Words: Simon Dudding Photos: Leo Batger

Featured in Issue No. 227 — Grab Yours Here

Building a unique car can lead you down several paths. Those that are more focused on the finished product, and have the appropriate funding, can raid the performance parts catalogue and fire a parts pile at an appropriate hotrod shop. If you’re more inclined to enjoy the journey of the build, you might even have a go at putting all those aftermarket parts together yourself — something that is fairly common in the modified car community. At the other end of the modification scale is building a unique performance car using a combination of the performance aftermarket parts market and global OEM parts bin. It takes a lot of research and industry knowledge to know what can work and if it can obtain the performance expectations required.

Clint is no stranger to modified cars having moved through the ranks of Japanese performance cars like many of us that are currently aged in our mid 40s. Clint also obtained an early affliction with Australian-built Chrysler Valiants and over the past 20 years a fair few have passed through his hands. While Clint was preparing another Valiant VG body, this American-built 1968 Plymouth Valiant was offered for sale. This was a pretty easy choice for Clint as there was a bit of history behind the car and, in particular, the relationship with the previous owner. Seb Bell had owned the third-generation Valiant two-door sedan and was talked into purchasing it by Clint as a stock six-cylinder ‘nana spec’ car.

This was after selling Seb’s Toyota AE86 as he had also decided it was time to hop into a V8-powered street cruiser. Seb drove the Plymouth in standard spec for as long as he could until poor health thwarted the modified V8 route he was hoping to achieve. Unfortunately, he lost a battle with cystic fibrosis before his dream could come to light. Seb’s parents held onto the car for a few years before deciding to offer it to someone they thought would appreciate it and fulfill Seb’s vision. Having seen Clint’s passion for Valiants and knowing he was going to build it right, Lorraine and Dave Bell passed on the car. It was fairly justified that Clint ended up with the Plymouth as, when the pair of friends went to view the car, Clint said if Seb didn’t buy it he would as it was that clean and unmolested.

The Plymouth, although familiar to Clint, threw up a few more challengers than the usual right-hand drive variants he was used to. Luckily Clint gets lots of inspiration through his day job working as an LVV certifier. Many modifications and unique builds have crossed his desk and through his shop in East Tamaki. Over the years he has seen all the right ways of modifying and many, many substandard modifications that need to be corrected before the LVVTA tag gets the green light. Clint pondered over the car and drove the Plymouth in factory spec 225ci slant six auto for half a year before pulling it off the road. He had the donor 318ci small block Chrysler engine ready to drop in as it had been the powerplant of a previous Valiant project car. That white four-door Valiant even graced the pages of NZV8 back in 2015 and had lasted the test of time under Clint’s heavy right foot.

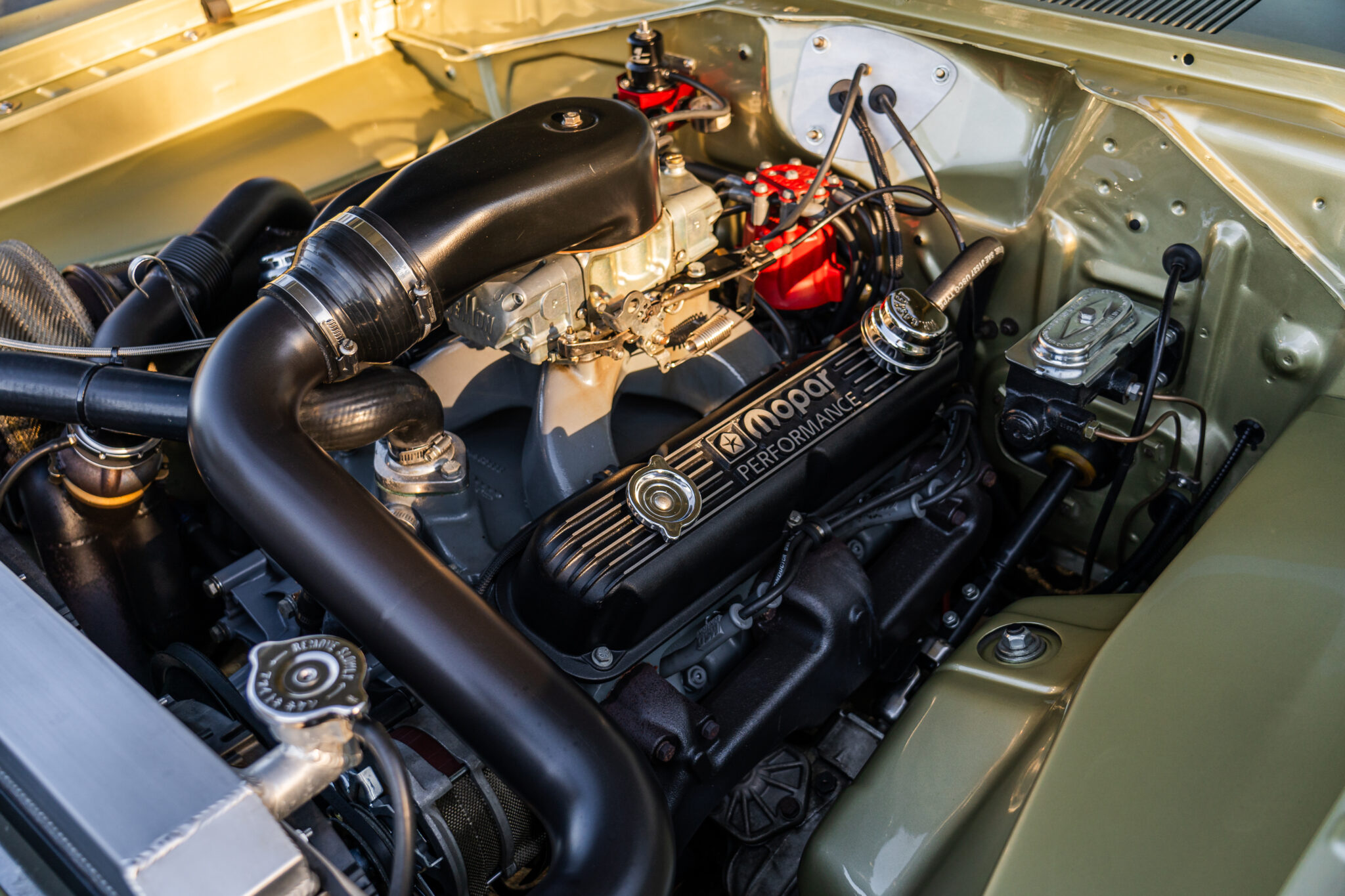

The Chrysler small block is generally a breeze to fit in Valiants even with the engine being oddly offset to clear the rather porky steering boxes of the ’60s and ’70s American spec cars. Having a single Garrett GT4082 turbo hanging off the right-hand side makes fitment tight as there were additional self-imposed requirements to be adhered to. These were simple on paper but even with the ample-sized engine bay, having the 3.5-inch exhaust straight off the turbo makes packaging tricky. The other necessity of stock appearing bodywork meant that there weren’t going to be any holes haphazardly cut through firewall or inner guards to make the assembly fit. This was going to need a rearrangement of factory fitted parts to make it work and have the desired look.

While test fitting the engine, it was decided that some things just couldn’t stay where they were. Anyone who’s tried to put a set of big tube headers in an old Mopar will know that the front torsion bars always manage to be right in the way, running inside the front chassis rails. After a bit of pondering, it was decided the front suspension would have to change to get the desired look. The K-member was seam welded and the shock towers on the inner guards strengthened to take a coil over upright. While the inner guards were strengthened, Matt at Tin Tricks smoothed and mirrored the guards by deleting the factory battery mount and filling up unnecessary holes in the process.

To make the engine bay tidier, Matt also filled the holes left by the deleted heater and relocated the wiring loom, while Clint moved the wiper motor to the inside of the firewall. It’s not something that you notice straight away but it gives the engine bay a much cleaner look. While the panel work was being completed in the engine bay, a new shifter mount was fabricated for the transmission tunnel. The body is in fairly good shape and has the just right look for a sleeper build so the rest of the tin work was left just as it rolled off the production line all those years ago. The body is still in a rust-free state after a repair carried out while at Tin Tricks that was required under the vinyl floor covering. It’s fairly remarkable that the floors were not in worse condition as vinyl seems to be an incubator for corrosion even at the best of times.

The front suspension uses a combination of improved factory items and custom built Bilstein coilovers and marks the start of Clint’s dive into the OEM parts bin. The lower control arms were strengthened and modified to suit VJ Valiant spindles and ball joints. These were chosen for their shorter steering arms to aid the fast ratio manual steering box. The new adjustable coilovers allowed fine tuning the suspension for the new powerplant and to get the front end down to the desired height. The front corners were finished off vented brake rotors from the same VJ Valiant and four-pot Toyota Hilux Surf brake callipers. Using one of the few good parts out of a Ford Explorer, the 8.8-inch complete diff was acquired.

The housing was modified to use two short axle tubes which makes it a perfect width for an A-body Mopar. Lee at Diffs Are Us carried out the work and rebuilt the limited slip differential head with new highway/burnout spec 3.23-ratio gears. These rear ends have a good following on the other side of the Pacific Ocean and have proven to be a reliable factory item. A Moser housing cover braces the differential centre, keeping all of the rotating parts in line and where they should be. The factory Ford rear brake system was retained and sits alongside a set of new spring perches. To complete the rear end and reset the ride height new lowered Mopar Super Stock leaf springs have been fitted with additional lowering blocks. KYB shock absorbers and a custom made pinion snubber keep the rear end under control when the power is being applied.

Before the engine could have a final fitment to the car, the sump was removed and bearings checked. In the previous car, it had seen one or two extended burnouts, a bunch of drag strip passes, and many street miles. The bearings and internals looked happy so the sump was buttoned up after some additional baffles were added along with swapping the oil pump back to a standard from a high-volume pump. The engine itself seems fairly basic, mostly off-the-shelf items with no parts that would be considered wild for a street car. The Jakes Performance modified carburetor and Kelford Cams camshaft really make the unusual engine combination work. Clint had built the engine himself 14 years ago and while being fairly handy with most aspects of car building, some things are better left to those with experience.

The transmission rebuild was farmed out to Eric from West Auckland Engine Reconditioners, as giving it to a Mopar specialist meant the 727 Torqueflite transmission would keep the reliability party going. Torqueflite transmissions are fairly strong but they do need some special attention, so Eric changed the essential parts for reliability with increased horsepower in front of it. A bolt in sprag stops the transmission from scattering itself on the ground and heavy-duty clutches found their way in to keep the car moving. A manual reverse pattern valve body keeps the engine revs in the horsepower sweet spot via a B&M ratchet shifter.

To feed exhaust gas to the truck-sized Garrett turbo, Dodge Ram cast iron exhaust manifolds were flipped to face forward and a custom Y-pipe fabricated. Once the exhaust gasses have done their job and spooled up the turbo the exhaust flows down to the rear of the car through Clint’s own handy work. The diminutive noise of the car really puts a stamp on it being a true sleeper. The cold side of the turbo setup flows through 3-inch piping to a front-mounted intercooler. An aluminium radiator from a Toyota Landcruiser sits just behind the intercooler. Using twin Spal fans this works well in winter but is borderline for summer — something that might get upgraded in the future anyway. After using a variety of different manufacturers for parts, MSD was called on to provide all of the spark control, including a boost retard module to keep the timing in check.

With a bunch of 11-second time slips, it’s a quick true street car and rolls around on a set of colour-coded steel wheels that make the car almost look stock from the outside. The addition of bucket seats to the interior and a few gauges are really the only thing that gives the game away. The car has proven itself as a true street cruiser as Seb wanted, just with Clint’s own twist of near-on 500hp on tap to play with at a dab of a right foot. Not that he would use that on the street, of course!

DRIVER: Clint Field

CAR CLUB: Oldschool.co.nz

AGE: 45

OCCUPATION: LVV certifier

PREVIOUSLY OWNED CARS: Lots of Chrysler Valiants, 1UZ V8 powered Nissan ute with air-bags, turbo Nissan Skyline, and currently a Valiant VG sedan and dropped Chevrolet Silverado

DREAM CAR: It’s an ongoing mental battle that changes every day

WHY THE PLYMOUTH? Completing a build for a friend who couldn’t

BUILD TIME: Five years on and off

LENGTH OF OWNERSHIP: Eight years

CLINT WOULD LIKE TO THANK: Lorraine and Dave Bell, Matt Kessing @ Tin Tricks, Nick @ Ron Wood Auto Electrical, Grant Walker @ GT Refinishers, Eric Livingstone @ West Auckland Engine Reconditioners.

VEHICLE: 1968 Plymouth Valiant

ENGINE: Chrysler 318-ci small block, factory steel crank, ARP bolts and studs, Scat connecting rods, forged pistons, modified baffled sump, heavy-duty flexplate, Powerbond harmonic balancer, Edelbrock aluminium cylinder heads, Kelford Cams hydraulic turbo grind camshaft, Comp Cams roller rockers, upgraded valve springs, Mopar M1 intake manifold, front mount intercooler, Jakes Performance modified Holley Demon 650-cfm carburetor, Dodge factory cast iron exhaust manifolds swapped to forward facing, custom Y-pipe collector, Garrett GT4082 turbocharger, 3.5-inch custom exhaust, AdrenalineR muffler, MSD distributor, MSD super conductor ignition leads, MSD 6-BTM ignition module, MSD boost retard box, two-step rev limiter, modified HJ Toyota Landcruiser radiator, twin Spal radiator fans, 16-gallon Jaz fuel cell, Bosch 044 high-pressure fuel pump, ½-inch fuel lines, Aeromotive fuel pressure regulator

DRIVELINE: Chrysler 727 Torqueflite rebuilt by West Auckland Engine Reconditioners, reverse pattern manual valve body, bolt in sprag, heavy-duty clutches and bands, 2500-RPM stall converter, deep sump, Ford Explorer 8.8-inch differential, factory Ford 31-spline axles, factory Ford limited slip differential, Moser Engineering braced differential cover, Driveshaft Specialists custom heavy-duty drive shaft, B&M Pro Ratchet shifter

SUSPENSION: Front: deleted factory torsion bars, seam welded K-member, strengthened lower control arms, braced upper shock mounts, Bilstein coilovers custom built by Ian Wilson at Autolign, VJ Valiant spindles, VJ ball joints, manual steering box. Rear: Mopar Super Stock leaf springs reset 2-inches lower, lowering blocks, KYB shocks, custom pinion snubber

BRAKES: Plymouth dual circuit master cylinder, Wilwood adjustable brake bias valve, Front: modified VJ Valiant vented rotors, Toyota Surf 4-pot callipers. Rear: factory Ford Explorer callipers and rotors.

WHEELS/TYRES: Front: Wheel Vintiques 62 series steel 15×6-inch, Federal 185-65-15 tyres. Rear: Wheel Vintiques 62 series steel 15×8-inch, Federal 225-60-15 tyres.

EXTERIOR: Original paint and body work with authentic patina, engine bay smoothed and inner guards mirrored for shape, windscreen wiper motor relocated to inside the firewall, engine bay repainted factory green

CHASSIS: Chassis connectors, strengthened front shock towers, chassis seam welded

INTERIOR: Recaro front bucket seats, Autometer tachometer, oil, boost and temperature gauges

PERFORMANCE: 11.30@120mph at Meremere dragway