data-animation-override>

“This Capri may have run nine-second passes way back in the late ’90s, but it never looked as good as this!”

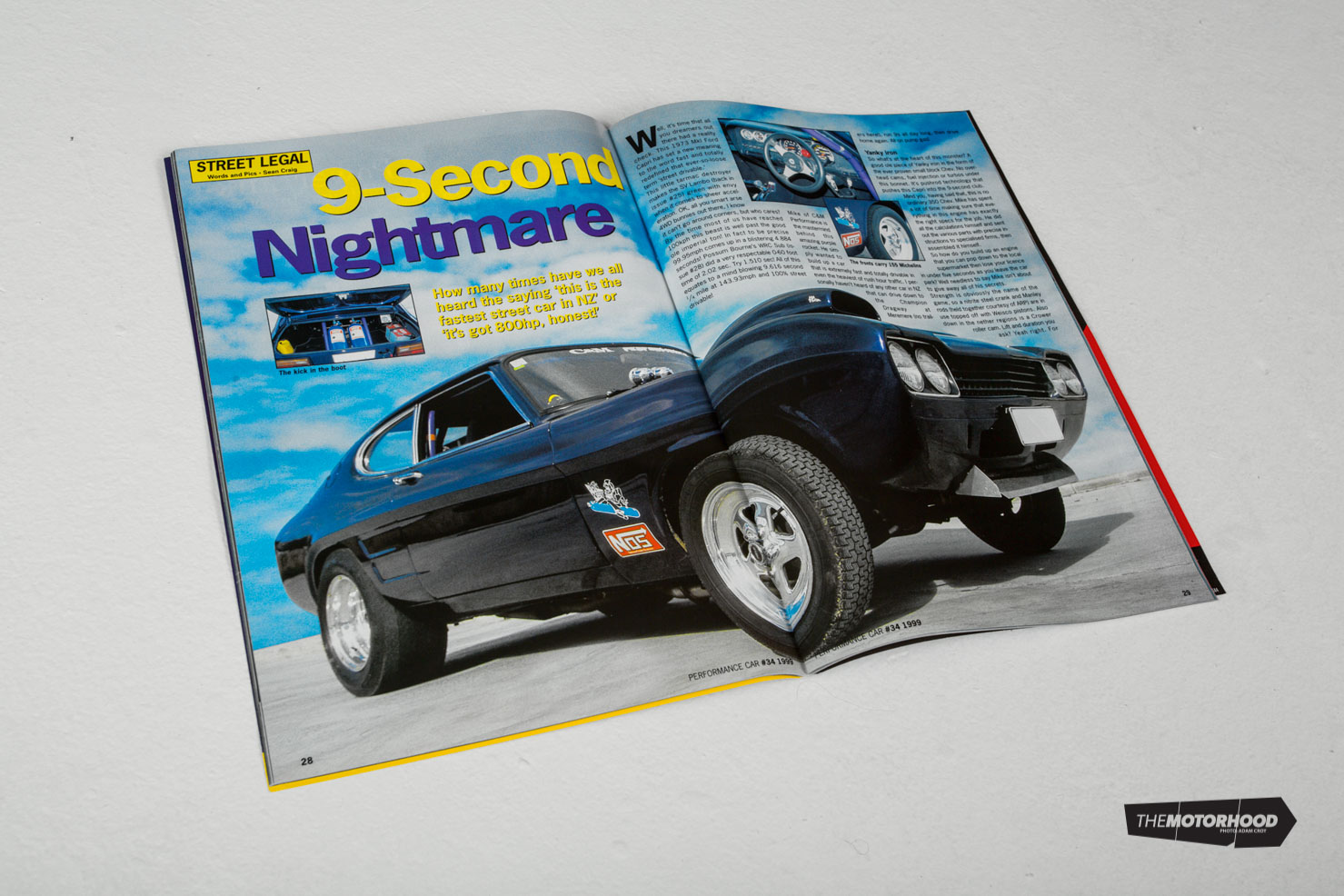

Back in the mid to late 1990s, if you were involved in the drag racing scene then chances are you would have seen, or at the least heard of, Mike Bari’s Capri. The nitrous-fed small block–powered Pommy machine was painted purple right in the midst of the early Pro Street movement. Being able to drive to the track, run mid nines, and drive home, the car was at the seriously pointy end of the street cars in this country. In fact, even today, if that same car were to run the same times, it’d still get plenty of attention.

But what if that same car could now run even quicker and looked a whole lot better? Then it’d surely be one of the top street machines in the country, right? Whangarei’s Peter Morrison was around the street and drag scene back in those days, and knew of the car, but it wasn’t until seven years ago that he decided to build a Capri of his own.

Our sister magazine NZ Performance Car actually featured the Capri way back in September 1999, which was just a few months before Mike sold it. Back then, the writer claimed the car to be the fastest true street car in the country. The car as it is in this article is essentially the same as it was when Pete bought it, apart from the motor.

After searching high and low for one, he finally stumbled across a car sitting unloved in a storage shed down country. When the seller assured him it was that same purple machine that Pete had fallen in love with a decade before, a deal was done on the phone and the car was purchased sight unseen. While he knew that was a big risk to take, a few phone calls with the original builder and owner of the car, Mike Bari, assured Pete that the car was well worth the asking price. Having a young family, and having been out of the car game for a while, Pete’s plan was just to turn the car into a cheap but tidy street and skid vehicle.

As Pete dragged the car home to Whangarei, it soon became apparent that the years of neglect since Mike had sold it had taken its toll, but the good thing was that the car was essentially complete as last raced, apart from the motor. When pricing up the sort of engine he was after, Peter discovered it was too much of a stretch for his budget. So, being a painter by trade, he turned his skills to sorting out the body while he saved the cash required. Using a mate’s panel shop, he spent a year caressing the panels back to perfection.

While he was sorting the few small areas of rust that had crept in and planning a new paint job, Pete took the opportunity to attend a Tony Vowels airbrushing course. Once he’d completed it, Pete needed a canvas on which to try out his newfound skills. Before he knew it, both sides of the car had sprouted full-on drag-racing murals and flames. While each side is different, the high level of details and workmanship is the same.

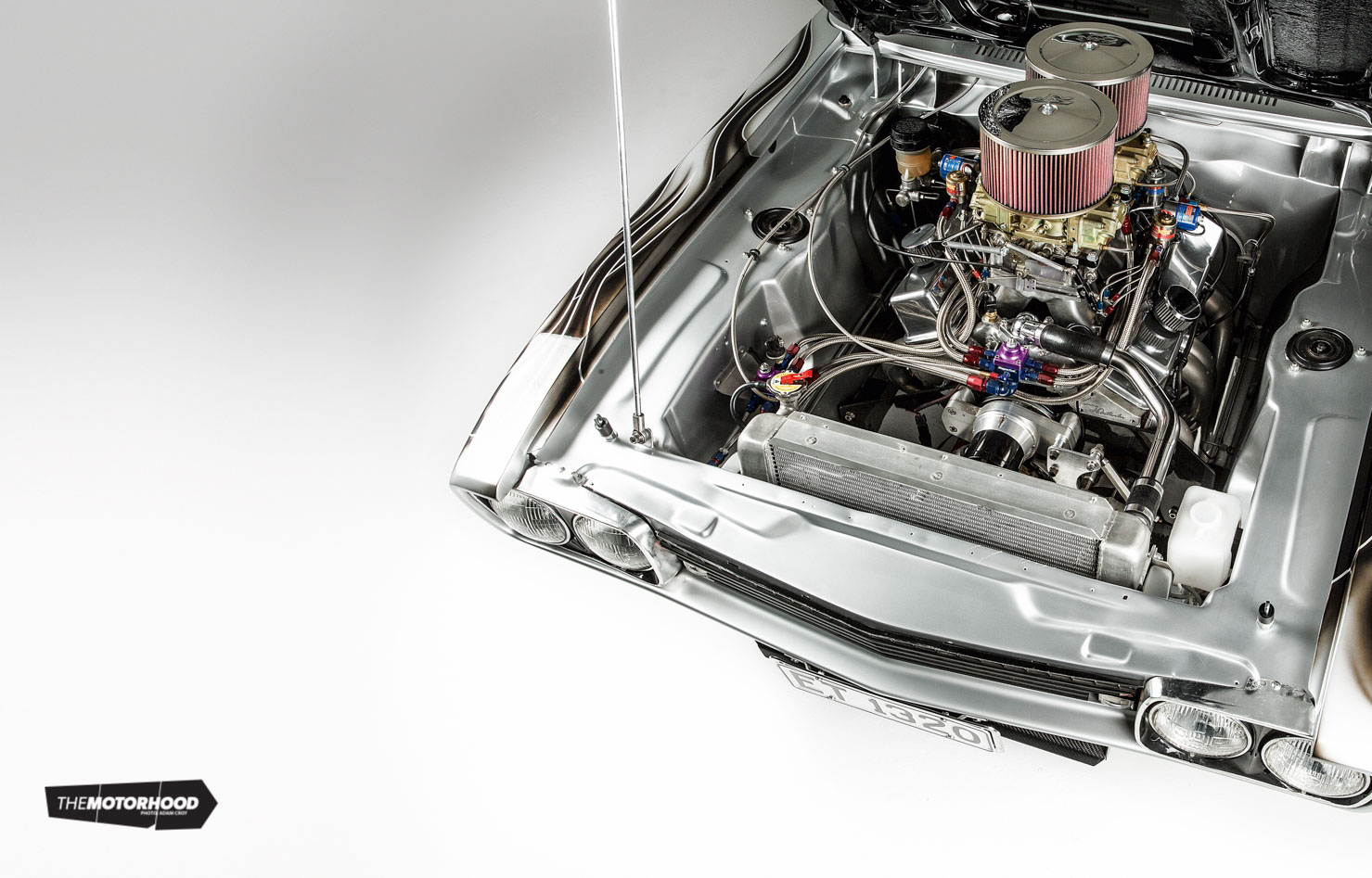

At this time, Pete and his partner owned a wheel and tyre franchise, and one of the fellow franchisees was looking to leave the country, but had been talking for a long time about the 1000hp small block he’d been building. While he didn’t really want to sell it, he ended up with no option, and Pete got what can only be described as the bargain of a lifetime. Assembled by Dave Moyle, the Dart Small M block was filled with an Eagle crank, Eagle rods, and SRP pistons, and held together with ARP fasteners. Ported Trick Flow heads were secured above and filled with stainless valves, which were fed instructions from a Comp Cams solid roller cam. The more Pete looked at the motor, the more good parts he found, including a twin tunnel ram with twin Holley 600cfm carbs and an ignition system with every conceivable MSD item included.

With the car having both plate style and fogger nitrous systems working together, there’s serious horsepower available. Each system can work independently, though allowing for the car to leave the line with either one or no systems working and the nitrous engaged once the car is down the track. Once Pete is comfortable behind the wheel and the car is run at full power, it should, theoretically, be good for mid to low nine-second passes.

While the engine would be a seriously powerful item on its own, the previous owner’s goal to create a four-figure power output led Pete to fit a Pro Shot fogger as well as twin Big Shot nitrous plate systems.

The purchase of the engine stepped the car up far beyond where Pete’s original intentions for it had been, which, of course, added to the cost and length of time of the build. After enquiring about the price for getting the car wired up, Pete again had to wait and save some cash, so he turned his attention to the interior.

Despite not having worked with carbon fibre before, Pete was soon creating his own custom door skins for the car. He then built a carbon-fibre dash, making sure to mount the stereo and Auto Meter gauges along the way. This was followed by a carbon-fibre parcel tray, which also houses a pair of Fusion speakers. With Pete’s ability to get a good finish, he decided to try his hand at making a carbon-fibre bonnet, all the while saving up for the bits he couldn’t do himself.

It was at this point that Mike made contact with Pete to see if he was keen to sell the car, but Pete refused as, by now, he was too deep into it to let it go. Instead, Pete asked Mike if he would be able to help fit the motor and get it running, since it had been sitting for a few years.

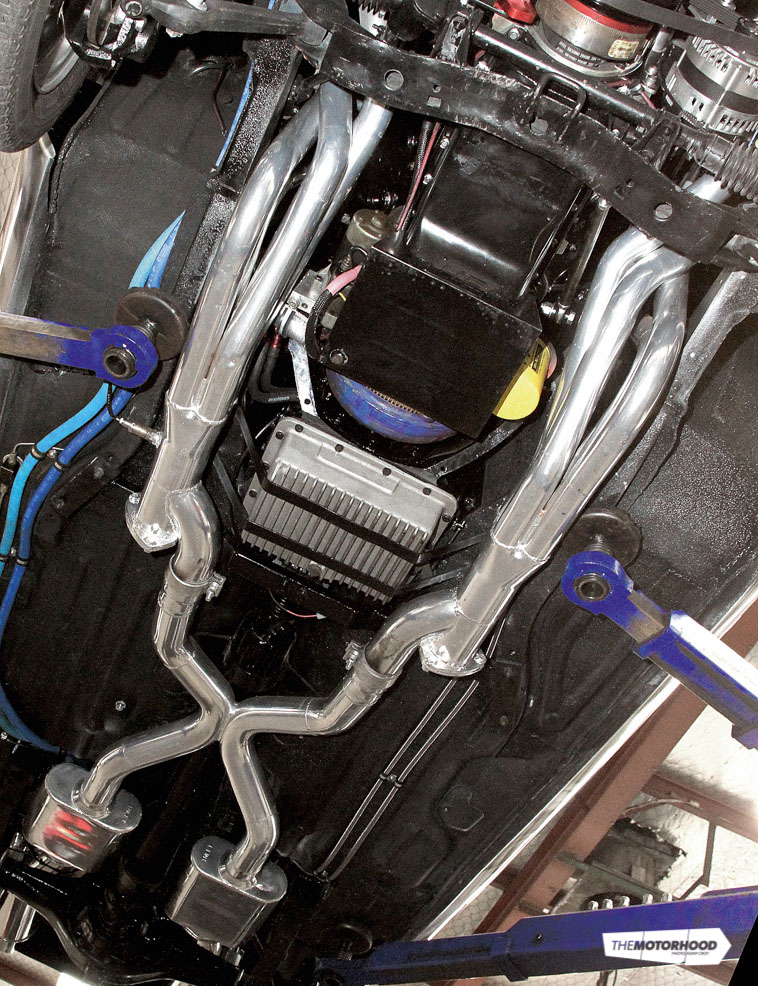

When the car arrived on a transporter at Mike’s business, Auto Care Services, Mike knew straightaway that, with the quality of the car’s interior and paintwork, there was no way he could simply drop the engine in as he’d been asked; it just wouldn’t do the car justice. “It still had the same old exhaust that I’d built years ago, and the wiring was a mess; I just couldn’t do it,” says Mike. Instead, he offered to help Pete get the mechanical side of the build up to scratch aesthetically.

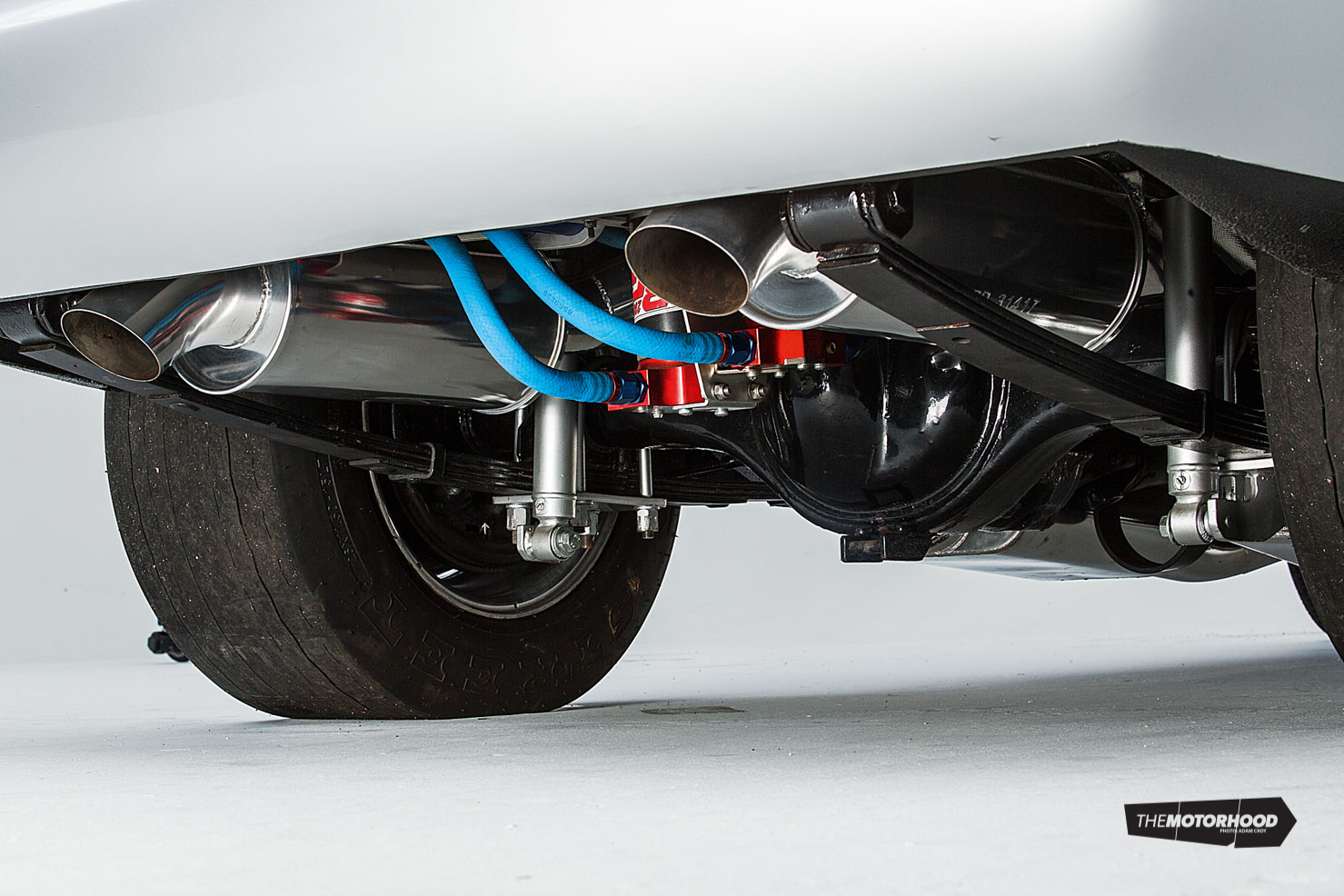

This process would take a further two years, with Pete travelling from Whangarei to Auckland almost every week to spend a day working on the car. While plenty of components were reused, everything was pulled apart, repaired, and tidied up before being refitted. Those parts that were replaced, such as the exhaust, were built from scratch, with Mike taking plenty of care to ensure that the finish was flawless.

The Powerglide transmission and nine-inch diff that Mike had fitted years before remained but were freshened up for their return to duty, while all-new fuel and brake lines were run. Essentially, though, the car is as it was back in the ’90s, with the exception of the engine having more power and the appearance being beyond anything dreamed of back then. Adding to the connection with the past, when working on the car Mike soon discovered that the tunnel ram was the exact one he’d used on it many years before, almost as if it were meant to be.

As yet, Pete’s only had the car on the road for a few test drives as the final touches are still being added. When it’s up and running, he’s keen to drive the wheels off it and also to run it down the strip as, despite having such a drag-focused machine, he’s never once drag raced. We have no doubt that, when the car does hit the strip again, it will create a whole new decade of fans — just as it did back in the ’90s. Who said that history never repeats itself?

Specs

- Vehicle: 1973 Ford Capri

- Engine: 377ci small-block Chev, Dart Small M block, Eagle crank, Eagle rods, SRP pistons, ARP fasteners, Trick Flow heads, stainless valves, Comp Cams solid roller cam, Jesel belt drive, twin tunnel ram, Holley 600dp carbs, Pro Shot nitrous fogger, twin Big Shot nitrous plate system, Barry Grant fuel pumps, MSD 6AL digital ignition, MSD coil, MSD leads, 2-inch headers, twin 3-inch exhaust, Flowmaster mufflers, custom alloy radiator

- Driveline: TCI Powerglide transmission, 4000rpm stall converter, transbrake, 9-inch diff, 31-spline axles, Detroit locker, 3.9:1 ratio

- Suspension: Koni adjustable front shocks, stock front springs, Koni rear shocks, extra rear leaf, Nolathane bushes

- Brakes: Japanese booster, Mitsubishi master cylinder, MK3 Zephyr front discs, Capri V6 calipers, Ford drum rear

- Wheels/Tyres: 15×4.5-inch and 15×10-inch Weld Pro Star wheels, 145/50R15 Michelin and 26×11.5×15 Hoosier Quick Time Pro tyres

- Exterior: Shaved bumpers, carbon bonnet, PPG silver paint, custom airbrushing

- Interior: Carbon dashboard, carbon door skins, carbon parcel tray, carbon boot trim, full custom roll cage, Sparco steering wheel, TCI Outlaw shifter, Auto Meter gauges, Sparco driver’s seat, Fusion audio

- Performance: Untested (car ran 9.61 at 145mph with old engine combo)

This article was originally published in NZV8 Issue No. 112. You can pick up a print copy or a digital copy of the magazine below: