data-animation-override>

“Eight-inch, nine-inch, 10-bolt, 12-bolt — what does it all mean? What should you look out for? We address these questions in Part II of our two-part diff buyer’s guide”

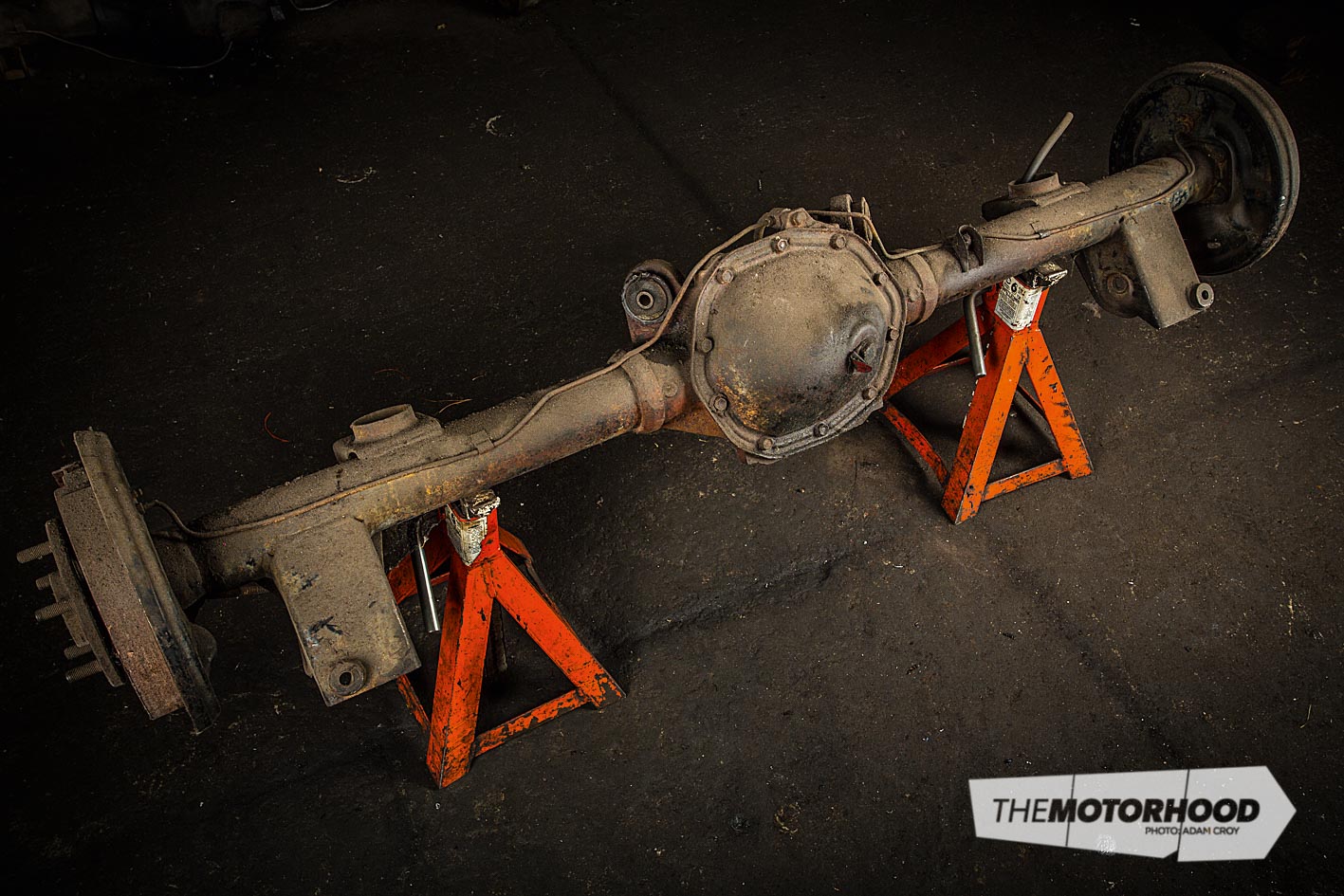

Every single car has a diff of some form, and, while names are bandied about the whole time, the technical make-up of diffs is somewhat less known, as is what to look for when you’re looking at buying, upgrading, or repairing one of your own. Over the next few pages, we aim to help buyers know what they’re looking at — be it at a swap meet or brand new in store. If you missed Part I [which covered Ford nine-inch and eight-inch, Chrysler 8¾, Dana series, and Jaguar diffs], you can check it out here.

GM 10-bolt

Chevrolet used the 10-bolt on passenger cars and Corvettes for a long time, so, consequently, different versions and sizes are available. The one that is ideal is the 8.5-inch, as it is not only strong but also has the largest aftermarket support.

Sometimes referred to as the ‘corporate 10-bolt’, the 8.5-inch 10-bolt began production in 1971 to replace the 8.2-inch 10-bolt and 12-bolt diffs. The 8.5-inch version comes with a 30-spline pinion, uses C-clips, and either 28-spline or 30-spline axles, depending on the year. Ratios available include 2.56:1, 2.73:1, 2.92:1, 3.07:1, 3.08:1, 3.31:1, 3.36:1, 3.42:1, 3.55:1, 3.73:1, 4.10:1, and 4.11:1.

The easiest way to tell if a 10-bolt is an 8.5-inch or 7.5-inch version is to measure the distance between the very bottom bolt cover and the next adjacent bolt. On an 8.5-inch, the distance will be 3¾ inches, while, on a 7.5-inch, it will be 3¼ inches.

Interestingly, GM fitted these diffs with different-shaped tags to differentiate ratios although, sadly, most of these are long gone. The housings were also stamped with different casting codes that delineate in which year the diff was produced and, in some cases, which head was fitted.

Expert’s Opinion

Lee from Diffs R Us says: “These are common because lots of cars got a 10-bolt, for example, 1967–1969 Camaros. It doesn’t matter whether they were a six-cylinder or an eight-cylinder, they all had a 10-bolt. But anything that was a performance car got a 12-bolt. You can’t make a 10-bolt as strong, but, with the aftermarket parts that are available, you can make it pretty close. The only issues you have are due the C-clip setup they’re hard to narrow down to use for other applications. That’s why people go to a 9-inch, as they’re easier to adapt.”

GM 12-bolt

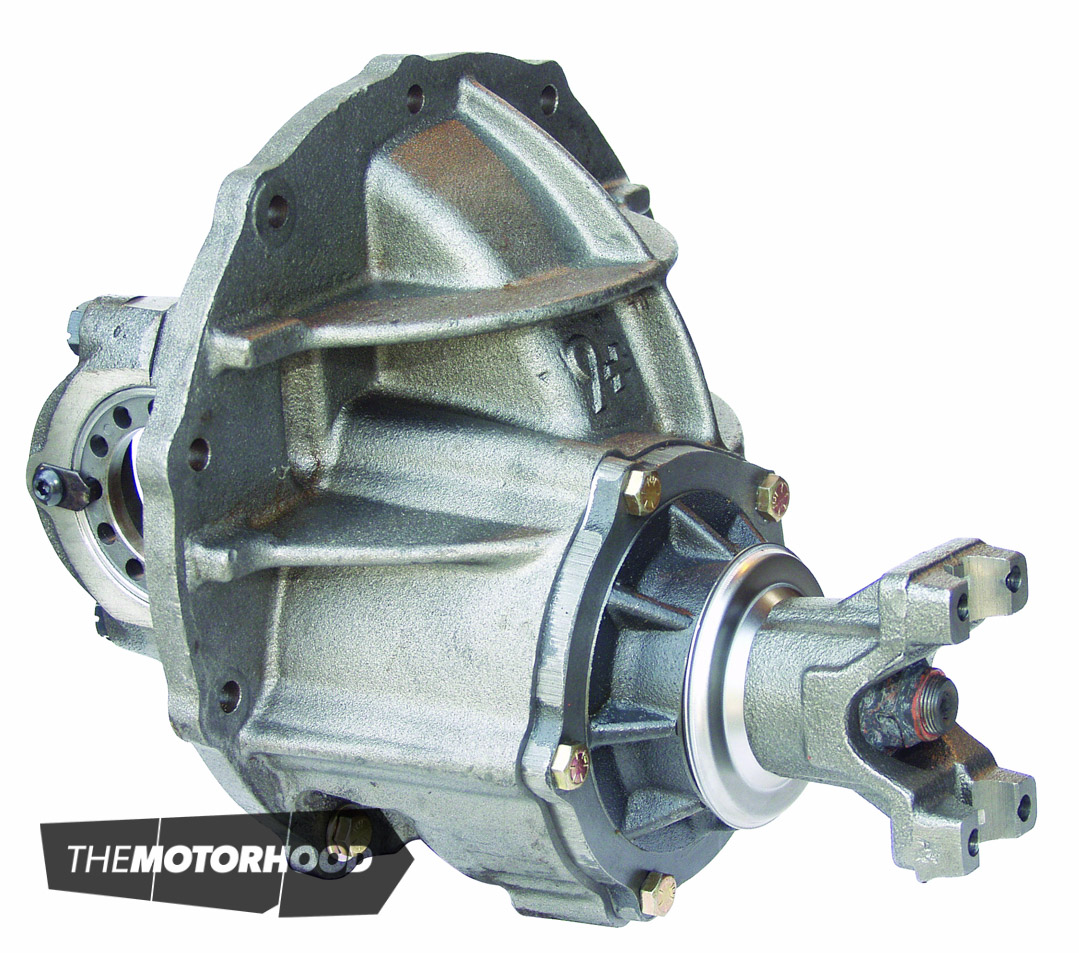

If you’re after a tough diff for your Chev, and find the idea of fitting a Ford nine-inch blasphemous, then it’s hard to go past a 12-bolt. GM 12-bolt diffs were available in limited-slip, Positraction, and open formats, but open diffs can also be easily adapted to Positraction with the wide range of aftermarket parts now available.

While GM Positraction rear ends have been produced since 1957, the 12-bolt (8.87-inch) Positraction was most often used in 1965–1972 passenger cars. A 12-bolt from a Chev pickup is not interchangeable with a 12-bolt car item, the former being identifiable by its smaller 1.43-inch-diameter pinion shaft and the size of the rear cover. The truck covers are larger and more irregularly shaped, measuring 107⁄8-inches square. The pinion shaft on passenger-car variants is 15⁄8 inches in diameter and the cover is oval, measuring 10–15/16 inches wide by 105⁄8 inches tall.

Three different types of 12-bolt Positraction carriers are available, each designed to be adaptable to a range of ring-and-pinion gear combinations, better known as ‘carriers’. Interchanging between them is possible, but at a cost.

The most common 12-bolt is a type two. These were found mainly in standard-performance Chev passenger cars and had ratios ranging from 2.29:1 to 2.73:1.

Larger ratios will not fit without the carrier being changed, as, despite a larger ring gear being able to bolt on to the type-two carriers, you will not be able to obtain the proper spacing. A type-three carrier is thicker, and designed for use with ratios ranging from 2.76:1 up to 3.73:1. Type-four carriers are the thickest, and available in several ratios ranging from 3.73:1 to 4.88:1

Twelve-bolts tend to have information stamped on their housings, including the casting date on the rear left of the centre housing. The date is indicated by a letter representing the month of production, followed by three numbers indicating the day and the last digit of the year produced, so, for example, ‘C158’ means March 15, 1968. A number on the right-hand axle tube includes the ratio, where the unit was assembled, and whether the carrier is Positraction.

All 12-bolt Positractions use 30-spline axles with a C-clip to hold them in place. When looking at running high horsepower, it’s advisable to change the C-clip for a C-clip eliminator kit, to ensure that, if an axle breaks, it doesn’t simply slide out.

When buying a 12-bolt, pay attention to the spring mounts, as full-size Chev cars, such as Impalas, have coil springs and four trailing arms along with a Panhard bar, while Chevelles have four trailing arms but in a different configuration, and Camaros and Novas run leaf springs. Widths include 60 inches, 61 inches, 62 inches, and 62.4 inches.

Expert’s Opinion

Lee from Diffs R Us says: “Every New Zealand–new Impala had a 12-bolt, but the overseas cars didn’t. The only cars that got them were station wagons and high-performance cars, such as those fitted with big blocks. Lots of Kiwis assume that every Impala made got a 12-bolt, but it didn’t.”

Holden [large] Salisbury

Most older Holden fans will know the name Salisbury. The Salisbury diff is sometimes referred to as a 10-bolt because it has 10 bolts holding the crown wheel and there are 10 bolts holding the cover on. However, despite the similar name, there are absolutely no interchangeable parts between these and American GM 10-bolt diffs.

The Salisbury came out in all V8-powered HQ-WB Holdens, HQ-WB one-tonners (six cylinder and V8), and V8-powered VB-VK Commodores, and was optional in non-V8 VB-VHs. Both open and limited-slip variants were produced, both with 28-spline axles.

The first generation, as found in the HQ range, used a larger front yoke with 1.125-inch universal joint, while all the others used a one-inch item.

All Salisburys have a cast centre, but, in HQ-WB utes, the ears to which the coil-sprung vehicle’s upper trailing arms mount are not machined. Holden one-tonner diffs also had heavier-duty axles and wider bearing retainers on the axles, so if you find one, consider yourself lucky.

Salisburys were available in a range of ratios, including 2.60:1, 2.78:1, 3.08:1, 3.36:1, 3.55:1, and 4.44:1. The 2.60:1 and 2.78:1 gear sets use a slightly different carrier from the other ratios, so 3.08:1 and up cannot be swapped into the 2.XX:1 centres.

The Salisbury’s two-pinion spider gear arrangement is its weak point, and it is prone to breaking in higher horsepower applications. Unfortunately, as these are Australian only, the aftermarket parts are restricted, but there are still options to strengthen them over standard.

While the factory LSD can be rebuilt, if strength is the order of the day, something a little tougher will be needed. Due to the higher price for parts, if you’re looking at upgrading your Salisbury, you may be best to look at changing to a nine-inch or similar.

Expert’s Opinion

Lee from Diffs R Us says: “They’ve got a bad reputation, from the days when they were cheap and people would buy an HQ, go out and skid it, break the diff, replace it with something equally flogged, and do it all again. They’re actually not bad, though; it’s just that they were all worn out to start with. I know guys [who] have paid $1K for one, as they’re getting harder to find. The Aussies do make brand-new four-spider limited-slips for them, which seem to work well.”

BorgWarner (Commodore)

The BorgWarner BW78 is better known as a VN–VS or VL turbo diff, and was called ‘BTR 78’ by Holden. Three sizes are available: the VL turbo at 1400mm, R31 Skyline at 1410mm, and the 1440mm VN-onwards item, which is the most common these days.

The 25-spline two-spider versions of the BorgWarner that came out in later VK (aka VK½) Commodores, most VLs, and a mix of Valiants and Fords, run 25-spline axles and are known to be weak.

All R31 Nissan Skyline and VN–VS Commodore versions came with a four-spider 28-spline set-up, making them a more popular option. Crown wheels and pinions are interchangeable between both, which gives a wide range of ratios, including 2.77:1, 2.92:1, 3.08:1 (standard on VN-VS), 3.23:1, 3.45:1, 3.7:1, 3.89:1, and 3.91:1.

While some came with a cone-type LSD, similar to the Salisbury, these are not known for their strength. The cast-steel pinion housing also adds to this, as they can easily have mounts welded to them for fitment into different vehicles.

One thing to note is that, while the VK ½ BorgWarner is the same width as the VL version, it has a different centre offset, so these are not suitable as a direct replacement for one another.

Expert’s Opinion

Lee from Diffs R Us says “Even the 28-spline versions still run a cone-type LSD. Harrop’s website says it offers an Eaton Truetrac for these; if it does, that’d be the way to go. Basically, if you can buy a genuine Eaton Truetrac for any diff, you’d be foolish not to. We’ve seen some really bad Truetrac-style diffs, though, so make sure you buy only the genuine thing stamped with the Eaton trademark.”

Hilux

While not often used in American cars or hot rods, the Toyota Hilux/Hiace diff is a very strong and well-priced option. Often referred to as ‘Japanese nine-inches’, these diffs are known to be remarkably strong and offer a wide range of widths and ratios.

As one of these diffs has no external markings, ideally, you’d want to see an ID plate on the vehicle’s engine bay to see the ratio and head option of the diff without having to open it up. The ratios range from 3.30:1 to 7.63:1, with 40 ratios in between those figures.

Diffs with ratios 4.87:1 and above have a slightly different crown-wheel position on the centre. So, if ratios below 4.87:1 are to be fitted, select a diff with a ratio below 4.87:1 or vice versa if shorter ratios are to be used.

Four different centre combos were produced: two-pinion open, two-pinion limited-slip, four-pinion open, and four-pinion limited-slip, but due to their popularity in the off-road market, plenty of aftermarket options are available. Those sourced from 4WD vehicles will have six-stud axles, while those from a 2WD vehicle will have 5×114.3 (Ford) PCD axles, allowing for a wide range of wheels to fit. The 2WD-sourced diffs will be fitted with leaf-spring brackets, while 4WD variants are more likely to have coil-spring mounts.

The drum brakes fitted to both options are generally considered to be of high quality, although the design allows for an easy change to discs if preferred. If you’re looking at fitting a different PCD wheel, then a 4WD diff may be best, as it is possible to re-drill the hubs without needing to weld up the old holes. However, 4WD versions are likely to come with lower ratios, which are not suitable for many vehicles.

Widths include 53.4 inches, 55 inches, 58.5 inches, and 60 inches.

Expert’s Opinion

Lee from Diffs R Us says: “Lots of people have tried to use these but have trouble with the ratios, as they’re all wrong. They’re a good, strong diff, and there are plenty of combinations out there, but, for guys running V8s, the ratios just aren’t right. V8s want to run in the threes; the best I’ve ever seen in a Hilux is 3:45, but there are very few around. So, it can be best just not to go there.”

What does it mean?

Positraction

‘Positraction’ is simply Chevrolet’s factory name for the type of clutch-style LSD it offered for many years. This type of LSD has all the same components as an open diff, but it adds a spring pack and set of clutches. The spring pack pushes the side gears against the clutches, which are attached to the cage. Both side gears spin with the cage when both wheels are moving at the same speed, and the clutches aren’t really needed — the only time the clutches step in is when something happens to make one wheel spin faster than the other. The clutches fight this, wanting both wheels to go at the same speed. If one wheel wants to spin faster than the other, it must first overpower the clutch. The stiffness of the springs, combined with the friction of the clutch, determines how much torque it takes to overpower it.

Spool

A full spool is illegal on the road but great for drag racing, as it replaces the spider gears and internals with a straight carrier into which your axles slide. Simply put, a ‘spool’ locks both wheels together, which doesn’t help at all with cornering, since the inside and outside wheels travel different distances, and the only way for them to match speed is by one tyre chirping/skipping.

Calculating Ratios

If you’re looking at a diff but are unsure what the ratio is, it’s not hard to work it out. Simply mark one tooth on the crown wheel then count how many teeth there are. Do the same on the pinion, and you’ll end up with the two numbers you need. If you’ve got 41 on your crown wheel, and 10 on your pinion, for instance, you need to divide 41 by 10, giving you a ratio of 4.1:1. Count carefully, as one tooth can make a big difference!

PCD [pitch circle diameter]

Vehicle manufacturers use different stud or bolt-hole patterns for the fitment of their wheels. It’s worth keeping this in mind when replacing a diff, unless you want to go changing wheels or re-drilling axles. ‘PCD fitment’ is a measurement showing, first, the number of studs / bolt holes and, second, the distance that they these are spaced out. Common ones for our market are 5×120 (Commodore), 5×114.3 (Falcon), and 5×5, which refers to five inches, for some American vehicles.

The PCD on a four-stud hub is simply a straight line from the centre of one stud, through the centre of the hub, and on to the centre of the stud opposite. Put simply, a 4×110 PCD would be four bolt holes / studs evenly spaced around an imaginary 110mm circle.

The principle is the same with five-stud wheels: a 5×120 PCD would be five evenly spaced studs/holes around a 120mm circle — although it’s a bit harder to measure, because there’ll be no stud or hole directly opposite the stud from which you are measuring. Instead, a straight line must be drawn from the centre of the first stud, through the centre of the hub, and on to the edge of the imaginary circle between the near-opposite two studs.

New or Old?

When you consider that most factory nine-inch diffs are now 40-plus years old and come with a history of heavy loading, modification, and abuse, buying new can make sense. As Tim from The Krysler Shop says: “To revamp a Ford housing, you need to remove the existing brackets, garnet blast the exterior, steam clean inside, and visually check that it’s not a banana before you can start the narrowing process; that all adds up in labour and consumables. Why go through all that, when, for a modest price, you can purchase a new aftermarket housing that is stronger in design and needs no prep?”

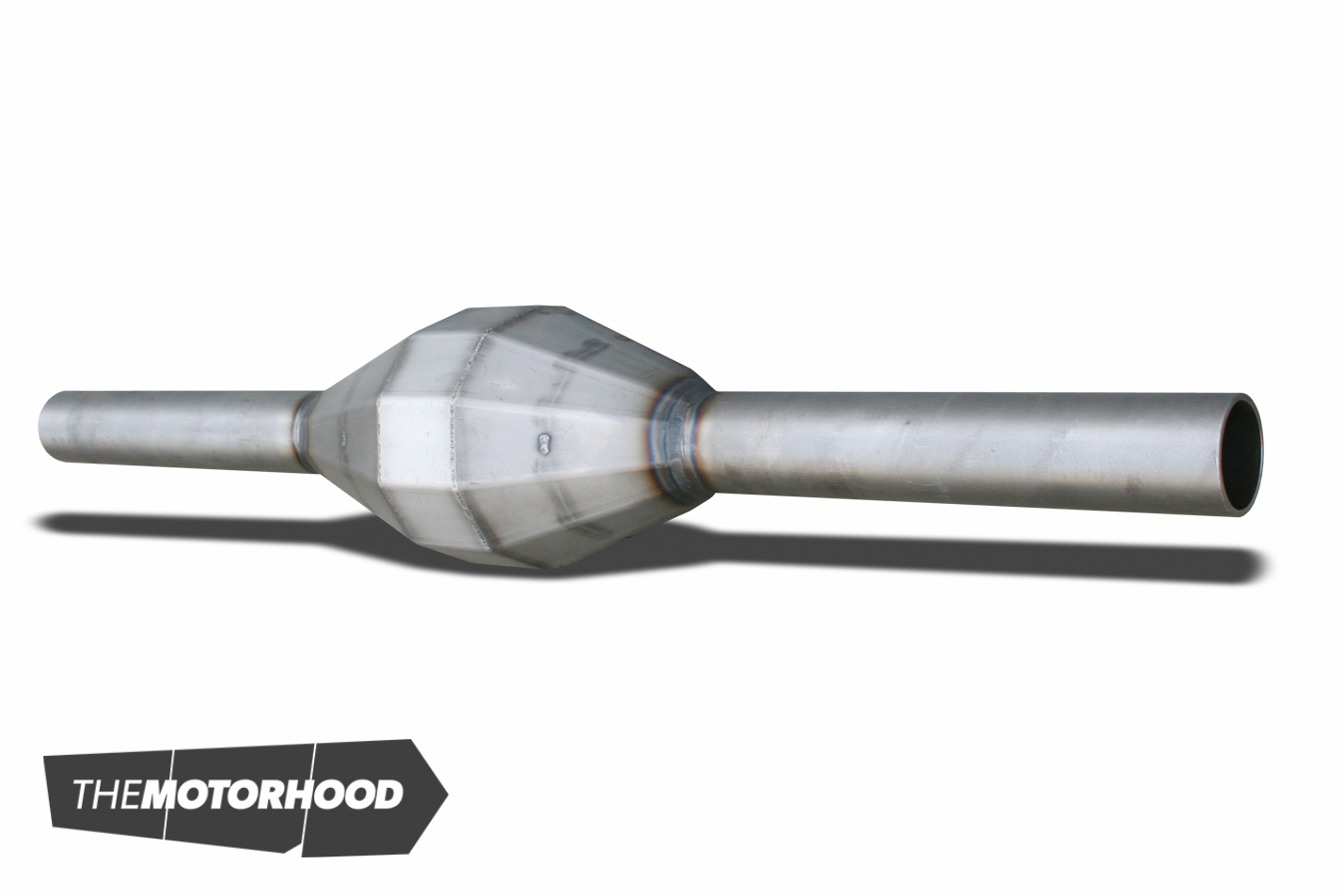

Most new street and strip housings come with not only a new housing centre but also three-inch axle tubes and late-model large bearing housing ends, making them strong from the get go. Companies such as Currie Enterprises and Moser Engineering manufacture various housing styles, such as traditional hot rod, heavy duty, and fabricated.

Tim says: “These have come a long way in recent years and are just like buying a factory nine-inch conversion. We offer our own crate-style rears for Australian-built vehicles. These include CAD laser-cut and TIG-welded bracketry, ready for people to bolt in.”

With the new housing coming solely with large bearing ends, you get a larger journal on the axle (as opposed to Mustang small bearing ends) and a choice of 28-, 31-, or 35-spline set-ups. Wheel stud pattern can be drilled to GM, Ford, or custom, and in whatever stud diameter you prefer. Tim recommends going to at least a half-inch stud, pointing out that the 7⁄16-inch GM stud becomes the weak point in any nine-inch conversion. He goes on to say: “I like the Strange two-inch or three-inch screw-in studs, where the axle flange is drilled and tapped rather than a pressed stud used. Over 800hp, move up to the Strange 5⁄8-inch stud kit.”

When asked about brakes, Tim points out, “There is a good choice of brake kits available that are built to the Aftermarket Brake Configuration Standard (ABCS). These are direct bolt-on to the late-model large bearing housing end with a 2.5-inch brake offset (distance from housing-end flange to axle flange). The advantage of the bolt-on kits is that there is no fabrication time setting up rotors and caliper brackets, so you can put your money into the brakes rather than into additional labour.”

On the subject of diff heads, Tim echoes Lee’s advice to buy only genuine brand parts. He has a wide range of options available, depending on different horsepower levels and applications. You can find out more by contacting The Krysler Shop on 021 059 4701 or visiting thekryslershop.co.nz

Thanks: Big thanks to Lee Mariner at Diffs R Us for his help with this article. Diffs R Us can be reached on 09 270 0855 or at 4 Kaka Street, Otahuhu, Auckland

This article was originally published in NZV8 Issue No. 112. You can pick up a print copy or a digital copy of the magazine below: