Before the internet was around, finding your next project was sometimes a bit of a mission. It involved scouring the various papers, followed by plenty of phone calls and driving around to take a look at everything. Thankfully, with websites like Trade Me, eBay, Craigslist, and RacingJunk, sourcing cars and parts is now a whole lot easier. It’s no surprise, then, that when Taranaki’s Hamish Hiestand went looking for a Ford Bonus, the internet was the place he started his hunt.

Produced from 1948 to 1952, the Bonus is not a common vehicle on the roads of New Zealand, with low numbers sold here and most of those living hard-working lives, so a good New Zealand–new one is a rare truck indeed. So, when Hamish found a Bonus hot rod project for sale on the Turners Auctions website, he was surprised, partly because it’s not the place you normally find a hot rod, but more because it looked OK in the photos, so he thought he’d try to secure it.

Come auction day, there were a couple of bidders at the auction rooms who were interested in the old girl, so, from his home in Eltham, Hamish started hitting the bid button, too. Based on his assumption that those on-site must see the value in it, Hamish kept bidding until he owned it. While he was rapt that he had won, he was not exactly sure what his nine grand had bought.

The trip north to collect it revealed what he had got for his money, and that wasn’t a lot — at least, not much that was good. Yes, it was a ’49 Bonus, or parts thereof, with an OK cab and guards on a rolling chassis, but as for the 302 Windsor and C6 transmission — well, they were still lying in the tray of the truck!

This was always going to be a home-built hot rod, so, once it was back in Eltham, Hamish and a couple of mates from Egmont Rod & Custom Club got stuck in and pulled the Bonus apart, hoping to have it all back together for Americarna in a few months’ time. Unfortunately, as the Bonus turned out to be what Hamish describes as “a pile of poo”, the timeline was soon to stretch from a few months to a few years.

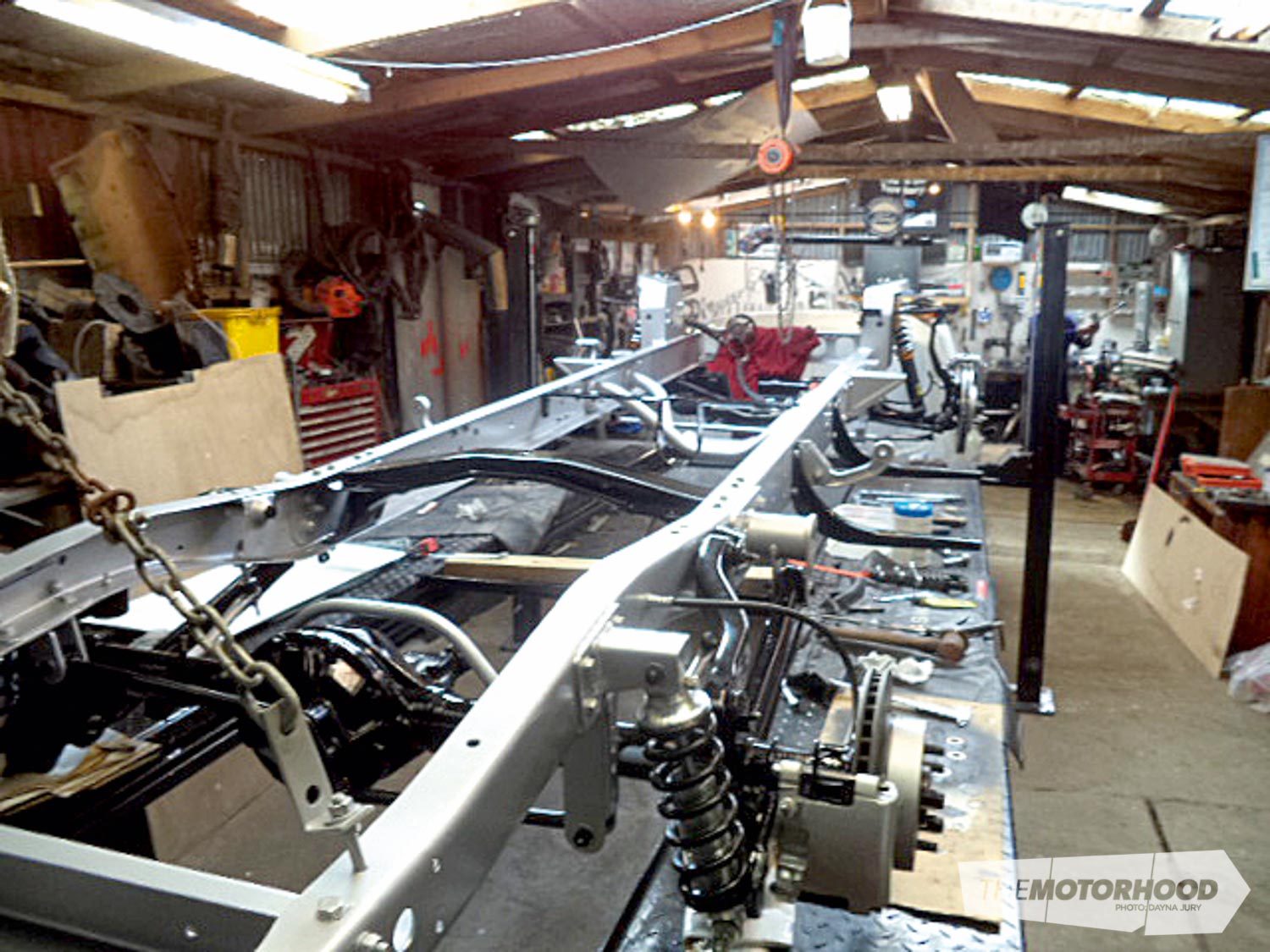

Once the body was off the chassis, Hamish got busy sandblasting the frame to mount the 302 and C6 that came with it. While he was doing this, both were given a freshen-up in preparation for being installed. A bit of a wheeler and dealer, Hamish had been rebuilding and selling the odd engine and using the proceeds to fund the Bonus build. Just after he’d sold the last engine, a local guy popped in to see if he had any Windors for sale. The potential buyer had a BA XR8 Falcon, which his son had crashed, and he was trying to fit the XR8 running gear into a Mk1 Cortina but it was just too big. The upshot was that he was looking to do a deal on the quad-cam engine for a Windsor, and Hamish’s rebuilt one was just the ticket. There was a sweetener to the deal: the guy told Hamish that he could also have the complete front end from the BA and anything else he wanted or needed for the Bonus. The idea of the late-model EFI engine and the independent front susension appealed, and this was where the simple rebuild took a whole new direction.

The standard chassis would need a major upgrade to make it all work, and, fortunately for Hamish, another Egmont club member, Merv Hooper, repairs trucks for a living and has all the toys for building truck chassis. He and Hamish did a labour swap, with Hamish helping him as time allowed, and, in return, Merv would work hour for hour rebuilding the Bonus chassis with the BA front. It took many months of work and a full sheet of 4mm steel plate to box and rebuild the chassis and create new strut towers, cross members, and so on. Hamish had a spare disc-braked Falcon diff with LSD head, so they fitted that, too, using ’90s Falcon trailing arms and Watt’s linkage. They mounted this with QA1 adjustable shocks, which, when combined with the new front end, gave the Bonus a suspension set-up like no other. To make sure the pickup would stop, a set of Brembo calipers was fitted, along with 350mm FPV front rotors, while the rear rotors were upgraded to slotted units. Not wanting to run the BA computer-controlled auto, Hamish adapted the old shift-kitted C6 to fit the quad-cam engine.

As the months were turning into years, other club members got involved to help Hamish along. It sounds like the truck would still be a work in progress if it weren’t for Glen Theyers, who spent 15 months helping with the fabrication, wiring, bodywork, and paint. Glen had been getting frustrated with the slow pace of the build, so he jumped into the project and, before long, grinding sparks were flying at anybody who dared to walk in the door, as the body was rapidly ripped back to bare steel. With the body laid bare, another club member, Geoff Wakeling, offered to lend a hand. Bringing out all his panel-beating gear, Geoff set to work on the rust repairs and panel straightening. Once these were completed, it was time for a number of custom touches, such as the tilt front with custom stainless grilles and alloy fabricated inlet manifold with twin throttle bodies that Hamish and Geoff spent a lot of hours creating and detailing.

Not everything went to plan, but nothing was insurmountable — just a lot of time spent redoing things that didn’t quite work out. Hamish liked the idea of using a few modern touches to match the late-model engine, and grafted BA Falcon door handles and catches into the Bonus doors. They looked and worked great — well, until the glass went in. With the windows up, everything worked fine, but, with the windows down, linkages hit and didn’t work, so the glass came out, along with the quarter-lights this time, and the doors were reworked with poppers instead.

Once the panel work was completed, Hamish and Glen etch-primed the steel before getting stuck in with a few tins of bog to smooth out any little blemishes. A few months later, they had something worth painting.

Living in rural New Zealand, Hamish knew he would have his work cut out to get a top-quality paint job, as there just aren’t the flash mega-dollar spray booths that can be found in the big smoke. Undeterred, he spoke to the PPG rep, who was keen to help with the product and assured Hamish that, with the right gear and a bit of care, he could spray the truck himself. Hamish had an old cowshed on the property, which had been lined and used for calf rearing, so he and Glen set to work converting it to a temporary spray booth, water blasting the inside before sealing it and decking it out with fluorescent lights. Once it was sealed and airtight, a window was removed and an extractor fan fitted. Hamish now had a spray booth as good as any out there! The results speak for themselves, with the custom mix of PPG Poison Ivy green looking flawless with not a single bug or speck of dust in sight. Even the PPG rep was impressed with the paint job that a couple of self-taught country boys managed in a cowshed!

The interior was a blank canvas, as the previous owner had ripped everything out, so a new gauge cluster, Flaming River steering column and shifter, and pair of leather Fairmont Ghia seats were fitted before the Bonus was handed over to Normanby Upholstery for a full custom stitch job.

Another local who is a whizz-kid with computers put his hand up to sort out the engine management, to make the most of the new custom intake and exhaust. His system of choice is the MegaSquirt, which, while not as popular as some other ECUs, does everything Hamish asks of it. There is nothing better after a full rebuild like this than to have it fire up first time and drive as well as this Bonus does. Local certifier (and founding member of Egmont Rod & Custom Club) Bruce Jamieson, was impressed with both it and the quality of work, summing it up well by saying that the Bonus drives and handles better than an XR8 ute. As for Hamish, he’s rapt with the way the Bonus has come up — with the help of his club mates and the tolerance of his wife, he now has a great-looking old hot rod that drives like a new car and looks even better. What more could you ask for?