data-animation-override>

“It may not look it, but this rat rod is one of the more advanced pieces of vehicle engineering you’ll ever see”

Depending on vehicle preferences and depth of automotive knowledge there are a few different reactions people have when they see the 1928 Model A Ford-based rat rod that’s currently glaring at you.

To the uneducated, it’s nothing more than a collection of parts thrown together, which probably cost no more than a couple of grand all up and had no real thought put into it.

Those who are more up to speed with the automotive scene, recognize it as a rat rod … essentially a bunch of parts thrown together, most likely with some thought put into it. However, it’s obviously an incomplete one, due to the lack of radiator, pullies, belts and distributor cap … not to mention the holes in the sump.

Regardless of which category you fall into, you’ve just been visually assaulted and should consider yourself well and truly fooled. Sure it’s a rat rod, but this is no slapped-together machine made from parts found lying around. Instead this is one of the more cleverly built vehicles to have ever graced the pages of NZV8.

The owner of the vehicle was looking for a new project about two years ago now, and when he found the ’28 Ford body mounted to a decent-looking chassis, he could see potential for a cool machine. Originally the intention was to simply drop a small block Chev in and get it on the road. Somewhere along the way, things blew out in spectacular fashion.

The body and chassis were the work of Chris at Blackjack Engineering, but while in his possession the only intention was for the car to do skids, hence, when it was purchased it had no rear brakes, among other things. Still, the bodywork was very well done and the chassis itself beautifully built, and the vision of what it could become was too strong to not turn it into a roadworthy vehicle.

The plan to keep things simple didn’t last long at all. In fact, it was when searching for a suitable motor that things went well and truly off track. Budget and timeline blowouts ensued, but the end result speaks for itself.

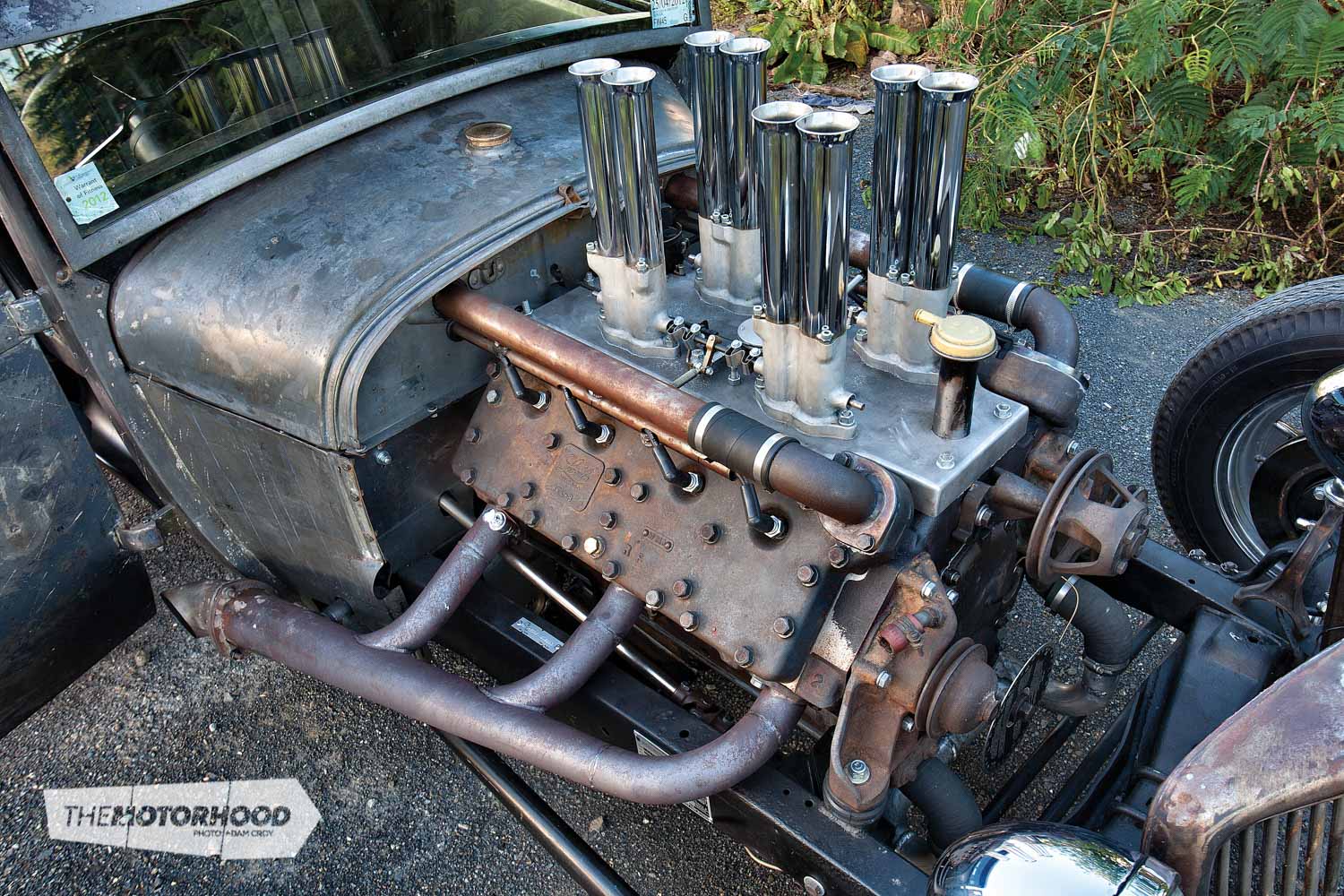

Paul Dunkley is the man responsible for making the 337ci Lincoln flathead into the visual and mechanical work of art that it is today. The giant motor has been stripped of its antiquated internals and now houses a bunch of high-performance parts made especially for the job. After all, when was the last time you saw Lincoln flathead parts available? Included in the engine’s new internals are eight-inch custom-made rods, custom valves and pistons, custom solid adjustable lifters complete with modern-style valve springs, and a modified oiling system.

The original crank has been polished and the intake ported and machined for the newly fitted oversized valves. With the custom oversized pistons and new rods, capacity has been increased to 351ci.

But (in my opinion at least) it’s not the internals of the motor that make it cool. Instead it’s what’s on, or more specifically, what’s not, on the outside that makes it what it is.

The factory water pump drive pullies are still in place, but now spin freely since they’re no longer connected to any impellers.

To make the motor look like it doesn’t run, some serious thinking has gone into it. A custom pulley, which mounts to the crank between the engine and flywheel, now provides drive for the alternator, while an electric water pump keeps the coolant flowing.

Wise eyes will notice the water pipes head back over the top of the engine and disappear through the firewall. After ducking below the car, they join up to a large alloy radiator mounted in the boot. Like a sumo wrestler in swimming togs, the boot area is stuffed to the brim with things that either make the car run, or keep it cool.

The only thing that didn’t end up fitting was the battery, which now lives in the passenger’s footwell in a sealed-off box. In a car that’s already had a few inches sliced out of the roof and channelled a few inches over the chassis, it makes for a tight space.

The drivers’ side is obviously a bit better, but not the best place to be if you’re suffering from claustrophobia. But more on that later.

The stacks that point skyward from the giant flathead would lead people to believe it’s in the process of being set up to run mechanical injection. Again, this was all part of the ploy. The reality is a custom manifold has been created, which hides electronic fuel injectors and fuel rails in the valley of the engine. The AMS ECU, which runs the whole show, takes its signal from a crank trigger, which allows the car to run with no distributor. Although, just to add to the incomplete look, the lower half of a dizzy is still present, and spins as it would when capped.

Those lucky enough to take a close look at the car may notice the apparent small holes in the sump, where the engine has obviously been sitting on the ground for many years. A false floor on the inside of the sump is what really contains the oil. The whole combination is brilliantly executed to fool the casual observer, although even those who choose to look closer still won’t find any trace of wiring, such is the level of commitment to the incomplete look.

A T5 manual gearbox hangs off the back of the Lincoln, and shifting is by a skull gearknob, which now sits atop an almost spine-like custom-made shifter. There’s no fancy stereo, no carpet and no frills, just the bare bones that a rod such as this should have.

I was lucky enough to be thrown the keys to the car and, despite being too tall to fold myself comfortably into the cabin, it was an awesome experience that I’d happily re-live in a heartbeat.

With Ford drum brakes on the back, a hybrid disc and caliper set-up on the front, and the EFI looking after the engine tune, how it drives is a world away from how it looks. And that’s what cars like this should be all about. It absolutely oozes character on the outside, even more so in the engine bay, but deep down it’s a functional vehicle. It was neither a cheap nor quick task to build such a machine, and not without it’s fair share of difficulties, but the result is mind-bending, even for those who understand the engineering within.

1928 Ford Model A

- Engine: 1949 Lincoln flathead V8, 337ci bored to 351ci, custom rods, custom valves, custom pistons, custom solid adjustable lifters, modern-style valve springs, modified oiling system, custom sump, polished crank, two-inch headers, twin 2.5-inch pipes, AMS ECU, custom manifold, custom fuel rails

- Driveline: T5 manual gearbox, nine-inch diff

- Suspension: Transverse leaf front, dropped I-beam axle, coilover rear, 4-link

- Brakes: Disc front, drum rear

- Chassis: Model A, modified by Blackjack Engineering

- Wheels/tyres: 15×5- and 15×10-inch rims, 5.60/15 Firestone and 285/70R15 Silvertown radial whitewall tyres

- Interior: Custom shifter, not a lot else

- Exterior: four-inch roof chop, three-inch channel, louvered boot lid, removed boot floor

- Performance: Looks like it should have none

This article was originally featured in a previous issue of NZV8. Pick up a copy of the edition here: