data-animation-override>

“Is this amazing ’39 Ford New Zealand’s most beautiful car? We think it might just be”

“I’m not really a hot rodder,” wasn’t what I expected to come from the mouth of the owner of what is undoubtedly one of the most modified vehicles to ever grace these pages.

“I knew the guy who owned it, and the guy who worked on it, and knew that their workmanship was top class. Unfortunately the owner needed to sell the car to free up some cash for a property deal. I thought the car was beautiful, so made him an offer,” Peter goes on to say.

Sure, he may not be a hot rodder — or might not have been until now — but he’s certainly got good taste in cars, and can often be found behind the wheel of one seriously quick Formula 5000, or taking in the countryside on a classic motorbike. With fast toys like these, the ’39 was the perfect addition to the collection, allowing him to enjoy things at a bit of a slower pace.

The story of how the car came to be is a long one. Previous owner Tony Ryan owned the car for close to 25 years. However, its history as a hot rod goes back before then, as the roof had already been chopped before he bought the car for just $6500 in 1986.

Tony’s first build, he’ll openly admit, wasn’t his finest hour, and involved adding a three-inch skirt to the bottom of the body. The effect of the low roofline and tall body sides just didn’t do the swoopy-looking machine any justice. Come the early ‘90s, and he set about rectifying that.

Colin Jacka of Steel’s Real Restoration was selected for the job of transforming the car into what it should have always been. With Steel’s Real Restoration specializing in European vehicles, and Tony also being a Euro fan, inspiration was taken from the likes of Bugattis and Delahayes. Flowing curves, long extended guards, smooth lines, and intricate details were the order of the day, and that’s exactly what the car received. A mind-numbing amount of work went into the build. To fully appreciate just how different the car is, you’d really need to see it parked next to a stock one.

The bonnet alone is a work of art, created by taking a 1940 Mercury hood with the stock ‘39 Ford sides and extending the lot by six inches. Once the two were seamlessly stitched together, an impressive 222 louvres were pressed in to give it the full custom look.

Below the new bonnet now sits a custom grille, with equally impressive construction. Made up from 50 separate pieces, the grille blends the angular front end of the car into the customized guards flawlessly. That seamless blend of what’s original and what’s not is what confuses passers-by about what the vehicle really was to begin with.

The front guards alone consumed hundreds of hours, and are unrecognizable as ’39 Ford items thanks to being extended both front and rear as well as having the wheel openings re-radiused. From the factory, the guards ended before the door opening, so more than a foot and a half of extra length has been added. Making the most of the space provided by the guards, the battery is now hidden behind the passenger side, and can be accessed through the door jamb when required.

With the suicide doors open, you can see just how thick the cavity is. Keen eyes will also notice the step up into the body, which not only illustrates where the doors have been extended lengthways, but also just how far the body has been channelled over the chassis. A full five inches is the answer, but before this could take place the chassis itself was also the recipient of Colin’s attention.

The rear has been C-notched to allow the car to sit closer to the tarmac, while the rest of the chassis has been boxed and strengthened, both in preparation for some power and to ensure that the time-consuming bodywork isn’t damaged by any twisting.

As if the five inches taken from the floor height wasn’t enough, the already chopped roof was re-chopped and the screen laid back. Luckily, being a soft top, the screen and pillars were all that was required to bring the height down. Matching this is a newly constructed, non-retractable soft top, which features far more clever construction than it may first appear. Although it’s not a big job to remove the top, the feeling is unanimous that the car looks better with it on.

This discovery led Colin to rolling a pop-riveted stainless steel roof lining up and attaching it to the welded up frame. With it being bare unpainted stainless, it’s easy to see how much work has gone into this one aspect alone.

The rear guards have been extended as per the fronts and the wheel openings modified into a teardrop shape to suit. Thankfully the plan was to move the fuel filler to the trunk anyway, as it soon made way for the custom spats that were painstakingly created. With the long guards adding shape to the usually flat rear end of the vehicle, the bootlid soon looked out of place thanks to its lack of curves and detail.

The solution to this was to add a ridge up the centre, which extends to the rear panel. While working on the rear, the bumper mounts were removed and a number plate recess added. The tail lights you now see fitted are from a ’41 Studebaker, but have had the bezels extended before being mounted.

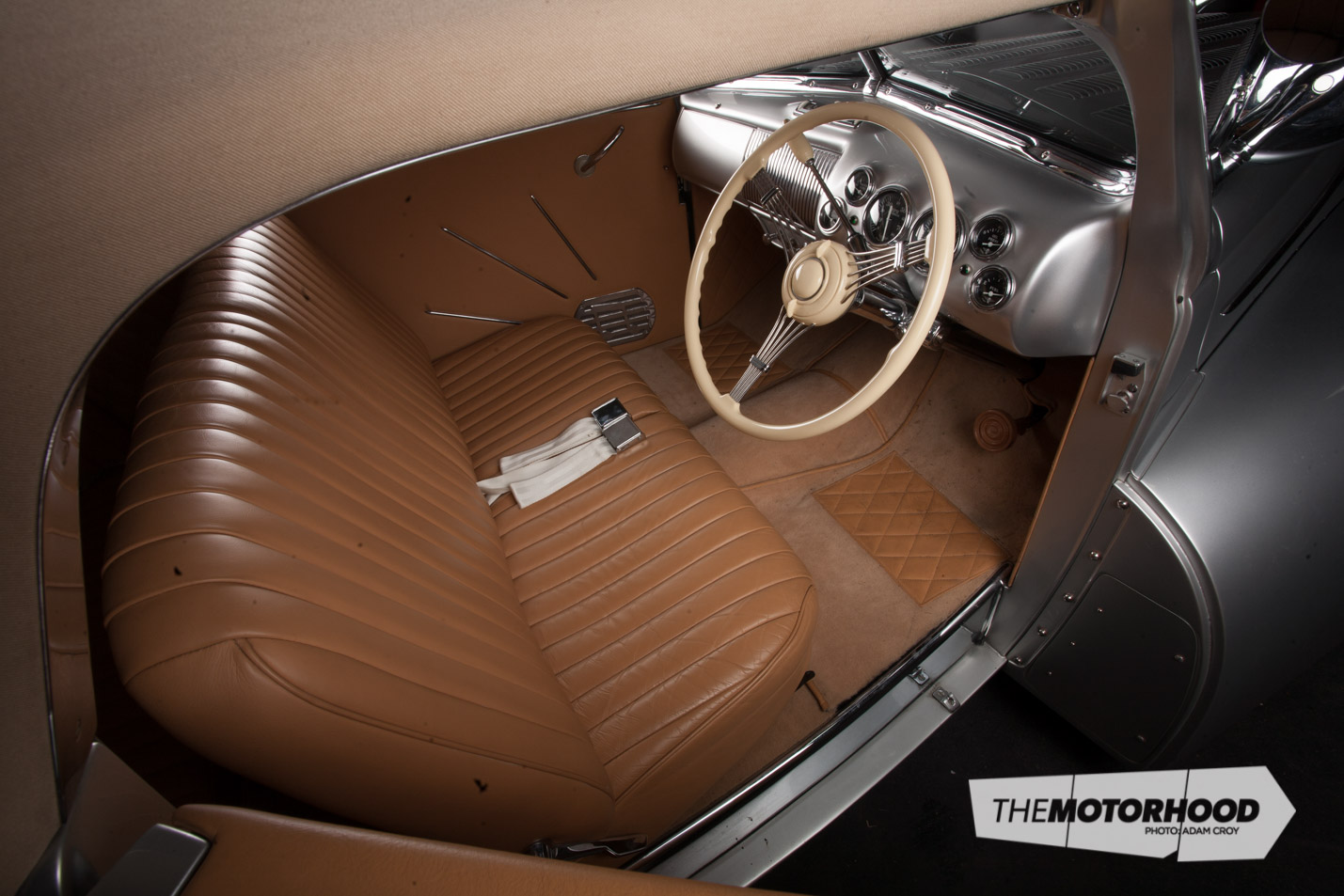

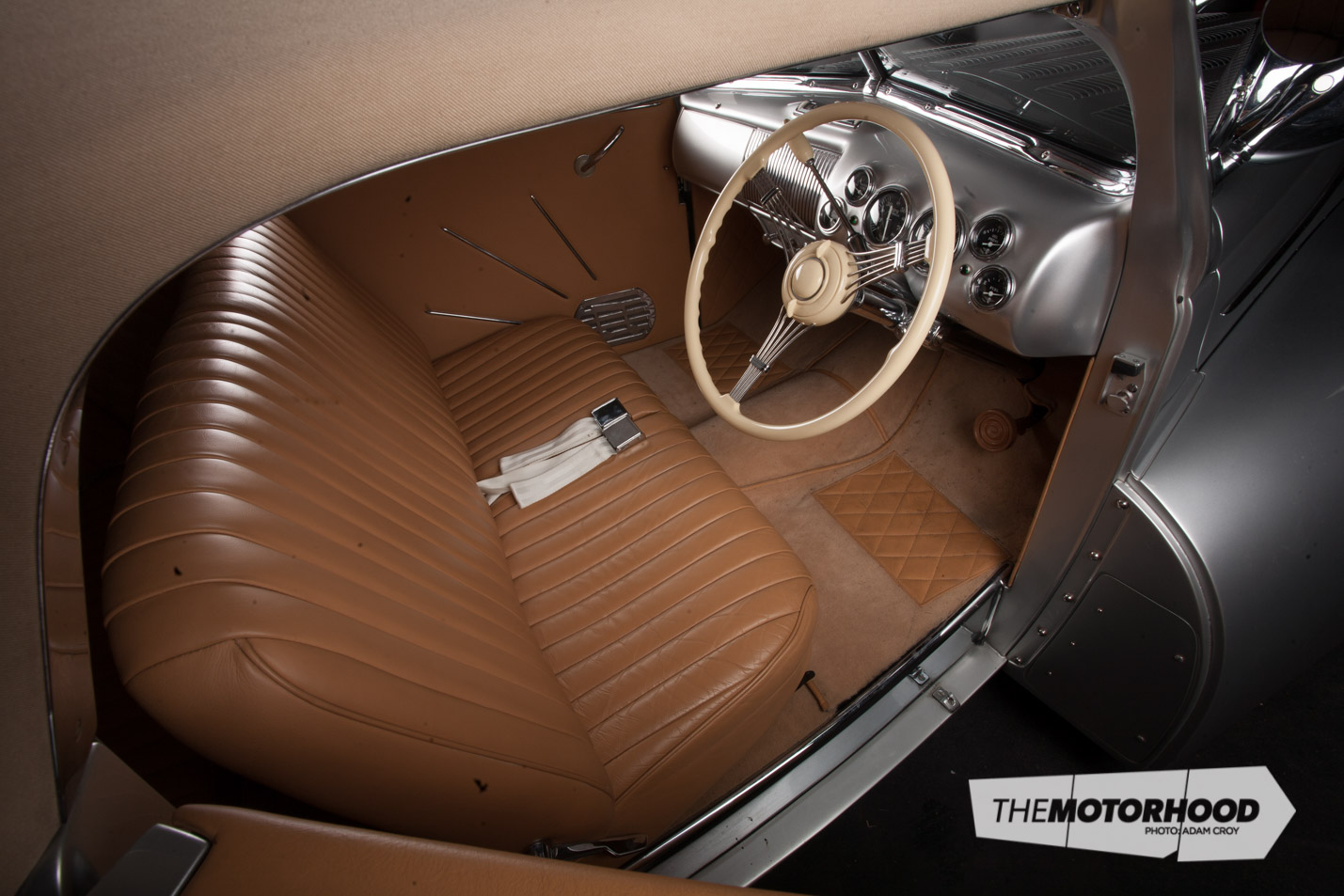

The attention to detail and perfect panel gaps took the labour on the exterior alone into the thousands of hours, and the more you look, the more you see the effort involved. This flows on to the interior, where a Triumph 2000 seat was cut down to fit the front, and a rear seat was made from scratch. The combination of Connelly leather and matching carpets compliments the custom silver exterior finish perfectly.

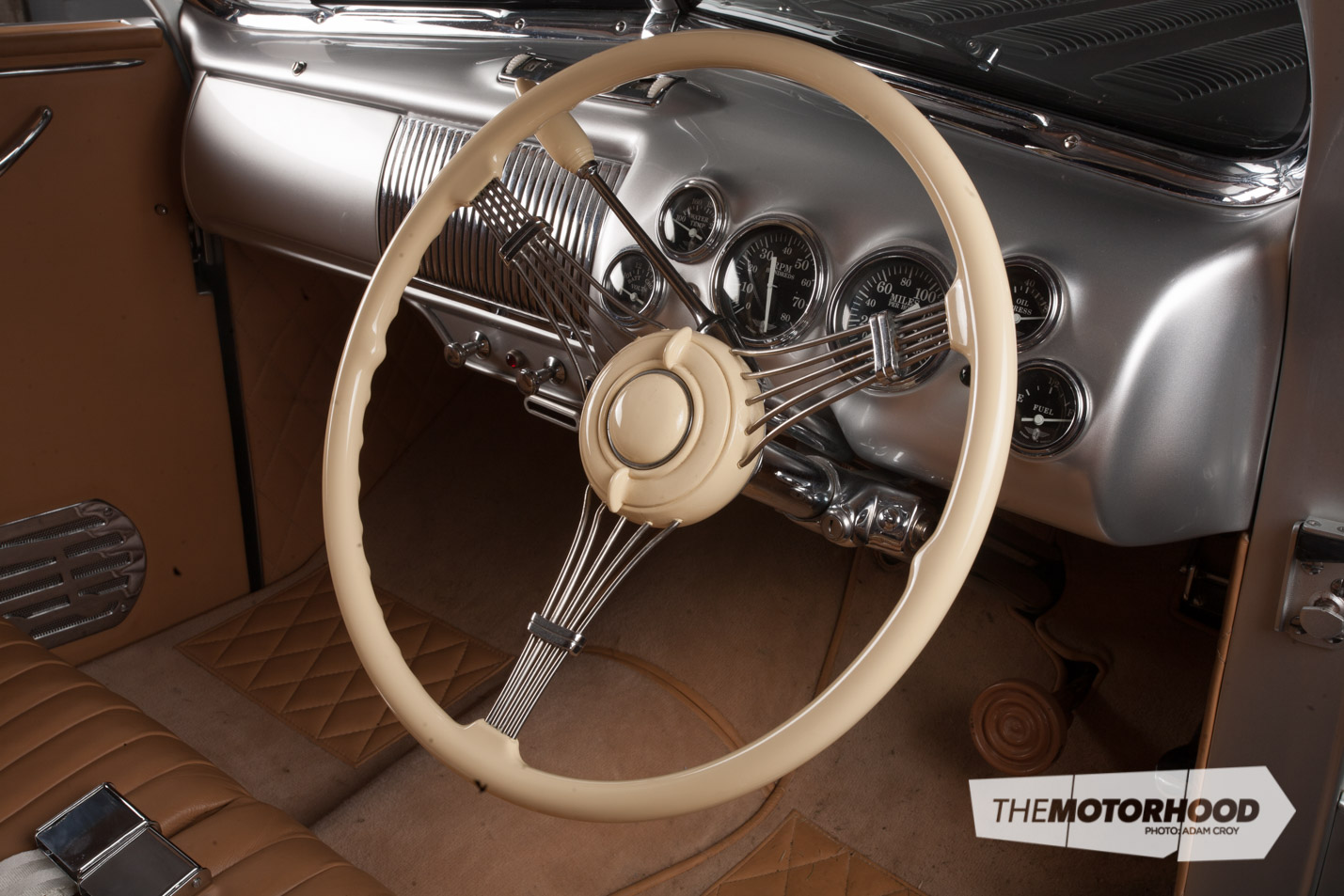

A custom dashboard was handcrafted, and Tony chose to adorn it with Smiths instruments, although to be suited perfectly to his taste he had a watchmaker recreate the dial faces. All switches have been moved off the dash, including the indicator switch, which now hides just out of sight but within easy reach. Despite the small area behind the dash, a heater has been fitted. It may seem odd for a car with no side glass, but Tony’s plan was always to drive the car, and he did, including trips of around 350km from his home in Melbourne to events up the coast.

The understated exterior colour was chosen specifically not to stand out too much, and instead let the workmanship and lines of the body speak for themselves. This is also the reason why it was painted in acrylic, using old spray gear, rather than the latest and greatest methods and materials.

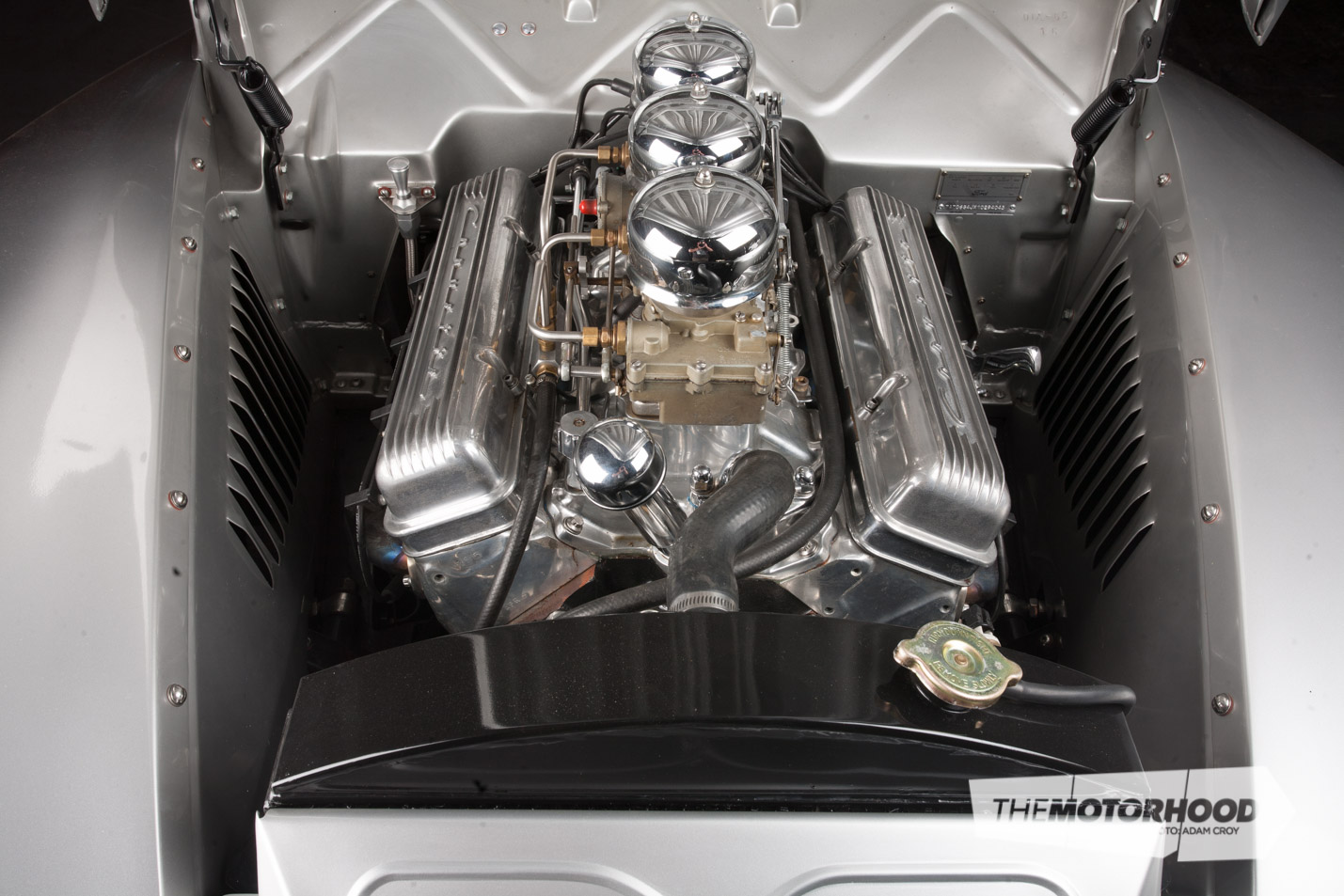

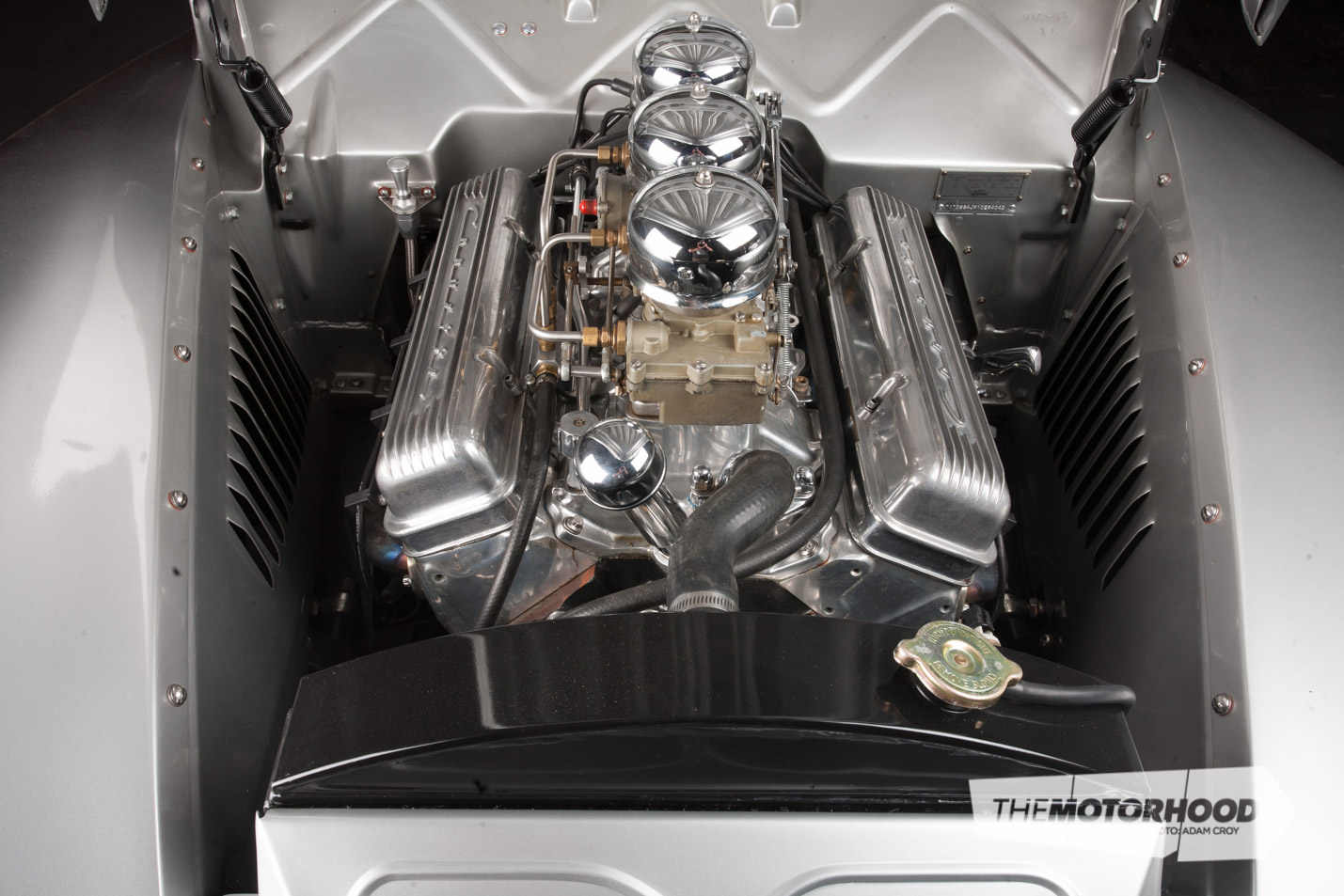

Although it was no doubt tempting to use an angry motor in the car, instead Tony choose to keep the small block Chev crate motor that was in the car when he purchased it. It did, however, receive a freshen up and the all-important triple carb setup and Edelbrock manifold. With a TH350 transmission backing it up, the car drives really nicely, a fact that’s helped by the coilover suspension out back and custom A-arms up the front. There are also Wilwood disc brakes hiding behind the 15-inch rims and Sombrero hubcaps, for a bit of added confidence when driving.

Since its new owner Peter brought it into New Zealand, it’s seen fewer miles than the owner anticipated, with a busy race season and business commitments both getting in the way of taking the car out. Once business is back to usual and race season is finished, keep your eyes out for the car, as hands down it’s one of the most elegant you’ll ever get the chance to lay your eyes on.

1939 Ford

- Engine: 350ci small block Chev, crate motor, triple Stromberg carburettors, Edelbrock manifold, Cherrybomb mufflers

- Driveline: GM TH350 transmission, Ford nine-inch diff

- Suspension: Custom front A-arms, four-link rear, coilovers

- Brakes: Wilwood discs and calipers

- Chassis: Boxed chassis, rear C-notch

- Exterior: Four-inch roof chop, five-inch channel, lengthened Mercury / Ford hybrid hood, lengthened and re-radiused guards, de-bumpered, shaved, custom wheel spats, customized 1941 Studebaker tail-lights, customized bootlid, custom soft top, custom grille, suicide doors

- Interior: Custom dash, Smiths gauges, hidden audio, modified Triumph seats, Connelly leather, hidden switches

- Performance: Stunning!

This article was originally published in NZV8 Issue No. 72. You can pick up a print copy or a digital copy of the magazine below: