data-animation-override>

“The only thing this nine-second streeter melts faster than tyres is people’s minds!”

Matching tracksuits, matching tattoos, or perhaps matching hair cuts — some friends do weird stuff together. The owner of this mind-blowing HQ Monaro could be considered one half of such a friendship. What Warren Black and best mate Brendon Shearing have in common are two of the wildest HQ Monaros you’ll find on the planet. We featured Brendon’s car a few months back; with its super-slammed stance, blown 509ci big block, and low nine second ET slips, it’s a hell of a car. But if you were blown away by that, then your brain will be completely melted when you check out what Warren’s done to his Monaro.

As those of you who read our article on what’s commonly known as ‘the red one’ may recall, Brendon had a Monaro in the build when he found one that was closer to completion. The car he originally had in the build is the one you see here now. While it was in primer when Warren managed to pry it out of Brendon’s hands, the first thing he did was have it blasted back to bare steel so he could start from scratch.

The initial plan was just to build the car as a tough streeter, but the more the build progressed, and the more the red car progressed, the more Warren stepped up his game. After witnessing the work that Roger and Andrew from Balclutha Automotive Services had done on Brendon’s car, Warren knew they were the best people to look after the build. As Warren puts it: “After seeing what an awesome job Roger and Andrew were doing on Brendon’s car, and meeting Roger — he is an all-round genuine, nice, helpful guy, something that’s getting harder and harder to find these days — I decided that he, backed by his team of Andrew and Tania, was the man for the job.”

One of the first things Roger and Andrew did was to tub the rear end of the car to allow the fitting of the monster 20×15-inch Billet Specialties rims. Up front, the subframe was strengthened and modified to allow for a front engine plate to be fitted. With the aim of getting the car as low as legally possible, custom cross members were also stitched up and modifications were made to the front shock towers. A set of McDonald Bros Racing tubular control arms was then bolted to the modified set-up, complete with a set of QA1 adjustable coilovers and two-inch drop spindles. To sort out the steering, a Blacks Racks rack was fitted. It would later be mated with a reversed Honda pump. Out the back, matching QA1 coilovers were fitted, along with a custom four-link to get those monster rims tucked way up under the guards.

While this all sounds relatively straightforward, Warren’s wedding was fast approaching and the car needed to be present — even if it only looked the part from the outside — which added a bit of stress to the build.

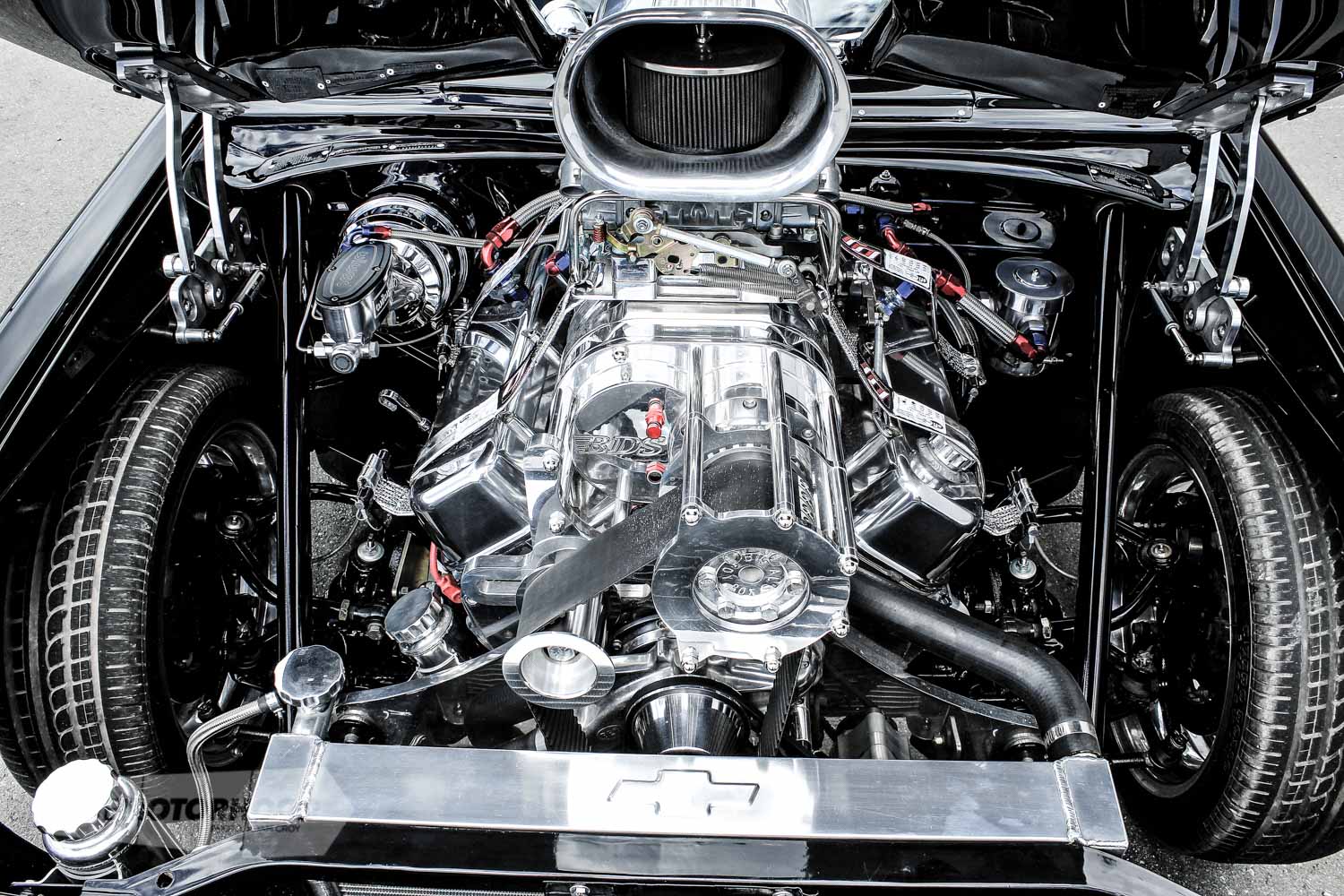

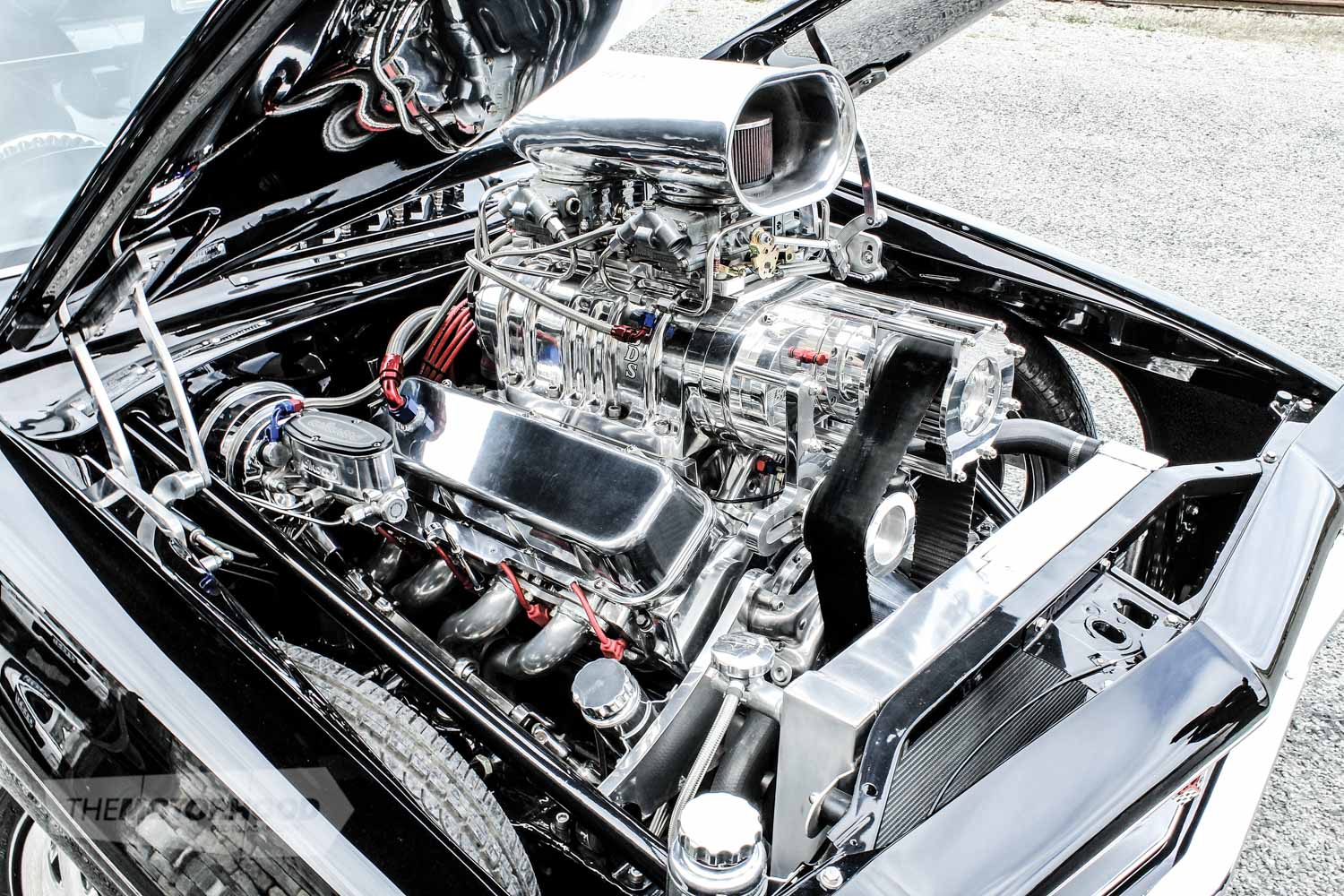

In this case, part of the outside is the massive lump of shiny metal that protrudes through the hood. After talking to well-known American-based engine builder Al Lombardo of Big Al’s Toybox fame, Warren soon purchased a suitable motor. “I’d been talking with Al about a 540-cube big-block Chev, then he said he’d made a 555ci engine for a customer who for some reason hadn’t picked it up. A really good deal was made — Al sorted the shipping with a company he has used in the past to get engines to New Zealand and made the whole thing real smooth,” Warren says of the experience.

While the engine was on its way, Chuck Mann was called upon for his transmission expertise — or, more specifically, to build a Turbo 400 that could handle the huge amount of torque the blown big block would soon deliver.

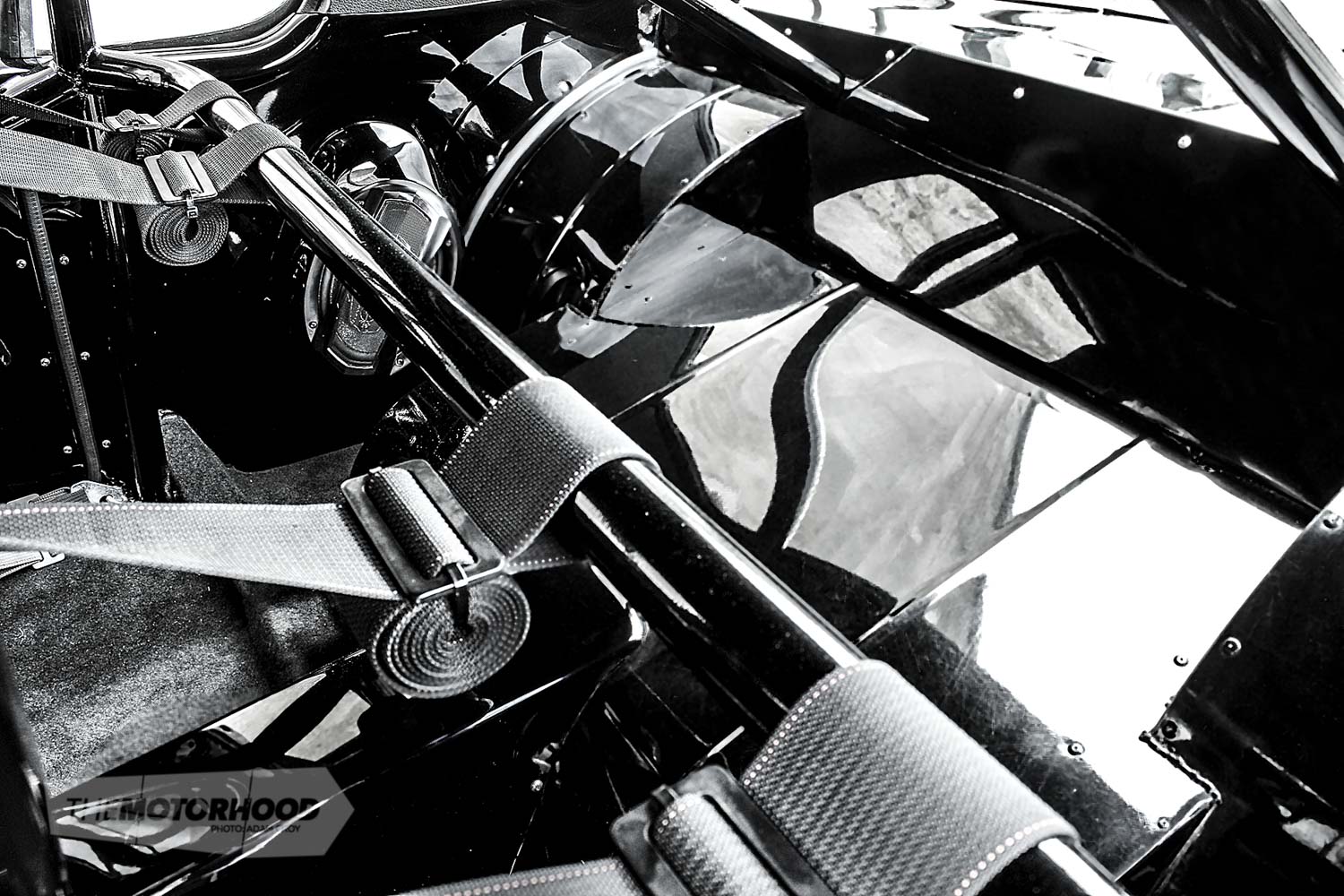

While the engine and driveline are essentially a simple recipe, the body mods that Warren wanted were not. Luckily, Roger had just the solution. It was to get Quintin Smith of South Otago Customs on board — not only was he just around the corner, but he just so happens to be damn good at what he does. Included in Quintin’s long list of tasks was to add a flat steel lining to the underside of the bonnet, shave off unwanted trim, smooth the cowl vent, add GTS Monaro flutes to the guards, and coat the whole car in the deepest, darkest black paint he could find. That all sounds easy enough, right? Well, take a look at the interior, for which Quintin was also responsible; it took as much work as getting the body as arrow straight as it now.

“I really like the lines and curves of the HQs, especially the coupes. This is why I ended up redoing the dash, as it had the only square edges on the car — it had to go!” says Warren of his decision to go for an all-steel interior.

From the complex curved dash and the door skins through to the wheel tubs and everything in between, Quintin’s handiwork is what really sets the car apart. Finishing off the fancy metalwork are a touch-screen audio set-up, a bunch of Auto Meter gauges, and some neat Billet Specialties accessories. The clean and simple look is jaw dropping at first glance; look a little more, and you’ll be amazed — and wonder why no one in New Zealand has stepped this far out of the box before.

The finished engine bay is equally breathtaking, with every imaginable item either polished or painted to perfection, and the only hints of colour coming from a few braided hose fittings. The clean look is aided by the full custom wiring loom created by the team at Balclutha Auto Electrics, as well as more of Quintin’s metalwork magic. A set of equally shiny HPC-coated three-inch exhausts snakes its way beneath the car, through custom cross members and up over the painted nine-inch diff. The meticulous attention to detail and quality fabrication work extend into the boot, which houses a massive 100-litre fuel cell.

Don’t go thinking that, just because the engine bay and the underside look so mint, Warren is afraid to drive the car — that couldn’t be further from the truth. After making an appearance at his wedding, it went back to Balclutha Automotive for the finishing touches. Since then, Warren has clocked up plenty of street miles, collected a bunch of show trophies, and earned thousands of fans on the internet.

More important to Warren, though, he’s also had some damn good fun with the car on the drag strip. Running a 10-flat on its first pass gave a good indication that the car has the power to match its brutal looks. Since then, it has dropped further into the 9-second zone. We’re sure that, with a bit more seat time and better track conditions, there’s plenty more to come.

As Warren explained to us, “We are heading in the right direction, so with some more time in the seat for me and some changes to the car, we should be in for some fun times ahead. We’re still a way off Brendon’s time, and he’s got a new motor coming, but it should be a bit of fun trying to catch him.” He continued, “The only downside to the drag/show car thing is weight. The steel looks cool but she’s got a fat arse! I might go with the plate IFATHQ, as [the car’s] 1850kg with me in it.”

Luckily, that statement is followed by, “There’s only one way to fix it, and that’s to add more horsepower!”

As if the car isn’t mind blowing enough already, it looks like there’s still more to come from Warren Black and his epic Monaro!

1972 Holden Monaro LS

- Engine: 555ci big-block Chev, Dart four-bolt mains block, Eagle double-keyed 4340 forged steel crank, Eagle H-beam steel rods, forged pistons, 8.5:1 compression ratio, Comp Cams 673/673 roller cam, roller lifters, double roller timing chain, Moroso sump, polished 360cc CNC ported aluminium heads, Manley stainless steel valves, 10-degree chrome moly retainers and locks, Comp Cams springs, ARP fasteners, Comp Cams chrome moly roller rockers, Jomar stud girdles, BDS 8-71 supercharger, two Holley 950cfm boost reference blower carbs, Aeromotive regulator, Aeromotive A1000 fuel pump, 100-litre custom fuel cell, MSD7 ignition, twin three-inch exhausts, custom headers, Aussie Desert Cooler Burnout King radiator

- Driveline: Turbo 400 transmission, 3500rpm stall, reverse pattern manual valve body, trans brake, Winters full floating 9-inch diff, Strange 40-spline axles, alloy diff head, 4.11:1 gears

- Suspension: McDonald Bros Racing tubular top and bottom A-arms, two-inch drop spindles, custom hubs, QA1 coilovers, custom four-link, Blacks Racks steering rack, custom shock mounts, reversed Honda power-steering pump

- Brakes: Eight-inch booster, Wilwood master cylinder, stainless brake lines, Wilwood six-pot front calipers, Wilwood four-pot calipers, Wilwood rotors

- Wheels/Tyres: Street: 18×7-inch and 20×15-inch Billet Specialties Dagger rims, 225x45R18 Michelin front tyres, 29x18x20 Mickey Thompson rear tyres; Drag: 15×14-inch Billet Specialties Comp 5 Double Beadlock rear wheels, 31×18½x15 Hoosier Quick Time Pro rear tyres

- Exterior: Lined bonnet, shaved locks, shaved rear indicators, Monaro GTS flutes added, smoothed cowl vent, Billet Specialties grille vents, Spies Hecker super deep black paint

- Chassis: Tubbed rear end, strengthened front subframe, modified shock mounts, custom cross member

- Interior: M&H race seats, five-point harnesses, Billet Specialties steering wheel, Billet Specialties steering column, B&M Street Bandit shifter, Auto Meter gauges, six-point roll cage, full steel dash, steel door trims, steel centre console, Billet Specialties accessories, Pioneer audio

- Performance: 930hp, 9.97 at 138mph

This article originally appeared in NZV8 Issue no. 118. Grab yourself a print copy or digital copy at the links below to read this, and more wicked articles.