data-animation-override>

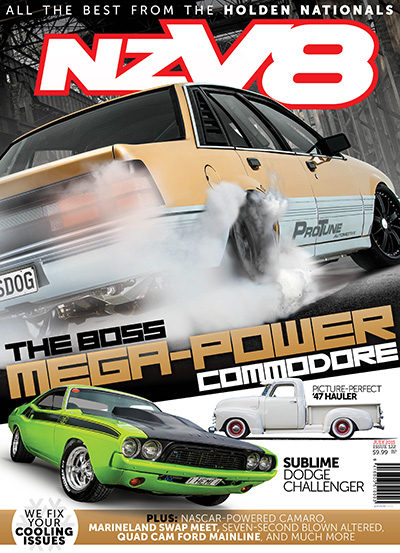

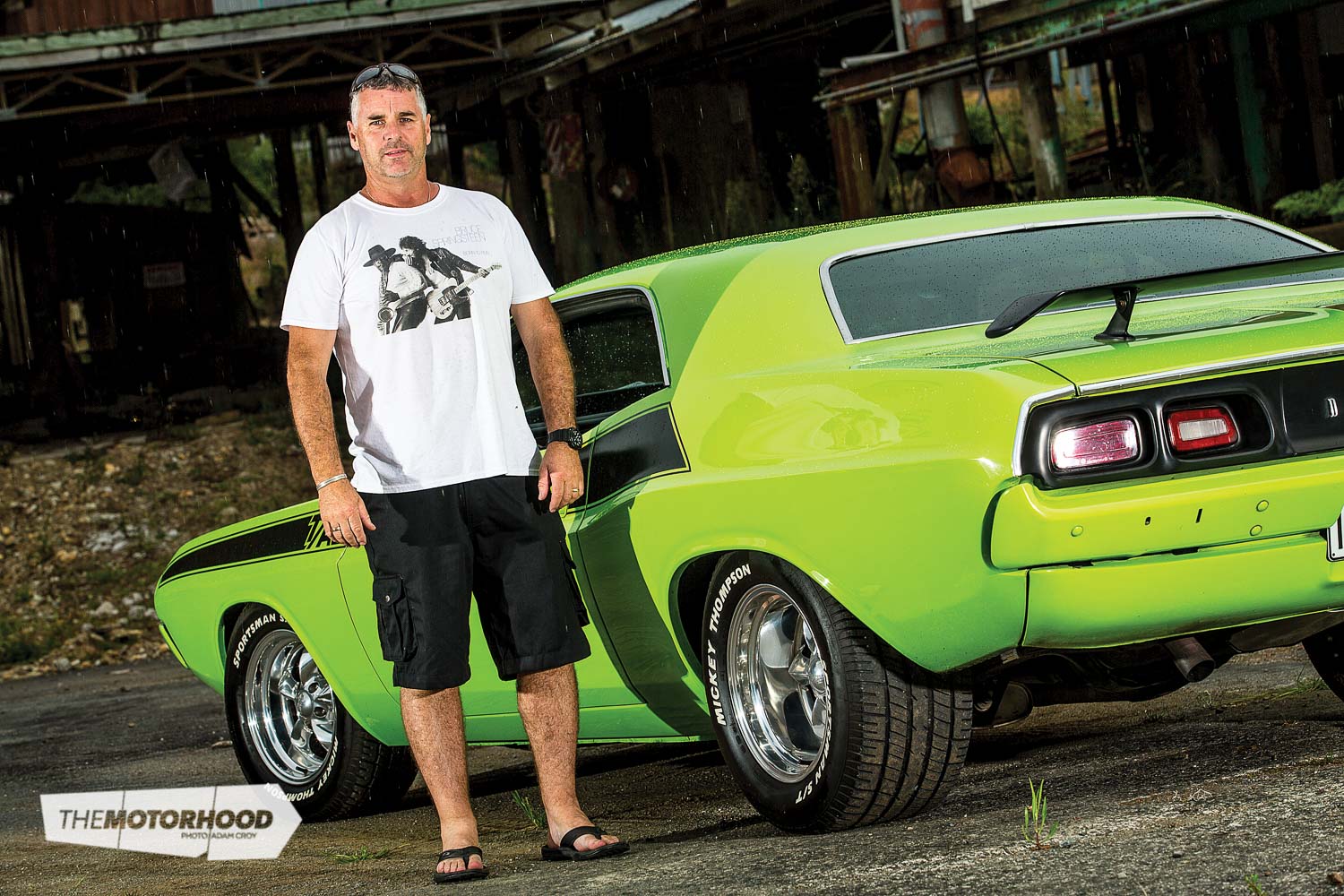

“Tony Ewens told his wife that if he bought his dream car, then he’d never need to modify it … Seven years later, there’s still no end in sight in the quest to build the ultimate Dodge Challenger”

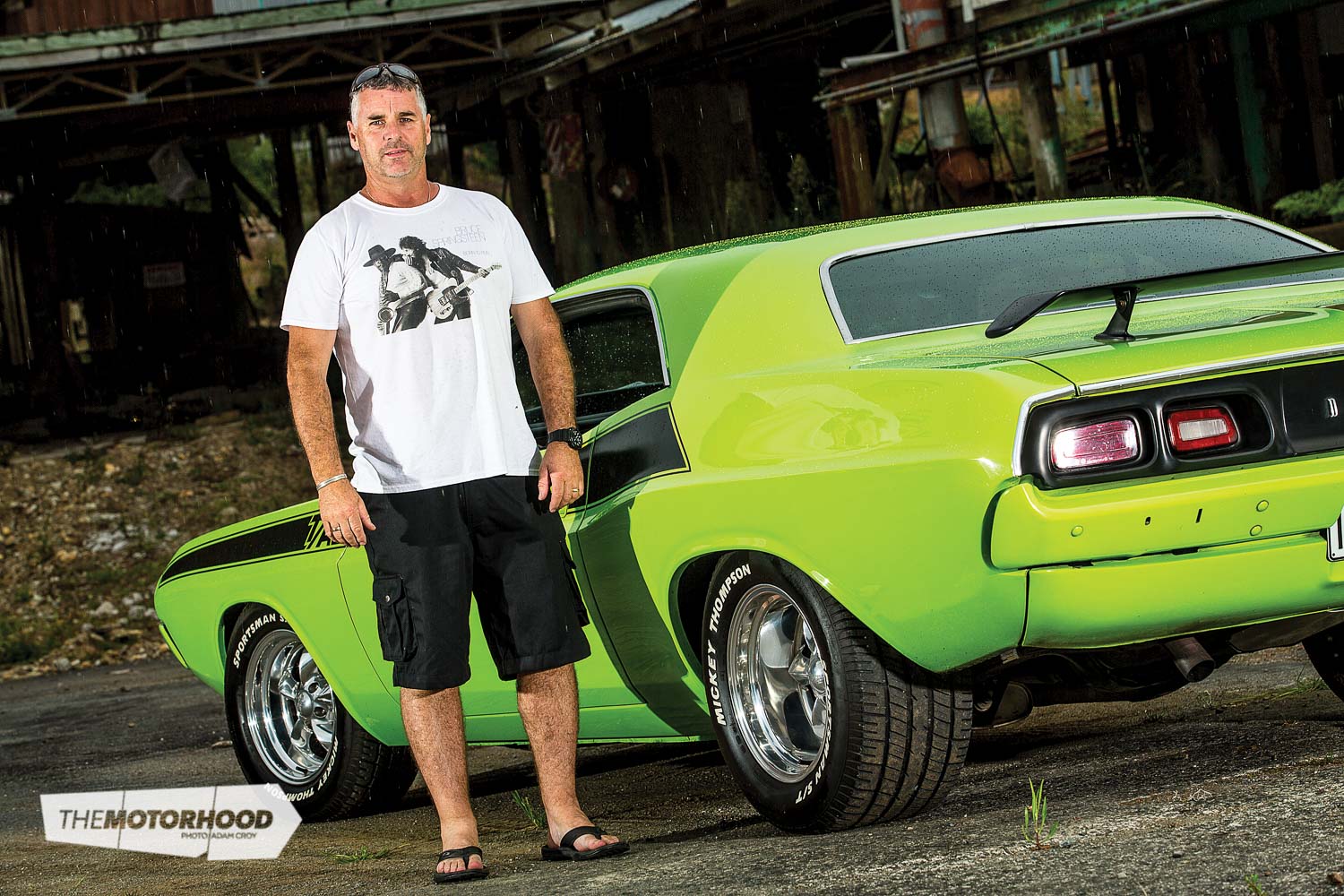

“I found it on Trade Me and hit the ‘buy now’. It was that easy when it all started,” reminisces Taranaki’s Tony Ewens of purchasing his 1973 Dodge Challenger seven years ago. “Of course, I now know they’re called a Challenger for a reason,” he laughs — and, when you hear about the challenges Tony’s faced along the way to transforming the car from a bitch to bitchin’, you soon see where he’s coming from. The initial road trip from Dunedin back to Taranaki should have been taken as a sign of things to come, with charging issues, starting issues, exhausts falling off, and plenty more unexpected excitement. That’s all a distant memory now, while the thrill of the road trip remains. Even at the time, though, after years of playing with race boats, Tony couldn’t have been happier with his first American muscle car.

A few upgrades over the following years saw a serpentine belt set-up added to the car’s 440ci big block and a custom gauge cluster created — the excess amount of gauges a throwback to Tony’s days of boat racing. “I collected the specific gauges needed over the past few years to keep that strong muscle-car look. I dragged the dash out over winter to create something that no one else has. Of course, it’s a matter of personal taste, but, coming from the racing environment, I had a strong desire to know exactly what’s happening with the engine; this was excellent preparation for the new motor.”

That new motor — as the number plate may indicate — was once destined to be a Hemi, considered by many to be the pinnacle of Mopar muscle. Not that the 440 was any slouch, but for a guy who’s used to going more than 150kph on water, without brakes, it wouldn’t be just any motor that would satisfy his desire for high horsepower. The plan to fit a Hemi changed when fellow Taranaki muscle-car fan Rhys Humphries got his hands on a freshly built all-aluminium Keith Black big block Chrysler engine. The engine had been pieced together by Scott Koffel in the USA for race use by Warren Brown, with the intent of making 830hp on alcohol. “A deal was done between Rhys and me, as it was to be a great chance for Rhys to acquire the Hemi block that would end up in his Top Street Cuda. I thought this [buying the motor] would save me heaps of time and money — the engine was complete, so it’d just need a simple detune to get it running on pump gas, and we’d be done, right?” Tony explained.

As it turned out, that was far from being the case, and Tony called upon the services of well-known engine builder Craig Hyland at Engine Dynamics to assist.

“Craig spent hours planning the project, as the deeper we looked, the more we found that had to be done. It was no street motor,” Tony says. “There were no oil galleries to the lifters; they were fed from spray bars in the rocker covers — great for drag racing, but no good for long-duration driving — so the KB had to be machined for galleries and new lifters. Water cooling was another issue. With nothing on the exhaust side of the cylinders, more machining was required to achieve equal cooling to the block and heads, then a custom sump was built to fit around the steering arms and K-member.” Rather than be put off by the amount of work, Tony continued to transform the race motor to street duties, adding a windage tray to the custom sump and swapping out the cam for a more street-friendly hydraulic roller item.

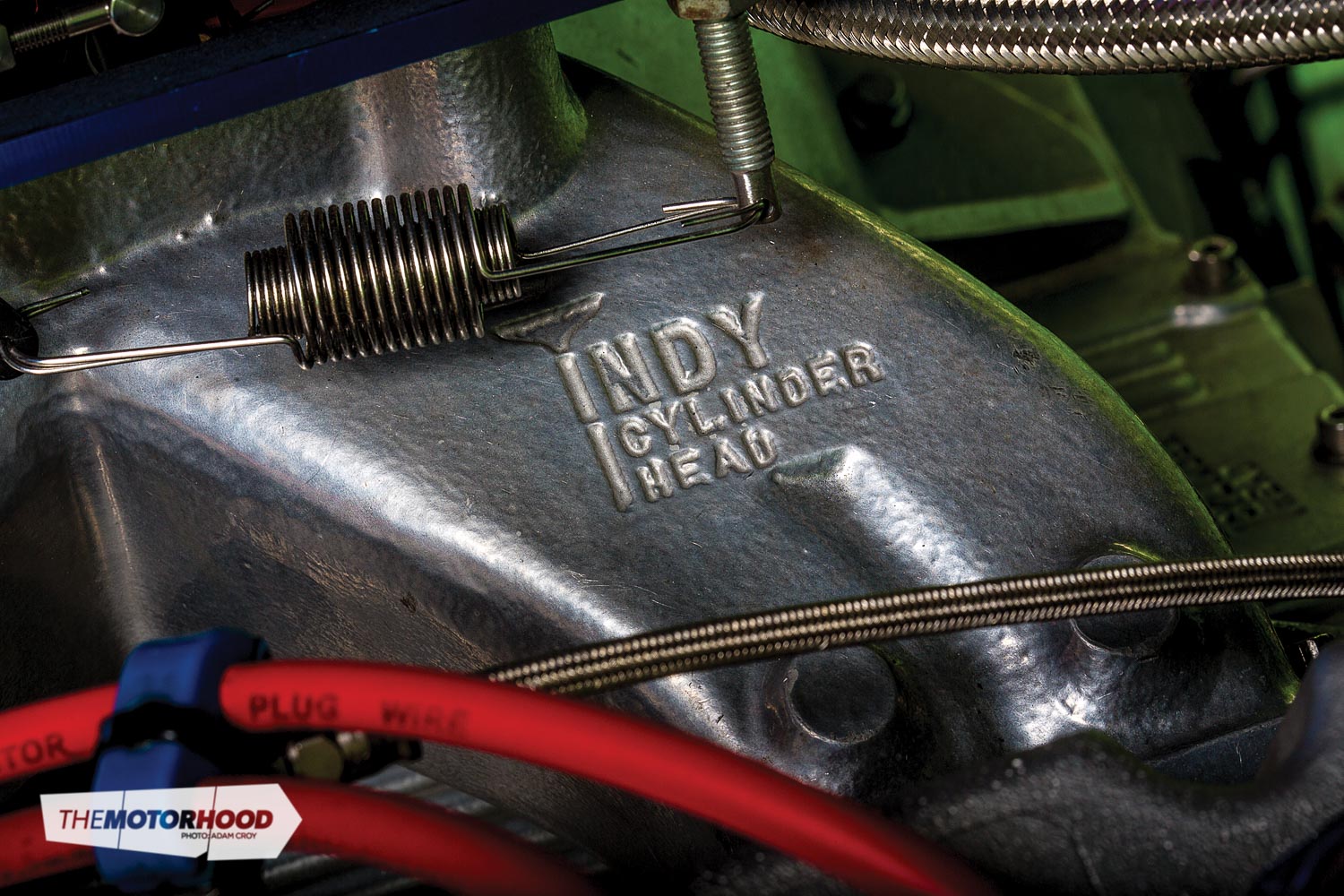

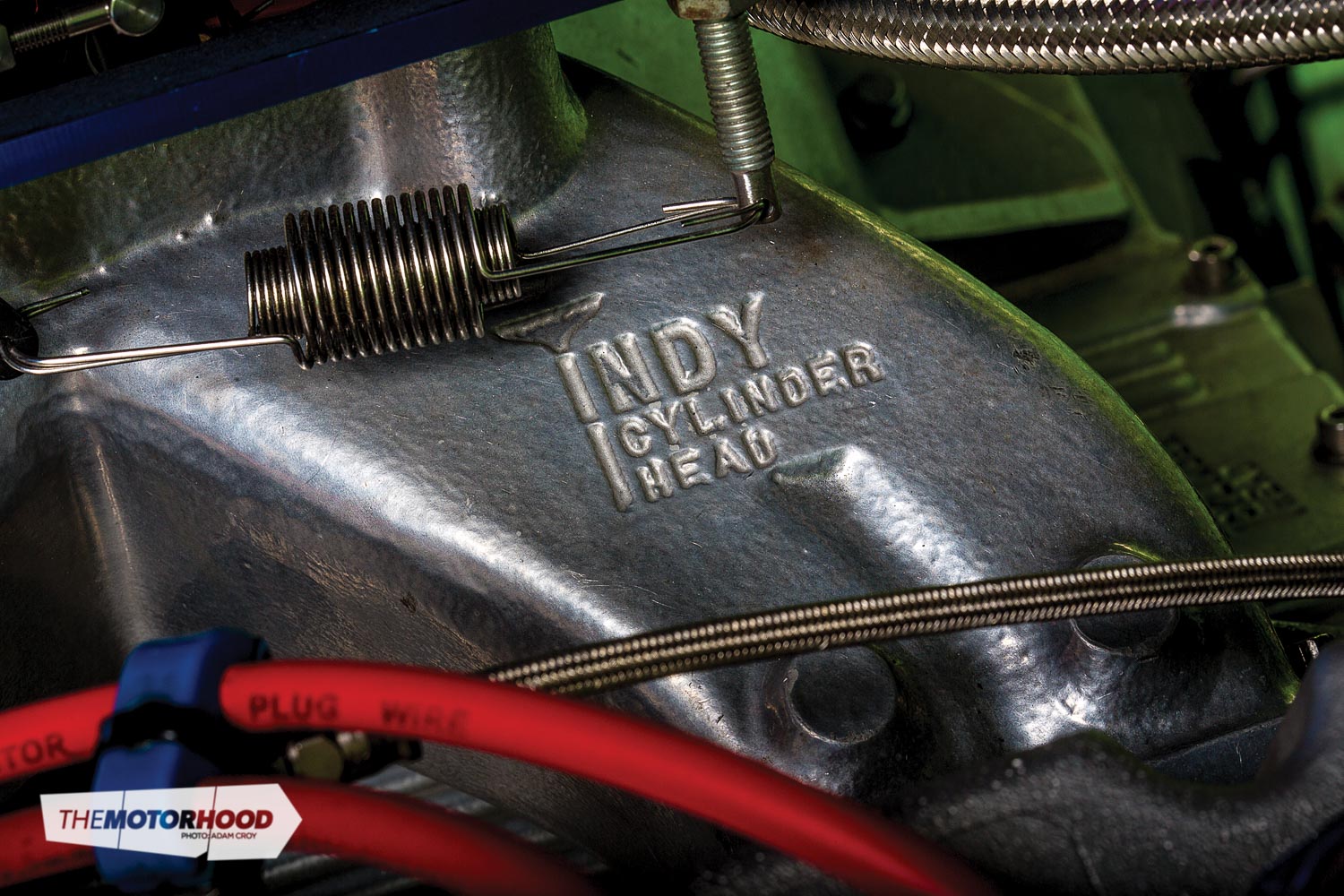

“Craig and I discussed changing the gear drive for a chain, but I decided to stick with the gear drive. There’s now an ongoing joke between us about it, to see if this stays or goes, but I’m sure it’s going to stay,” continues Tony. The rest of the 572ci combo consists of 4½-inch Ross Racing pistons fitted to 7.1-inch Manley Performance Pro Series I-beam steel rods swinging off a 4½-inch knife-edged Callies crank. Feeding the instructions to the 2.25-inch Ferrea inlet valves and 1.81-inch Ferrea exhaust valves is a Comp Cams hydraulic roller cam with 0.598-inch lift, while a set of 1.6:1 T&D rocker arms completes the top end.

Externally, the combo runs an Indy high-rise intake manifold with Holley 850cfm carb sitting up top, fed by -8AN fuel lines. For ignition gear, the MSD catalogue was raided for almost every possible component, and, for oiling, Milodon was the brand of choice.

Once the unexpected engine rebuild had been completed, the fun part — or, more accurately, what should have been the fun part — could commence, and that was dropping the engine in the hole and going out for a skid. Again, it wasn’t all that easy, with the engine going in and out of the freshly painted engine bay a number of times before it could be left in there for good. Even once the engine was in, Tony’s woes continued, as it now struggled to make oil pressure, needing to be manually primed before starting. “We didn’t want to risk any cold-start damage, or, worse, risk having no oil pressure at all. Something had to be wrong in the oil plumbing, as the Accusump wouldn’t prime, so all the oil was going straight back into the sump, and the pump was always dry after resting,” Tony explains.

Thankfully, the answer was a simple one. Tony tells us, “A quick call to Jeff Dobson at Pirtek to help find a suitable non-return valve was all we needed. These were installed in the dual -12AN pick-up lines, and work perfectly — no more manual priming, and the Accusump re-primes the engine well now.” Given the brute power now hiding under the bonnet, you’d expect to be reading next about a string of driveline breakages. Fortunately, early on in his ownership of the car, Tony had upgraded the diff to a Ford nine-inch with Trutrac head and 28-spline axles. At the time, he thought they’d be overkill for any engine combo the car ever received — looks like the ‘better safe than sorry’ mentality does pay off.

Tony took the same approach with the transmission. When he had West Auckland Engine Reconditioners (WAER) give it a 500hp-capable overhaul, he thought that was the end of it. Little did he expect that the transmission would break on the car’s maiden voyage with the new motor. This was a cruel coincidence, as the engine never ran beyond 3000rpm.

“Eric [Livingstone; WAER] said he’d never seen one break where it did,” Tony says — then again, being built for 500hp, and recieving 657 along with 692lb·ft of torque, any weak link was bound to be exposed.

With Tony and his wife, Amanda, being regulars at events such as Americarna and Beach Hop, they’d already paid plenty of attention to sorting the cooling system and the creature comforts such as a decent audio system. Sure, in a car like this, the sound from the engine alone is music, but Tony didn’t see why he couldn’t have a decent audio system, too. Included in this were carbon-fibre speakers, a 12-inch subwoofer, and liberal use of Dynamat insulation. Being handy with metal, Tony knocked up the install himself, before turning his attention to creating a custom centre console — just the thing to house the B&M ratchet shifter.

With so many unexpected dramas with the swap from the 440 to the 572, the car wasn’t completely on the road till the week before Repco Beach Hop 15. One of the finishing touches was having a friend, Tony Etheridge, paint the newly scooped hood in satin black, the perfect complement to the sublime green and T/A graphics the rest of the body wears.

That Beach Hop trip went perfectly. Sure, the Challenger isn’t the most economical cruiser, but in terms of smiles per gallon, the car is right up there with the best. At the event — as has been the case since he first purchased the car — Tony needs to allow plenty of time for every gas stop; it’s not just a matter of filling up and leaving, but a matter of answering everyone’s questions and letting them take photos, before he can hit the road again. Of course, for Tony, with every stop there’s a go, and with every go, there’s now plenty of tyre smoke. With a 657hp big block up front, you can’t blame him!

1973 Dodge Challenger

- Engine: 572ci big block, Keith Black aluminium block, billet steel main caps, Manley Pro Series I-beam steel 7.1-inch rods, ARP fasteners, 4½-inch Ross Racing pistons, 4½-inch Callies knife-edged crank, Comp Cams hydraulic roller cam, 2.25-inch Ferrea inlet valves, 1.81-inch Ferrea exhaust valves, Comp Cams springs, ported 440-1 Indy heads, 1.6:1 T&D roller rockers, Indy high-rise intake manifold, Holley 850cfm carburettor, -8AN fuel lines, Mallory electric fuel pump, Holley fuel pressure regulator, MSD 6AL ignition, MSD crank trigger, MSD coil, MSD leads, 1⅞-inch headers, twin 2½-inch exhausts, custom aluminium radiator, twin electric fans, CSI electric water pump, Billet Industries serpentine system, Milodon oil accumulator, Milodon oil pump

- Driveline: TorqueFlite 727 transmission, reverse-pattern valve body, SFI flexplate, 3000rpm stall converter, Ford nine-inch diff, Truetrac head, 28-spline Strange axles

- Suspension: One-inch torsion bars, air shocks, stock rear leaves, custom front sway bar

- Brakes: Stock disc/drum

- Wheels/Tyres: 15×8-inch and 15×10-inch Boyd Coddington wheels, 245/60R15 and 295/50R15 Mickey Thompson Sportsman S/T tyres

- Exterior: Sublime green paint, Challenger T/A stripes

- Interior: Momo leather steering wheel, B&M ratchet shifter, Hurst pistol-grip line lock control, Auto Meter gauges, aluminium dash insert, custom centre console, Dynamat insulation, Sony and Pioneer audio

- Performance: 657hp at 5700rpm, 692lb·ft at 4300 rpm

- Owner: Tony Ewens

- Car Club: American Muscle Car Club

- Age: 48

- Occupation: Health and safety manager

- Previously owned cars: XA Falcon, 600hp Chev-powered Kwik Kraft jet boat

- Dream car: Dodge Challenger; this one, when it is finished

- Why the Challenger? Mopar or no car! The Challenger is arguably still the best muscle car around. When I bought the car, I told my wife, Mandy, that it was exactly the car I had always wanted and I wouldn’t need to change a thing. I have spent the last seven years changing it

- Build time: When it comes to building cool, you don’t keep time or count money

- Length of ownership: Seven years

- Tony thanks: Amanda, my wife, who enjoys the car as much as I do; Craig Hyland at Engine Dynamics; Tony Etheridge at Total Paint Supplies; Jeff Dobson at Pirtek Taranaki; Eric Livingstone at West Auckland Engine Reconditioners; Rhys Humphries, Jai Ewens, Nick Ewens, and Maurice Doyle

This article originally appeared in NZV8 Issue No. 122. You can pick up a print copy or a digital copy of the magazine below: