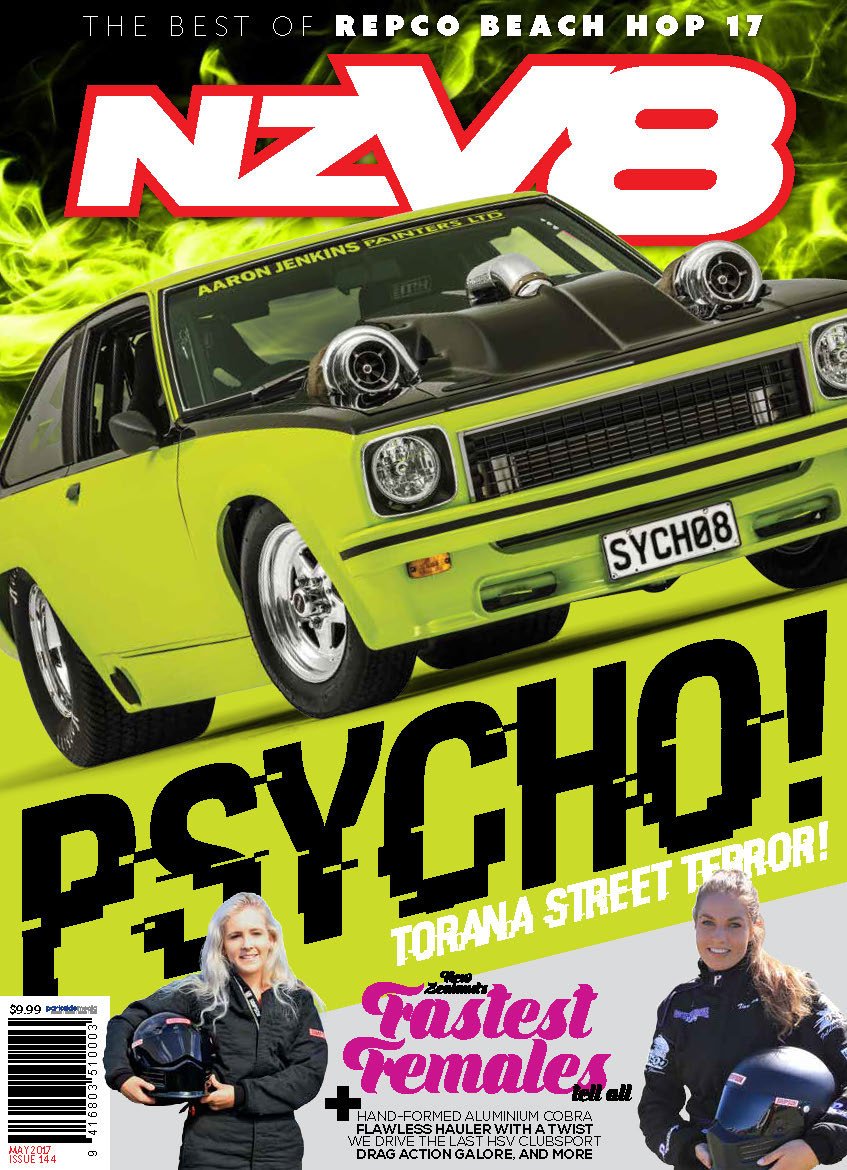

Aaron Jenkins likes speed as much as he likes big cubes — lots! Throw a healthy serving of boost in to top it all off, and we’ll let the results speak for themselves

Photo: Lance Farrow

Aaron Jenkins does what he wants. If he wants to do something, that something is going to happen. That’s why this Torana exists, and why, beneath its severely exaggerated appearance, you’ll find a mechanical masterpiece built almost entirely by one man in the depths of a Waikato shed. If you’re thinking his name sounds familiar, there may be good reason for that. Over a decade ago, this magazine featured Aaron’s ‘SYCHO8’ Holden HQ Monaro on the cover of Issue No. 15. A street-legal family cruiser powered by a tunnel-rammed 496ci big block with a NOS 250 shot on top, that thing could move — eventually, into the nines. What couldn’t move, though, was everything stopping it from going any quicker — it was far too nice to tub, let alone tear half the interior out for a roll cage.

The best course of action seemed to be for Aaron to start from scratch, essentially building a drag car he could drive on the street. Selling the Monaro for money that he could put towards the mortgage, and keeping his wife happy in the process, he spent a boring three months with nothing in the shed to tinker with. He did have a plan, though, and it centred on a battered LX Torana hatchback. The next year was spent coming up with a 10-year build plan, as well as squirreling away whatever spare coin could be put towards the ambitious project. If you could have seen the state of the Torana before Aaron got started, you’ll understand why ‘ambitious’ best describes the build.

“It was basically a shell. Everything else, including the floor, was stuffed,” Aaron recalls.

Though it did come with a back-halved chassis, what was there was in no way, shape, or form up to the standard Aaron wanted. That left him with only one realistic option — to build it himself. Daunting prospect though that was, he wasted no time in buying a copy of the LVVTA’s NZ Hobby Car Technical Manual [NZHCTM; now known as The New Zealand Car Construction Manual (NZCCM)] and reading each and every aspect relevant to his plans. In doing so, he was reassured regarding his ability to do what he wanted rather than deterred by requirements that were ‘too hard’. Aaron got himself a TIG welder; taught himself to weld; and, once happy with his ability, went to see his LVVTA certifier, Neil Miller, to show him what he could do. No dramas there. Aaron could finally begin the build, and you’ve gotta give credit where it’s due — he might be a house painter by day, but the man can weld.

Following the guidelines to the letter, Aaron spent nearly every spare moment working on the chassis he wanted under the Torana. A large rear chassis kick-up was fabricated, with a range of four-link adjustments, along with a Heidts independent front suspension (IFS) front subframe with front-mounted steering rack. The reasoning behind this was the legal requirement for a scratch-built chassis to be right-hand drive, plus it would free up cross-member space for a rear sump. Aaron also elected to run a manual steering rack, to provide much-needed space in the engine bay. As he’d proved himself a competent welder, he also got to work on the roll cage; if you didn’t already know it, you’d never pick that it was built in a shed in the heart of Waikato.

That cage needed to be there. Aaron wasn’t doing all this work to go slower, and he’d dipped the Monaro into the nines before selling it. With his eye on eights, he intended to have the power to get there. An old-school V8 guy at heart, Aaron has a penchant for displacement — the more the better, especially if there’s a little something else on top.

“I originally planned for a 600-cube big block with nitrous, but the cost of nitrous would have been too high,” he says. “It was expensive with the Monaro, and that was running a 250 shot — with the Torana, I’d want more like 500!”

That made forced induction the next place for Aaron to look, and a supercharger was almost instantly ruled out of the equation on account of his need for drivability and street legality. Yep, after telling his son there was no way he’d ever run “those rice-burner things”, Aaron found himself thinking very seriously about a method of boost that he’d never given the time of day. His research led him to the conclusion that a twin-turbo 540 would be the best way forward, and the rest is history. Snapping up the 540ci Reher Morrison big block and Chuck Mann–built Powerglide out of Rex Duckett’s Corvette, Aaron had the bones of an eight second–capable package — more than enough for a street car! Of course, with a high rise and big Double Pumper running on C14, this high-compression warhead was not exactly built for boost. Streetability was key.

This meant rebuilding it to be boost-friendly, with a package sourced from Steve Morris Engines in the US. This included pistons, rods, a boost-profile camshaft, and top-end package. Most notable, though, is the pair of Master Power turbos sticking through the bonnet and feeding into the huge C&S Specialties blow-through unit. While Aaron had Mike at Sinco Customs take care of the aluminium intake welding, he was more than happy to have a crack at the rest, and the turbo manifolds, dump pipes, and wastegate pipes all look like they could have been fabricated at a professional shop. It’s all functional, too; on a diet of E85, the team at C&M Performance managed to extract a solid 799hp at the wheels and 1150hp at the crank, on just 8psi of boost. The rear-wheel figure will increase, as a stuffed stall converter was discovered to be causing a disproportionately high drivetrain loss.

However, the rest of the kit is well equipped to hold up to the abuse it is inevitably going to receive. The JW Powerglide has been given a once-over by Chuck Mann, while the nine-inch diff now features a Detroit Locker, Strange 35-spline axles, and a seriously narrowed and braced housing. As much as the oily bits may seem right at home in a purpose-built drag car, Aaron meant for it to be street drivable, and that had to extend beyond a couple of windscreen tags — we’re talking sound deadening, carpet, headlining, and proper upholstery. A large portion of the Rare Spares catalogue found its way into Aaron’s shed, along with a second-hand fibreglass dashboard that he found for the right price. This was promptly butchered to fit around the roll cage, and, with it roughly in place, Aaron began to learn how to fibreglass, modifying the dashboard to fit as though it had always been that way. When he was happy with the result, it was sent with the door cards to DR Trim in Morrinsville, to be wrapped in black vinyl.

Interestingly, creature comforts also extend to electric windows and central locking. Due to the roll cage X-bar, Aaron saw the risk of a manual window-winder being left in a position to be broken by the bar as the door closed. To mitigate this problem, he purchased a Bluewire kit that bolted straight in, with centre console–mounted winder switches. Shawn at Avery Auto Electrical was then given the honour of wiring it all in, advancing the build a step closer to completion.

Don’t fall under the impression that this was an easy build, though. Having a 10-year build plan from the outset, Aaron’s done well to smash it out in just five years — especially considering that he suffered a heart attack near Christmas of 2015, at the ripe old age of 42. Then again, for a bloke like him, that’s just more motivation to get it done. Motivation can be hard to find on a build this big, even for an onto-it guy like Aaron, and he is grateful for Nigel Dixon’s long phone calls pushing him to get back into the shed at each step of the build.

Now that the Torana was beginning to look like a complete car, Aaron handed the fibreglassing reins over to Steve Woodd — fibreglasser extraordinaire and fellow NZV8 feature-car owner. Steve’s work extended to customizing the bonnet to clear the multiple protrusions, as well as narrowing the fibreglass bumpers to sit closer to the bodywork and integrating the chin spoiler into the one-piece front. With this done, and the Torana approaching a stage ready for paint, Aaron wheeled the Torrie over to Tom MacRae at Tom’s Auto Body Shop, knowing there was only one way to go — Holden’s loudest factory colour, Barbados Green, in stark relief to the gloss black bonnet and window surrounds — as if the turbos hanging out like dog balls weren’t enough to get the attention of anyone with a half-functioning pair of retinas.

Since rolling the Torana into our studio, the Torana has now gained a new metal plaque, and that legality also applies to the intended purpose of the car. Having sorted his medical test, tech inspection, and MotorSport New Zealand (MSNZ) roll-cage exemption, Aaron was all set for his licensing passes at Meremere Competition Meeting 4. His first full pass was a 9.8s at 145mph, backed up by a 9.6s at 147mph, and that was just off the foot brake with a 1.65-second 60-foot time. The car ran straight both times, and Aaron didn’t even need to lift the bonnet. Now, he’s hanging out to use the transbrake in his mission to run an eight-second pass. After all he’s achieved with the car so far, we’d be stupid to wonder whether it’ll happen — after all, it’s Aaron Jenkins behind the wheel.

Aaron Jenkins

Car Club: IHRA/NZDRA

Age: 43

Occupation: House painter

Previously Owned Cars: Holden HQ Monaro

Dream Car: This, maybe

Build time: Five years

Length of Ownership: Six years

Aaron thanks: My wife, Kelly, and the kids; Mike Reid, for getting me over the last hurdles; Nigel Dixon, for motivation; Steve Woodd; Shawn Avery, Avery Auto Electrical; C&M Performance; Sinco Customs; Chuck Mann, Rotorua V8 Performance; Neil Miller; DR Trim; Tom MacRae; all the boys; the guys on the GMH-Torana Forum

1977 Holden Torana LX

Engine: 540ci big block Chev, Dart Big M iron block, splayed four-bolt mains, Scat 4.25-inch stroke crankshaft, Engine Pro rods, Diamond pistons, 30-thou over (0.030-inch), 9.1:1 compression ratio, Steve Morris Engines roller camshaft, solid-roller lifters, Brodix BB-2 X aluminium heads, T&D shaft-mount roller rockers, Reher Morrison rocker covers, Reher Morrison single-plane intake manifold, C&S Specialties E85 blow-through carburettor, two Master Power GT45 turbos, Extreme Velocity O-ringed aluminium intake elbow, Sinco aluminium intake piping, two Turbosmart Race Port 50mm blow-off valves (BOVs), two Turbosmart Power Gate 60mm external wastegates, owner-built exhaust manifolds, two-inch primary pipes, four-inch exhaust, custom wastegate pipes, MSD distributor, crank trigger, ICE 10A two-step ignition, ICE Pro 100 9mm ignition leads, Aeromotive belt-driven fuel pump, boost regulator, -12 braided fuel lines, owner-built fuel cell, Monteith and Parker alloy radiator, Monteith and Parker oil cooler, custom radiator shroud, two thermo fans, Moroso electric water pump, -16 braided radiator hoses

Driveline: JW Powerglide two-speed auto, 4000rpm stall converter, transbrake, nine-inch diff, Detroit Locker centre, Strange 35-spline axles, three-inch chromoly driveshaft, Strange universals

Suspension: Heidts IFS front subframe, tubular A-arms, QA1 adjustable front coilovers, custom adjustable four-bar rear, diagonal track bar (lateral axle locator), Competition Engineering rear sway bar, rose-jointed linkages, QA1 adjustable rear coilovers,

Competition Engineering wheelie bars

Brakes: Wilwood reverse swing-mount pedal box, two master cylinders, unboosted brakes, Wilwood four-piston calipers, Wilwood discs, internal drum handbrake, Wilwood brake pedal, custom braided brake hoses, DJ Safety parachute

Wheels/tyres: 15×5-inch and 15×14-inch Weld Prostar, P175/70D-15 Hoosier Quick Time front tyres, 31×18.50R-15LT Hoosier Quick Time rear tyres

Exterior: Fibreglass front clip, fibreglass bumpers, fibreglass bonnet, carbon-fibre rear hatch, custom firewall, custom floorpan, custom transmission tunnel, custom rear firewall, extended sills, custom parachute mounting bracket, under-dash wiper motor, custom windscreen wiper linkages, DeBeer Barbados Green paint, DeBeer gloss black paint

Chassis: 1150hp at the crank, 799hp at the wheels, 8psi boost; 9.42s at 148.85mph; SS/AA class

Interior: Fibreglass dashboard, Auto Meter gauges, B&M Pro Bandit ratchet shifter, Lokar handbrake, leather trim, full carpet, new headlining, M&H fixed-back bucket seats, RJS five-point harnesses, custom owner-built roll cage, custom parachute release, Dynamat insulation, Bluewire electric windows, Bluewire central locking

Performance: 1150hp at the crank, 799hp at the wheels, 8psi boost; 9.42s at

148.85mph; SS/AA class

This article originally appeared in NZV8 issue No. 144 – to get your grubby mitts on a print copy, click the cover below