data-animation-override>

“After growing up in the back of this 1960 Dodge Seneca, Tut Waihape’s kids couldn’t think of any better way to say thanks than giving the car back to him 30 years later”

“You should have seen the look on her face. Her heart missed a beat,” says Tutura (Tut) Waihape, of his wife May first seeing the 1960 Dodge Seneca hearse reverse up her driveway. The year was 1979, and at the time the car was being worked on by a mechanic who happened to be a friend of Tut’s, and who figured that Tut’s place was the perfect destination for a test drive.

Once May’s heartbeat had returned to normal, the situation could be laughed about, although it’d never be forgotten, as there was something about that car that Tut fell in love with.

Fast-forward a few years and the Waihape family was once again growing. A larger family car was needed, and wouldn’t you know it, that very same Dodge was for sale by the funeral home. The car had been sitting for sale for a year without so much as a bite on it, as at the time no one wanted a hearse due to the stigma that came with it. Tut didn’t mind the car’s past though, as he was fascinated by its flowing lines and the V8 that sat under the hood. Besides, with just 43,000 miles on the clock, the car still looked and drove like new.

After a quick test drive and experiencing the smoothness of the engine, Tut knew it had to be his.

The price? A cool $2000, which included the coffin rollers being removed and the brand-new unused rear seat refitted. It wasn’t long until his mates got wind of the purchase and nicknames like ‘Dead Loss’ and ‘Stiffy’ were being thrown around. But laugh all they like, Tut knew he had an incredibly rare car, hearse or not.

For the next few years, the Seneca served as a reliable family wagon, often with kids overflowing out of all areas of it. Tut reveals, “As time’s gone on, curiosity and crowds around the car still remain, but for a different reason. In the old days, before we owned it, the questions were about who was in the back; now it’s all about what’s under the hood. The mere sight of the car is able to loosen people’s lips and they share their own stories of classic cars.” In saying that, it has been used to take a few friends on their last ride also …

Over time, the family grew up and moved out of home, and the big wagon began to sit in the shed and look a bit unloved. “My wife would say ‘All that car does is gather dust’, to which I’d reply, ‘No honey, it’s gathering money’,” Tut laughs.

Little did Tut know what his sons, Cory and Levi, were scheming. Because without mentioning a word to Tut, they’d already developed a plan to rebuild the car, and they already knew exactly who they’d get to do the work. With a full plan already in place, they casually mentioned the idea of giving the car a quick tidy-up to Tut, and asked what his wish list would include. “Better brakes, power steering, air conditioning and a reconditioned engine,” was the reply, which was met with laughter from the boys, who then informed him that they already had a full rebuild scheduled, and it’d be far more comprehensive than that. Better still, it was their shout!

When planning the project, West Auckland Engine Reconditioners’ name kept coming up as the place to take it to, and it was here that the majority of the build would take place. While open to suggestions from the West Auckland Engine Reconditioners (WAER) team, there were also some specific requirements for the build that had to be adhered to along the way, such as the original engine and transmission had to be used. With both Cory and Levi having owned a bunch of cool cars themselves, their plans were somewhat more radical than their dad’s. Things like tubbing the rear end, supercharging the engine and adding fuel injection were on their list. The catch was that Tut wouldn’t be kept in the loop about what was going on, and would only see the car once during the seven-year rebuild!

With the car dropped to WAER, it wasn’t long before the mechanicals were pulled out and the body sent to Profile Autobody, where it was to be disassembled even further. From here it was sent to Rotorua to be dip-stripped. Being five-and-a-half metres long, we can only assume it would have tested the size of the stripping tank! With the naked shell returned to Profile Autobody, the repair work could begin. The stipulation from the start was that the car must be painted black, and getting panels as long as the Seneca’s straight enough for that was an equally as large task in itself. As we’ve come to expect, Greig and the team at Profile Autobody got the car arrow-straight though, working out the dents and imperfections along the way. Also included in their list of tasks was the tubbing of the rear end, to allow the massive 20×14-inch Intro rims to fit. It was a long and time-consuming process, but Cory and Levi couldn’t have been happier with the outcome, especially as Profile Autobody managed to recreate the one piece of missing trim on the vehicle that couldn’t be sourced.

With the bodywork completed, and sprayed in layer after layer of deep Aston Martin Onyx black, the car was returned to WAER where the mechanicals were being worked on.

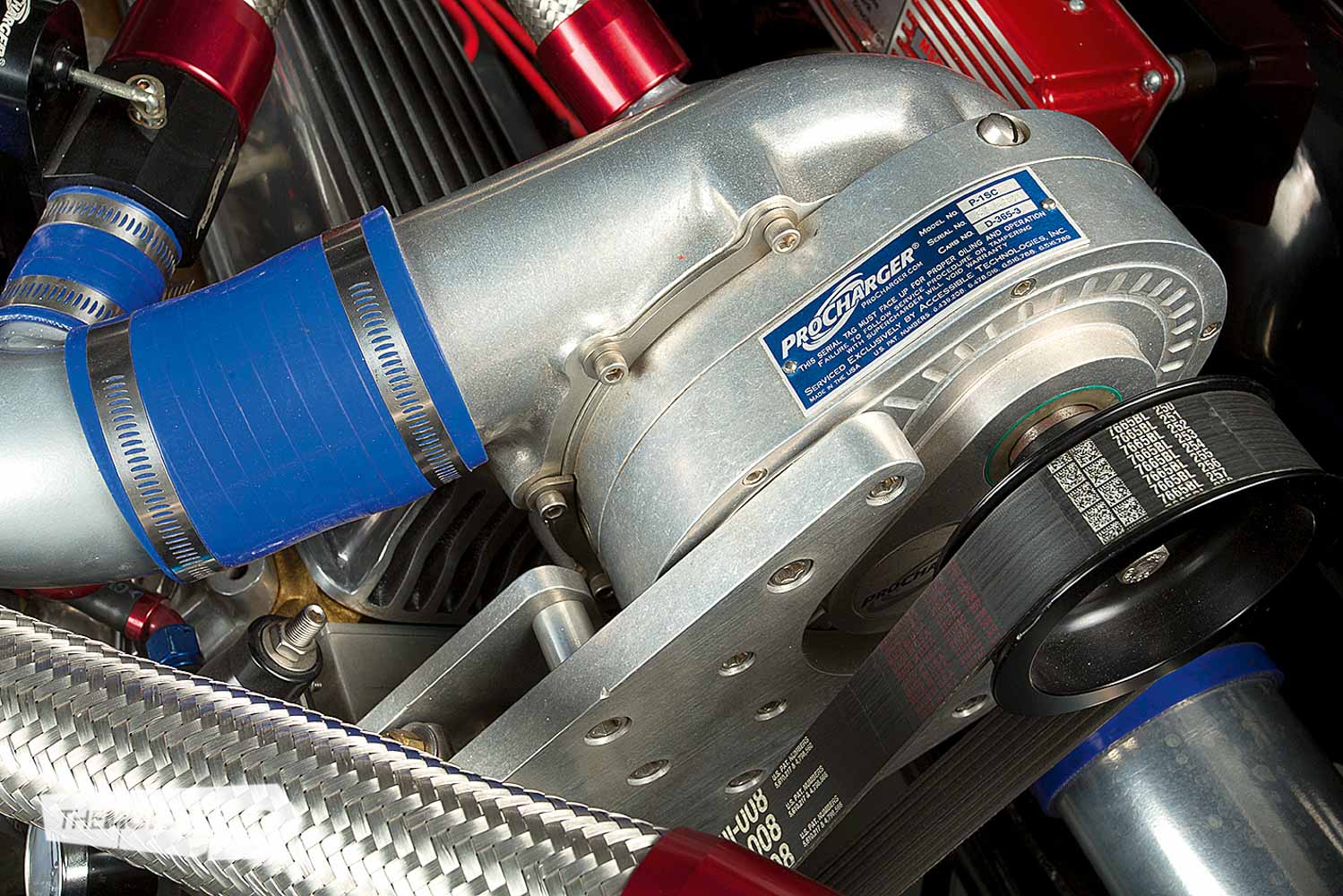

While it would have been easy to exchange the motor for a larger item, the rules were the factory-fitted 318 and push-button transmission must remain in the car. Of course, that didn’t mean it couldn’t have any power though, as Levi was dead set on fitting a Procharger. To handle this, 8:1 compression pistons were fitted, as were H-beam rods to the stock steel crank. The heads were ported and fitted with new valves and bushed rockers, while a mild cam was fitted below. To keep things reliable — and simple for Dad — the boys had WAER set up the engine with a FAST ECU and EFI throttle body system. Add to this a bunch of MSD ignition components, a Weiand manifold and twin 2.5-inch exhausts, and you’ve got one of the toughest 318s ever assembled.

With the Chrysler PowerFlite transmissions not being known to handle massive amounts of power, the set-up has actually been detuned for reliability’s sake to a still impressive 320hp at the rear wheels — more than enough for a cruiser like this. Behind the trans sits a Mopar 8¾-inch diff, albeit in a seriously narrowed fashion and fitted with Strange axles. Rather than go for a four-link, the diff actually sits on the stock leaf springs, which have been mounted inboard and fitted with Teflon bushes. Up front, a Moog suspension kit works in conjunction with the stock torsion bars to bring the 20×9-inch rims back closer to the guards. Bilstein shocks have been fitted to each end, as have Wilwood calipers and 13-inch rotors all round. I guess it’s fair to say the boys took the “it needs better brakes” comment from Dad fairly seriously.

While Tut’s ideas for the interior only extended to air conditioning, the boys wouldn’t settle for anything less than a full custom leather retrim, and, as you can imagine, in a car this size, that’s not a small job. Hidden below the trim is a full layer of Dynamat. “There’s enough to do two large cars in there,” laughs Cory — and he’s not joking. Of course the air conditioning was added as requested, as was a decent Sony audio set-up, and a dashboard full of Auto Meter gauges.

The reality is that there’s not one aspect, nut, or bolt that remains the same as when the vehicle first rolled off the production line in 1960, such is the extent of the rebuild. Of course, the catch here is that Tut had no idea what the boys were doing with the car, or why the build was taking as long as it was. In fact, it wasn’t until after our photo shoot, and after the engine had been run in (there’s gotta be some perks in building your dad a car, right?), that he was finally invited to check out the car for the first time. You can only imagine the look of shock, awe and satisfaction on his face once the boys pulled the covers off the ultimate gift. It may have taken seven years, but when getting given back a car that’s this good, it could have taken 20 and there still wouldn’t be cause for complaint.

We bet that back when Tut first bought the car to carry the kids around in, no one ever thought the kids would return the favour 30 years later by giving the car back, not only with everything he dreamed of, but so much more than he ever could have imagined.

1960 Dodge Dart Seneca

- Engine: 318ci Mopar, 8:1 compression, forged pistons, H-beam rods, steel crank, remote oil filter system, ported heads, adjustable rockers, mild cam, 1370cfm FAST throttle body, FAST ECU, Procharger P1SC supercharger, FAST dual sync distributor, MSD 6AL ignition, MSD Blaster coil, MSD leads, twin 2.5-inch exhaust, Flowmaster mufflers, custom alloy radiator, SPAL electric fan

- Driveline: Chrysler PowerFlite push-button automatic transmission, 8¾-inch diff, Strange axles

- Suspension: Torsion bar (front), Moog suspension kit, stock leaves, Teflon bushes, Bilstein shocks

- Brakes: Wilwood front hubs, Wilwood Superlite calipers, 13-inch rotors

- Wheels/tyres: 20×8.5- and 20×14-inch Intro V Rod rims, 245/45R20 and 29/15/20 tyres

- Exterior: Aston Martin Onyx black paint

- Interior: Full custom leather retrim, Auto Meter gauges, push-button shifter, Sony audio install, custom console, aftermarket air conditioning

- Performance: 320 rwhp (detuned)

Driver Profile

- Age: 63

- Occupation: Butcher

- Previously owned cars: Mk4 Zephyr, LJ Torana, various motorbikes

- Dream car: Bentley

- Build time: Seven-and-a-half years

- Length of Ownership: Thirty-plus years

- Tut thanks: Levi, Cory and Dustin Waihape for their time, patience and lots more, Eric and the team at West Auckland Engine Reconditioners for their dedication and skill, Greig and the team at Profile Autobody for their insight, skill, time and ease to work with, Wayne and the team at Western Auto Electrical, and everyone else who worked behind the scenes

This article was originally published in NZV8 Issue No. 101. You can pick up a print copy or a digital copy of the magazine below: