data-animation-override>

“Drifting puts unique strains on all your driveline components, and none more so than your gearbox. Tech guru Andre Simon from High Performance Academy explains why a dog engagement gearbox is the strong solution if you’re sick of blowing gearboxes ”

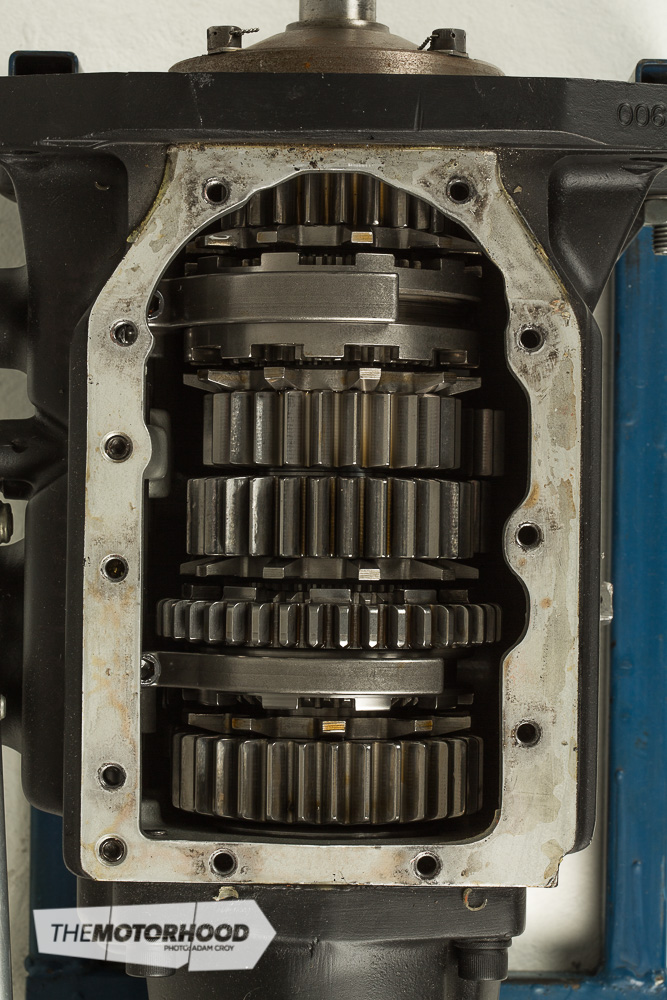

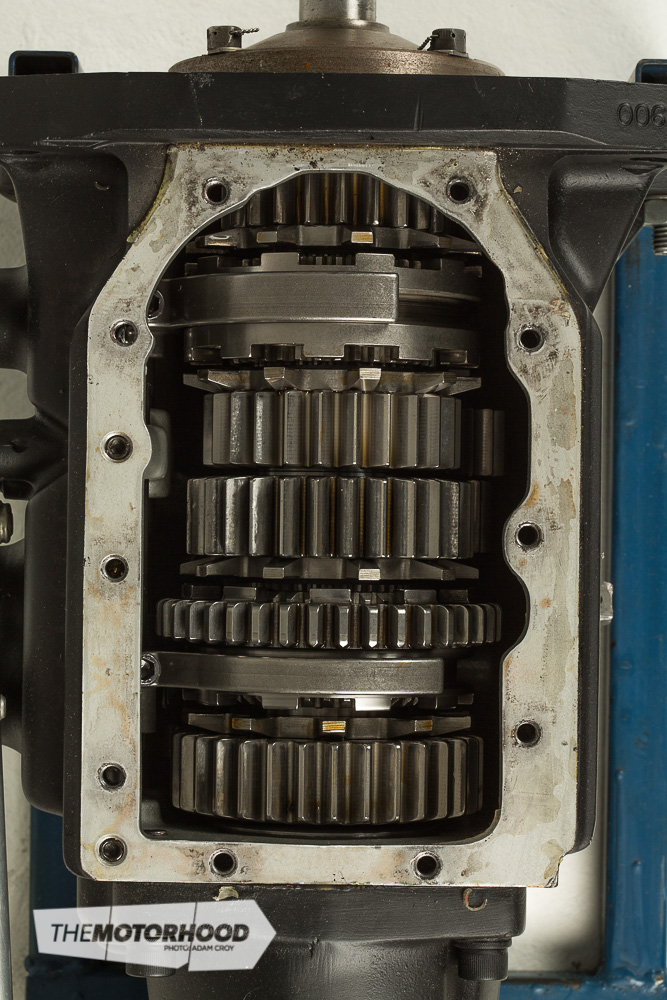

If you follow any form of professional motor racing, you will most likely have heard the term ‘dog engagement gearbox’, which refers to how the gears inside the gearbox are selected by the driver. When we change gears, the relative speed of the shafts inside the gearbox must be matched to allow the selector to engage the next gear. In a road car gearbox this is done via a synchromesh system that relies on friction of a synchro ring to match the shaft speeds to allow the next gear to engage.

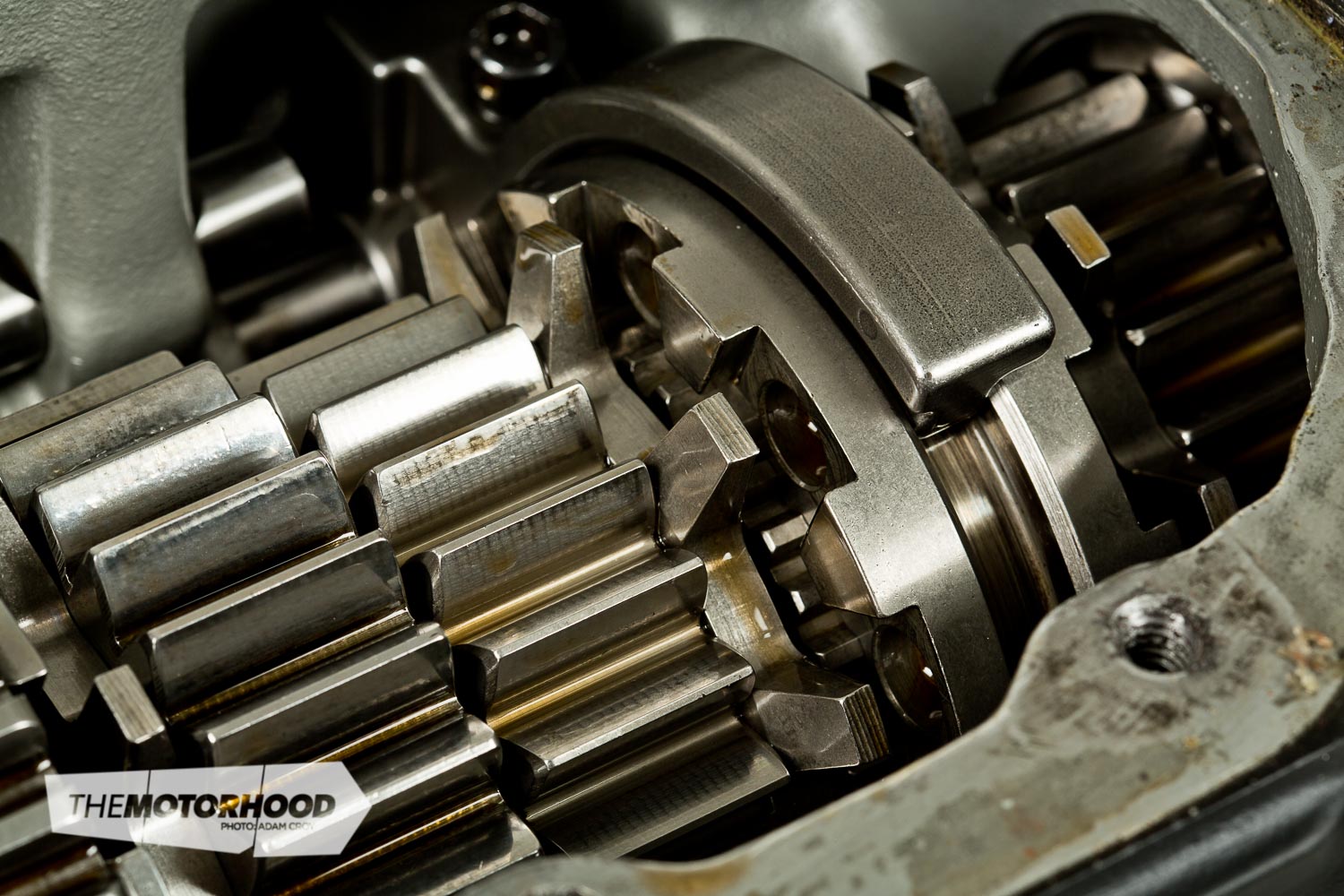

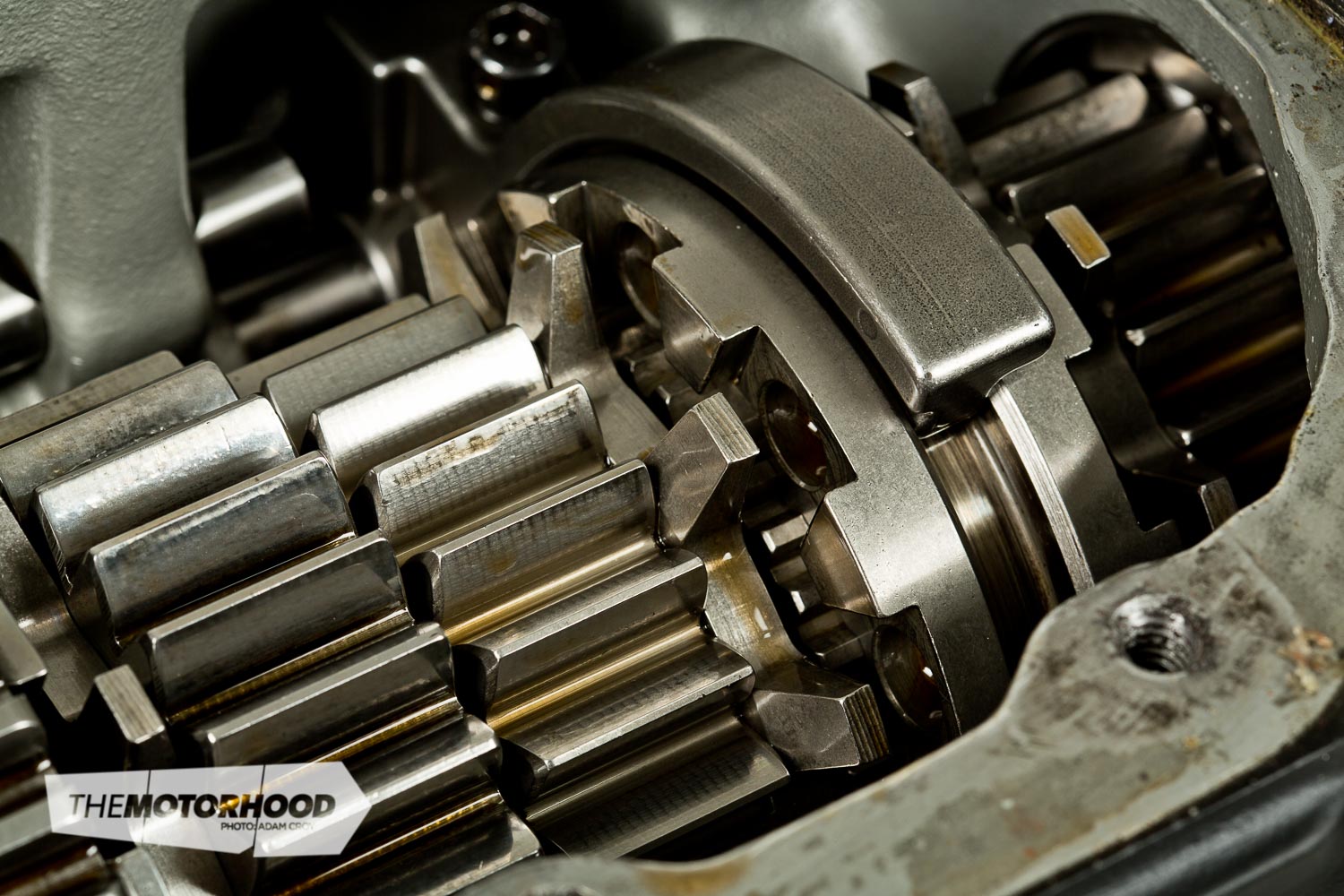

The synchromesh gearbox is smooth, easy to drive and quiet, which makes it ideal for road cars, but in drifting use the shift speed is slow (forcing shifts quickly results in worn synchros), and synchromesh boxes don’t work well at very high engine rpm. The solution is dog engagement. In this sort of gearbox each gear has a set of ‘drive dogs’ which protrude from the side of the gear. The selector that slides between gears to select the gear that we want is called a dog ring, and has matching ‘dogs’ on both sides. When the driver wants to change gear, the dog ring moves across, and the two sets of dogs engage. The drive dogs have a slight back cut or taper on them which means once they are engaged, the torque of the engine prevents them disengaging.

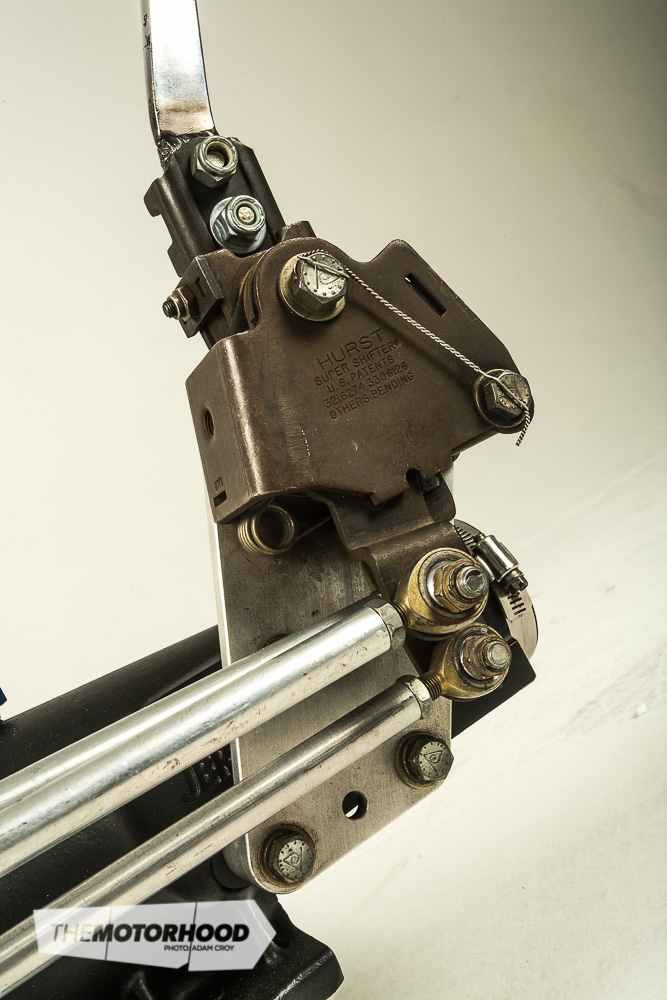

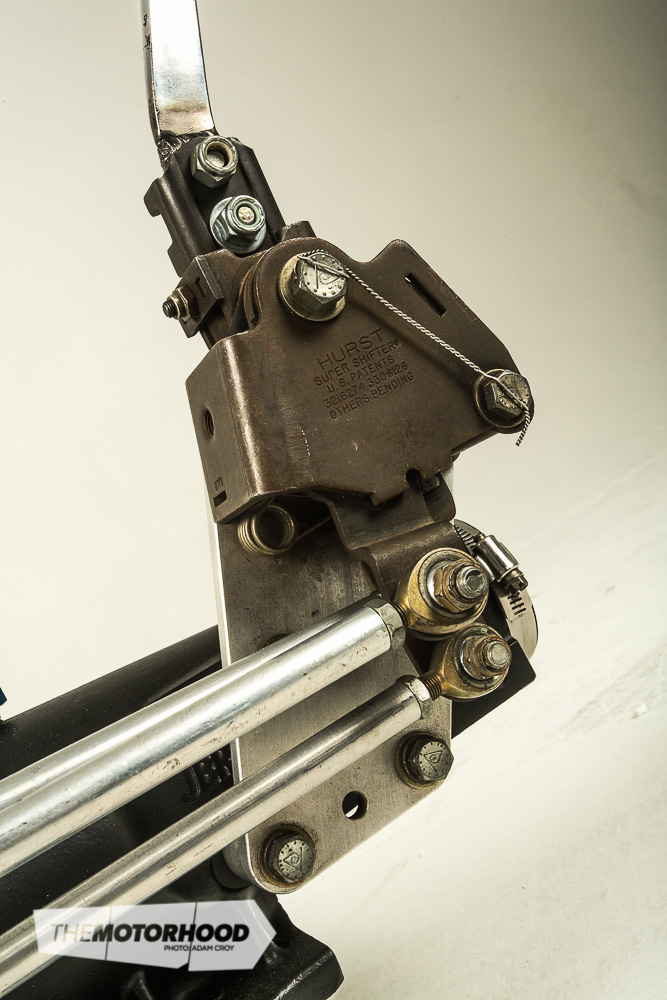

Dog engagement gearboxes offer several advantages for race use. Firstly the gear changes are significantly faster than a conventional gearbox, and it’s possible to shift without using the clutch — all that is needed is a slight interruption to the engine torque to allow the dogs to disengage. This torque reduction can come from the driver lifting off the throttle slightly, but many ECUs now provide a gear-change ignition cut to help speed the shift. This function cuts the ignition when the driver wants to change gear, allowing shifting at full throttle. In drift use that can allow the driver to change gears mid corner, or even mid drift, without upsetting the car’s balance.

So what about gearbox strength? Well there are a couple of reasons why dog boxes win here. When people think of gearbox failures, broken gears or stripped teeth will usually spring to mind, however, synchro and selector problems are also common with synchromesh boxes, and nobody likes a box that won’t change gear. Next we have gear strength. While a factory box is built with stock engine power in mind, dog boxes are purpose designed for competition use, and the gears are understandably bigger, stronger, and made of superior material.

The downside of a dog box is that it is noisy, with each shift accompanied by a solid ‘clunk’. They also must be shifted aggressively or excessive wear on the drive dogs will result. This makes them generally unsuitable for road-car use.

This article was originally published in NZ Performance Car Issue No. 227. You can pick up a print copy or a digital copy of the magazine below: