He got in touch with Mark Stead, made a plan, and had the Falcon soda blasted before being transported up to Big Shed Customs in Blenheim, so that Mark would know exactly what he was dealing with. Mark replaced the door panels, tweaked the rear wheel arches to help soften the Falcon’s slab-sided profile, and finished off the remainder of the rust-repair work. The Falcon was returned to Mike, but it was around this time that Mike’s plans began to change drastically, although undoubtedly for the better.

“Once the Falcon was back home, I had the idea of changing the motor, after deciding I wanted fuel injection for reliability,” he says. “After a measure, I was confident I could make it fit.” Cue another long-haul trailer session, with the Falcon taken for its second trip up to Big Shed Customs, where the firewall was recessed and the shock towers were notched, allowing space for the new power plant — a 5.4-litre Boss V8 and ZF six-speed auto from a late-model BF-series Falcon.

Mike brought the car back home to Christchurch once more, but it wasn’t long before his active mind saw him trailering it back up to Blenheim for even more fabrication work.

Mike chose front bucket seats from a BMW convertible, as they incorporated a self-contained seat belt — perfect for a pillarless body such as the Falcon’s: “I searched high and low for something that would work, then I stumbled across a BMW E36 convertible in a car park. The hunt was on, but, surprisingly, they were not easy to find — I eventually found a pair on eBay in the UK, and had them shipped over to New Zealand.”

With the seats sourced, Mark now had to get them into the car. He chopped the floor out to get them sitting right and fabricated new support points to account for the new loading and stress points resulting from the altered seat-belt configuration. Unfortunately, the very next day, Christchurch was hit by the massive February 2011 earthquake, and Mike had to push the Falcon from his mind while damage to the property was addressed. Perhaps it was a stroke of luck that the Falcon was so far removed from the damage, but it still ended up sitting in Big Shed Customs for the better part of nine months, before Mike was ready even to think about it again.

Once the final spate of modifications was complete, and the car was once again at his fingertips, Mike began preparing the Falcon for the build’s final stages and shopping around for the place he would entrust with the work. “I chose Avon City Ford in Christchurch, as they were keen to paint it, and within my budget,” Mike says. While they clearly did a great job of coating the Falcon’s smooth panels in iridescent layers of custom-mixed Leonard Green PPG paint, it wasn’t quite done there — in a case of déjà vu, a large aftershock decided to mess with Mike the day after the Falcon was taken home from the painter. This time, the damage was not to the property but to the car — although, fortunately, it was nothing that couldn’t be repaired.

Now that the Falcon was beginning to resemble a finished car, the remainder of the bolt-on stuff could be fitted. The running gear was installed for the final time, and then it was time to sort all the other little things that needed ironing out. Matters such as ensuring the ECU — in charge of the functions of the fuel-injected motor and the electronic transmission — was wired in correctly, were sorted out by Mike’s brother-in-law, Malcolm, from Langleys Auto Electrical in Whakatane. Then there were the small tasks, such as sorting out the exhaust and fuel systems, which were taken care of by Ryan at Spec Performance. Intricate custom headers were painstakingly fabricated to clear the strut towers and steering shaft, flowing into a twin 2½-inch exhaust system.

Because of the Boss motor’s fuel injection, careful attention had to be given to the fuel system. A 95-litre fuel cell was custom made for the job, with a surge tank and return reservoir carefully incorporated into its design and a pair of Walbro electric fuel pumps taking care of business. Moving onto the final stage of the build, Mike took up his Sherlock Holmes hat and pipe once more, carefully deciding exactly who he would like to upholster the interior. Glenn Burke was chosen for that particular task, due to his reputation as an upholsterer as well as the quality of his past work, and he’s done a great job — any interior components not lathered in body-coloured paint were trimmed in a fine combination of grey leather and suede, providing a supremely comfortable and refined cabin, whether Mike’s cruising through town or blasting down the drag strip.

All ready to hit the road, Mike’s grand plans were again slowed down as a number of minor issues required remedial action for an LVVTA cert. Nine months later, he was all good to go, with a fresh cert plate riveted on. “As of Friday, October 20, 2015, it was all legal to be on the road, and our first cruise was to the New Brighton Rockabilly Show and Shine,” says Mike.

This was where we first saw the Falcon in the flesh, and it really is something to be seen in reality, with your own eyes — truly spectacular. It’s hard to see the toil and hardship that have gone into any car as well finished as this, but, at least, for Mike, it has all been worthwhile. The build may have taken longer than expected and featured a few more setbacks than one could ever expect, but the end result is a lesson in vehicle building done right, brought to you by that old southern resilience.

Mike Blackmore

Age: 38

Occupation: Sales manager

Previously owned cars: Ford Escort Mk. II, Honda Integra, Honda Civic, Honda Class 8 off-roader (currently own)

Dream car: I own it

Why the Falcon? I wanted a two-door, and something not too common

Build time: Seven years, with earthquakes and numerous moves and re-repairs due to damage

Length of ownership: 10 years

Mike thanks: First of all, my lovely wife, for all the hours away from her and the kids, night after night, in the garage; my mates Richie, Jason, and Jeremy for their help over the years; Mark Stead at Big Shed Customs for all his effort and for putting up with me; my brother-in-law, Malcolm, from Langleys Auto Electrical in Whakatane, for hours of work painstakingly getting everything connected and running through the car; Glenn Burke, for the upholstery; Shane at Safe-R-Brakes; Dave and Pete at Avon City Ford for the panel and paint; Scott at A C Auto Parts; and Mathew and Alex of RRS Australia

1964 Ford Falcon XM

Engine: 5.4-litre Ford Boss V8, rotated stock intake, custom headers, twin 2½-inch exhausts, fabricated 95-litre fuel tank with surge tank and return reservoir, twin Walbro electric fuel pumps, custom radiator, factory Ford ECU

Driveline: ZF six-speed auto, nine-inch diff casing, 31-spline Moser axles, Truetrac LSD, one-piece slip-type driveshaft

Suspension: RRS rack-and-pinion steering, RRS front coilovers, custom strut brace, RRS rear three-link, QA1 adjustable rear coilovers, Nolathane bushes

Brakes: RRS under-dash brake booster, PBR front calipers, DBA 335mm front discs, RRS rear calipers with built-in handbrake, DBA 320mm discs

Wheels/Tyres: 18×8-inch Ridler wheels, 245/35R18 Hankook tyres

Exterior: PPG Envirobase Leonard Green paint, custom-rolled bonnet bulge, removable front radiator bar, flared rear wheel arches, shaved trim, shaved door locks, shaved boot lid, notched rear bumper, flattened floor pan, recessed firewall, custom transmission tunnel

Chassis: Notched for starter-motor clearance

Interior: Ididit tilt-adjustable steering column, Billet Specialties steering wheel, standard dashboard, modified gauges with electronic input, BMW convertible front bucket seats, custom grey leather and suede re-trim, Alpine IDX-305 head unit, Rainbow six-inch component speakers, Alpine 12-inch subwoofer

Performance: Untested

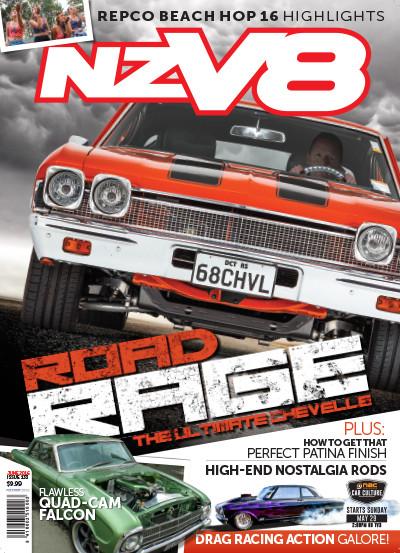

This article originally appeared in NZV8 magazine issue No. 133 — click the cover below to get your hands on a print copy of the mag: