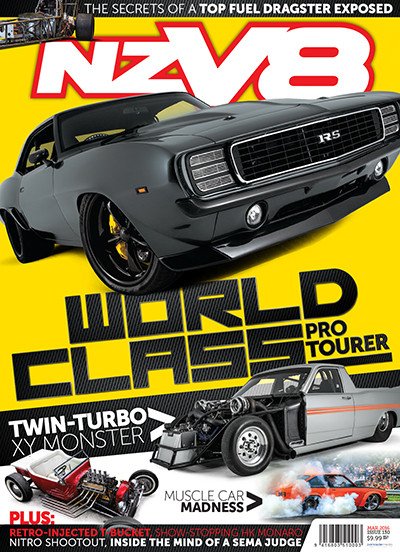

Tradition and technology are usually considered bitter enemies; however, when they coexist, the results can be spectacular — just look at Jason Sellars’ twin-turbo Falcon XY drag ute, blending the best of new and old!

Tradition is an odd thing — it is almost infinitely recurring nostalgia, an unquestioning method of doing things that runs parallel to the old adage of ‘If it ain’t broke, don’t fix it’. Nowhere is the influence of tradition more evident than in the culture of automotive modification.

Ever since the hot rodders of a century ago began hotting up their Ford Model Ts, there were methods that were generally accepted because they achieved what was intended and ways of doing things that were dismissed as no more than fanciful thinking.

Once GM’s Detroit Diesel Roots-type supercharger entered the world of hot rodding, nothing was ever the same. These blowers offered substantial increases in power and torque, and, when coupled with highly volatile alcohol-based fuels, quarter-mile ETs dramatically tumbled, trap speeds skyrocketed, and a new tradition was born: if it was a ‘real’ top-tier drag car, it had to be blown. This tradition has continued, largely unquestioned, for the better part of half a century — if you want to get down the drag strip as quickly as possible, you’re gonna need big cubes and a suitably large blower.

Recently, however, an increasingly obvious fly in the ointment has surfaced — a ‘glitch in the matrix’, so to speak. That glitch is technological progress, and it’s aided and abetted by the mortal enemy of the Roots supercharger: the turbocharger — long dismissed by die-hard V8 builders and racers as a toy to help import drivers keep up with the big boys, yet its performance benefits are becoming harder to ignore.

In the US, huge numbers of drag racers are realizing the performance benefits offered by turbocharging a large-displacement V8 engine. It’s got to the point at which it’s now common to see more turbocharged V8s at drag meetings than supercharged or naturally aspirated engines. Meanwhile, little old New Zealand — in true-to-form laid-back fashion — is still playing catch-up, but at least it’s being done in a spectacular fashion. For all the evidence you could want, you need look no further than Jason Sellars’ incredible 1971 Ford Falcon XY drag ute.

A gifted engineer and fabricator by trade, Jason has always been into old Fords, especially Falcon XWs and XYs from the early ’70s. Some 10 years ago, he decided to shop around for an XY ute with which to relive the fond memories of an XY he’d once owned. A suitable candidate was found locally, and was driven back home in standard — albeit rusty — condition.

The potent combo of factory straight-six engine and three-on-the-tree manual was nevergoing to cut it, especially given Jason’s plan to transform the ute into a back-halved street and strip weapon. He was halfway there, with the motor mocked up in position, when he thought to himself, That doesn’t look fast enough — so the engine was gifted to a Falcon XW sedan Jason had in the build, the rear clip ended up in his brother’s Holden EH, and it was back to the drawing board.

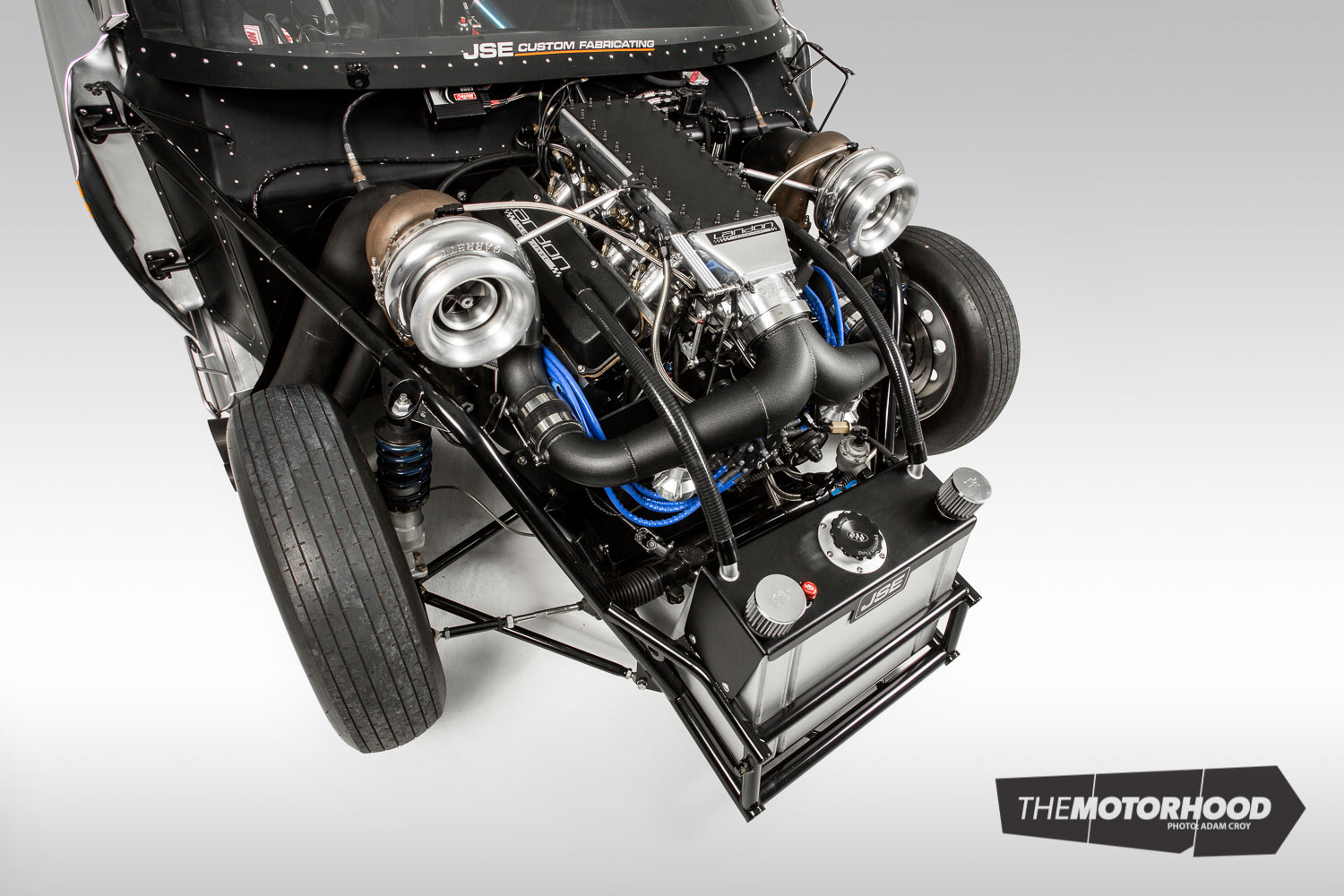

This time around, Jason decided that a full tube chassis would be the go. Over a long, labour-intensive period of time, Jason custom fabricated an engineering work of art from lengths of chromoly tubing. The chassis alone is a masterpiece, but it’s difficult to take it all in alongside the myriad other intricate custom touches adorning each and every square inch of the vehicle.

For example, the rear wheel arches have been subtly extended to accommodate the huge 32.0/14.0R15 Mickey Thompson ET Drag tyres — not that you’d ever notice, although most of the rear end’s sheet metal is new. This extends to the custom alloy panels that line the undercarriage, huge alloy wheel tubs — their function should be obvious — and enormous sheet-alloy drag wing. The tailgate is also a custom-folded sheet of alloy — the work of one Nakija Klaus, whose hands have fabricated some of the best panels seen on NZV8 pages. The attention to detail extended to consistent use of 1⁄8-inch button-head stainless cap screws wherever possible.

Of course, the most notable exterior feature is the one-piece carbon-fibre front clip. The new front end was crafted in-house at JSE Custom Fabrications, using the original XY front end as a plug, with the help of good friends Cory and Jeremy Abbott. What makes it extra special is the attention to detail lavished upon it to make it look like a real front end — “I didn’t want it to look like an airbrushed front end,” Jason states matter-of-factly.

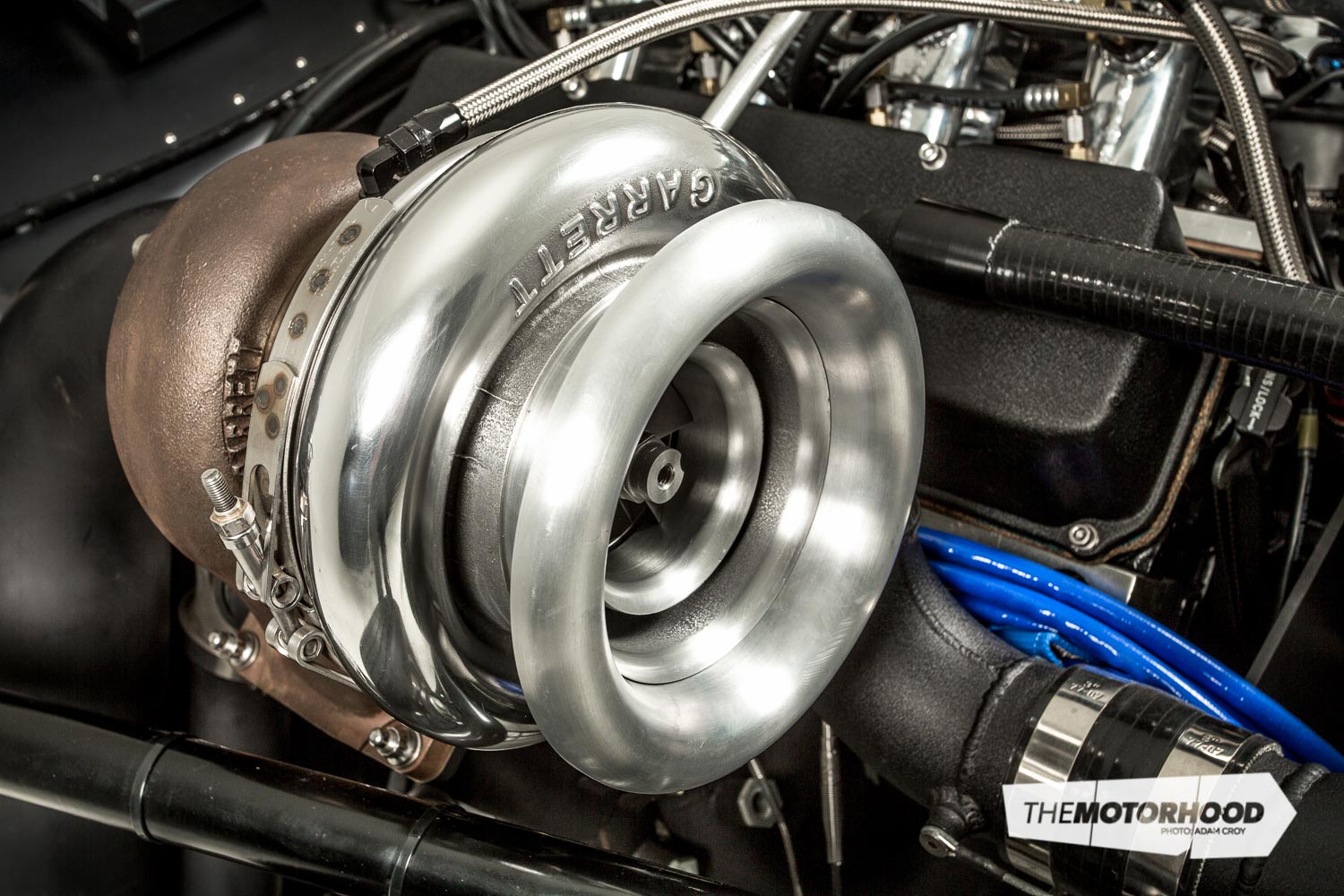

This slightly downplays the work behind the project, though — the original grille was retained and reinstalled for a proper, three-dimensional look, and the trim around the Lexan windscreen was modified to stay on the removable clip. The front has also been sloped slightly downwards, in an effort to make the XY slightly less brick-like, and custom ‘bubbles’ have been grafted into the bonnet to clear the twin Garrett GT42 turbos residing beneath.

Yep, you read that right — turbos. While the body might be clearly identifiable as having its origins in the ’70s, Jason’s build is quite clearly of the present day. If the chromoly tube frame — unfathomable in those olden days — isn’t enough to convince you, and those bell-mouth intakes in place of the GT driving lights don’t indicate anything out of the ordinary … well, you’ll just have to take a look at what lurks within the engine bay.

“Who in their right mind would do a Cleveland with this set-up on it?” Jason asks. “Well, I like Clevelands, and the plan was to make the fastest all-iron stock block set-up.”

To achieve that, Jason knew that a hefty pair of turbos would be the go, and that more than explains the tremendous power plant nestled between the front struts. Based off a 351 Cleveland block, the stock block’s bottom end has been beefed up as thoroughly as possible by the pair of engine wizards at Landon Motorsport, Dean and Warren. The block has been filled with grout — to one inch beneath the deck — and retains its two-bolt main-bearing caps, although it benefits from a main-bearing cap girdle and fully forged rotating assembly, all held together by ARP fasteners.

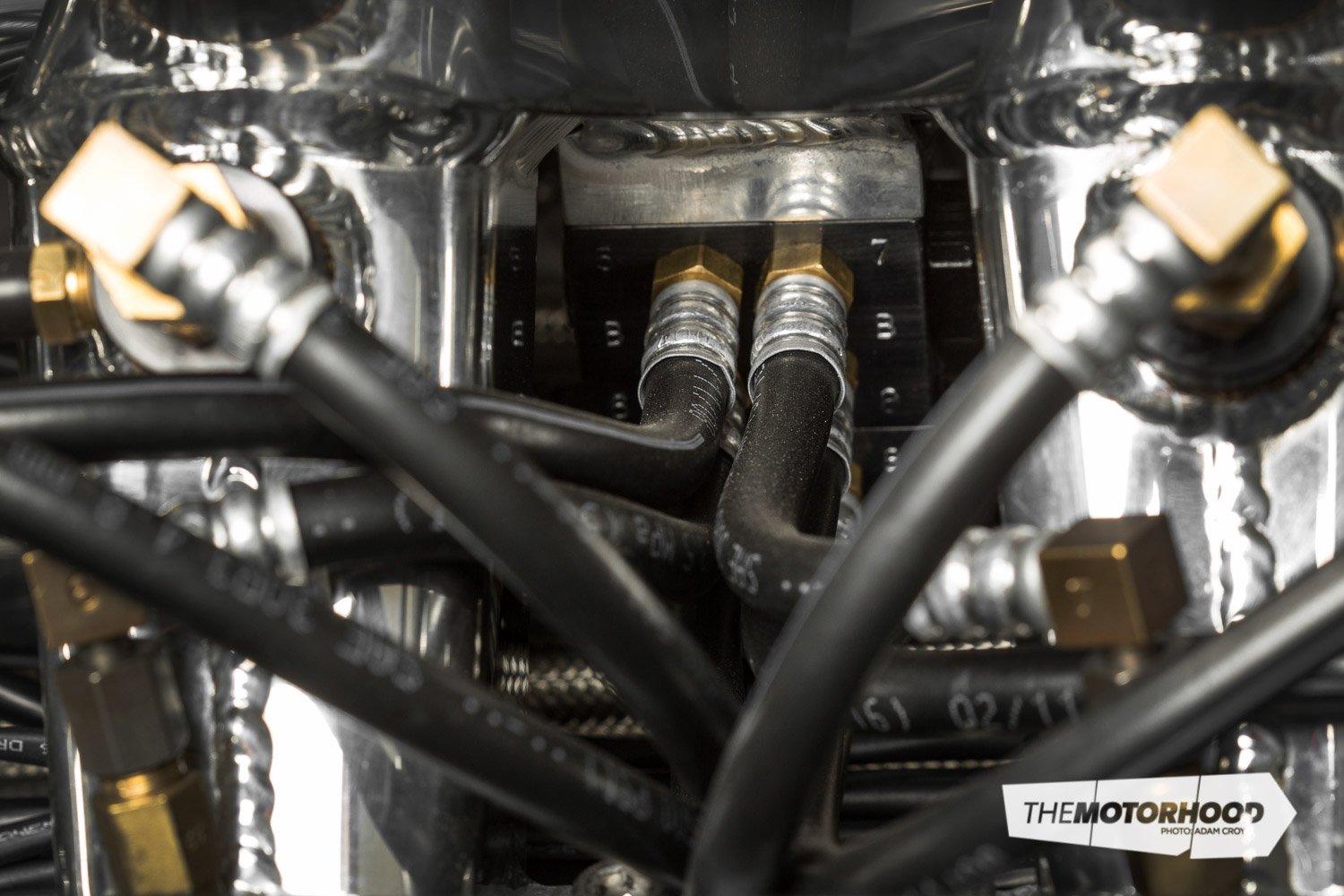

The top end features Cleveland 4V iron heads, with Dean spending hour upon hour porting and cutting the valve seats. High-port exhaust plates have also been installed to maximize the Crower solid-roller camshaft’s exhaust flow into the pair of Garrett GT42 turbos.

These Garrett power-adders are bolted onto thin-wall tube turbo manifolds fabricated by Jason. Two TiAL 60mm external wastegates regulate boost pressure and vent any excess exhaust gas through 2½-inch wastegate pipes that are plumbed into the turbos’ four-inch straight-through dump pipes. As these terminate just behind the front wheels, you can be assured of a glorious racket whenever Jason manhandles the XY through a full-boost quarter-mile pass.

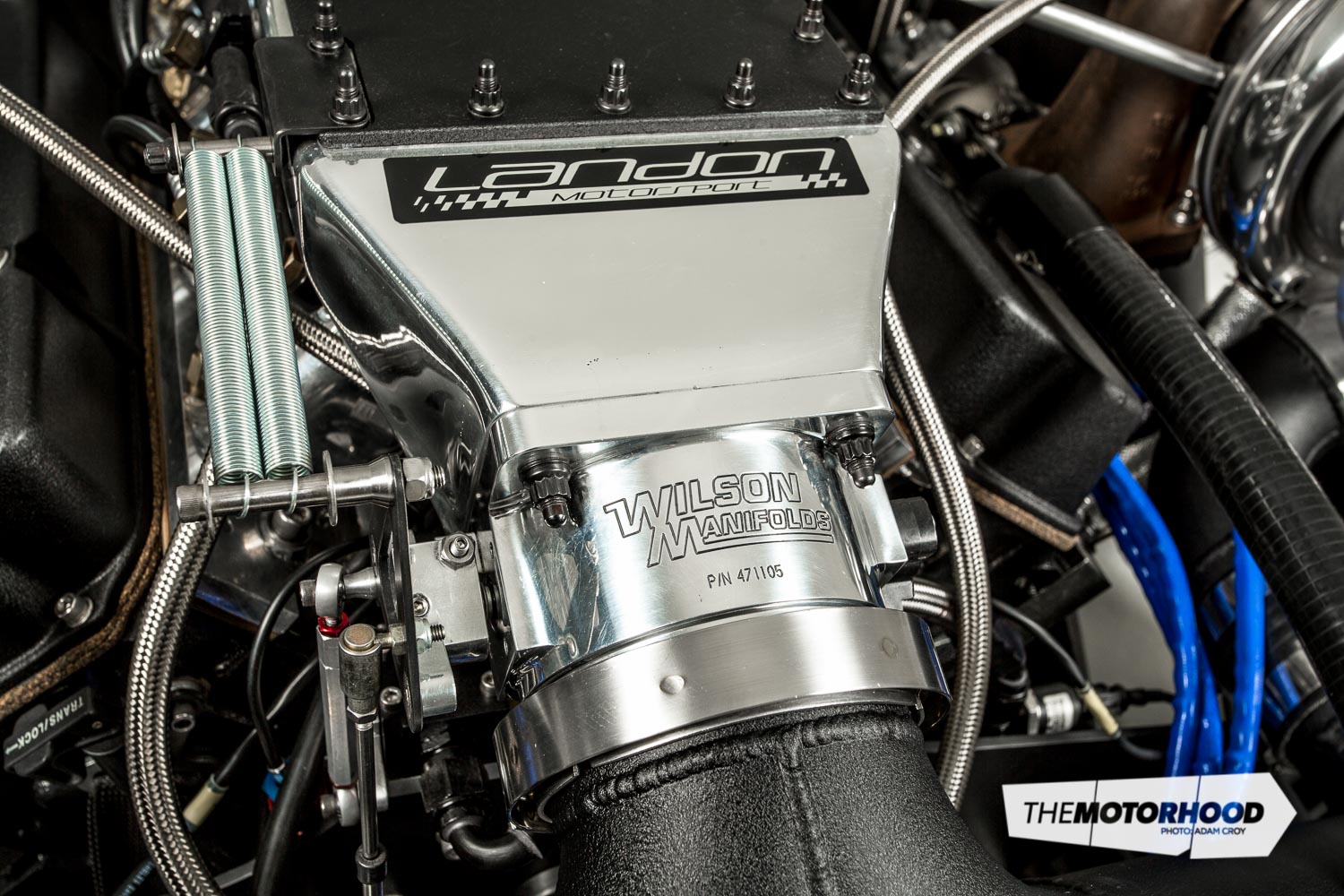

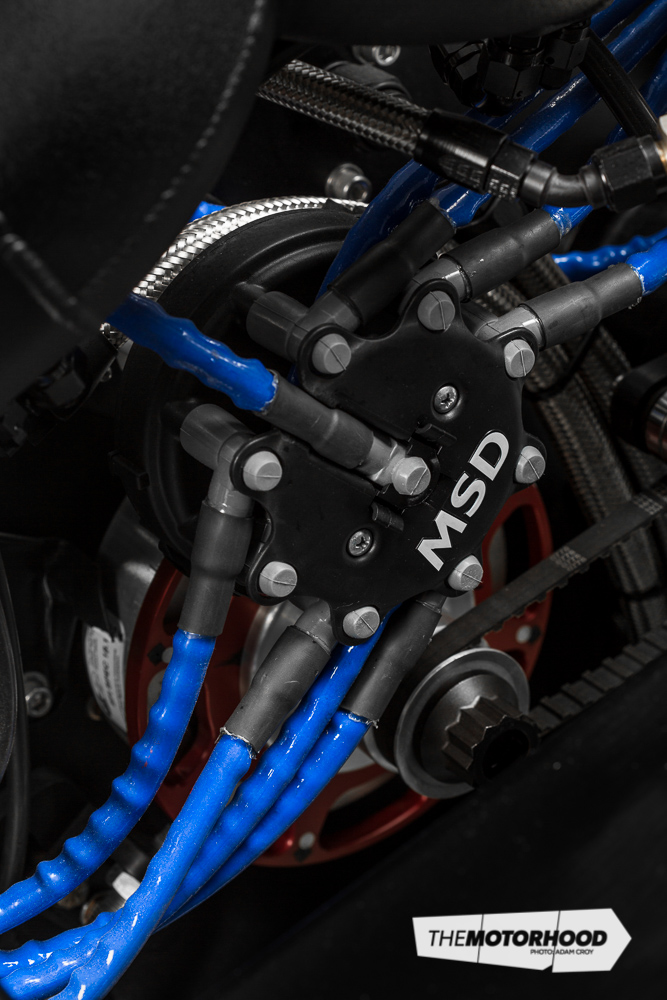

That noise is accompanied by the distinctive smell of methanol, as Jason’s induction system blends tradition’s finest with the unquestionable advantages of modern technology. That’s why you’ll find the intriguing combination of a Hilborn mechanical fuel-injection system alongside a MoTeC M800 data logger and ICE Race Series 24V ignition.

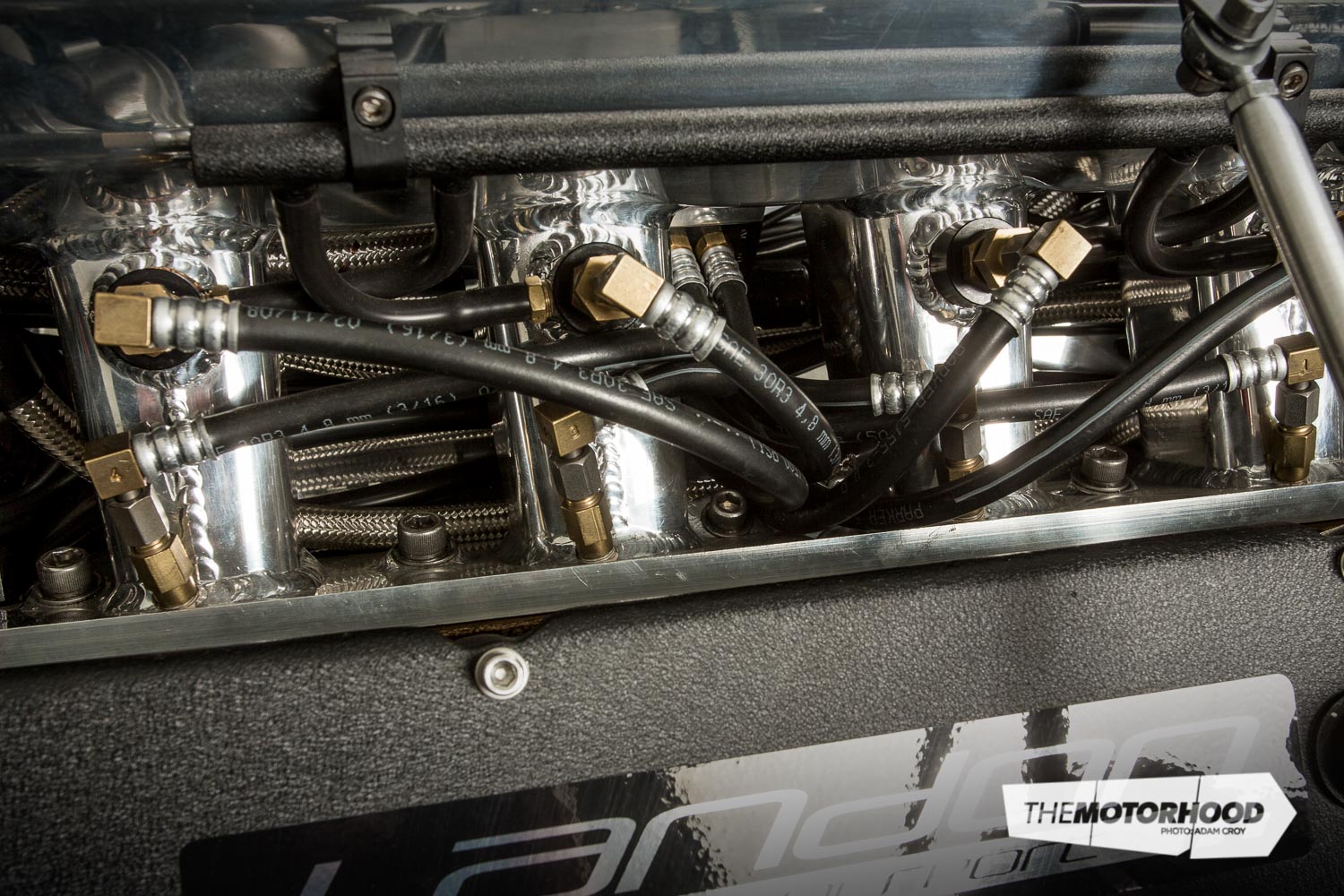

Dean has painstakingly perfected the mechanical injection system, with a pretty trick barrel valve linked to the 102mm throttle body, all mounted on a sheet-metal intake manifold custom fabricated by Jason and the Landon boys. The old-school Hilborn belt-driven fuel pump feeds into a Hilborn boost-compensator valve, with 16 injector nozzles keeping all eight cylinders well fed. Tradition clearly has its place, since alcohol and mechanical fuel injection have been the drag racer’s best friend for nigh-on half a century!

This old-school method of fuel delivery contrasts starkly with the sophisticated electrical system wired up by Warren, but, like everything else on this car, the technology is there for a reason. To produce power, the turbos first need to spool. For that to happen, the engine needs to be under load, and that requirement has the potential to create problems in the staging lanes of the drag strip.

That’s where the MoTeC comes in. The C4 transmission’s transbrake, used in conjunction with the three-step’s launch-control function, allows the turbos to build boost — and therefore power — in the staging lanes, unleashing the full boosted fury as soon as the lights turn green. Such a violent release means that the drivetrain needs to be substantially worked over, and nothing has been overlooked here.

The C4 transmission was built by Performance Automatic in the US and features a Torque Converter Engineering (TCE) torque converter. It also has an SFI-approved scatter shield, in case anything goes wrong. The custom driveshaft includes Strange chromoly billet yokes and Mark Williams non-greaseable universal joints, while the diff is a custom chromoly nine-inch housing fabricated by JSE, containing a Strange Ultra head, full spool, and 40-spline gun-drilled axles. Even with a full-power wallop slammed through it time and time again, this driveline won’t be breaking in a hurry.

That dose of power is loaded into 15×14-inch Weld Prolite wheels wrapped in gigantic — and sticky — 32.0/14.0R15 Mickey Thompson ET Drag tyres, which will allow for a blistering 60-foot time. The abundant power on offer has proven good for trap speeds well in excess of 150mph, explaining the Simpson parachute strapped to the XY’s tailgate.

The Wilwood and Strange components in the braking system are more than up to the task, but the ’chute is mandatory, and, nearing the end of a 1320-foot sprint, Jason will have his work cut out for him inside the cabin of the ute. There’s a huge Auto Meter tacho directly in his line of sight, Hurst Pro Stick shifter and parachute release lever easily within reach, and a Grant steering wheel to keep everything aiming roughly the right way.

While it’s a fairly spartan office — and not a terribly comfortable-looking one, either — the detail in here is just as meticulous as elsewhere on the ute. It is by no means a rough-and-ready race car; infinite time and attention have been poured into making sure everything is as functional and well presented as can be.

Ten years after he embarked on his ‘back-halved Falcon ute’ project, Jason has finally got it to a stage at which he’s happy with it. You can expect to see this work of art at a drag strip near you sometime over the upcoming drag racing season — just remember that it was originally supposed to have a WOF and rego firmly pasted on the windscreen!

Now, with an 8.22-second pass on his first outing, and sevens on the way, we can only wait and see what will happen to that XW sedan of his. He may claim to be happy with how it’s going currently, but you never know what might happen …

1971 Ford Falcon XY

- Engine: 380ci Ford Cleveland, 351C two-bolt block, grout-filled block, forged rotating assembly, CP forged pistons, main-cap girdle, ARP fasteners, Milodon gear drive, JSE custom wet sump, Accusump oil accumulator, Cleveland 4V heads, extensive porting, high-port exhaust plates, Crower solid-roller camshaft, Manley valves, custom sheet-metal intake manifold, Wilson Manifolds 105mm throttle body, JSE custom intake piping, Hilborn mechanical fuel pump, Hilborn boost-compensator valve, Hilborn barrel valve, 16 Hilborn injector nozzles, twin Garrett GT42 turbos, JSE custom turbo manifolds, twin TiAL blow-off valves, twin TiAL 60mm wastegates, twin four-inch exhausts, 2½-inch wastegate pipes, front-mount distributor, crank trigger, MoTeC M800 data logger, ICE 24V ignition, Meziere remote water pump, JSE custom fuel and breather tanks, custom brackets

- Driveline: Ford C4, TCE torque converter, transbrake, custom nine-inch diff, chromoly housing, Strange Ultra head, full spool, 40-spline gun-drilled axles, 5⁄8-inch studs, Strange moly/billet driveshaft yokes, Mark Williams universal joints

- Suspension: Strange adjustable struts, Strange double-adjustable rear shocks, Hyperco springs, moly four-link, rear wishbone, rear needle roller–mounted sway bar

- Brakes: JSE custom pedal assembly, Strange master cylinder, Strange front calipers, Strange front rotors, Wilwood rear calipers, Wilwood rear rotors, Simpson parachute

- Wheels/Tyres: Weld Prolite, 15×4-inch and 15×14-inch wheels; 25.0/4.5-15 Mickey Thompson ET Front and 32.0/14.0R15 Mickey Thompson ET Drag tyres

- Exterior: Stretched rear wheel arches, JSE custom one-piece carbon-fibre front clip, custom floor panels, custom firewall, Lexan windows, custom-folded tailgate, custom sheet-alloy drag wing, Spies Hecker custom silver paint

- Chassis: JSE custom chromoly chassis

- Interior: Alloy race seat, re-trimmed, window safety net, Hurst Pro Stick shifter, Grant steering wheel, Auto Meter gauges, chromoly roll cage, anodized alloy gauge cluster pod

- Performance: 8.22 at 160.25mph (so far); 1430hp at the wheels

Driver profile

- Owner: Jason Sellars

- Car club: Bay of Plenty Drag Racing Association

- Age: 44 — same as the block!

- Occupation: Engineer/Fabricator

- Previously owned cars: Ford XW and XY Falcons, Ford Fairlane ZL

- Dream car: Other Falcons still in the build

- Why the Falcon? I’ve always wanted a tubbed XY ute

- Build time: On and off for six years

- Length of ownership: 10 years

- Jason thanks: Dean and Warren at Landon Motorsport; Karl Butterworth for the bodywork and paintwork; Cory and Jeremy Abbott for giving a hand when needed; John Key at TransAmerica Ltd for bringing in my parts; Shawn at Action Canvas & Upholstery for the seat and other sewing needs; Nakija for the tailgate; Shannon, my partner, for the support

This article originally featured in the March 2016 issue of NZV8 (Issue No. 130). Don’t miss out on having this mag in your collection. Grab one of the last print copies, or grab a digital copy below: