Some say you can’t teach an old dog new tricks, but this veteran of the burnout scene has injected some serious new-school tech into his latest build

Words: Marcus Gibson Photos: Rod Dunn and Maria Panova

Progress is a polarising thing that you either embrace and exploit to your advantage or despise and try your damnedest to curb, ignore, and discredit. But there is one thing for sure — it’s almost impossible to stop it, especially when we’re talking about motorsport. Some might moan that it has ruined some disciplines, and we’d agree there is merit to that line of thought, but when was the last time you heard anyone complain about what it’s done to burnout cars and competitions?

The progression curve in the sport has been a steep one, both in terms of the on-pad acrobatics and, more important, the machines that allow the drivers to do these. What was competitive 20 years ago would struggle to raise an eyebrow these days, and all it takes is one walk around the pits of any half-decent event to understand that some serious hardware is now required if you wish to hang with the big guns. Someone who’s been involved with it from the early days on both sides of the Tasman, and smoked them on stages as big as Summernats, is Steve Saul. Steve has seen first-hand this progression, and for the most part that was from behind the wheel of his blown small block F150.

The big bright yellow pick-up was a regular sight on the pads, both here and over in Australia, for over a decade, but when Steve stumbled on an old Capri drag car shell on Facebook Marketplace, he couldn’t resist the opportunity to take his skid game to the next level. The Capri, a ’74 Mk1 facelift to be exact, was a regular on local strips in the ’80s but had sat dormant in a barn not far from the Meremere strip for around two decades before being listed for sale.

Strip for around two decades before being listed for sale. So, while it was rough, it wasn’t rusty — a huge upside. Once delivered south to Christchurch, the build started with the chassis, and began with the removal of everything it acquired in the ’80s, apart from the tubs. Up front, original chassis rails were grafted back in, and these were then tied into the new roll cage.

Unlike the F150, the Capri was to be a dual-purpose machine, built for both strip and pad duty, so drag racer Adam Thompson was called in to help with building the rear end, a QA1-equipped and four-linked sheet-metal nine-inch, complete with floating 35-spline axles and full spool centre.

The brakes came from Wilwood and, like many pro-level tyre-poppers, have dual pedals to allow each side of the car to be braked independently — a real help in tightening up those tip-ins. Another little trick added in during this stage was air jacks to speed up rear tyre changes — anyone who has swapped popped tyres on a tubbed car like this will attest to how annoying it is getting a jack in and under there.

It was during the 2020 Covid lockdowns that the worker, Steve, who is a towman, was able to keep things moving at a great rate. Once the chassis work was completed, it was on to the bodywork, which was sorted with the help of another mate, Aaron ‘Ronny’ Brown from Hammonds Collision Centre.

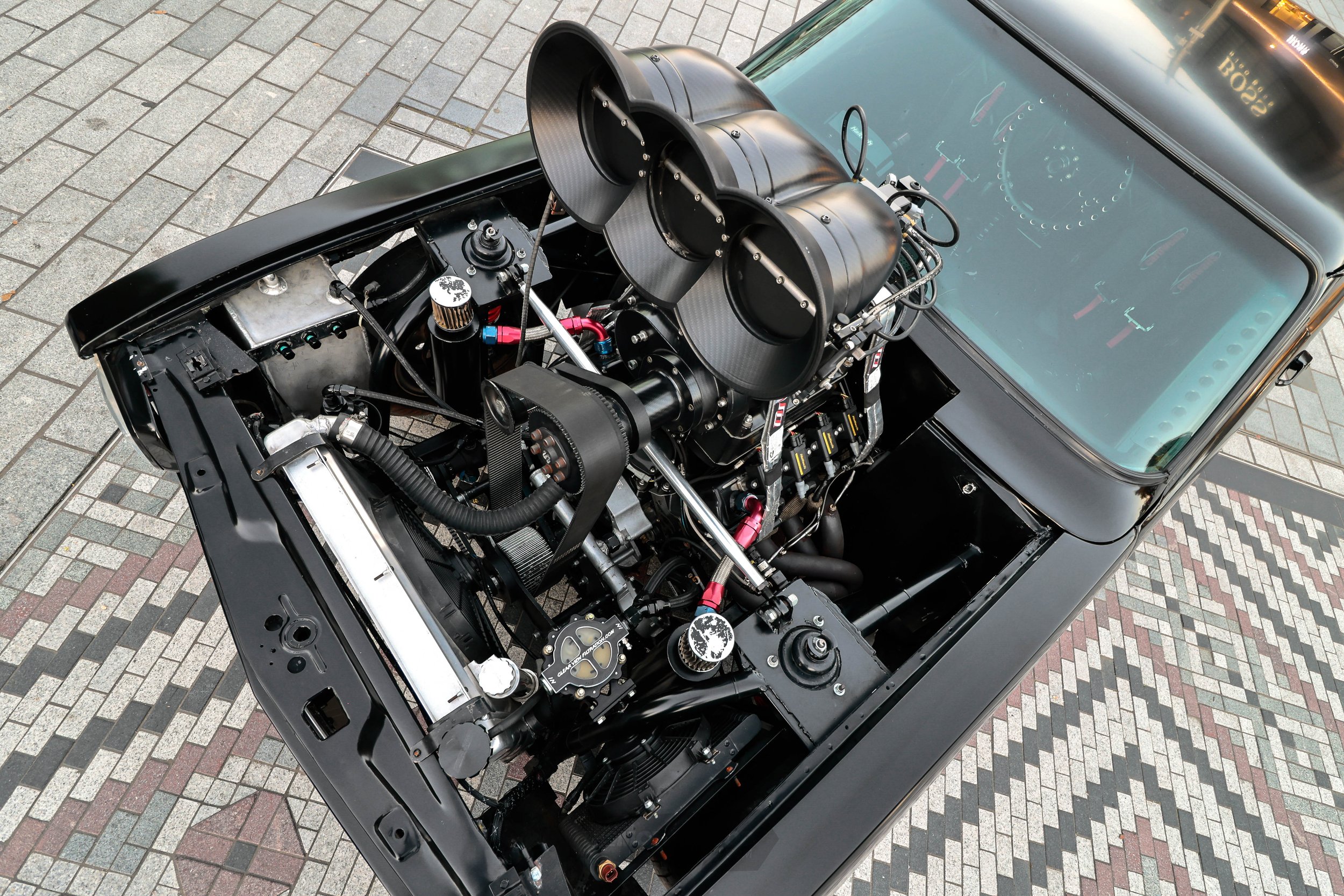

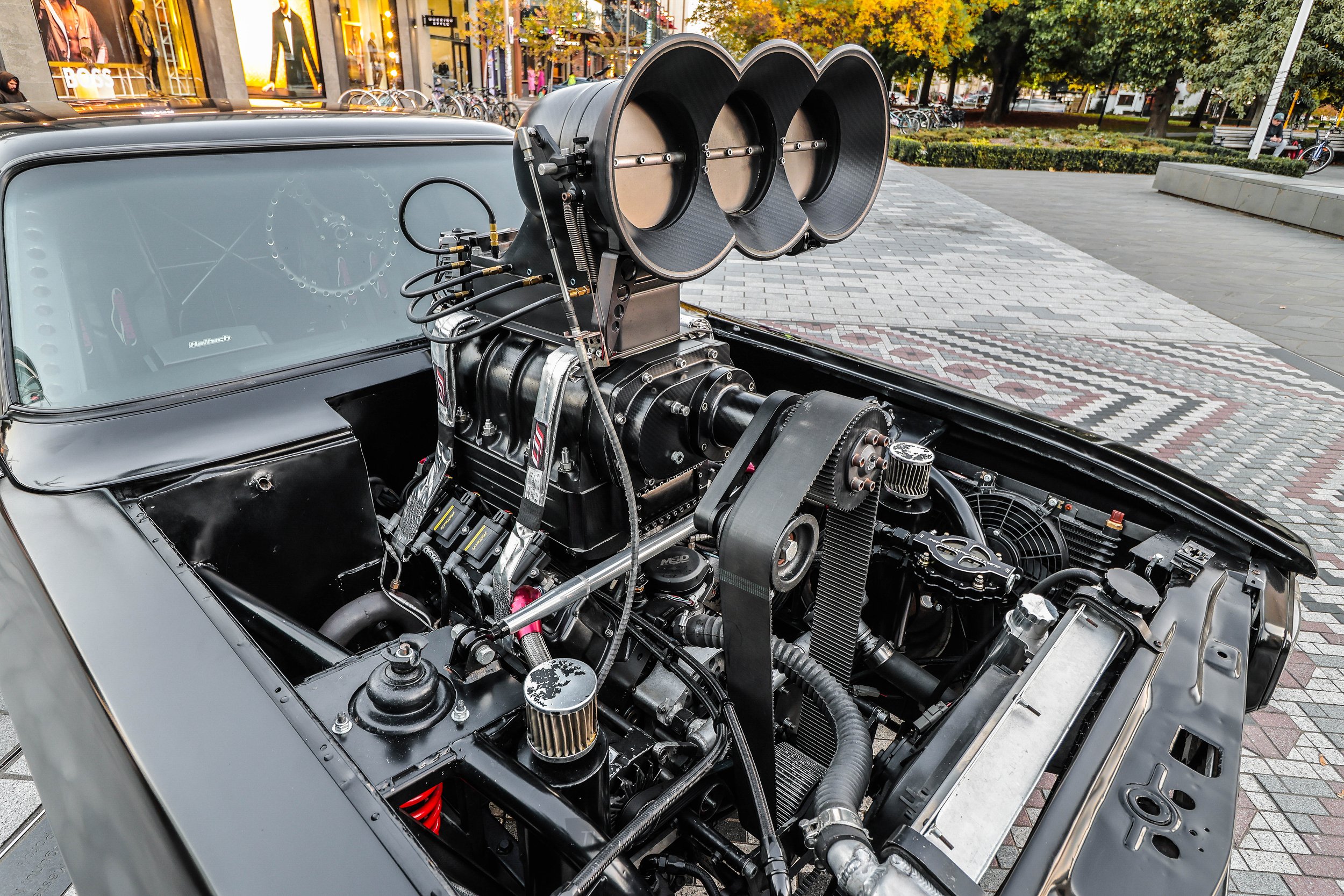

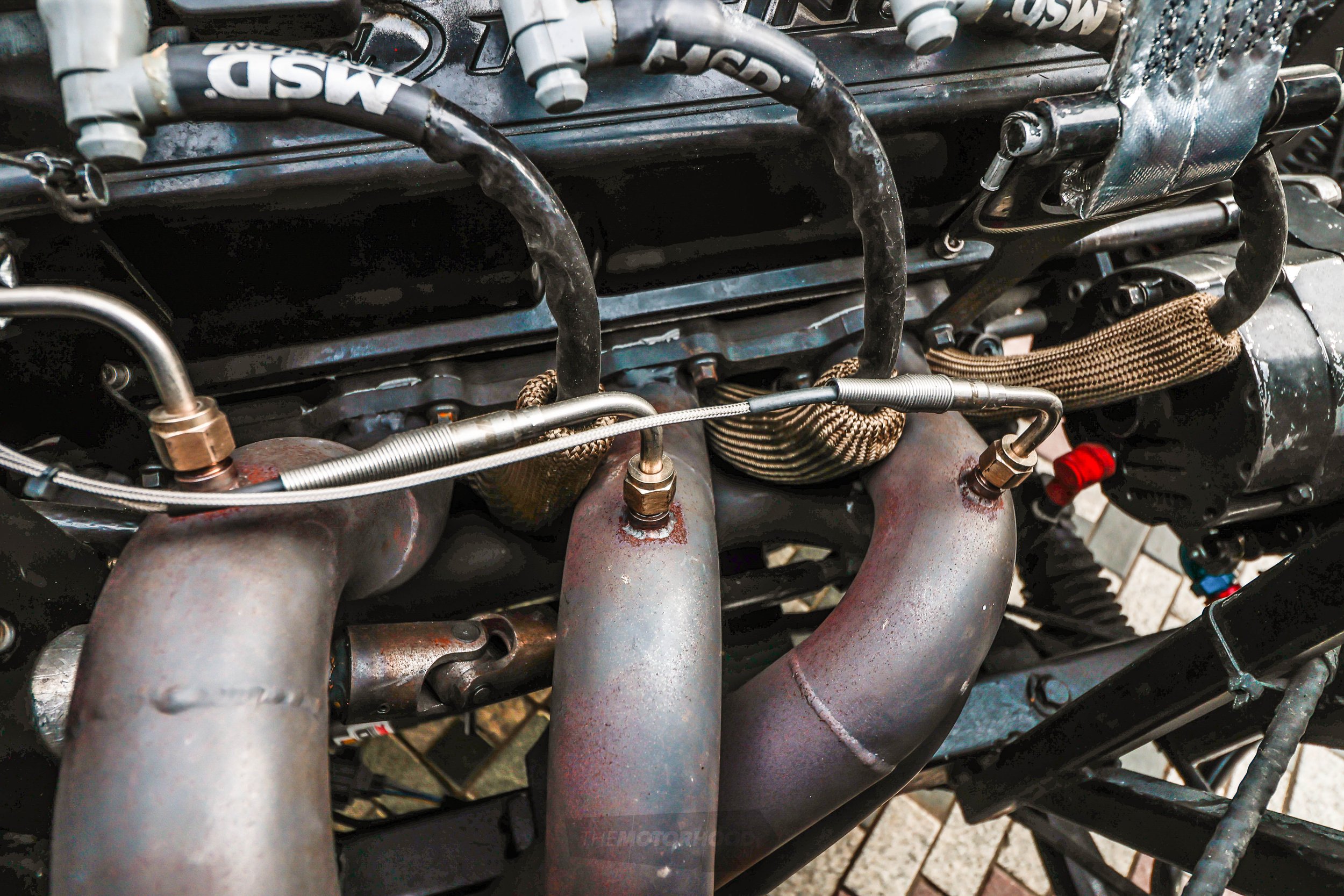

Thankfully, as mentioned, those two decades it spent sat in a barn were kind to the little Ford’s tin, so the only sheet-metal work required was lengthening the rear arches to allow for the 31×15-inch slicks wrapped over 15×14-inch Weld Draglites. Then it was given a lick of the finest Satin Black. While this work was going on, the team at HPE Automotive Services were prepping the F150’s old blown mill in preparation for more boost and a switch to mechanical methanol injection, via a Joe Blow injection system and Good Vibrations Big ‘n’ Ugly out of Aus. The Dyer’s-prepped 6-71 and the heads from the F150’s combo — a set of old BNT V8 cast items that have been heavily modified — were also carried over. Then another mate, Sam Chambers, was called in to help with some TIG welding, fabricating new headers to suit the chassis, and the engine bay–mounted meth tank. The last piece of the puzzle was a complete rewire from front to back. Only nine months after cracking into the build, the combination, backed by a manualised TH400, was throwing down around the 750hp mark and ready for war — or so Steve thought.

Its debut was a fitting one, given that it was very probably at the last track that the Capri ran all those years earlier. Only this time not on Meremere’s strip, rather the burnout pad for the Burnout Nationals. But despite the early skids being wide-open-throttle crowd-pleasers, the weekend ended abruptly when a rod decided to exit the block; not a great way to kick things off. Never one to give up, Steve soon had the block back out and at HPE for a rebuild, while a plan to stop a repeat was also forming. What’s now sitting between the struts is another step up and one of the more serious combos you’ll find in any New Zealand burnout car.

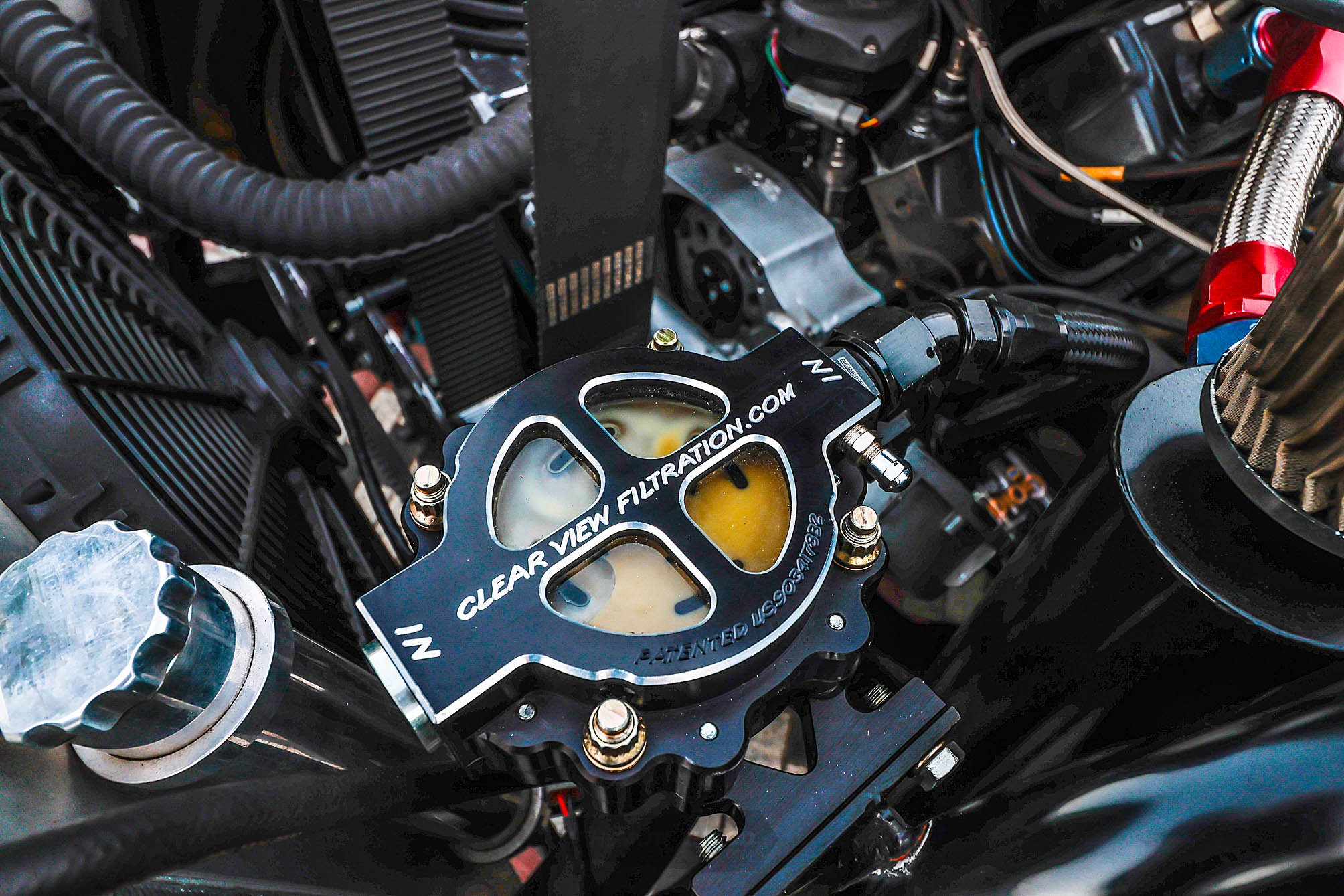

The Ford Motorsport Boss block is swinging a Callies crank, Callies rods, and JE Pistons. The top end remains as previously, from Good Vibrations blower hat down to the heads, but fuel delivery and ignition were all change with the switch over to a Haltech ECU with individual smart coils and, more important, EFI. Safety comes in the form of the likes of EGTs and every failsafe you can programme into the ECU, so that Steve can worry less about what’s going on up front (we’d say under the bonnet, but that barely covers a fraction of it) and more about mashing the gas and keeping control of the short-wheelbase monster.

As you can imagine, going from the long-wheelbase F-truck to the little Capri has been a huge shift, one that Steve is loving. There is, however, still one weak point in the combination that has on occasion killed the buzz: the transmission. Steve’s fried his fair share of these over the years, including one just before Muscle Car Madness this year. So, by the time you see the Capri out and in action again, a built 2400hp Powerglide will be backing the blown donk. A wise investment if its true potential is to be realised down the quarter-mile, which is where we’re really interested to see the Capri do work. It doesn’t take a genius to calculate that it’s a light little car with lots of tyre and even more motor, so once dialled, the timeslips should be impressive.

Interestingly, despite it being a full-blown race car with four-digit-power-making ability, Steve still wanted to keep some level of street car comfort, which is why you’ll notice that the interior has been trimmed — no bare bones tin work around here. The interior is immaculately presented, and looks like something out of a pro-streeter, with the right balance between street and strip (or, in this case, pad).

It’s all part of that progression we talked about earlier, with the quality of these builds just getting higher and higher. There is no doubt that Steve has raised the bar a few notches when it comes to local burnout builds!

This article originally appeared in NZV8 issue No. 206