data-animation-override>

“Seven years ago, Jason Fell’s Camaro was the cutting-edge in high-end Kiwi builds. Now, thanks to a 1000-plus horsepower, twin-turbo big block, it’s still on top!”

We live in an ever-changing world, in which technology, culture, and trends are all changing as quickly as they develop — ‘dynamic’ is the word they’d likely use if you were to explore the concept at an academic level.

One area that has remained relatively immune to these dynamic effects has been this very car scene — hot rodders and the builders of tough, old-school cars generally subscribe to the similarly old-school ethos of ‘If it ain’t broke, don’t fix it’. So, if you want to make power, you traditionally do so in one of two ways — big cubes and high compression for an angry naturally aspirated monster, or big cubes and a screaming supercharger for the ultimate in presence, both power-wise and aesthetically.

Jason Fell, proprietor of Waikato Motor Trimmer, has never been one to get comfortable with things, and that’s seen his incredible Camaro manage to stay fresh and ahead of the game for about as long as he has been working on it. Its first iteration was featured on the cover of NZV8 Issue No. 42 in November 2008 and was a revelation at the time — with an aggressive stance, flawless finish, and huge power, the car had everything it took to be a standout.

What really marked it out from the rest, though, was lying beneath the discreet cowl-induction hood — a 482ci big block with a Vortech V7 centrifugal supercharger hanging off the side. Even then, a mere seven years ago, centrifugal superchargers had yet to properly take off in our V8 scene, although they’re now seen as one of the best value-for-money power-adders on the market.

So, when Jason began to get comfortable with the supercharged big block that powered the car, he knew it was time to take it up a level once more. With the goal to do something different, which would make others think, he decided to make good on his long-held desire for a twin-turbocharged big block.

“I’d done the whole centrifugal supercharger thing and thought it was time to go up another level. At the time, there were only a few V8 turbo cars around,” Jason says. That was a mere two years ago, but turbos were still an obscurity in the local V8 scene — nowadays they’re popping up everywhere, as more people realize the unparalleled bang-for-buck they afford, in terms of outright power, drivability, and ease of fine-tuning.

“I ordered all the parts required for the new build through Marsh Motorsport and from Shane at Segedins, and Tony [Marsh] did all the machine work for me,” Jason says of the new build’s beginning. “We got a lot of the fabrication work done in Hamilton between different shops, but a lot was also done in-house at Waikato Motor Trimmer.”

The paint you see the Camaro wearing today is the same paint the car wore the last time it was featured, masterfully applied by Warren down the road at Flamin Body Shop all those years ago. The immaculate paintwork is in as good a condition as ever and is layered over arrow-straight panel work performed by Shane Latto.

The aesthetic changes the Camaro has undergone have actually been extremely subtle, for the most part. Disregarding the enormous cowl induction hood, the most obvious visual change has been in the wheel department. The old 18×8-inch and 20×10-inch Foose Nitrous rims have been switched for the 19×8-inch and 20×10-inch billet Intro V-Rod wheels from Kevin Porteous’ Camaro, featured way back in NZV8 Issue 15.

Other improvements are of a less visible nature — a full Global West tubular suspension arm kit has been installed alongside a full Nolathane bush kit, with gas shocks at all corners. Two-inch drop spindles have the front end sitting right, and the rear has benefited from the addition of heavy-duty leaf springs and CalTracs bars — just the ticket for the monstrous torque that a twin-turbo big block is capable of sending their way. A full Wilwood brake package comprising master cylinder, four-piston calipers, and rotors help bring the car up from the insane speeds it is capable of achieving.

Being the proprietor of an upholstery shop means the absolute best in interior detailing would be a given. The interior, tastefully trimmed in the finest black leather, is very similar to how it was when the car was first featured on these pages all those years ago, with understated differences here and there.

Half of the Auto Meter catalogue has been raided, so that Jason can reliably keep tabs on each and every aspect of the Camaro’s anatomy, and touches like the subtly hidden B&M shifter work wonders in understating the car’s street-fighting nature.

A full sound system and a distinct lack of any form of roll cage underline the Camaro’s position as a street-driven weapon and there is little doubt that, should Jason ever traverse a drag strip, he’d be promptly told not to return without a cage — proper rear rubber should see an easy nine-second quarter-mile pass.

The rate at which the work on the Camaro was completed meant that Jason’s dream of having it ready for Repco Beach Hop 15 was a distinct possibility, and he wasn’t going to sit idle; he gathered up a team of mates — Scotty Stinson, Jarrod Mahon, and Damien Bush — to help him get the car finished in time. “We worked four nights a week on the Camaro, from 5pm until around 1am, and must have got food from every fast food shop in town. Jarrod claims he gained 31 kilos — bullshit!” Jason laughs.

Of course, we can’t forget that the entire build was centred almost entirely on the new engine, and it truly is a next-level piece of kit in its own right — almost worthy of a full feature article of its own! Based on a Dart Big M block, with a fully blueprinted bottom end comprising 4340 forged steel crankshaft, Eagle H-beam rods, and JE forged pistons, rest assured that this mammoth combo will be more than a match for the boost that smashes the power figure well into the 1000s.

That four-digit power figure means the top end has been built just as tough as the motor’s foundations. With an aggressive Crower turbo-grind camshaft controlling intake and exhaust events, the remainder of the 540’s respiratory system had to be up to the task. CNC-ported Brodix BB03 heads and a Brodix intake manifold ensure maximum airflow. Those heads are a seriously trick bit of kit in themselves, with a bulletproof T&D shaft-mount rocker assembly and titanium valves and retainers to handle the stresses of forced induction.

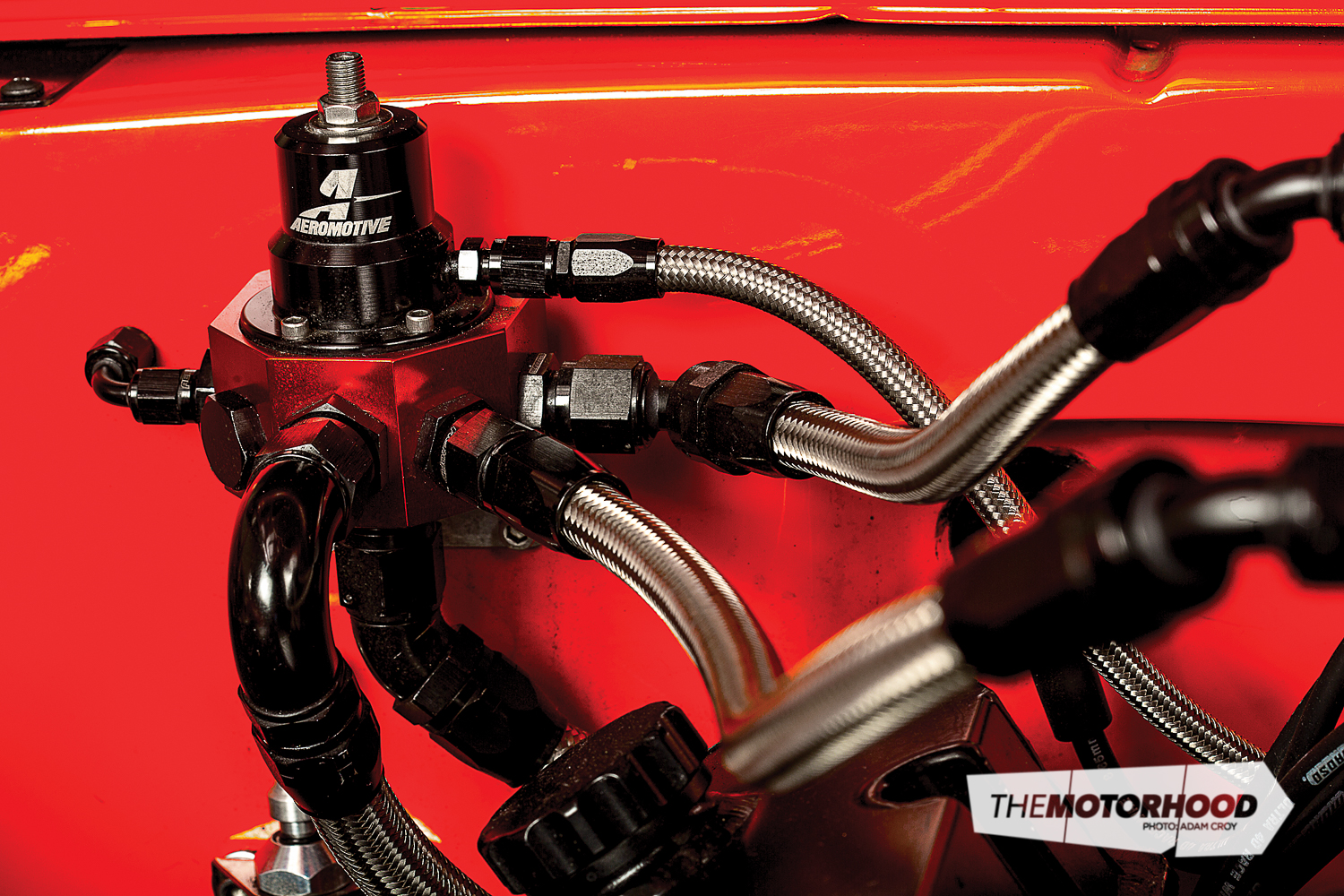

The combo is topped by a custom-built blow-through carburettor assembled by Jake Edwards from Australian-based Jake’s Performance. The reason for such an extreme induction set-up is made blatantly obvious when you catch sight of the pair of enormous snails hanging off the custom turbo manifolds.

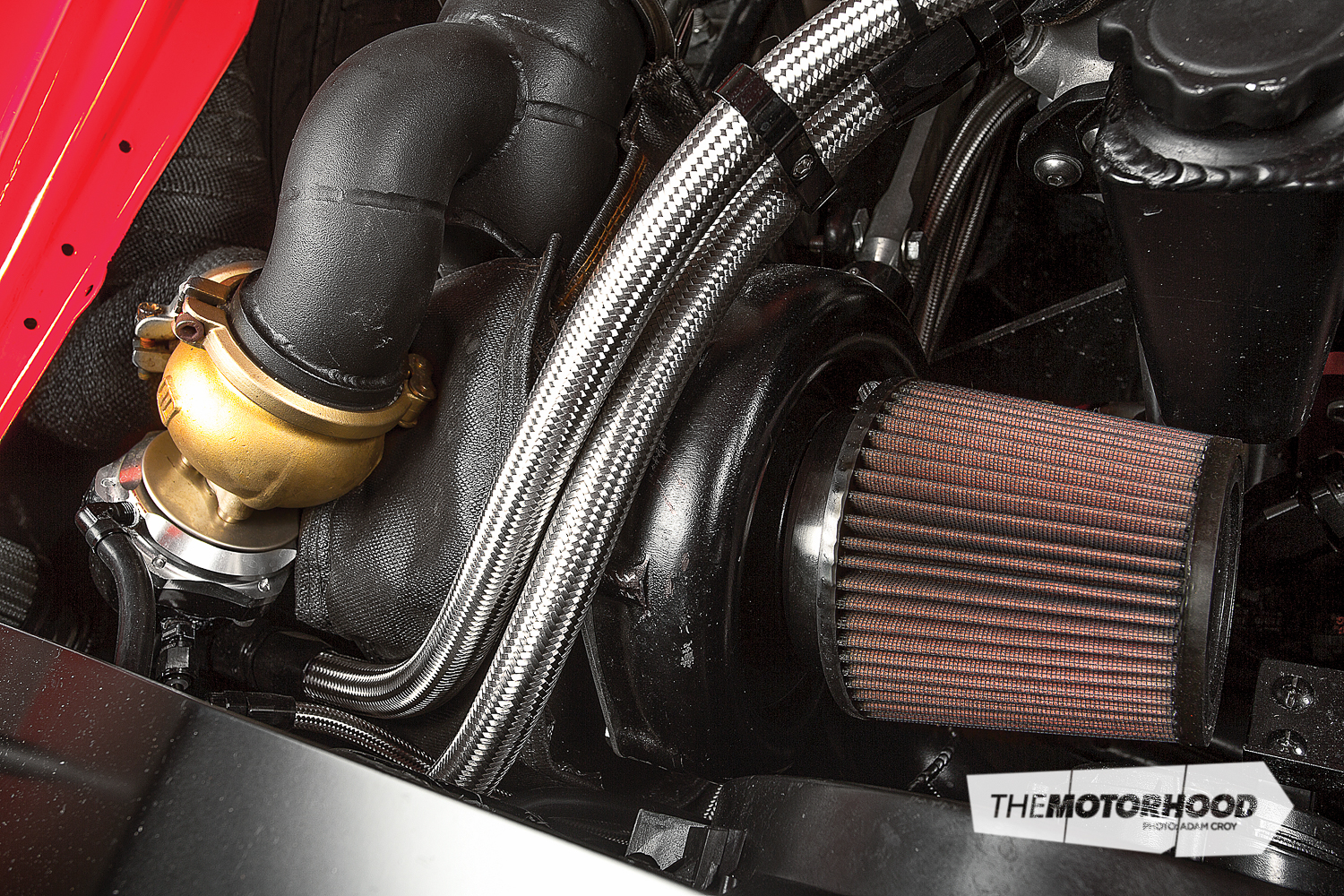

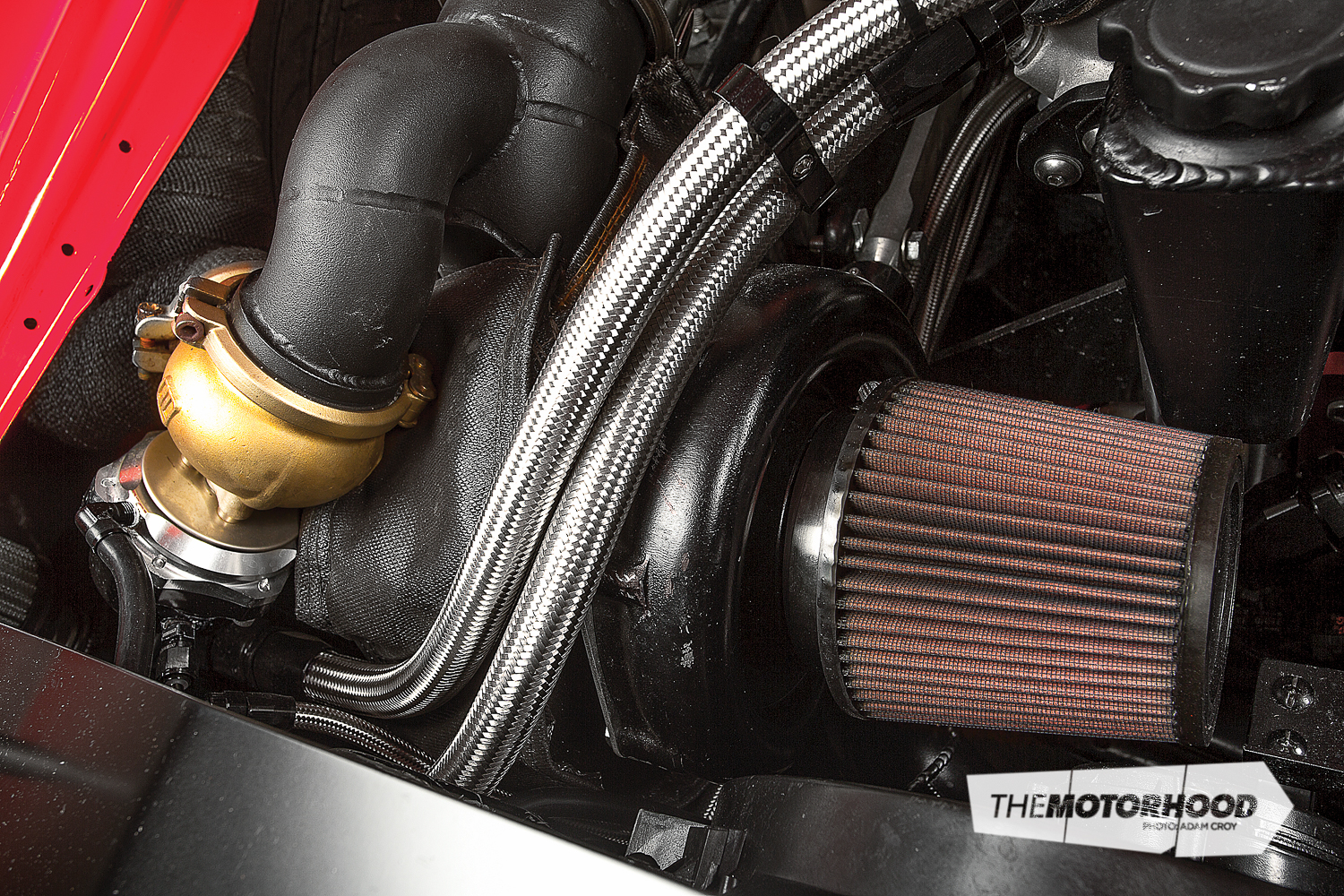

The custom 64mm turbos are mounted in front of the engine, and, due to space constraints given the sheer size of the big block, feature an extremely interesting — not to mention aggressive — plumbing layout. The 3½-inch exhaust system exits the turbos’ exhaust housings and is routed above the front wheels just inside the fenders — both to keep heat away from the core of the engine bay and for more efficient packaging. The pressurized air is ducted into the base of a gigantic front-mount intercooler, then it exits through a drainpipe-sized outlet leading to the carburettor. Everything’s big for a reason, as Jason never intended the engine to produce any less than 1000 horses.

As Jason’s intended use for the Camaro has always been a car both for cruising and for events such as Powercruise and the recent Mothers Chrome Expression Session — where he’d be hammering it — some other parts of the previous recipe would need to be changed to cope with 1000-plus horsepower of abuse. A tough TCI flexplate and 3500rpm stall converter with ARP bolts have been attached to the rear of the crank, and the TH400 has been given the works by Chuck Mann — billet shafts, a reverse-pattern manual valve body, and transbrake mean it’s about as serious as you’re gonna get in a car with a current WOF and rego on the windscreen.

The driveshaft is a custom 3½-inch unit with billet yokes, and the old GM 10-bolt diff was also dumped in the bin and has been replaced by a Strange nine-inch that’s filled with about as much tough gear as possible. A Strange iron diff head with Strange 3.0:1 crown wheel and pinion gears and 35-spline axles ensure that the Falken 285/30R20 rear tyres are the only things that will be destroyed by those massive numbers on the dyno sheet.

That dyno sheet would be pumped out in the weeks following Beach Hop — thanks to liberal burning of the midnight oil, the team managed to make it down to Whangamata on the Thursday night. But, as happens with builds of this scale, especially on such a tight deadline, there were teething problems — there’s no eloquent way to word it: the engine ran like shit. Jason called Jake Edwards in Australia for advice, and the reply was that, for a small fee, Jake’d fly over to New Zealand and tune it.

“That was a turning point for me because there were too many faults to list, and I was a bit out of my league,” Jason says. “Jake set to fixing all the issues. After six hours — and a lot of running around Auckland to get parts — he fired it up on the dyno at Revolution Dyno Centre.

“We finished tuning the car at about 8.30pm on the Friday night, happy it was done but with nowhere near the horsepower I was expecting. The turbos weren’t big enough to get the power and the valve springs were too soft — there is a lot more potential in the car yet.” Jason says.

They ended up spinning more than 1000hp at the treads. The valve springs have already been sorted, and, with the larger turbos that Jason’s planning on fitting — sized around the 88mm region — anywhere up to 1800hp can be expected.

For now, though, Jason’s more than happy with how the Camaro’s performing — since he’s able to smoke the rears down the entire Hampton Downs straight, you can’t blame him. The only problem we can see is how the car could possibly be upgraded from its 1000-plus horsepower, twin-turbo big block; but once Jason gets used to it, we’re sure that’s what he’ll be keen on doing. Perhaps he’ll put it up for sale should that ever happen — he’s made noises about selling the car for the right money, though we can’t think what he’d replace it with. All we know is that, whatever his next build would be, you’d be seeing it on the cover of a future issue of NZV8.

1969 Chev Camaro SS

- Engine: 540ci big block Chev, Dart Big M block, 4340 steel crankshaft, JE pistons, Eagle H-beam rods, ARP fasteners, Crower camshaft, CNC-ported Brodix BB03 heads, T&D rockers, titanium valves and retainers, Brodix intake manifold, custom Jake’s Performance blow-through carburettor, Holley 1050 Pro Series bowls, custom headers, one-piece CNC merge collectors, twin custom 64mm turbos, custom front-mount intercooler, custom intake piping, twin Turbosmart BOVs, twin Turbosmart external wastegates, 3½-inch turbo dump-pipes, 3½-inch twin exhaust, twin Adrenalin R mufflers, Holley Black lift pump, three Bosch 044 external fuel pumps, five-litre surge tank, billet fuel log, -10 feed and return lines, Aeromotive fuel-pressure regulator, braided lines, Aeroflow black anodized fittings, MSD Digital-7 ignition, Jake’s Performance boost box, Turbosmart e-Boost 2 boost controller, Aussie Desert Cooler triple-core radiator, -20 braided coolant lines, PWR oil cooler, PWR transmission oil cooler, Moroso oil pump, Moroso sump, Moroso oil filter relocator

- Driveline: GM TH400, 3500rpm stall converter, TCI flexplate, ARP bolts, billet shafts, deep pan, reverse-pattern manual valve body, transbrake, billet 1350 tail shaft, Strange nine-inch diff, Strange iron head, Strange 3.0:1 LSD, 35-spline axles, billet Daytona supports, billet diff yokes, 3½-inch driveshaft

- Suspension: Global West tubular arms, two-inch front drop spindles, rear triple leaf springs, gas struts, CalTracs bars, full Nolathane bushes

- Brakes: Wilwood brake booster, Wilwood Dynapro four-piston front calipers, Wilwood 12.19-inch front rotors, Wilwood rear calipers, internal handbrake, Wilwood 12.19-inch rear rotors

- Wheels/Tyres: 19×8-inch and 20×10-inch Intro V-Rod wheels, 225/35R19 and 285/30R20 Falken tyres

- Exterior: Custom orange paint, smoothed firewall, removed front inner guards, cowl induction scoop

- Chassis: Global West body stiffeners, chassis connectors, Moroso solid front and rear motor plates, Global West gearbox mount

- Interior: Modified factory seats, black leather upholstery, Momo steering wheel, B&M shifter, Auto Meter gauges, carbon fibre dashboard, Alpine head unit, front component speakers, 6×9-inch rear speakers, boot-mounted sub

- Performance: Over 1000hp at the wheels

Driver profile

- Owner: Jason Fell

- Car club: Te Awamutu Rod and Custom Club

- Age: 43

- Previously owned cars: BMW M5, BMW 540, Subaru WRX, Ford Falcon FG XR6, VW Touareg V8

- Dream car: This one!

- Why the Camaro? Friends told me about Camaros 11 years ago; then I saw Kevin Porteous’ Camaro at Beach Hop and had to own one

- Build time: 11 years on and off

- Length of ownership: 11 years

- Jason thanks: My wife, Erin, and my kids, Corbin and Danica, for putting up with my obsession; and a big thanks to everyone who helped, including Scott Stinson, Jarrod Mahon, and Damien Bush; Chuck Mann; Brett at Kaipaki Kustom Kars; Warren at Flamin Body Shop; Dave at Engine Parts; Jason at Te Rapa Auto Electrical; Jake Edwards, from Australia — now my good mate; Mike at Sinco Customs; Shane Latto; Darren at Revolution Dyno Centre

This article originally featured in the December 2015 issue of NZV8 (Issue No. 127). Don’t miss out on having this mag in your collection. Grab one of the last print copies, or grab a digital copy below: