data-animation-override>

“Meet ‘RATTLM’, the Rattla team’s latest weapon, a Shelby Mustang that stings far worse than the Falcon ever did”

When the Rattla Motorsport team arrived on the New Zealand drifting scene, the crew came from a background in speedway and, later, Targa. Although they were new to the drifting world, the team didn’t take long to make waves, thanks to the hardware they brought with them. The Rattla Falcon, an absolute monster of a Ford Falcon, was first powered by a 6.7-litre (410–cubic inch) small block, then, later on, by a 7.67-litre (468–cubic inch) small block Ford: when the loud pedal was stomped, it emitted a noise that would make any petrolhead cry with joy. But, as amazing as it is, the car was never engineered to drift; it was originally intended to be a Targa machine for team owner Chris Allen, although, after an incident, he never made it behind the wheel. He passed his driving duties on to son Shane, who, despite a very promising career in speedway, chose to pursue drifting. So, for the past few D1NZ seasons, Shane has wrestled with what must be the hardest car to pedal on the D1 grid, and, although they continued to develop it, it was always Chris’ car, and bending it was never an option. Thus, it was time for the team to build a purpose-built drifter, so that Chris could finally get behind the wheel of the Falcon in Targa and Shane could put his best foot forward towards claiming that ever-elusive podium top step.

When looking for a new car, there was really only one manufacturer the team would consider, and it doesn’t take a genius to work out that that’s Ford! But the team didn’t have to search far, as, sitting next door to their workshop, was something a little special: a factory-built race-only 2008 Shelby GT500 shell — not an ex-road car but a zero-kilometres-on-the-clock shell, one of only 500 ever produced. Imported into the country by its first owner, it was meticulously seam welded and received an eight-point roll cage before the project ground to a halt. It was therefore the perfect base for the Rattla team to take over and turn into their version of the ultimate pro drift car.

Unlike the Falcon, the Mustang base is a well-developed drift platform in America — an ex–Formula Drift (FD) championship winner with many parts available off the shelf. Most important, though, is that it’s easy to source the steering kits for, which is a very key element of any successful drift build — the lack of any choice in that department still plagues the Falcon to this day. The team put in the call to FD driver Justin Pawlak, better known as JTP, to order up a full lock kit and coilovers.

Steering and suspension aside, everything else in the car took a more traditional Rattla Motorsport route. The crew made a call to Craig Highland at Engine Dynamics for a new 7.67-litre small block, as found in the Falcon. However, this time, thanks to the ability to run a bigger base circle on the cam, to allow more lift and lighter valve springs, the new engine could make a ton more power and torque. The block is an aftermarket Dart item with JE pistons, a billet Callies crank, and Callies rods with a pair of heavily modified D3 heads, as commonly found on a nascar. Craig is no stranger to building big-power V8s, and the D3 heads received CNC porting, super-lightweight titanium valves, and that aforementioned big-lift roller cam. The dry-sumped 7.67-litre engine revs to a maximum of either 7000 or 7500rpm thanks to a dual MSD ignition system that is switchable in-cabin, just in case Shane needs a little extra to reach a clipping point. With the flick of a switch, he can instantly swap between either coil to change the rev limit. The result is a staggering 597kW (800hp) and 1016Nm (750lb·ft) of torque at the rear wheels.

Keeping a driveline alive behind this amount of torque is not easy. In the past, the less-powerful Falcon had an appetite for gearboxes — it ate as many as six race boxes in one season — but, in the Mustang, the team has used a new product, the HGT five-speed sequential, and an alloy modular nine-inch diff. Why no quick-change, you may ask? The torque figures are well outside the recommended tally for such a unit — so, that was a risk the team was not willing to take.

In testing, the Mustang feels fast, and Shane told us there is way more grip on offer than with the Falcon, so much so that they will dial some out to help keep the car sideways off throttle. But, right out of the gate, the Pony was on point in the steering department, and the extra throttle response was noticeable.

The team has a busy season ahead, sitting out the full D1NZ series but making up for it with a ton of extra events alongside a few selected D1 rounds, all with the aim of getting Shane comfortable behind the wheel and able to really work the Mustang’s potential. Chris has already told him to not worry about putting a scratch on that faultless paintwork. The steel widebody has been moulded, and Chris expects Shane not to hold back.

This is the biggest monster to come out of the Rattla stables to date, so hold onto your hats, folks, it’s about to get real wild at a drift track near you.

Tuning Menu

MAKE AND MODEL: 2008 Ford Mustang Shelby GT500

Heart

ENGINE: 7.67-litre (468ci) Dart Ford small block built by Engine Dynamics

BLOCK: JE pistons, Callies rods, Callies billet crank, ATL Super Damper

HEADS: Modified CNC ported Nascar D3 heads, roller cam, titanium valves

INTAKE: Braswell-built Holley carb, single-plane high-rise manifold, K&N filter

EXHAUST: HPC coated two-inch 4-1 headers, 3.5-inch dual exhaust, dual Flowmaster mufflers

FUEL: Nascar belt-driven pump, XRP in-line filter

IGNITION: Switchable twin MSD HVC Blaster coils, MSD twin-feed distributor

COOLING: Fenix radiator, Bob Drake water pump

EXTRA: Dry sump system, Jones Racing power-steering pump, boot-mount Peterson oil breather, remote oil filter, AN fitting and braided lines throughout

Drive

GEARBOX: HGT five-speed sequential

CLUTCH: Tilton triple-plate

FLYWHEEL: Tilton

DIFF: Alloy modular nine-inch (3.25 ratio), Peterson oil breather, Driveshaft Shop carbon one-piece shaft

Support

STRUTS: JRI Motorsports external reservoir coilovers

BRAKES: Tilton 600-Series floor-mounting pedal box (F) Endless six-pot calipers, Endless two-piece rotors, Endless pads, hydraulic handbrake (R) Endless Drift 6R six-pot calipers, Endless two-piece rotors

EXTRA: Woodward steering column, JRI front knuckles, adjustable three-link rear, adjustable Watts link, seam-welded chassis, custom chromoly lower control arms, modified steering rack, custom toe and bump-steer kit, F&R three-piece sway bars, air jack system

Shoes

WHEELS: (F) 18×10-inch Work Meisters (R) 18×12-inch Work Meisters

TYRES: 265/40R18 Zestino semi slicks

Exterior

PAINT: Custom Rattla green sprayed by Rodney’s Restorations

ENHANCEMENTS: Custom steel widebody, carbon doors, Lexan windows, livery designed by AWS and applied by Launchpad

Interior

SEATS: OMP Champ R, Sabelt six-point harnesses

STEERING WHEEL: Momo suede

INSTRUMENTATION: Full Auto Meter Phantom gauges, Auto Meter shift light

EXTRA: Eight-point roll cage

POWER: 597kW (800hp), 1016Nm (750lb/ft) at 7500rpm ATW

DRIVER PROFILE

Driver/owner: Shane Allen

Age: 24

Location: Hampton Downs

Occupation: Crane driver

Build time: Two years

Length of ownership: Three years

Thanks: Hemi Frog at The Mount Shop, Richard Fleming at HGT, Gulf Western Oils, Scott at Autostop, The Bling Company, BOC Gases, South Auckland Motors

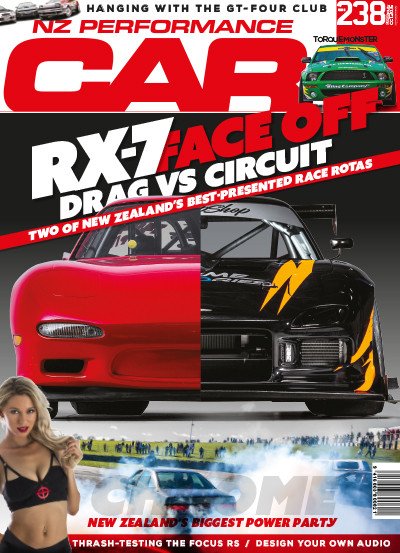

This article originally appeared in NZ Performance Car Issue No. 238. You can grab yourself a print copy or digital copy at the links below: