data-animation-override>

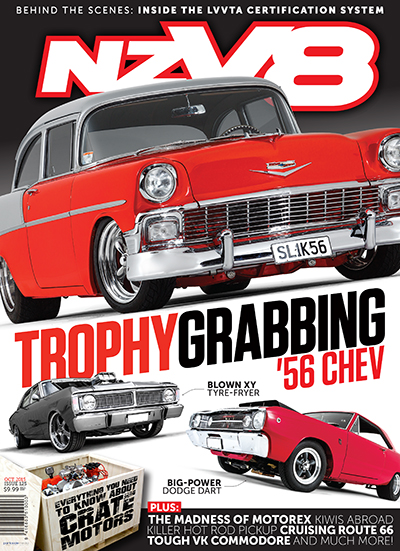

“A seasoned drag racer, Steve Milne didn’t let go of his Top Doorslammer quietly — his quest to build a cruiser he and his wife, Leanne, could enjoy culminated in this ’56 Chev that’s got it all!”

Steve Milne has been into drag racing for about as long as he can remember, with his straight-line efforts seeing him wind up in a super-serious Camaro running a blown and injected 427ci big block that ran as quick as eight seconds flat in Top Doorslammer class. So, a few years ago, when he decided to extract himself from the world of drag racing — well, actively participating, at least — and instead spend his money on a comfortable cruiser that he and wife Leanne could both enjoy, there was little doubt that it’d be anything other than top tier.

With the Camaro safely in the hands of Rotorua’s Russell Lowe, Steve could begin thinking about what he’d like to build next. Having always been a fan of Tri-5 Chevs — but preferably a ’55 or ’56 — he knew that’s what the car needed to be, and it had to be a coupe.

With those two simple requirements in place, the hunt began. Renowned Tauranga hot rodder, John Key, found a ’56 Chev 210 two-door post sedan overseas, and it was up for a remarkably good price. While it wasn’t perfect, it was a lot of car for the money. Steve was initially hesitant, but John convinced him that it was a damn good deal, and that he’d buy it if Steve didn’t — well, Steve owned the car not long after, despite having never even set eyes upon it.

As soon as Steve took possession of the car, it was wheeled straight into the shed and the build began in earnest. Steve had a fair idea of what he wanted; it was simply a matter of finding the right people to help in the right places to make it a reality.

Steve admits that he cocked up by not taking the car through the VIN process immediately, rather than initiating it as the build began. That said, he does say that, when he began to look into it, the VIN process couldn’t have been easier. Steve also had his LVV certifier, Paul ‘Pins’ Sattler, look the car over for the planned modifications.

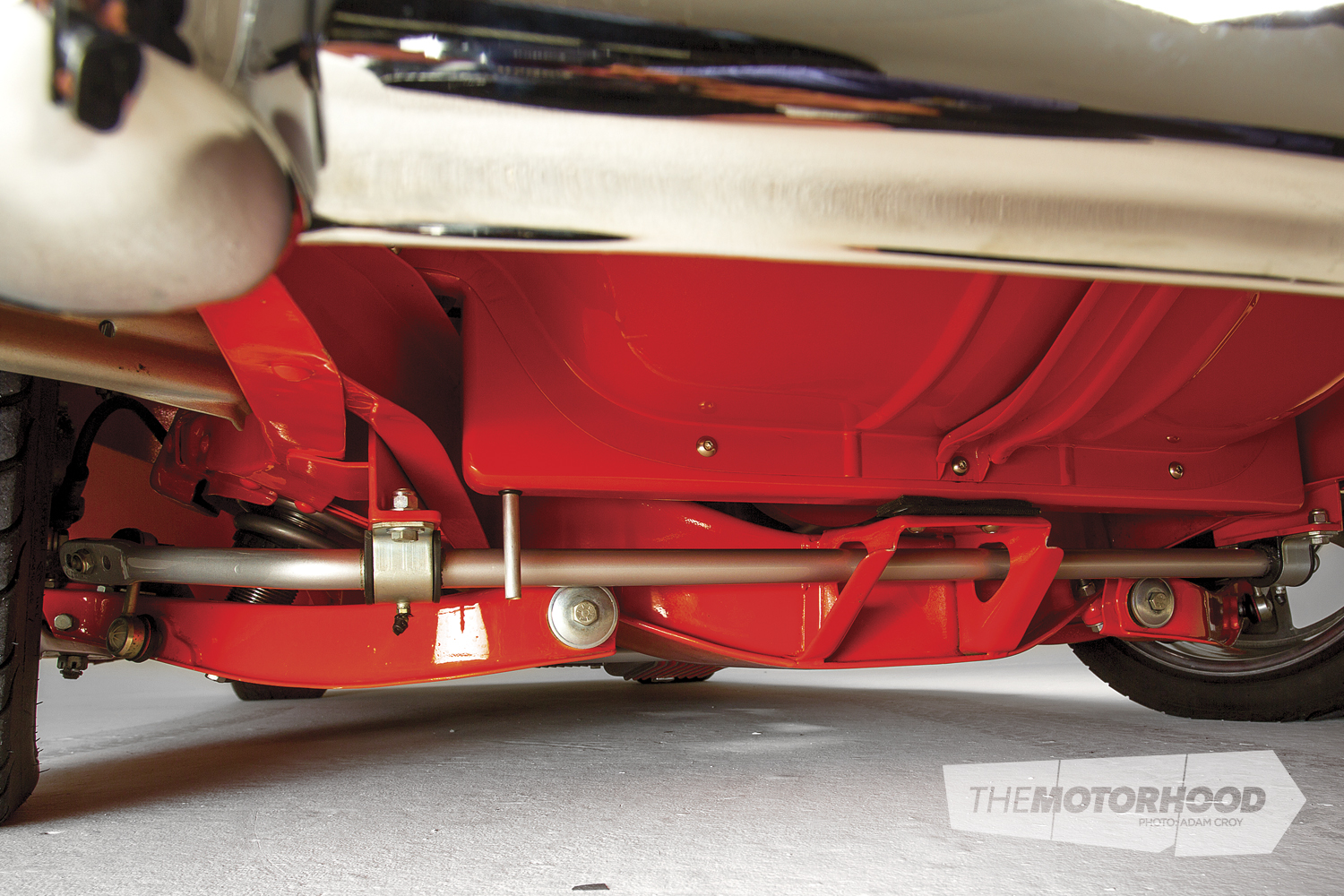

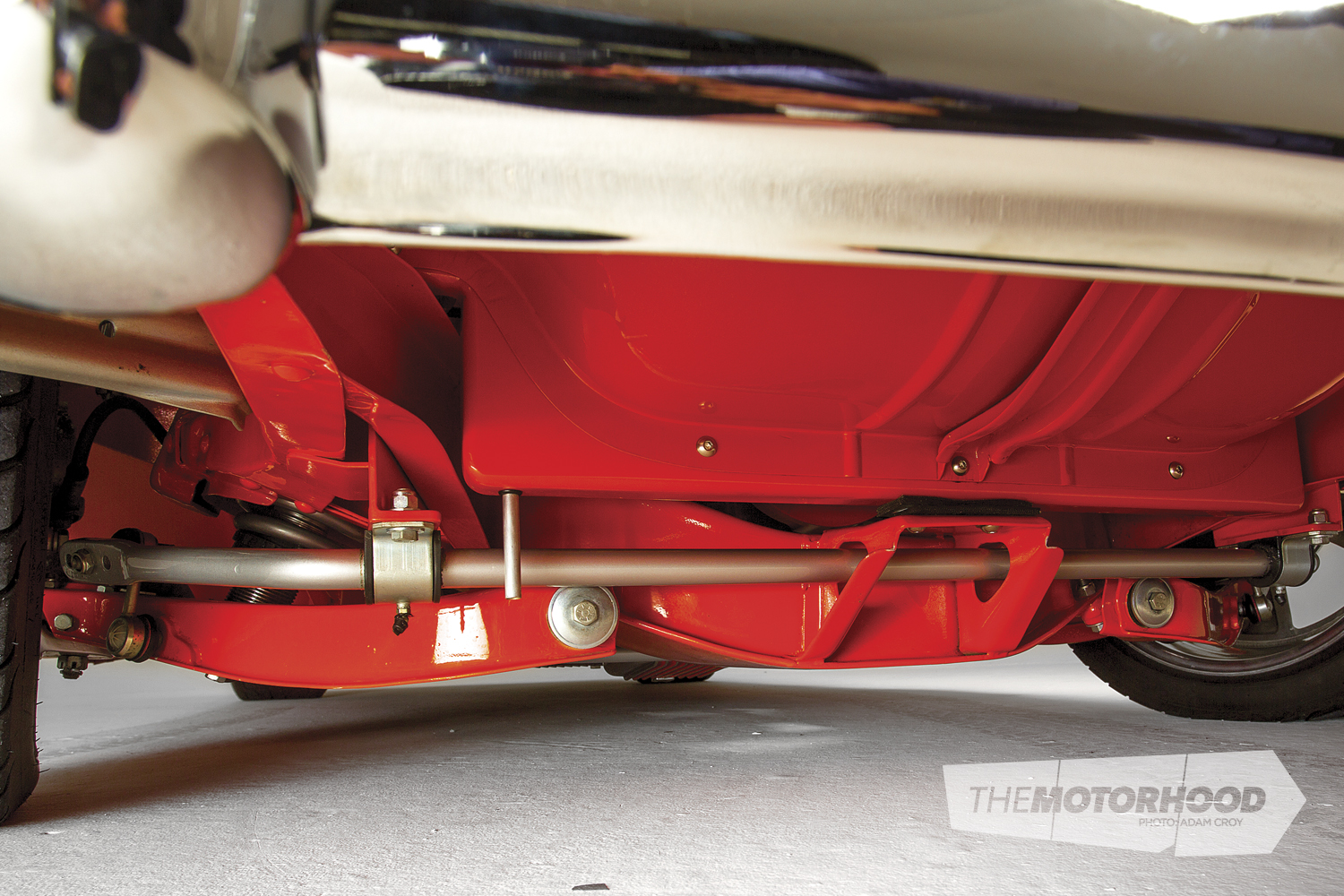

Tauranga-based fabricator Jason Sellars performed a large proportion of the fabrication work on the car, starting with the chassis, and it really is a top-shelf product throughout. The chassis has been extensively modified, with smoothed front cross member, completely custom centre-section modelled off an Art Morrison chassis, and Art Morrison triangulated four-bar rear. Both front and rear ends have been modified to accept adjustable coilover shocks — QA1s in the front and Strange in the rear — for far superior ride and handling. The added bonus is that Steve can adjust the ride height to his version of perfection, and adjust the dampers to ride exactly how he wants.

Getting the car to sit right was a major part of the build, and one that has been absolutely nailed, thanks, in part, to the subtle mini-tubbing and the extremely minor C-notch in the rear chassis rails. The notch, which can’t be much more than ¾-inch deep, is just enough to tuck the big 18×11-inch American Racing Torq Thrust II rims right up into the ’56’s guards, for a stance that is both functional and extraordinarily tough. This is replicated up front, where the factory control arms have been extensively modified to accept coilover shocks while retaining optimal suspension geometry that allows the vehicle to sit as low as Steve wanted it to. With dropped coilover mounting points in the lower control arm, and extended-length Chrysler ball joints in the upper control arms, the front end sits extremely low over the ‘not too big, not too small’ 18×7-inch wheels, with just the right amount of forward rake to look right but not overdone.

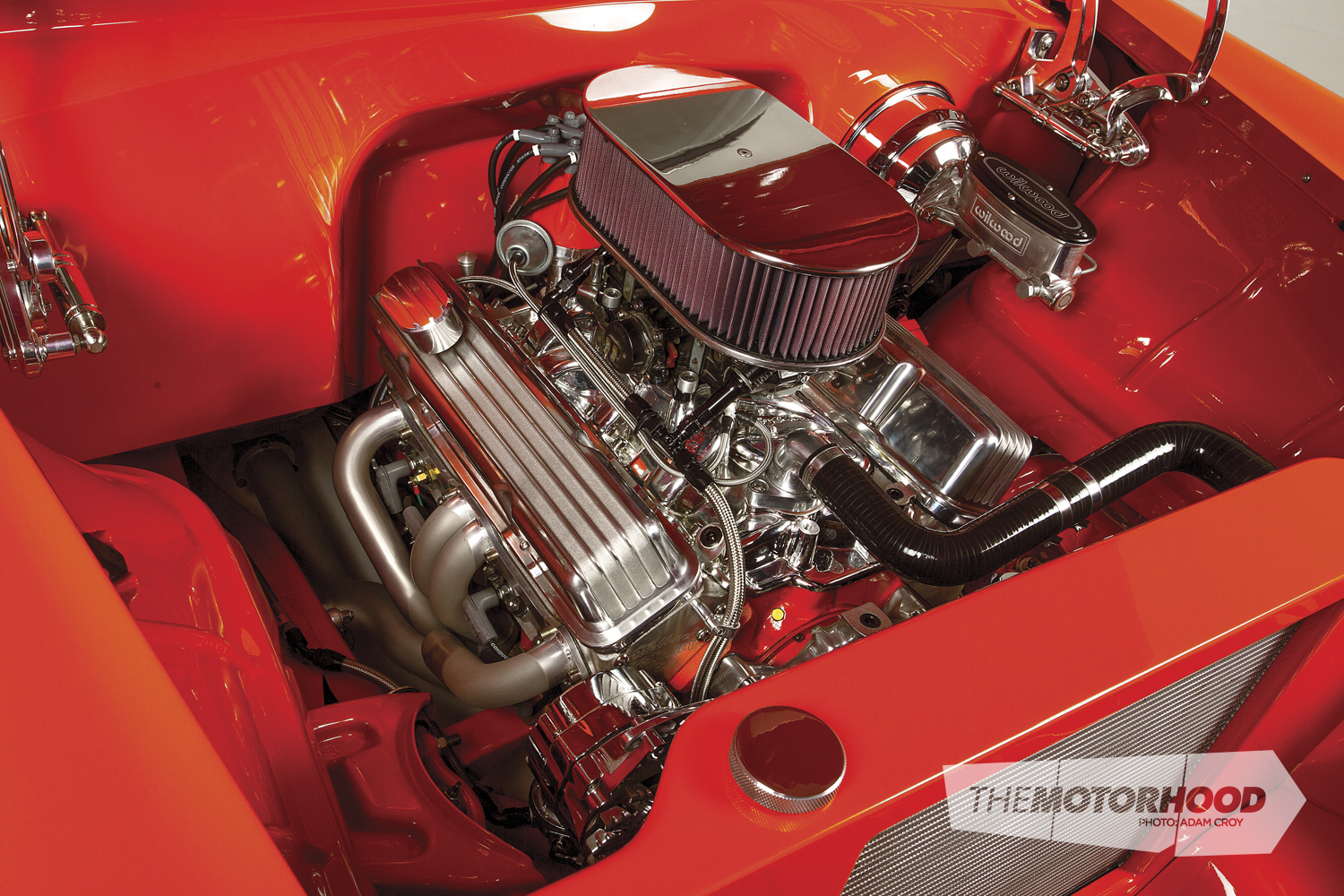

With Steve being well seasoned in 1320-foot bursts of high-speed straight-line driving, you can bet that whatever motor was to be bolted to the front cross member, it’d be more than capable of getting the ’56 to speeds not favoured by the local constabulary. That said, the whole purpose of the vehicle was to be a comfortable cruiser that both Steve and Leanne could enjoy — this meant that, first and foremost, the engine and drivetrain would need to be smooth and refined. Steve found the best of both worlds in a stroked 385ci small-block Chev, assembled by Bruce Ericksen. The motor utilizes the block that the car originally came with, although it has been subject to a fair bit of warming over since it first landed on New Zealand shores. Justin Rice, at Rotorua Precision Motors, was tasked with all the machining work required for a properly blueprinted build. The bottom end, comprising Scat stroker crank, Scat rods, and Sealed Power pistons, was then given to Wayne Stonehouse for balancing, before Bruce pieced the whole package together.

The small block carries a full array of ARP fasteners, and features a Lunati camshaft which, when coupled with the 1.5:1 ratio Crane Cams roller rockers, gives gross lift of 0.507 inches. The breathing potential is maximized thanks to ported Edelbrock E-Street alloy heads with modified chambers — the final compression ratio is 10.5:1, which is just right for producing both good naturally aspirated power and an engine that is not too rowdy to drive on the street. It’s all topped with a Weiand dual-plane intake manifold, Holley 850cfm double pumper, and full MSD ignition system.

It’s a clean-looking motor — they even went to the trouble of deburring the casting flash from the block, just for the sake of cleanliness — and it looks right at home in the immaculate engine bay. All the panelwork has been smoothed or custom fabricated, and it sure looks the part, especially when you realize the radiator has been mounted on the inside of the support panel, simply to clean up the outside appearance of the engine bay. The detail touches even extend to the chromed CPP brake booster being ‘frenched’ just for the aesthetic cleanliness this brings.

Underneath, things are just as tidy, with everything being finished in either the custom-mixed Spies Hecker orange (it’s very orange) or the silver that adorns the car’s arrow-straight exterior panels — thanks to the brilliant work of Joel Kamo. Even the oily bits are a joy to behold. Parts like the shift-kit TH350 transmission built by Chuck Mann and the nine-inch diff custom fabricated by Jason Sellars have been finished superbly, and give a whole new depth to the finer details — details that most definitely have not been missed in the piecing together of this car.

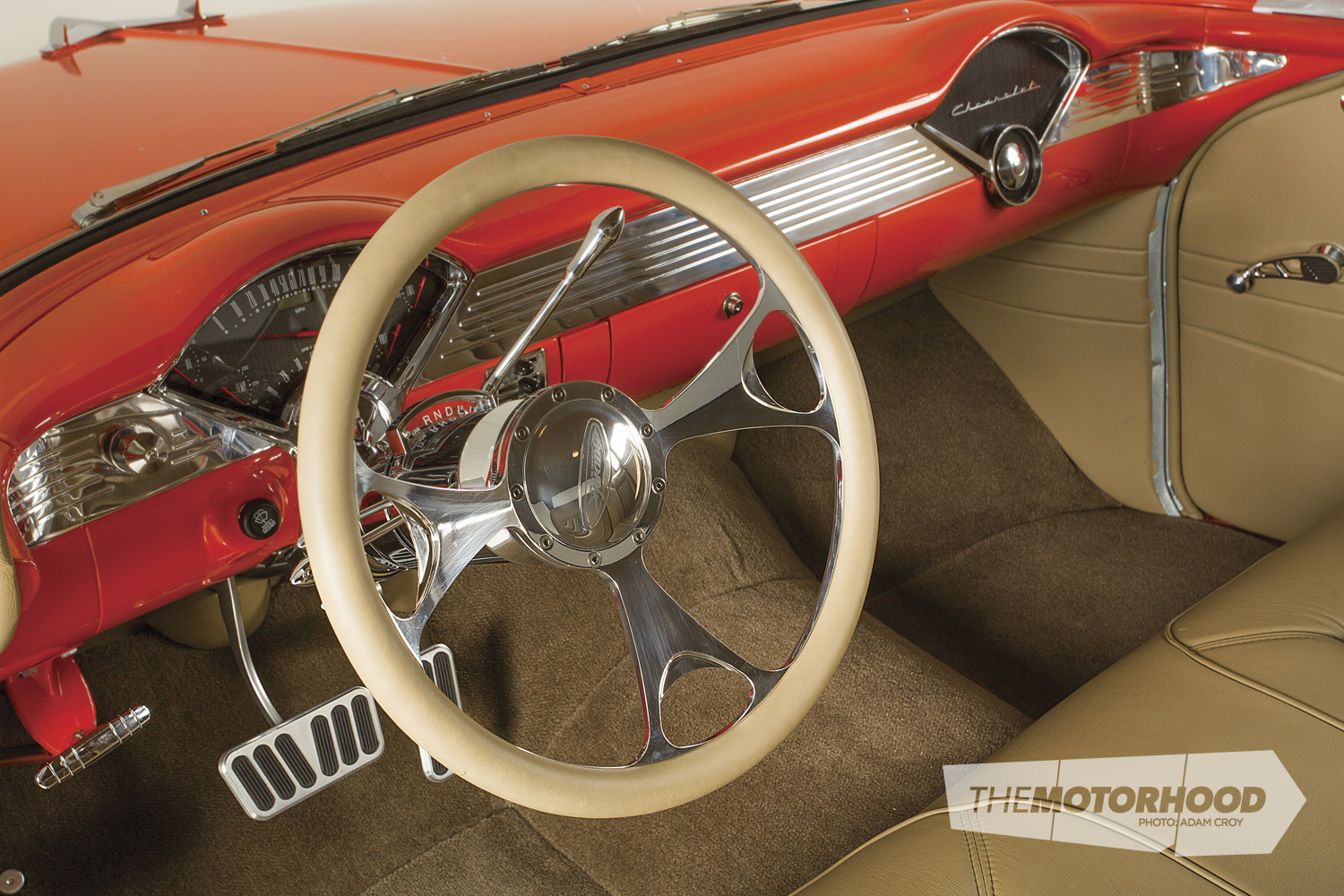

With such effort put into making the exterior as aesthetically pleasing as possible, the interior was never going to be anything short of a masterpiece — it’s where Steve and Leanne will be spending the majority of their time with the car, after all. Beneath the lavish upholstery that adorns every last bit of the car’s innards, it’s been fully blasted, powder coated, and given a coating of Lizard Skin sound deadener — not a single square millimetre has been neglected.

A New Vintage Tri-5 gauge set fits the ’56’s dash perfectly, while offering a reliable source of information about what’s going on within the car, and the Budnik wheel perched atop the Ididit tilt steering column gives supreme control of the fine riding and handling machine. The Glide Engineering front split-bench seat and the rear seat, which has been slightly modified for the mini-tubbing, have been upholstered in a beautiful leather and cloth mix by Shawn Horwood at Action Canvas & Upholstery, in Mt Maunganui.

This leather trim extends to the firewall, door cards, and even the headlining. All up, Steve tells us that five whole hides were used, but the end result is one of unparalleled luxury — this truly is a cabin in which you could cross a continent and emerge as fresh as when you first got in.

Although the ’56 hasn’t been completed all that long, Steve and Leanne have already clocked up 300 miles just cruising on rod runs, and a lot more long distance cruising is on the cards. The car was built to drive, and drive it they will — it just so happens that it’s been built to a standard that will allow it to hold its own against cars built solely for shows, as evidenced by the Milnes’ Best Street Machine Sedan and People’s Choice awards in the Teng Tools Grand National Rod and Custom Show Show at this year’s CRC Speedshow, where the car was debuted for the first time. Now they’ve just got to wait, with bated breath, for that first stone chip to appear — after that, they’ll just drive it some more.

This article was originally published in NZV8 Issue No. 125. You can pick up a print copy or a digital copy of the magazine below:

1956 Chev 210

- Engine: 385ci small-block Chev, 350 four-bolt mains block, Scat stroker crank, Scat rods, Sealed Power pistons, ARP fasteners, Edelbrock E-Street heads, ported and polished, 10.5:1 compression, Lunati camshaft, Crane Cams 1.5:1 roller rockers, Rollmaster double-row timing chain, Weiand dual-plane intake manifold, Holley 850cfm double pumper, MSD distributor, MSD coil, MSD leads, mechanical fuel pump, Mellings high-volume oil pump, crank scraper, windage tray, alloy radiator

- Driveline: TH350 transmission, shift kit, Ford nine-inch diff, Strange 31-spline axles

- Suspension: Modified stock control arms, QA1 adjustable front coilovers, Art Morrison triangulated four-bar rear, Strange adjustable rear coilovers, custom front sway bar, Art Morrison adjustable rear sway bar

- Brakes: CPP polished booster, Wilwood master cylinder, CPP front calipers, CPP front discs, Ford Falcon EL rear calipers, Ford Falcon rear discs

- Wheels/Tyres: 18×7-inch and 18×11-inch American Racing Torq Thrust II wheels, 26x8x18-inch and 28x12x18-inch Mickey Thompson SR tyres

- Exterior: Spies Hecker paint

- Chassis: Mini-tubbed rear, C-notch, braced cross members

- Interior: Glide Engineering front split-bench seat, modified rear seat, Budnik steering wheel, Ididit tilt column, custom shifter mechanism, aftermarket gauge set, Billet Specialties dash panel, Billet Specialties kick plates, Billet Specialties door handles, Billet Specialties window winders, custom seat levers, full custom retrim, Lizard Skin sound deadening

- Performance: Untested