data-animation-override>

“When Holden-loving Steve Woodd decided he was going to build a Ford, he knew it had to be something special — and it is”

As a kid, Steve Woodd sat on the hill at Meremere Dragway, watching drag cars go by, and thought to himself, I want to do that one day. Small wonder, then, that he’s now doing exactly that, in what must surely be one of New Zealand’s toughest Ford Capris. In fact, this exact 1970 Ford Capri was seen racing down the strip by a young Steve, at the first drag meeting he went to — funny how some things have a habit of coming full circle.

Fast forward a few years, and Steve’s a Holden man, but he’s well into his Ford Capris — his out-of-control trip deep into the world of drag racing began properly after he bought his third Capri. Whilst stripping the car down, he found that it was not what it seemed; rather, it was a Capri-shaped pile of rust with doors attached. At least the GT dashboard and centre console were salvageable, and these were saved for future use. Whilst Steve was working on the car, Mark Hudson — drag racer extraordinaire, and a personal hero of Steve’s — popped in to check up on the progress. Mark drag races his ‘TUF351’ Capri, and Steve jokingly asked when he’d be selling his car. As it turned out, Mark actually knew of a Capri that might be for sale, and, even better, it had already been set up for drag racing.

“I gave them a call and asked them if I could come down and have a look,” Steve says. “They were blown away that I even knew about it, as it turns out they’d only talked about selling it amongst friends. My good mate, Geoff Dunn, and I jumped into my ute and drove down to New Plymouth to take a look.”

Guess what happened from there! The Capri was sold to Steve as a rolling body, already set up for a small-block Chev, and complete with transmission, extractors, roll cage, nine-inch diff, tubbed and four-linked rear end, and wheels and race tyres. All it needed to get moving was an engine, and, as luck would have it, Geoff happened to have a 355ci small block lying around. The little two-bolt mains engine pushed the Capri to an 11.7-second quarter mile pass, but they both knew the car had gone a fair bit faster under the old owners.

With some careful refinancing, a 600hp 454ci small block (yes, small block!) crate motor found its way under the Capri’s bonnet. That engine pushed the Capri into the 10s, still fully streetable. However, the first track outing with that engine resulted in a snapped axle. A Strange carrier, Strange full spool, and 35-spline axles successfully eliminated that weak link.

The next issue came in the form of the standard Capri four-stud hubs and solid brake discs, which were quite simply not up to the job. With a bit of help, vented five-stud Ford Falcon discs were paired with Holden HQ GTS calipers — the concept was taken from Mark Hudson’s Capri, and still serves the car faithfully.

With the Capri all sorted and the big-power engine in the hole, it was time to make some noise. “So I rock up to the Night Speed Drag Wars with my new engine, thinking I’m gonna be one of the fastest street cars there, and who shows up to shit all over me but Reece Fish in his freshly twin turboed ’56 Chev,” Steve laughs.

That’s when Steve accepted that, no matter what you build or buy, someone’s always going to have one better — even so, the temptation to go faster was too much, and a nitrous kit soon found its way home, just to dip the Capri into the nines. It worked, and Steve pushed a PB of 9.4 at 141mph out of the Capri.

Unfortunately, it was around this time that the Capri went into a kind of hibernation. With his fibreglassing business slowing down and the wallet getting a bit knackered, Steve’s priorities meant the engine had to be sold.

“Even though I had no money, very little income, and a dead-end career, I still had a dream and a few skills,” Steve said. “I knew that if the car would ever rise again, it needed to be worth the wait and bigger and better than before.”

With his skills in fibreglass, Steve made a few moulds of the Capri’s body panels, and borrowed Top Doorslammer driver Nigel Dixon’s big-block Chev to see if it would fit in the engine bay — suffice to say that it did, and, after seeing how it sat, there was no way Steve’s next engine could be anything other than a big block.

If he was going to go for a big block, though, a few things would be needed to ensure it’d actually work with the Capri body. A set of headers was high up on this list, and fellow Capri fan, Larry Holmes, then working at Mitchell Motorsports, was enlisted to sort it out.

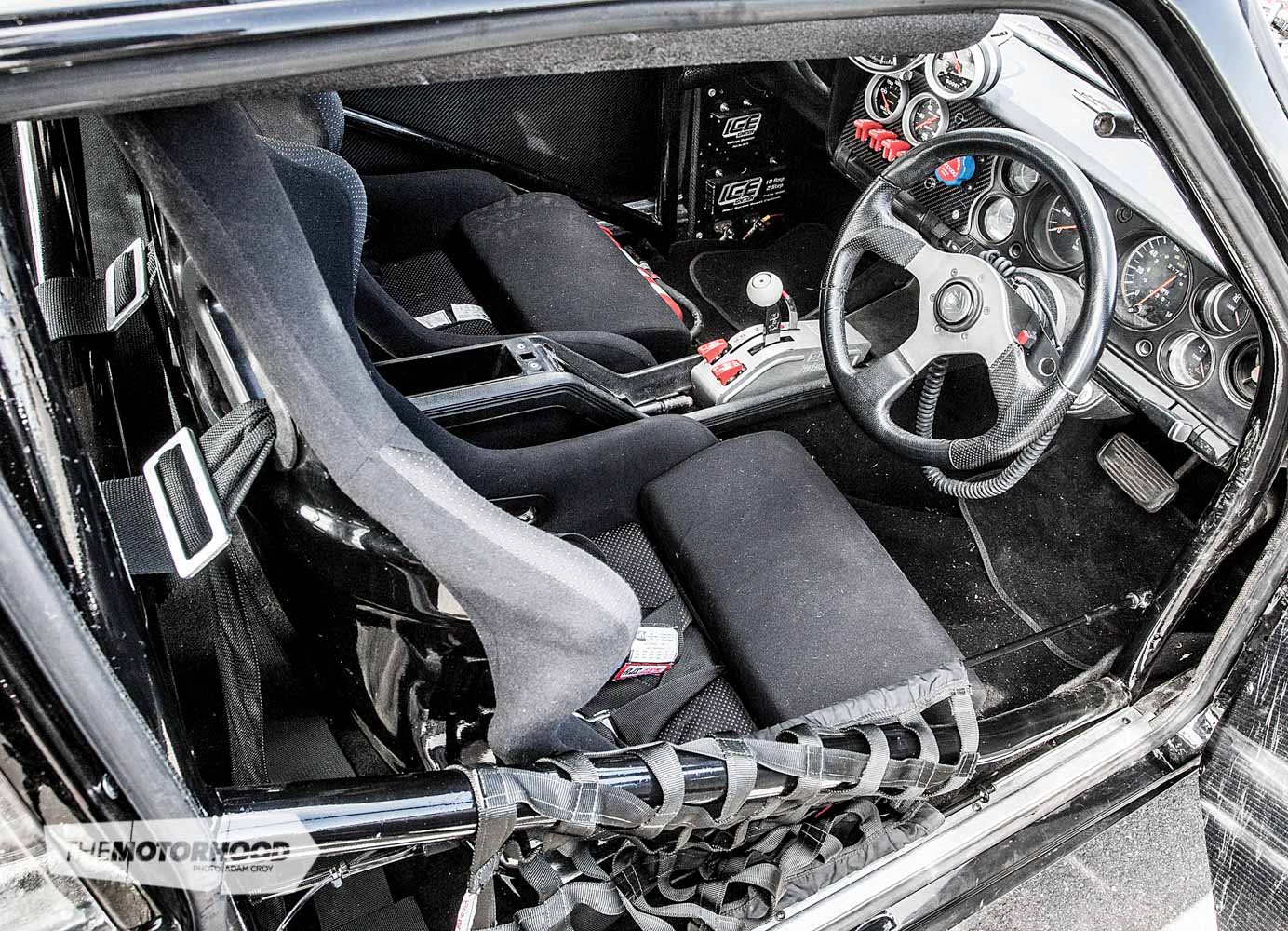

The headers look and function wonderfully, and their construction can’t have been an easy job, given the engine bay’s narrow confines and inconveniently located starter motor and steering rack. Whilst he was at it, Larry upgraded the roll cage, which ties in with the front strut towers, and added mounts for the new seats and five-point harnesses, which tie the rear chassis rails into the body. He also fabricated a custom under-dash pedal box for the new Tilton brake master cylinders — the size of the big block meant that a vacuum booster was out of the question.

Over time, a career change saw Steve once more in a position to look at working properly on the Capri. Nigel Dixon donated a second-hand two-bolt big block, and his old splayed four-bolt billet main caps. The ported 1960s cast-iron heads were left over from a drag car imported from the USA, which had recently made the change to alloy heads. These parts were dropped off to Jim Carlyle and Shane Parsons at Cambridge Engine Services, who assembled them into a 496ci drag engine — a good and reliable choice, as far as the ever-important power to budget ratio is concerned. The bottom end is filled with good stuff, including an Eagle 4340 steel crank, H-beam rods, and JE pistons, as well as a solid roller cam and trick valvetrain assembly.

Of course, when you love old-school muscle the way Steve does, it’s gotta be blown! For that reason, and to future-proof the engine’s power potential, a billet-cased 8-71 The Blower Shop supercharger was ordered from Als Blower Drives, to go with the pair of Quick Fuel 950cfm boost reference blower carburettors. Good friend, Geoff, sorted out the mess of wiring to get the engine running, and things were starting to look good. The final piece in this puzzle was sorting out cooling for the monster motor, which Steve completed over the course of three months — try fitting a suitably large cooling system into such a small engine bay, with blower pulleys and thermo fans in the way, and you’ll understand why it’s a little ‘in your face’. This engine build didn’t just happen overnight, either — assembling such a motor is no small feat, and it was built up over the course of a few years.

Chuck Mann, the transmission wizard, beefed up the TH400 to harness the big block’s abuse, and Hamilton’s ATL Balancing made up a suitably bulky 3½-inch driveshaft to suit. The diff was given another freshen-up, with new Richmond Pro Gear 3.40:1 gears and 35-spline pinion shaft and the Strange catalogue coming through for the billet pinion support and billet yoke. With that sort of muscle backing the potent engine, Steve now has no fear regarding launching off the line as hard as possible.

When you’re on the drag strip, power is important, but it’s of no use if your car can’t put it to the ground. To that end, the suspension system is a simple recipe that makes the best use of tried and tested components. Suspension Tech in Auckland built the custom front coilovers, with Bilstein 90/10 shocks and 600lb springs, while the rear gets a race-proven four-link set-up, comprising Afco two-way adjustable shocks and softer 120lb springs. The well-sorted suspension set-up also necessitated the installation of wheelie bars, to keep the car launching straight and reduce the risk of front-end damage.

With the car’s high-speed potential, a big rear wing was also added to keep the car stable. The DJ Safety parachute is a compulsory addition for any vehicle that exceeds 150mph down the strip. It’s a welcome addition, as the unboosted brakes can’t really enjoy slowing the Capri down from those speeds. Since this car was built to go fast on a budget, Steve made the rear wing and the frame for the ’chute at home, with a bit of help from Geoff, Supreme Sheetmetals, and Sinco Customs.

The exterior also received a once-over, thanks to the fibreglass panels Steve constructed from the moulds he’d made earlier. The fibreglass doors, bonnet, boot lid, front guards, and front valance were painted by Steve’s good friend, Andrew Kitson, in Holden Phantom Black to match the rest of the Capri’s bodywork. A few small bits and bobs here and there, such as the breather tank and belly pan, were required to get the car up to racing regulations and through the tech inspection. Then the drag strip was finally in sight.

The Capri was sent to Carl at C&M Performance for a tune, and, running on C16 at 15psi of boost — capped due to high intake temperatures — the engine made 685hp at the wheels (890hp at the crank). On this tune, the car ran a 9.17 at 148mph, but Steve knew it could do better and he wanted to do better. The carbs have since been converted to run on methanol, and the power output is now a huge 844hp at the wheels on 13psi of boost, with none of the intake temperature problems that plagued it on the last tune.

Unfortunately (or fortunately, depending on how you look at it) the dyno run on the methanol tune revealed that the carburettor’s needle valves can’t keep up with the engine’s demand for methanol — the fuel bowls empty and the engine runs lean. Steve is very thankful that this was discovered on the controlled dyno setting rather than at the track. He’s got some parts on the way, though, and, all going to plan, should have the Capri sorted and running eights in the very near future.

Should Steve ever tire of having a dedicated drag car, he’ll be able to convert the Capri back to road legality without too much fuss. The methanol fuelling would obviously have to go, but, that aside, only the questionable blower height is holding it back — when your career requires you to have a licence, you don’t want to risk losing it over something as trivial as blower height, but, as Steve puts it, “I like blowers more than I like warrants of fitness.”

Whether the Capri will see the road again is uncertain, but one thing you can be sure of is that Steve will never sell it, saying, “Even when I was pretty much bankrupt, and had to sell the motor out of it, I kept the Capri. No matter what happens, I’ll find a way to keep it.”

You heard it here first — so, when you’re next at the drags, keep an eye out for Steve and his Capri, and know that you’ll be seeing a lot more of him yet.

1970 Ford Capri

- Engine: 496ci big block Chev, two-bolt mains iron block, four-bolt splayed billet main caps, full stud kit, Eagle 4340 steel crankshaft, H-beam rods, JE forged pistons, 9.1:1 compression ratio, Cometic steel head gaskets, ported iron heads, custom solid roller camshaft, roller rockers, stud girdle, The Blower Shop inlet manifold, The Blower Shop 8-71 billet-case supercharger, Teflon rotors, two Quick Fuel 950cfm boost reference carburettors, 3½-inch exhaust, AdrenalinR mufflers, ICE 10A race ignition, ICE distributor, ICE leads, ICE coil, boost retard, two-step rev limiter, MAP sensor, triple-flow alloy radiator, custom shroud, twin thermo fans, Meziere high-flow electric water pump, custom swirl pot, external transmission cooler, 30-litre fuel cell, Barry Grant 400gpm fuel pump, Quick Fuel four-port regulator

- Driveline: TH400 transmission, transbrake, 3000rpm torque converter, reverse shift pattern, Richmond Pro Gear 3.40:1 gears, 35-spline pinion shaft, Strange diff carrier, Strange full spool, Strange pinion support, Strange billet yoke, Strange 35-spline axles, custom 3½-inch driveshaft

- Suspension: Modified struts, custom front coilovers, custom four-link rear, 90/10 Bilstein front shocks, Afco two-way adjustable rear shocks, 600lb front springs, 120lb rear springs, solid rose joints

- Brakes: Custom under-dash pedal box, Tilton master cylinders, remote reservoirs, Wilwood brake proportioning valve, XE Falcon discs, HQ GTS calipers, Ford Falcon drums (rear), DJ Safety parachute

- Wheels/Tyres: Weld Draglite 15×3.5-inch and 15×12-inch, 24x5x15 Hoosier Front Runners, 31×16.5×15 Hoosier Quick Time Pro rear tyres

- Exterior: Fibreglass doors, fibreglass bonnet, fibreglass guards, fibreglass front valance, fibreglass boot lid, custom rear wing, custom parachute frame, Holden Phantom Black paint

- Chassis: Rear half chassis, rear tubs, box-section rails

- Interior: M&H race bucket seats, Momo steering wheel, B&M shifter, Auto Meter gauges, Capri GT dash, six-point roll cage

- Performance: 844hp at the wheels, 13psi boost; 9.17 at 148mph