Oil is something most of us know enough about, without knowing much more. We got to talk with a real-deal oil scientist to find out everything you’d want to know about engine oils

Most of you reading this will know enough about engine oil. You’ll understand enough about oil viscosity, zinc content, and API ratings to know the difference between what goes into your daily-driver and what goes into your V8. The tradies among you who drive a late-model diesel vehicle every day may know more than most — after all, you can’t just run any old oil if you’ve got a diesel particulate filter (DPF).

However, beyond the surface-level stuff, the world of oil is largely a mystery. And, we’ll be the first to admit, it sounds awfully boring. Who really wants to know more about oil? Well, as it turns out, it’s not that boring. We were able to chat with Lake Speed Jr, a respected US-based ‘tribologist’ — an oil technician, if you were wondering — who was brought to New Zealand by Craig Hyland from Engine Dynamics. Lake Speed Jr works extensively with the Joe Gibbs Racing Nascar team and has had a long and intensive career in the motorsport industry, and he is the brains behind the premium Driven Racing Oil range of lubricants. We made the most of his enormous knowledge of lubricants to find out more, and dig into some myths, about engine oils.

Hi, Lake Speed Jr. Thanks for taking the time to do this. We’ve got a few questions for you. First of all, do oil additives really work, or are you better to start with a good oil and eliminate the need for additives?

The STLE [Society of Tribologists and Lubrication Engineers] have answered that question with a ‘no’ — you should never put an aftermarket additive in any crankcase. If you feel that the oil you are using in insufficient for the job it is doing, you should get a different oil, not put something in. In fact, on the exam to get [STLE] certification, that actually was a question — ‘when is it appropriate to use an aftermarket additive in a crankcase?’ — and the answer’s never.

Would that extend to oil flush?

I’d say so. Some of the oil flushes available do really weird things, and you really ought to be thinking about it. Even if you’ve got this old engine — say, it hasn’t been run for 15 years, and you’ve got no idea about the condition of the internals, then drain out what’s in there and put in a lighter weight of mineral-base oil. Let it run for 20–30 minutes, get heated up, then drain it out and replace it with, say, HR oil [15W-50 mineral base]. The key is in changing the oil when it’s hot — if the oil is not hot, then you’re not draining it all out. You’ve got to get it hot enough so the viscosity thins and it all flows out.

Playing with additives is like playing Russian roulette. One guy might say, ‘I used XYZ engine treatment and I picked up 5hp’; well, the other guy might say, ‘I used XYZ engine treatment and I lost five main bearings’. Which one’s lying? Well, neither of them is — the reality is that, in one case, the XYZ additive did not blend well with the additives in the oil already and had a bad result; in the other case, they worked together and it’s OK. Unless you’re a chemist and you know 100 per cent what you have and what you’re adding it to, it’s just a gamble. There’s a lot of guys out there with a lot of money tied up in their motor — is it worth taking that risk?

Is more expensive oil always better?

Nope. We get this question frequently — I think I’ve answered this one twice today, already. Race oil is more expensive, but it’s not better. Say I have a car that I drive to work, drive to the odd car show, then take to the track for drags or a drift do. I may think I have a race car, but I don’t, and I don’t maintain it like a proper race car. Race oil is low detergent, low dispersant, and needs changing every 800–1000km — that level of maintenance is not happening with that car. So, while race oil is more expensive, it is not actually the right choice for the application. A good way to know if you should run a race oil or a high-spec synthetic is this: if you use pump petrol, use a high-spec synthetic like Driven’s LS30; if you use race fuel, use a race oil.

How about zinc content — is there only one type of ZDDP (zinc dialkyldithiophosphate)?

Nope, there’s almost 50. There are three classes of ZDDP — primary, secondary, and aryl. Within those three, there’s both short chain and long chain, as well as high molecular weight and low molecular weight, so there is a wide variety in ZDDP chemistry. If you do the math, it works out to around 49 possible combinations, and that’s not even with mixing. You can get some ZDDPs that are mixes between two. So, I could mix a short-chain primary with a long-chain secondary to try to get a mixture. You can say, ‘I’ve got ZDDP’, but what type? Some are proven to be more catalytic-converter-friendly and less so for anti-wear. Some are really good for anti-wear, and not so cat-friendly.

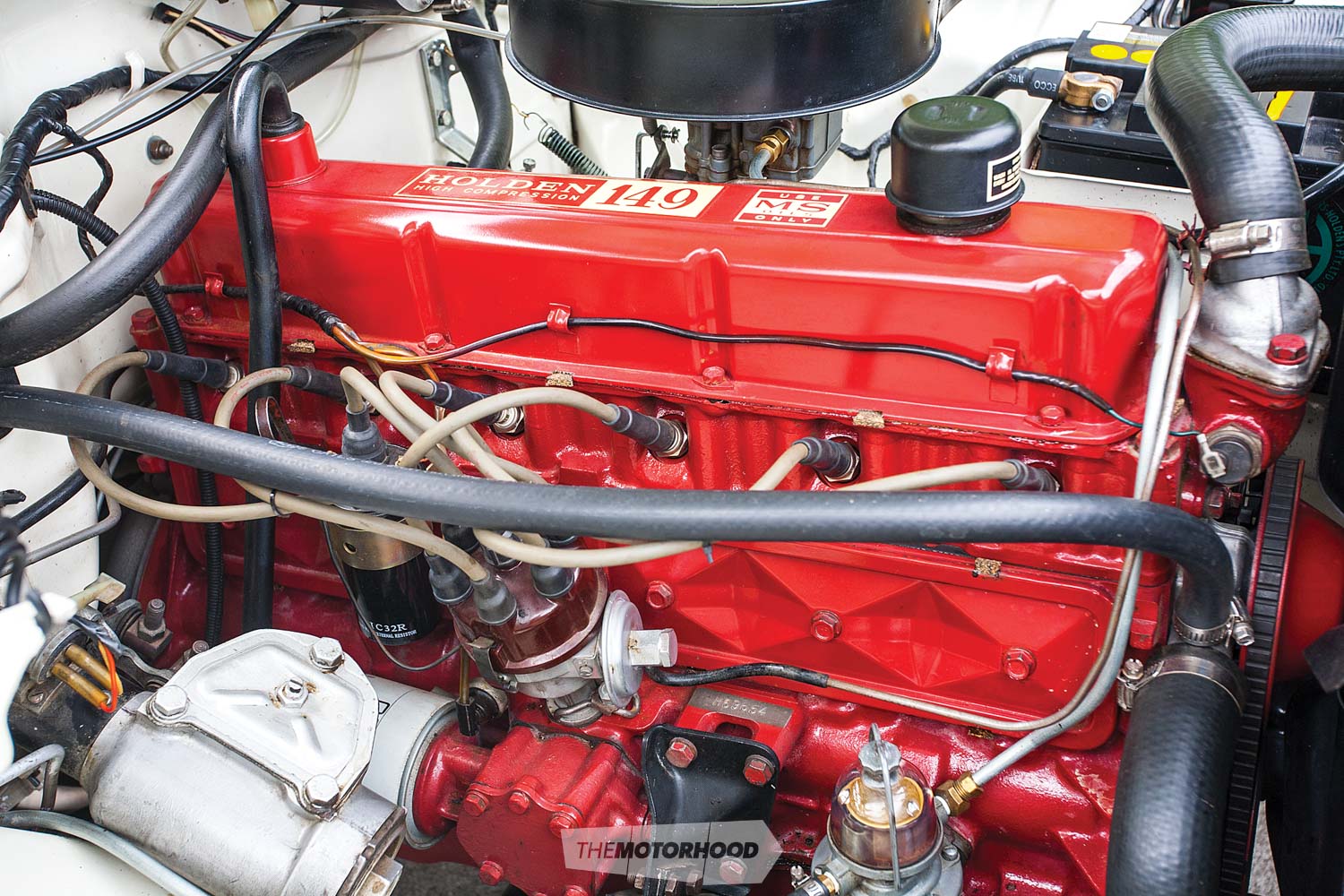

Is there a specific type of ZDDP that we should be looking at for our type of cars — older, pushrod-type stuff?

Yes. Older pushrod-style engines have very high contact forces in the valvetrain, so the ZDDP activity requirement is higher. You see, the ZDDP doesn’t know what the spring pressure is; it doesn’t care. It just knows contact load. So, if I have a four-valve engine that only has 80 pounds on the seat, but my contact area is super small, it could still be as high as a two-valve motor that has 140 pounds on the seat but has a much wider contact surface. Now, with the pushrod motor, you have more dynamic weight because of all of the valvetrain’s mass. That’s where the overhead-cam engines generally have a lot more leeway, because they don’t have the mass, so some of the inertia forces don’t do the weird things that pushrod engines do — the higher your rpm, they start doing funny things. The secondary ZDDP is the one that has the better anti-wear properties, so, any time you have a performance engine or a classic flat-tappet engine, the secondary ZDDP is your better anti-wear. In the classic and performance cars, they’re not so much worried about whether they’re going to get 75,000 or 125,000 miles out of a catalytic converter, so going with an oil loaded with secondary ZDDP like HR1 is a great option for outstanding wear protection. And that’s a really important point to make, because too many people have this fear that if they use a high ZDDP oil, their cats are going to go bad — that’s not gonna happen from the ZDDP. The ZDDP is never going to do that; the cat may not work as well, but it’s not just going to clog up. That only happens when you have, say, stuck rings and are using oil — like a quart every 100 miles.

Some guys have cars that only see a trailer. They fire it up, roll it on a trailer, and go to a show, and it sees less than, say, three miles a year, and they only do one oil change — OK, the oil you bought at the parts store is probably OK. Yes, by now the valve springs are probably only a fraction of the spring rate they were initially, but if he doesn’t do anything different to that car, then it’s probably fine. The problem is when that guy jumps on the internet and says ZDDP is all rubbish and that he doesn’t have any problems, and the guy that actually drives his car gets a flat cam because he listens to bad advice.

Is there any way to tell what type of ZDDP you have in your oil, so that if you’re shopping, you can lean towards a more preferable type?

Sometimes you can tell by oil analysis, but off the shelf — no. You can tell what’s not in it, though. Anything with an API SN grade has to use the new phosphorous retention ZDDP, which is a less active form of ZDDP. So, anything that’s an SN will not have the older, more aggressive type [of] ZDDP, and most of what you’re going to get off the shelf is SN.

Is there any guarantee that older grades, such as SG or SJ, will meet a particular ZDDP content?

No, but typically if it has an SG or an SJ on it, then those oils — and the fact that they’re even displaying that rating — means that they’re probably buying a package that has been accepted as that. Those are obsolete standards, so you can’t go and create and test an oil of that standard and get approval — you can’t even run those engine tests. So, to maintain that, the additive supplier is selling the package they sold back then, and you can claim it.

With those older oils, is there such thing as a shelf life? If you found an older package from 10 years ago, could it still be OK to use?

The basic rule of thumb in the oil industry is that the manufacturers will typically stand behind the oil for at least 24 months from the date of manufacture. There should be zero issues within 24 months. The next 24 months after that, you should be OK as well. That gives you four years. Anything past that, you might want to shake it up really good, but it really depends on how you store it. There are certain components that do lose their potency over time, so that can potentially be an issue.

What’s the deal with detergents being added to oils?

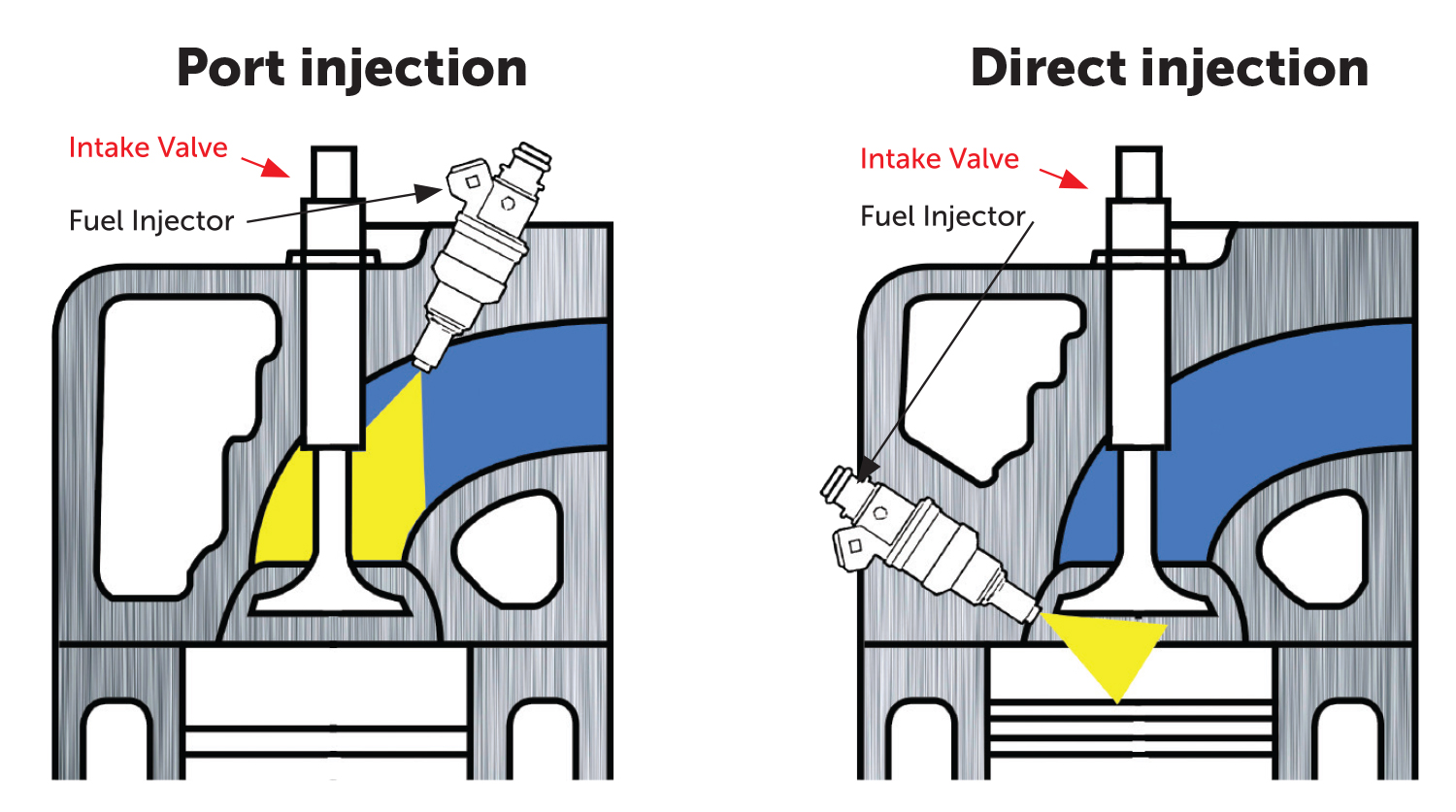

Think about modern engines and emissions; piston design, for example. On old-school engines, your top ring land used to be fairly far down. You had all this crevice volume, and all this crevice volume doesn’t burn. The low speed pre-ignition issue with DI [direct injection] engines, what they were finding is that the crevice volume is where it actually initiates the mega-knock event. So, one of the piston manufacturers worked with one of the test labs, and actually patented a crown design where the crevice design is actually tapered — it’s not a 90-degree angle; it actually runs a really oddball radius. The idea is that you can actually get the flame front to travel all the way down the top ring. That way, there is no place for it to build up and then light up from. The point being, with the ring land way down, that was pushing emissions. And with low-quality fuel, oil would build up in the ring lands, ring lands would start to stick, and the engine would start to use oil, impacting emissions. To run tighter piston-to-wall clearances, you run a higher ring land. So, to keep the [top] ring land clean, they had to run more detergent in the oils. The other thing was the government pushing factories to get longer service intervals, because used oil is an environmental hazard. They want less waste oil, so they push the OEMs to mandate longer service intervals, and they get credit for their emissions requirements — some of the things they say, like Porsche recommending 20,000km drain intervals. They pay a very high penalty, at least in the US, because of their fuel economy, but they actually get credits by other things.

“A direct injection system sees the fuel injected straight into the combustion chamber. As there is no fuel to wash the intake valve, an efficient crankcase ventilation system is of the utmost importance to eliminate the risk of contamination build-up, which can prevent the intake valve from seating properly”

So, government intervention has had a big impact on oil manufacturing?

That’s the primary reason that motor oil is different today than how it was 10 years ago, than it was 20 years ago. Those 20 years of changes have all been driven by government interventions, not because of anything the oil companies or OEMs felt like they needed to do differently performance- or protection-wise. But if you were in Los Angeles in 1994, compared to today, you’re definitely thankful for some of the things that have been done — you can actually see! They have made a difference there, but it has come at a cost. There is a trade-off, and as long as people are aware of what that cost is, then it’s all good. Take E85 — it’s not a bad fuel, but don’t think that it’s the miracle come from heaven with no strings attached. Everything that you do has some side effect, there’s some consequence or trade-off, but, as long as you’re aware of that trade-off, then you’re fine.

How does operating rpm affect viscosity choice?

The higher the rpm of the engine, the less viscosity, which is counter-intuitive to most people’s thinking; ‘I’ve got a high rpm engine, I need a 10W-60’ — no, you don’t. Tighter tolerances in engines also require lighter viscosity. So, take your current BMW or Porsche motors, even the modern Ford Coyote V8, that has VVT [variable valve timing], and set them aside, because they’re a different beast altogether. What you’re doing with VVT is asking the oil to not just be a motor oil but also a hydraulic fluid. All those systems have one thing in common — they use oil as a hydraulic fluid to actuate, at some point, the VVT system. Whether it’s Honda’s VTEC or BMW’s VANOS, there are different methods, but they all use oil as the hydraulic force to activate the unit they have. So, in hydraulics, you have to have oil pressure, because it’s fluid force. Typically, high-horsepower race engines do not need a lot of oil pressure. A non-hydraulic all-out race motor doesn’t need too much oil pressure; it needs oil flow. High-volume oil pumps don’t make pressure, they increase pump volume. If you’re not careful, your high-volume oil pump will drain your oil pan dry and then you blow up your motor. How did that happen? You’ve got an engine that’s built to run eight gallons of oil per minute, and your pump runs 14 gallons per minute, so all the oil gets pumped out of the pan!

Now, in a VVT engine with a hydraulically operated valvetrain, pressure does matter, as it’s the fluid force that moves the part. Some of them use a spraying mechanism, something with a counter-balancing force, so you have to generate enough force on one side to overcome it. Thus, you have engines that call for a 10W-50 or a 0W-40, something with very wide splits in viscosity. The oil’s got to go through these very tight clearances, but they’re also typically aluminium-block engines, which means that they get hotter, and those clearances expand. So, when the engine gets hot and the person steps on the throttle, there must be enough viscosity to make this thing work.

How about synthetic bases? Is it true that you shouldn’t run a synthetic oil in a flat-tappet cam engine?

Nah, that’s crazy. Every Nascar engine out there uses flat tappets and all run synthetic oil. That’s one of those myths that came because, when they first started reducing the ZDDP in the oil, the first ones to have lower ZDDP were the synthetics, because they were the premium oils for the newest, latest, and greatest. So, there probably were some guys who looked at this new 10W-30 synthetic oil and thought it’d give them more power, dropped it in their old 289, and wiped the camshaft — because they went from a 1200ppm zinc oil that had lots of sulphur in it naturally, to one with zero sulphur in it, because it’s synthetic, and lower ZDDP. ‘Oh, it’s the oil’s fault’ — no, it wasn’t the synthetic oil that was bad; it was the chemistry that wasn’t right for the engine.

Even if you had a mineral-base 10W-30, you wouldn’t be too keen to run that in an old Mustang, would you?

Oh, I would totally put a 10W-30 — just not an off-the-shelf 10W-30 but a high-zinc one — in a Mustang. Because of where the pickup tube is relative to the oil pump, it’s a relatively long pickup tube, these Ford motors benefit — especially at cold start — from a lighter weight oil. It’s very easy, in Fords with a wet sump, to put in a really heavy oil, and the engine won’t get enough oil moving through it. One of our customers is a guy in the UK who is a Ford specialist, and he had a really high-end Cobra — a real Cobra, not a kit car. They were running a dry-sump system, where they could obviously prime it really easily; well, FIA came out with a rule that the engine had to run an oiling system as per factory. They’d always run 20W-50 with the dry-sump system, went out to Donington early in the spring, it was a cool day, and they filled it up with 20W-50. So, they fired it up and went off, with 20W-50 in the wet-sump motor, and threw the rod bearings. They did it twice before they started questioning what was going on. We told them that, for the engine they’re running, they need to run a 5W-20. Well, they were sceptical but, by that point, he was two rebuilds in and had nothing to lose, so went with the 5W-20. He had to try something to fix it, so they put in our 5W-20 Joe Gibbs Driven XP1, went out, won the race and went all season without looking back.

The higher the oil viscosity, the less flow you have upon start-up, and the more wear that occurs in the engine — 70 per cent of the wear that occurs in the engine occurs on start-up. As long as you don’t run an oil that’s too thin for the engine, then you’re good. The right viscosity for the clearances is the right choice.

It’s a common belief that synthetic-base oils cause roller lifters to slide on cam lobes — is this true?

It’s basically the same variation of the flat-tappet deal — it’s not that it’s synthetic; you need the extreme-pressure additive. With flat tappets, you have this sliding action, where it’s trying to wipe away the oil, and you have that contact load. With a roller, you don’t have the sliding, but you have this rolling, this line contact, especially with needle roller bearings. So, if you don’t have enough viscosity to keep all those parts separated, and you don’t have the extreme-pressure additives, you will have a problem. When you see that sliding, that’s because it’s got so much load on itself that it’s trying to weld itself — it’s like a pothole; that initial little rippling is what causes it to slip and start hammering lifters and the valvetrain. Run those engines on a high-zinc synthetic oil, and they’ll run for a very long time without any roller-lifter issues.

Do all modern API-rated oils require lower ZDDP levels, or only those of lower viscosities?

The current API ratings use specific viscosity grades. So, anything that’s a 10W-30 or lower is required to be a maximum of 800ppm [parts per million] of ZDDP; 20W grades and higher can be up to 1200ppm, but the higher grades are still limited to 1200ppm max.

Could you, theoretically, run a car on running-in oil indefinitely?

You can, you’d just have to change the oil very regularly — the drain interval becomes very short, around every 1000km. The idea of breaking-in oil is no different to painting something — it’s establishing a more tenacious base. If you decide to paint a car without primer, your paint job may look good, but it won’t last very long. In an engine, it’s about establishing an anti-wear film — you’re not worried about having the oil in there for a long amount of time, because, during break in, you’re going to have the highest amount of wear metals. Around four times the amount of wear metals are created during break in compared to any other time in the engine’s life.

That goes back to one of the causes of the roller-cam synthetic myth, because people that typically have roller cams and run synthetic oils, what don’t they do? Change their oil very often, because the synthetic oils are marketed as having longer drain intervals. So, if I’ve got this brand new roller-cam and run synthetic oil, I don’t need to run break-in oil, and end up running this synthetic oil for 10,000 miles, or however long the oil pack says, then I wonder why the lifters and needles are crap. It’s because the number-one reason for roller-bearing failure is contamination, and what didn’t you do? Keep the system free of contamination. Low detergent, low dispersant oils are used for that reason — it establishes an anti-wear film and then removes contaminants from the system. You’re looking at two things: reducing wear, and then removing what is wearing, so that it is not continuing to move through the engine.

Are friction and wear directly related?

Nope. That is the most difficult thing to really comprehend, but reducing friction does not necessarily reduce wear, and reducing wear does not necessarily reduce friction. A reduction in friction and wear can occur at the same time, but the two things are independent, and you can never make the assumption that reducing friction to improve horsepower will also reduce wear. We’ve seen it over and over again, and you cannot relate the two.

ZDDP is a classic example; if you put the right type of ZDDP in the engine oil at a higher level, you will reduce wear in the engine, but also increase friction — because ZDDP is not a low-friction coating. You can replace it with a lower friction coating that doesn’t prevent wear as well, and you can improve your economy and all that, but wear increases.

Is more ZDDP always better?

Nope, it’s a balance. The whole thing about all of this is balance, which strikes against the whole racer mentality of ‘a little is good, so more must be better’. That’s not the case with oil — more oil pressure is not better, more oil flow is not better, too little flow is not good, too little pressure is not good. Same with viscosity, it has to be just right. Most oil conversations start at the wrong point, by talking about oil. We do not make engines to put oil into; we make oil to put into engines. So, the starting point of every oil discussion should not be the oil; it should be the engine — it’s motor oil, not an oil motor. Someone will say that a certain oil is better because it’s got this and this and this and this — no, no, no. Understand the application first. It could be a 289 in a classic car, or a 289 in a track car. Same engine, same components, different application, and you’re going to get two different oils.

Understand your application first — do I have a flat-tappet cam, am I running ethanol, etc.? Then select a product that has the right viscosity, the right chemical characteristics for the application, then pick the brands you trust to deliver all of these things. People typically start in the opposite direction — they’ll start with the brand and then they try to find the best oil [that] that brand offers, and then shoehorn it into their application. And then you try to justify your rationale for doing so. You’re wrong, and just because it didn’t blow up, [it] doesn’t mean you’re not wrong. Engines that blow up do not equate to bad lubrication, just as engines that don’t blow up don’t equate to good lubrication. Just like every doctor graduated from medical school, but not every doctor got an A in medical school.

What effect does camshaft profile have on oil life?

More aggressive ramps on flat-tappet cams are going be more demanding on the ZDDP anti-wear package in the oil. Think about a low-lift, low-duration cam profile as like a small carburettor. It’s not using a lot of fuel. Whereas your big-lift, really aggressive cam profile is like an 850 Double Pumper — it’s going to use a lot of fuel. The fuel in this analogy is the consumption of the ZDDP. In low-lift, low-duration, ‘low-use’ camshafts, you can get by with low-ZDDP oil in some applications, but the moment you try to take that low-ZDDP oil and put it in a ‘high-use’ situation, it’s going to fail. It’s not about how much ZDDP is in your oil — that’s the wrong question. It’s about the application.

It’s quite ingrained in people who own old vehicles to use mineral-base oils. Is there any particular application where you’d recommend a mineral- over a synthetic-base oil in a flat-tappet-cam engine?

Well, I would tell people to use a mineral-base oil over a synthetic, but there’s only two reasons why. One is the age of the seals, and the type of the seals in the engine. Original seals, rope seals, etc., were all developed around mineral oils with higher viscosities. These were solvent refined. Trace MEK [methyl ethyl ketone] solvent that’s still left in some of these oils causes these seals and O-rings to swell up, which keeps them sealing. You put in a synthetic oil that’s not solvent refined, they tend to just dry; shrink; crank; and, subsequently, weep. So, if you’ve got an old engine that has been run on mineral oil its whole life, then just stick with mineral oil.

Secondly, if the car is not used very much, only goes to car shows, and is driven less than, say, 1000 miles in a year, why waste your money on synthetic? Synthetic is designed to perform better under extremes, and if the car is not being put under any extremes, then why are you bothering? The guy who’s out there drag racing, go for it. You might get that day where it’s crazy hot, the air’s really good, or there’s a lot of grip, and you need that extra little bit of protection.

With regards to the rope main seals and mineral oil, does that only apply to original engine seals, or reconditioned engines as well?

Well, if you rebuild an engine and you run the same type of seal in it, then it still applies. If you put in a modern seal, say, neoprene, then it will no longer apply. That said, from an efficiency standpoint, you will always be better off with a synthetic.

How does fuel choice affect oil life; say, E85 over traditional pump gas?

There’s two factors that actually influence the life of the oil. One is the operating temperature of the oil, and the other is what we call the ‘oil-to-fuel ratio’. Rule of thumb is, for every 10°C you increase your oil temperature, you cut your oil life in half. You start from about four years if it’s not doing anything, but, as you crank it up and it gets hotter, you start to decrease that oil life.

The ‘oil-to-fuel ratio’ refers to how much fuel is run through a given volume of oil. So, a larger oil sump will live longer with the same fuel flow as a smaller volume of oil. Inversely, for a given quantity of oil, the more fuel flow you run through it, the shorter its life is going to be. So, if you’re running 92 octane — you know, pump fuel — at close to stoichiometric, you’re pretty good. When you run E85, you’ve increased your fuel ratio by almost double, so you cut your oil life in half. It’s a reality — the guy who runs race gas is going to have a longer oil life than the guy who runs methanol, because you’re going to run twice as much methanol as race gas, which shortens the life of the oil due to the higher oil-to-fuel ratio.

Does that mean PCV (positive crankcase ventilation) has an effect on oil life?

Crankcase ventilation is a good thing. You obviously want to get all of that vapour out. The trick is — let’s say, with a car like a 1965 Mustang versus a Mitsubishi Evo — the old-school car’s PCV vents to atmosphere. That’s super friendly — yeah, maybe not environmentally — for the oil, because it just goes out. In the Evo, it goes back to the intake manifold, so you’re rebreathing all this junk. So, now, your fuel does affect oil life. If your tune is fairly rich, you compound the problem because what you’re running through the oil also goes back into the PCV system, and it comes back in again. If you’re rich in the Mustang, it just goes in and goes back out, and you only have to see it once — that’s why you can smell older vehicles more than you can smell newer vehicles.

So, would PCV to a catch-can tend to be preferable, then?

Yes, it works. It is a mechanical device that works. Now you’re not putting those vapours and those chemicals back into the engine, [and] you can safely drain them off. So, if your car’s got a catalytic converter in it, it’s going to work better and last longer because of the catch-can keeping that stuff from getting to it. They’re actually a really good idea — especially when you start making performance mods and running the car harder. That was one of the first things that GM had to do with the 2014 or 2015 Corvette. It’s a DI engine, and they realized really quick that maybe they should put catch-cans in it. With a DI engine, it’s very important to have a good catch-can system, because there’s no more fuel flow to wash the intake mouth clean. So, they built the PCV oil separators into the valve covers; in each bank of the valve covers, there’s a PCV valve sitting in there, and the oil separators built into it. That way, you retain the oil in the engine — that’s the one downside to the remote catch-cans: you are removing that volume of oil and are not putting it back into the engine. If you’re running the car hard and slowly decreasing oil volume, the oil-to-fuel ratio is also going down, so it changes oil life.

So, if you have an external catch-can for PCV, you would not want to reuse that oil simply because of exposure to air?

No; you might be tempted to do that, but you wouldn’t want to.

Thanks for taking the time to answer all of our questions, Lake — we sure learned a lot!

Special thanks must go to Lake Speed Jr for taking the time to be interviewed, as well as Craig Hyland at Craig Hyland’s Engine Dynamics for helping to bring Lake Speed Jr to New Zealand for an informative seminar.