data-animation-override>

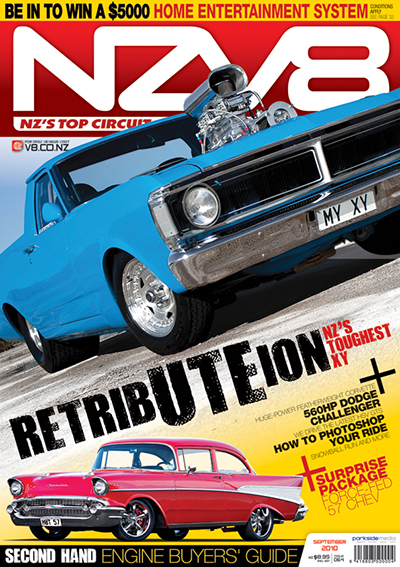

“When Mathew Patmore’s Fairmont was stolen, he didn’t get mad, he got even by building another Ford — a far better one”

We ended up pulling bits of it out of the Waikato river,” Mathew Patmore says, reminiscing about his previous project, an XY Fairmont, which had been stolen then dumped. “They didn’t need to chop it up, it was actually a mint shell, so it was a huge waste.”

That could have easily been the end of his modifying days, but Mathew was determined to finish what he had started. We’re glad he did.

Against all odds

Mathew’s been an XY fan for as long as he can remember, so the new car was always going to be another XY, and it would be tubbed and blown. His Fairmont had been stolen while in a local workshop, so Mat was determined not to let this Ford out of his sight, and he performed pretty much the entire build himself.

“The shell was horrible. It was crap. I didn’t want it, but my brother and I had driven an hour south of Taumarunui, down a goat track to get to where it was. It was like driving to the end of the earth. I was disappointed with it but bought it because it took us so long to find the place; I was determined not to go home empty-handed.” That may not be the wisest reason to buy a car, but Mat was aware just how hard it would be to find another XY ute. He bit the bullet, paid the cash and took the wreck home.

Got the skills

Having been in the sheetmetal industry for many years, and owning a sheetmetal business with his brother, Mat had both the skills and the tools at his disposal to turn the initial disappointment into his dream. The first step was plasma cutting out the rear tray floor. He was so eager to get started he didn’t remove the wheels, diff or fuel tank. Instead he took it out in one go, raised the hoist the ute was on and rolled the tray floor out to the scrap pile all in one piece.

It would be five years until the ute was on the road again under its own power. During that time, Mat turned it into what we believe is the toughest XY on the road today — if you think you know of one tougher, we’d certainly love to see it. The major metal surgery was first on the agenda — after taking a trip to buy the biggest rear tyres available, that is.

After hours at the sheetmetal shop, Mat chipped away building the new rear chassis section, narrowing a nine-inch diff and custom making a four-link to hold it all in place.

Those huge 33×19.5×15 Mickey Thompson Sportsman tyres wrapped around 15×15-inch Centreline Convo Pro rims leave little room for much else inside the smoothed-off tray.

Wanting to add something different to the rear end, Mat made a panel with the Ford logo pressed into it, which has been fitted to the back end of the cab. “I made about 10 of them and sold them off, which helped buy bits for the ute,” he says of the cool-looking panels.

While working on the rear end, he also constructed a custom number plate surround, which has been blended into the custom rear roll pan. Hiding in behind this is a drop tank also made by Mat.

Once he was happy with the rear end, attention was focused on the front. Hamilton Engine Reconditioners was chosen to build the stout 351 Windsor that now displaces 393ci. While the block was being fitted with JE pistons, an Eagle crank, H-beam rods and custom cam, Mat was using a dummy block to set up the engine bay. He obviously knows how to use a welder and bend metal, because the engine bay is super-smooth and well thought out.

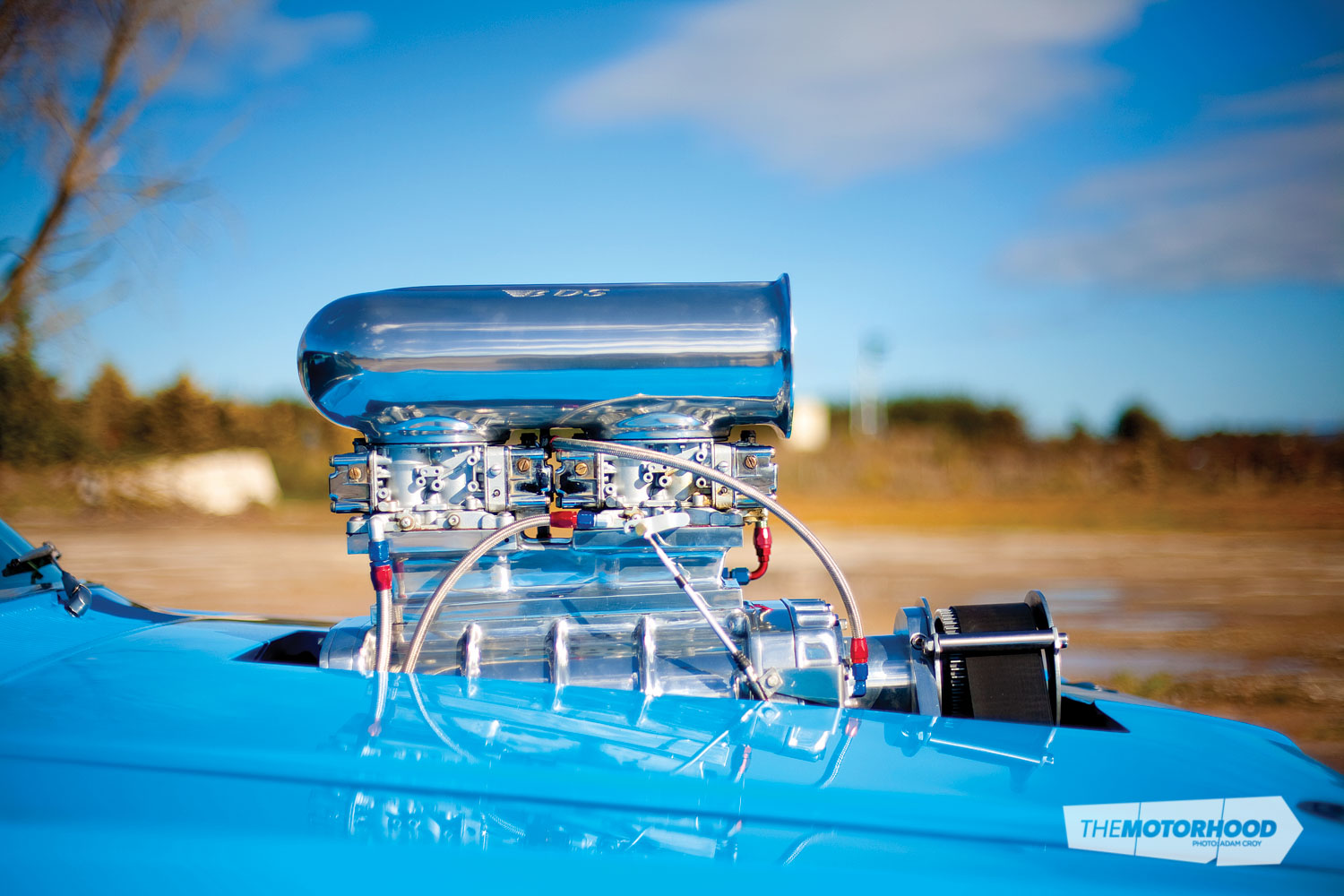

With the engine back from the builder, Dart Pro 1 alloy heads were fitted and a manifold was customised to mount the 6/71 supercharger, atop of which sits a pair of 660cfm carbs.

Many people might have stopped there and had the rest of the engine work outsourced. Not Mat. With a welder in one hand and some tube in the other, a set of custom headers was knocked up and fitted to a twin three-inch system.

One item he and his trusty welder couldn’t modify was the C4 transmission. This was sent off to Rotorua Automatics to be fitted with a shift kit and TCE 3000rpm stall converter.

Unexpected delays

By that stage the body was ready for panel and paint. The car suffered the common scenario of sitting in the back of a panelbeater’s workshop untouched, and more than once. Undeterred, Mat pressed on until he found PJS Panel and Paint in Hamilton, which was willing to get the job done. So impressed was Mat with PJS’s workmanship that he had the car painted in Ford Bright Blue while it was there.

With the paint barely dry, Mat was back into it, fitting Lovell heavy duty springs and Monroe shocks up front and EA disc brakes to the rear.

By now the vehicle was coming together well, with just the interior yet to be touched. With a bunch of Auto Meter gauges at the ready, a custom dash panel was folded up to house them all. Mat admits he’s got no idea why he mounted the MSD ignition to the panel too, and he’s keen to move it at some stage.

The curse of the bad tradesman struck again when getting the interior retrimmed, so it was off to Shane at Allen’s Upholstery in Te Awamutu, where the job was done right. The door trims feature custom embossing below the deep black finish, which is a subtle touch of quality, while the plush black carpets fit as they should have the first time around. Finally, a roll cage frames the M&H seats; after all, the car has the performance to back up its looks.

After five years in the build, the time finally came to take it for its first test drive. And wouldn’t you know it, a police officer happened to be passing the other way. Mat knew that with no WoF, Reg or Cert, it would be a messy situation. Much to his surprise, the cop just wanted to check it out, as he was a huge fan of the pro street look Mat had achieved. A lucky escape indeed. Even luckier is that the same thing also happened on the second drive…

Good things, good people

Just before our photoshoot, GPS tracking was added to ensure this one doesn’t walk away like the last one did, and the final bits and pieces for the Cert were signed off. After five years in the build, and a few bad tradesmen experiences along the way, Mat is understandably chuffed to be in the driver’s seat and clocking up some km’s. He’s modest about his achievements, though. Indeed, he wasn’t sure NZV8 would be interested in featuring his ute. Clearly, he needn’t have worried. We like to think good things come to those who deserve it, and after everything Mat’s been through, first with his sedan and then the ute, he certainly does.

1971 Ford Falcon XY Ute

- Engine: 393ci (6440cc) Windsor, 351 Windsor block, JE blower pistons, Eagle steel crank, H-beam rods, steel main cap support, Dart Pro 1 alloy heads, Manley stainless steel valves, Comp Cams roller rockers, two 660cfm centre squirter carbs, custom intake and blower plate, 6/71 blower, custom-built drive snout and brackets, BG400 fuel pump, dash 10 braided lines, two Mallory regulators, KB gauges, custom 90-litre aluminium fuel tank, MSD BMT electronic ignition, MSD billet distributor, Ford Motorsport 9mm leads, custom headers, 1-7/8-inch primaries, four-inch collectors, HPC coated twin three-inch exhaust, two Flow Master mufflers, 32x19x3 alloy radiator, twin 305mm electric fans

- Driveline: Ford C4 transmission, shift kitted, TCE 3000rpm stall converter, Ford nine-inch diff, 4.11:1 ratio, 31-spline axles

- Suspension: Lovell heavy duty springs, Monroe shocks (front), four-link rear, Spax adjustable coil-overs (rear)

- Brakes: XY front discs and callipers, EA rear discs and callipers

- Wheels and tyres: 15×5-and 15×15-inch Centreline Convo Pro rims, Mickey Thompson six-inch front tyres, Mickey Thompson Sportsman 33×19.5×15 rear tyres

- Exterior: Custom tubs, Ford embossed rear panel, debadged, custom roll pan

- Chassis: Owner-built box section chassis

- Interior: M&H bucket seats, Momo steering wheel, B&M ratchet shifter; Auto Meter oil, water temp, volt meter, boost, speedo and tacho gauges; custom dash, four-point roll cage

- Performance: 730hp (544kW)

Driver profile

- Name: Matthew Patmore

- Occupation: Sheetmetal workshop owner

- Previously owned cars: XY Fairmont with blown 351 Cleveland

- Dream car: XY doorslammer with Alan Johnson–built big block

- Why the ute?: It was unfinished business after the Fairmont was stolen

- Build time: Five years

- Length of ownership: Five years

- Mathew thanks: Bobby Owens — this car would have never happened without his advice and countless hours of help. Glen and Ferret from PJS Panel and Paint Hamilton, Deane, Greg and team from Deane Mark Auto Electrical Te Awamutu, Shane from Allen’s Upholstery Te Awamutu, Shane from Segedins Dominion Road, G and N Sheetmetals Hamilton, Brett from Redline Agencies Hamilton, Paul Tootill, brother Tim, my family, my partner Sinead and kids Daniel and Keira.

This article was originally published in NZV8 Issue No. 64. You can pick up a print copy or a digital copy of the magazine below: