Dave’s been down this road before, but ‘Phase Two’ of his ‘65 Impala build takes things to a whole new level of tuff

Words: Marcus Gibson Photos: Adam P Photographer, Lance Farrow

Power can do strange things to a person; give someone a little taste and nine times out of 10 that taste will soon no longer satisfy their hunger, leaving them yearning for more. While any kind of power can do that to a man, from wearing a badge to organising a community fundraiser, we’re talking the language of horsepower power here — one of the most intoxicating forms you can get. Add to that a sprinkling of the most addictive sports known to man — drag racing — and you’re in for a world of trouble. Goalposts are moved, dreams expanded, and sticking to a budget becomes nothing but a distant memory of simpler times.

Everyone, we’d like you to meet Dave Vea, a serious victim of the above circumstance, and a long-time fan of muscle cars of the blown big block persuasion. This is not the first time you will have come across Dave’s name on these pages. If you’re a long-time reader you will likely recall a tough-looking blown big block Impala that was knocking on the door of 1000hp in pump gas trim that we featured in 2015 — issue 126 to be exact. It doesn’t take a genius to figure out the reason we’d be revisiting the ’65 seven years later, but we’ll let Dave spell it out.

“I enjoyed it in that form, but, as you do, started to get, well not bored, but you get used to what you’ve got and you start thinking about going bigger and better. I started looking at potential upgrades. First up it was just changing the supercharger, and then it turned into the block as well, and then I was able to sell my entire old engine to Brodie.”

The Brodie he is referring to is none other than All Black Brodie Retallick, whose HQ was featured on our cover with said engine combo back in 2020. Dave says that, although Brodie was not really in the market for a blown big block, as his car was set up for a small block, after one drive, he could not get his hands on it fast enough.

With the old package now gone, the way was clear for Dave to crack on with what has been dubbed phase two. However, the goalposts of exactly what phase two entailed were rapidly shifting, and before long they had hit the point at which the body and the chassis became separated — but not for the reasons you might think. You see Dave has never been one to worry about inch-perfect door gaps, and concourse depths of gloss; he’d rather his money was poured into go-fast goodness and pro-street essentials. All his focus was put into reworking the underpinnings, with laser focus being on the engine bay. “My goal was to have one of the toughest Impalas in NZ while retaining some of the nostalgic classic features of an Impala, i.e. full interior and unobstructed boot, etc. I also wanted the engine bay to look a million bucks. To me, that was more important than door gaps or anything like that.” As with phase one, it was Craig Hammond of Pro Speed Performance who was responsible for — or perhaps guilty of — the build, and it just so happened that he had nearly everything right there on the shelf at his Hamilton shop, ready to go.

Dave recalls, “Basically, I built the car he was planning to build, so the parts were readily available. He was a very good salesman in convincing me of the benefits of whatever parts he had right there, so what do you do? You put them in.”

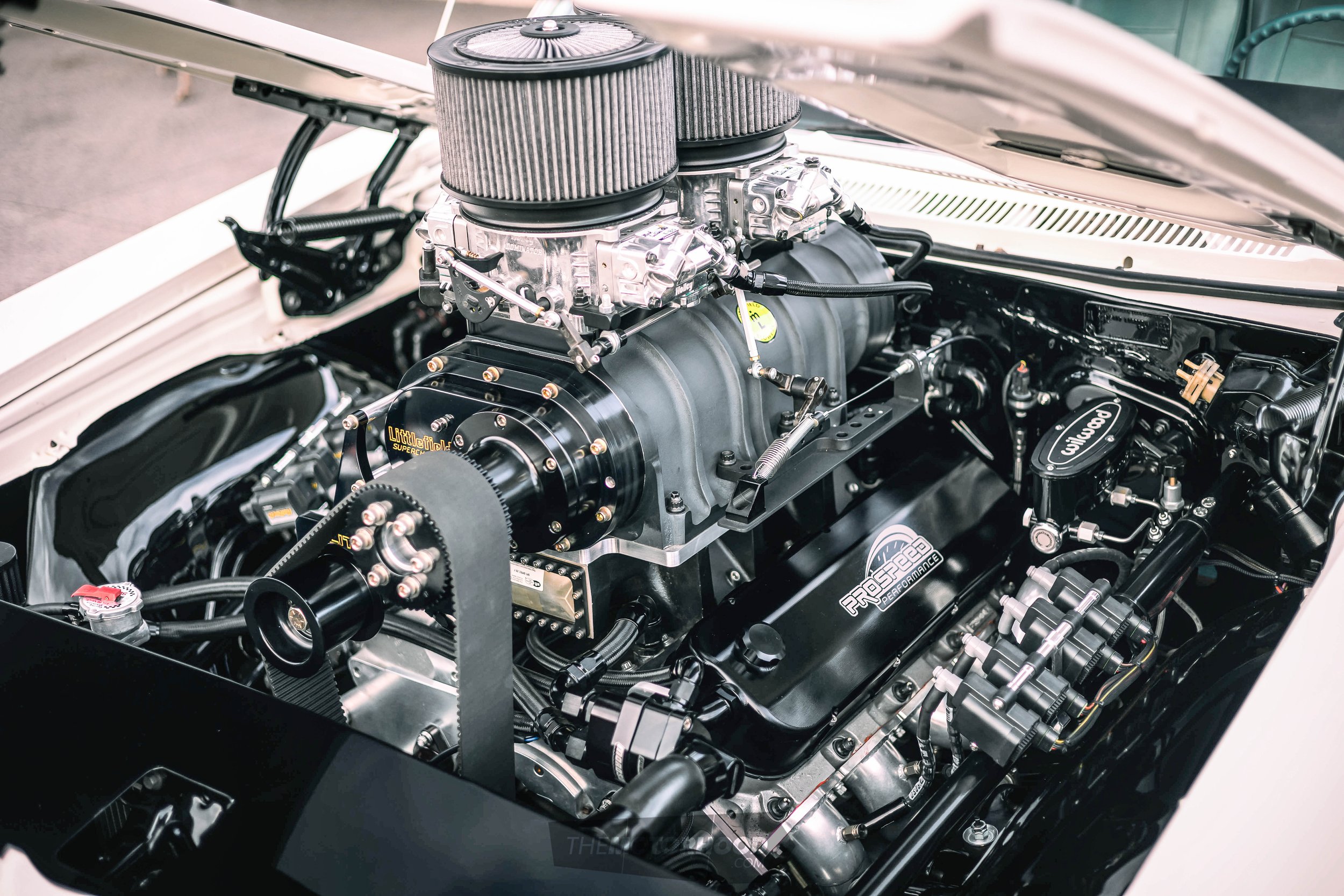

With the factory big block castings known to be pushing their luck holding together with four-digit power, where phase two was headed was no place for anything from a GM foundry. The build kicked off with the purchase of a Dart Big M block, which would receive a combination of 4-inch stroke Callies crank and Oliver 6.7-inch rods to create 532 cubes. CP pistons with Total Seal rings and beefy Trend pins bump compression to 9.7:1, to make the most of the intended fuel of E85. Marsh Motorsport took a pair of Brodix BB-2 Plus heads, gave them a port job, and readied them for Rev 2.300-inch intake valves and 1.880-inch Inconel exhaust valves. The heads also run a T&D shaft rocker system and take orders from a custom ground roller from Bullet Racing.

Sitting right on top is the blower that sparked phase two, a big ole Littlefield 16-71, and a pair of E85-specific 1150 cfm Dominators from the ethanol guru, Mark Sullens. Firepower would come from Haltech individual smart coils controlled by a Haltech VMS ECU. One of the big dogs of the Haltech range, the VMS gives the opportunity to run things like traction control and also control the CO2 shifter for the trans. However, what completely sold Dave was the built-in safety fail-safes that could be set.

“My fear was I’d have my foot up it and not be watching any of the gauges when something goes wrong. This way, the ECU should save the engine for me.”

Alongside wiring in the new ECU, the car was rewired from front to back with a complete new loom. Having a glance over the spec panel will tell you it’s a monster of a package, and, dare we say it, one of the wildest street combinations we’ve seen in some time — and it has dyno sheets to prove it. Before being slotted into the freshly painted bay it was strapped on the engine dyno at Marsh Motorsport where, with 1:1 pulleys (10psi) and a redline of 6750rpm, it punched out a healthy 1200hp and a chassis-twisting 1044ft·lbs of torque.

By no means is that the end of the road for this package; 1200 was just deemed a good starting point. Later this year Dave plans to bring out the big guns — a smaller pulley— in a dyno shootout with a good mate’s twin-turbo LS deal. On the line is a steak dinner. Just how much more the 532 has remains to be seen, but Dave is understandably eager to find out — wouldn’t you!

Even at the current output, the boys knew it would be testing the limits of the factory front end, so some clever tricks are at play. Under the dash you’ll find a bar from A-pillar to A-pillar that also has bars extending forward to connect the chassis. Combine these with the front and mid motor plates and the result is a very stiff front end.

“It’s tight,” Dave said. “I found as fast as it was trying to go, it felt safe and the car wasn’t moving around. For its size and the age, to me it sits on the road like a modern car; it’s not twisting, etc. — although that might be different once the front wheels leave the ground. I’m yet to attempt that.” The front motor plate also doubles as a mount for the accessory drive, a trick piece of CNC’d kit engineered by Craig. One thing you’ll notice missing is the power steering pump; this has been replaced with a boot-mounted Holden Vectra unit to keep things as clean as possible. The rear end is also completely new.

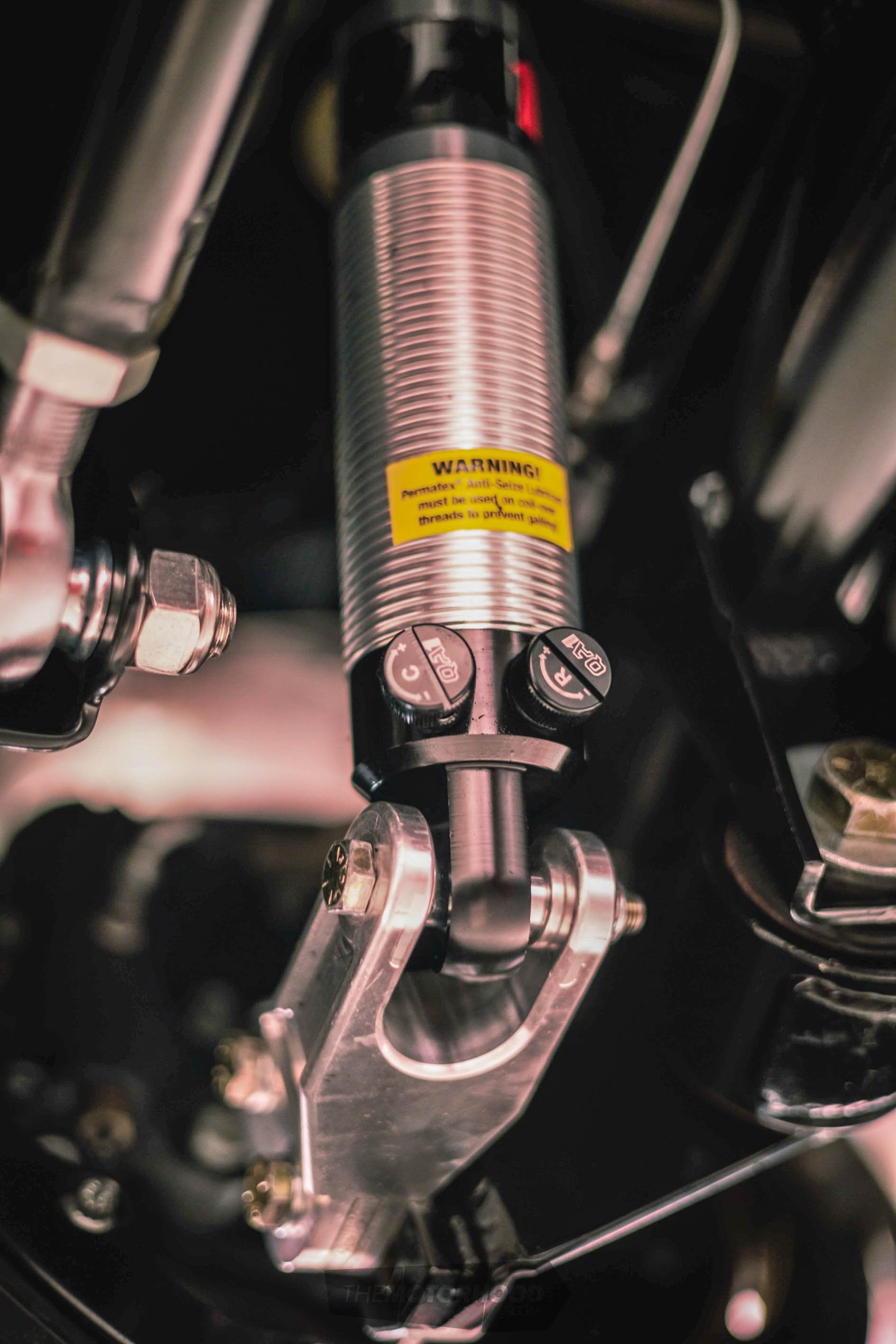

The tough 12-bolt from phase one was onsold to make way for a Strange nine-inch with 35-spline axles and a Strange S-track centre with 3.5 gears. Set up with factory mountings, it swings off a set of Global West control arms and QA1 double adjustable shocks. While Dave said he’d have loved to go full four-link, back halving the car wasn’t in phase two plans — you have to draw the line somewhere, right? The same goes for the tubs; there aren’t any despite the 295/65/15 Mickey Thompson radials. Instead, the inner guards received some serious nip and tuck to ensure the Impala would swallow the 30-inch tall tyres with ease.

This is, after all, a family hauler first and foremost, and tubbing and back halving may have deemed the rear seat surplus to requirements — not something Dave or wife Hayley would be keen on. It’s also why the roll cage that is going in this winter will have removable bars, with everything but the main hoop un-boltable for those Sunday drives. But, come race day, the nine-second spec cage can easily go back in.

Just before the magazine went to print, Dave got his first taste of racing. Having never been down the strip, and also driving an untested machine, he took things easy, both for his own benefit and to avoid the wrath of track officials by not breaking out in an uncaged machine.

“Two mates came, Glenn Boyd, and Jarrod (Half Truth) Mahon, who both have national records. He walked me through it all. I was instructed to run only to half-track. On my first run, I was so nervous I was in top gear after two metres, but I did what I was told and took the foot off and coasted to an 11.7. The second run was pretty much identical. They said just keep doing half-tracks, as I’d break out.”

By the fifth, and final, pass, and after a half-track power skid, Dave was ready to send it and risk getting a slap on the wrist. But fate intervened when the trans cried enough — it’s not just any old T400, either; it’s a 15000hp-rated unit from ATI. With no first or reverse, it was on the trailer for the day. But all-in-all a successful first time out, and the first of many we’re picking.

Over the winter months, the trans will be repaired and upgraded, the CO shifter set up, and other ECU trickery dialled in. With the cage also going in, along with new rear radials, it will be back to the strip for the new season, where full times slips await.

While we’re not going to jinx Dave, needless to say, once dialled, this has the makings of a seriously quick street car, one that can still go grab an ice cream with the kids on a hot summer’s day. What more could you ask for? As for phase three — well, I guess we’ll just have to wait until the buzz of 1200 horses underfoot wears off.

This article originally appeared in NZV8 issue No. 204