It’s what’s inside that counts, and, for all the patina this Galaxie wears, the underside is a work of art built around a 598ci Boss and full Art Morrison chassis

What the hell are those boys at NZV8 doing now, putting that thing on the cover!? you might be asking. Just wait a second before you pen that letter of indignation, half wondering whether we’ve all suffered the unpleasant side effects of daily methylated-spirits consumption. As that overused old adage goes: one should never judge a book by its cover. We’re talking here about the monstrous Galaxie bolted together by Brian Mathews and his mates.

However you look at the path the Galaxie has trodden to get to this point in its life, the concept of a gradually evolving build that has spiralled out of control is impossible to ignore. Then again, a degree of premeditation must have been involved, because one does not simply end up with a full Art Morrison chassis and 598ci Jon Kaase Boss Nine engine sitting in the workshop — although maybe a recycling bin overflowing with green glass bottles can take some of the blame for that.

Why such an oddball car in the first place? The first-gen Galaxie is not a terribly popular option when people think of these cars, but, as Brian explains the story, you begin to understand that things all came down to chance. Chance began one Saturday at the Kumeu Classic Car and Hot Rod Festival, when Brian and a group of mates stumbled across the car — a 1959 Ford Galaxie with some strange charisma.

“I kept looking at it, and it kept growing on me. We walked off, and, about half an hour later, I called my wife and said, ‘I’ve found a car. I know we can’t really afford it, but I think you’ll like it’,” Brian explains. “I sent her some photos, and her first question was, ‘Where are you going to park it?’” Telling the seller he was dead keen on the Galaxie, Brian handed over a $200 deposit. It’s lucky the seller was a man of his word — when the transaction was finalized the next day, he explained to Brian that he could have sold the car about six times over that weekend!

With its generous helpings of sunburn, surface rust, and overall patina, the Galaxie was the perfect low-maintenance cruiser and bar-leaner for Brian and the lads to enjoy. This stress-free period lasted for around two years, but, inevitably, he and the guys began considering that dangerous mantra: it’d go better with a bigger engine. “One day at smoko, my good friend Andrew Gate mentioned that he used to have a 429 in an XA [Falcon] and it went bloody good,” Brian says of the step that saw the build begin to spiral out of control.

A healthy 429ci big block of 1968 vintage was sourced through Silvester V8 Performance, and quickly taken to Marsh Motorsport for a complete freshen up, where it was dynoed at 400hp.

To maximize the fun factor that the car was all about, there was only one way for Brian to make use of the 429’s grunt — through an old-school four-speed manual box. A beefy Toploader was sourced, along with the Quick Time bellhousing, McLeod twin-plate clutch, and hydraulic components required for the conversion.

“We got it going for Beach Hop, but it was one of those stories [that] you hear all the time — we were working on it right up until a night or two before the Hop,” Brian says. “We drove it down there and, on the way, saw someone broken down on the Kopu-Hikuai [Road]. We went to help him out and left the car idling, and it began to overheat. Other than that, we had a really good time.” It would have been hard not to, as most will know that ‘429’ is a magic number in Ford folklore. Of course, despite it ticking all the right boxes, the big block was never destined for a ‘happily ever after’ ending, and a conversation with Graeme McNeill at Mac’s Speed Shop hammered the final nail into its coffin.

As Brian says, “I’d always wanted a Boss 429 motor, and Graeme told me of a guy in the US, Jon Kaase, who manufactured alloy Boss heads, rocker covers, intake manifolds — everything to bolt a Boss top end to a typical 429–460 big block.”

Heading home and browsing the internet simply sealed the deal for Brian, and, with wife Nicole’s enthusiastic permission, he found himself on the phone to Jon Kaase, explaining what he was after. Of course, Jon’s no one-trick pony, and, with a range of Boss options from an aspirated 429 through to a supercharged 600-cuber, Brian had a tough choice to make.

“I asked Jon, ‘What do you recommend?’ “He basically asked, ‘What do you want?’, and gave me the options. “I thought the [naturally aspirated] 598 sounded good,” Brian says. “Then I asked him what I should expect from it,” Brian laughs, “and Jon tells me, ‘You know how your 429 just wants to break traction in the wet? This thing will be like that, but in the dry!’” — and it should, as it was built to order, and dynoed at over 800hp.

The shipping side of things was taken care of thanks to the many overseas contacts of Brian’s good mate Scott Campbell, who operates Fast Parts, and the guys enjoyed a regular Christmas party when the shipment arrived — even though it was the middle of the year!

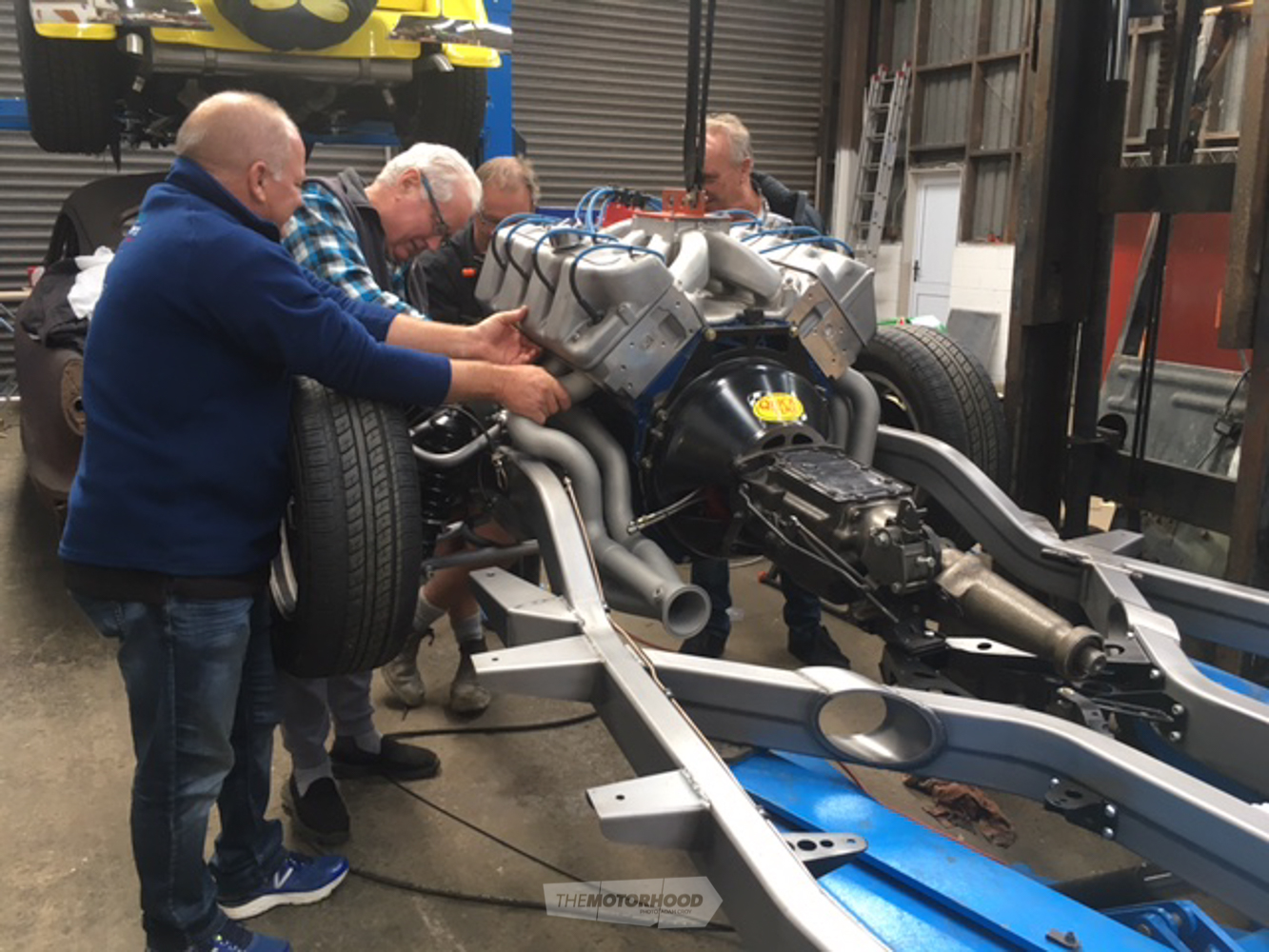

Of course, the huge motor was far from a bolt-in affair. No headers would fit the stock chassis, not to mention the fact that the chassis wouldn’t handle the torque anyway. “I went down the path of looking at an aftermarket front clip for it, but a few mates steered me away,” Brian recalls. “They told me, ‘Look, even though it sounds like a big purchase initially, you’d be best to get a full Art Morrison chassis.’ They were right on both counts — it was a big purchase, but I’m glad I did it.”

Luckily, Art Morrison had previously built a chassis for a ’59 Galaxie wagon, so plans were sent over. Before the order was placed, Brian and the boys spent many an hour going over the measurements and the car to ensure that everything would line up. “When the chassis arrived, I thought it would be easy — just take the body off, mount the engine and box, build the headers and exhaust, and drop the body back on. We pulled the 429 out and stripped the car in February 2017, with the goal of having it ready for Beach Hop — but that was never going to happen,” Brian ruefully admits, with the benefit of hindsight. However, thanks to the help of his mates, and master fabricator John Hinton, things certainly went a whole lot quicker and more smoothly than they could have.

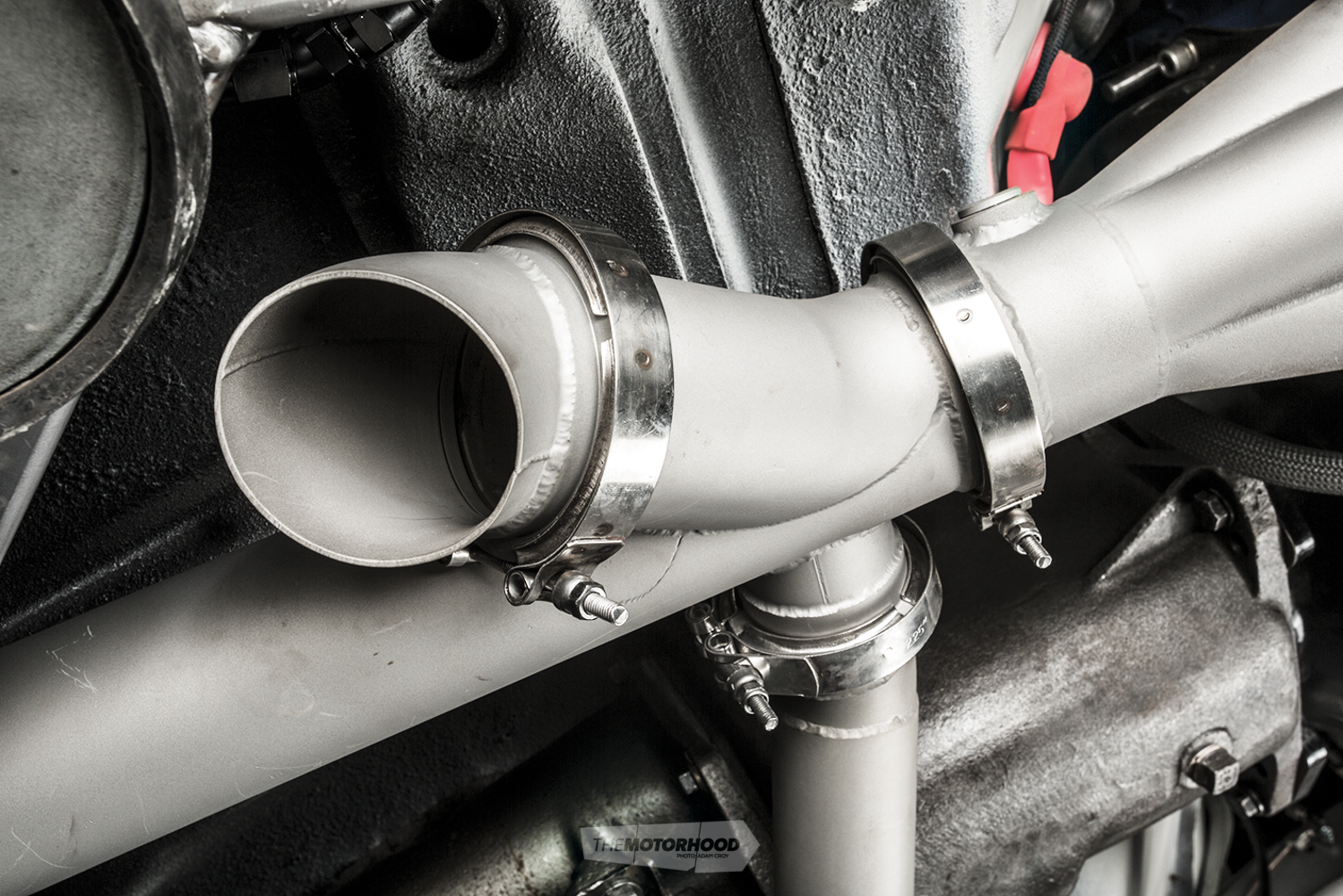

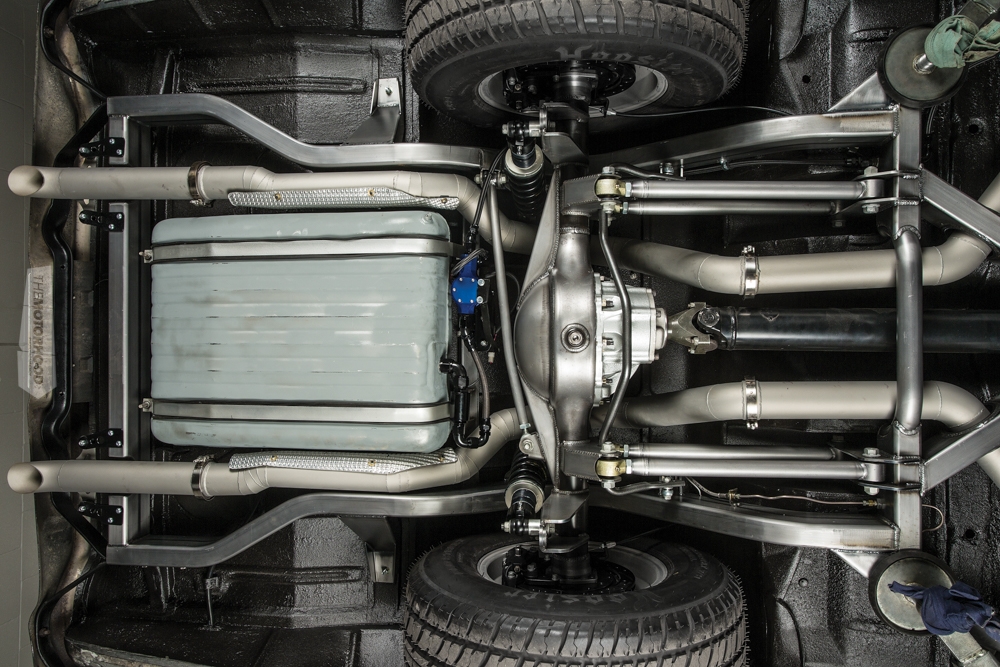

John mounted the engine and gearbox in the chassis, and made a custom set of engine mounts and transmission cross member, which meant that he could then piece together an intricate pair of four-into-one headers with massive 2¼-inch primary pipes, and a full three-inch exhaust system with the obligatory header cut-outs.

What you may not notice, though, is the care that John put into the fabrication — not just on the exhaust but with each and every bracket beneath the car, including those that will never be seen. From those that support the exhaust to the bracket on which the fuel pump is mounted, the quality of finish is to a consistent and extremely high standard.

That standard was carried through when John welded on the chassis outriggers for mounting the body, refabricated the boot floor around the new chassis and tubs around the 29×12.50R15 Hoosiers, and crafted enclosures in the rear seat area for the four-bar assembly. The crowning glory came courtesy of paint wizard Rodney Holland, who ensured that everything would be presented exactly as Brian wanted it — and we’re not talking about the patina.

“A lot of people thought I should paint the chassis, but it was finished in what Art Morrison calls ‘Bright Steel’, and I didn’t want to paint it,” Brian says. “I wanted to clear-coat it, and Rodney had just the stuff. We brought it over, rubbed it down, prepped it, and he sprayed on the clear. It looks awesome, and having what looks like an unpainted Art Morrison chassis under it is what freaks people out the most!”

The successful marriage of chassis, driveline, and body marked a great milestone in the build, which, although quick, had never once compromised on quality. This was finalized with Adrad custom-building a huge alloy radiator to suit, and Brian locking down his neighbour, Tony Conaghan, over a series of weekends to wire the whole thing up.

Now, with the Galaxie back in business and ready to turn pump gas into melted rubber and cheesy grins, all that’s left on Brian’s to-do list is to have the rear seat modified to fit around the tubs before summer rolls around — after all, it’s all about fun times with good mates, and the more who can enjoy the Galaxie with him, the better. Just a word of advice if you see him around — don’t ask when it’s going to be painted. As he and the boys say, “It’s taken 58 years for it to look this good, why would we paint it now?”

1959 Ford Galaxie

Engine: 598ci big block Ford, Kaase Boss Nine Shotgun package, Ford Racing cast-iron block, four-bolt mains, 4.60-inch bore, 4.50-inch stroke, 10.30-inch deck, Callies steel crankshaft, Callies steel rods, Diamond forged pistons, Total Seal file-fit rings, 10:1 compression, Comp Cams Kaase K2 hydraulic roller camshaft, Crane Cams Z-bar roller lifters, Trend pushrods, Kaase Boss Nine alloy heads, 2.30-inch intake valves, 1.90-inch exhaust valves, Comp Cams beehive springs, WW Engineering roller rockers, Kaase Boss Nine single-plane intake manifold, 1050cfm Quick Fuel Double Pumper carburettor, MagnaFuel electric fuel pump, MagnaFuel fuel-pressure regulator, modified stock fuel tank, MSD Pro Billet distributor, MSD 6AL ignition, custom four-into-one headers, 2¼-inch primaries, three-inch exhaust, crossover pipe, exhaust cut-outs, Flowmaster mufflers, Kaase aluminium oil pump, Moroso oil pan, Adrad alloy radiator, twin thermo fans, custom fan shroud

Driveline: Ford Toploader four-speed manual, Quick Time bellhousing, McLeod steel flywheel, McLeod twin-plate clutch, McLeod hydraulic release bearing, Art Morrison braced nine-inch diff housing, Strange Engineering alloy centre, 3.75:1 ratio, 31-spline Strange Engineering axles, Strange Engineering billet yokes, custom driveshaft

Suspension: Art Morrison tubular front control arms, JRi adjustable front coilovers, Art Morrison parallel four-bar rear, JRi adjustable rear coilovers, adjustable mounting brackets, rear Panhard rod, front and rear sway bars, power-assisted rack-and-pinion steering

Brakes: RRS under-dash brake booster, RRS reverse swing-mount pedal box, RRS master cylinder, Wilwood proportioning valve, Wilwood four-piston front calipers, Wilwood two-piece front discs, Wilwood four-piston rear calipers, Wilwood rear discs

Wheels/Tyres: 15×5-inch and 15×10-inch American Racing Torq Thrust D wheels, 225/60R15 front tyres, 29×12.50R15LT Hoosier Pro Street rear tyres

Exterior: Second-hand hood, original paint, tubbed rear guards, modified boot floor, modified rear floor, custom body mounts, custom radiator cover panel

Chassis: Full Art Morrison chassis, custom engine mounts, custom transmission cross member, custom mounting brackets

Interior: Original interior, Smiths gauges, Hurst shifter

Performance: 809hp at 6000rpm, 779lb·ft at 4900rpm

Brian Mathews

Car club: Southside Streeters

Age: 57

Occupation: Earthmoving contractor

Previously owned cars: 1970 Ford XW Fairmont, a couple of 1954 Ford Populars — one with a 351W four-speed, one with a 332 Y-block auto

Dream car: A late-model Bentley GT on an Art Morrison or John Hinton chassis, powered by a Jon Kaase Shotgun engine

Why the Galaxie? To be different. One thing led to another …

Build time: Nine months

Length of ownership: Five-and-a-half years

Brian thanks: Andrew and Glenis Gate from Andrew Gate Contractors, for allowing me to take over their workshop, and Andrew, for all his encouragement, counselling, and many hours of time and advice; Graeme McNeill from Mac’s Speed Shop, for suggesting [that] I check out Jon Kaase Racing Engines; Scott Campbell from Fast Parts, for organizing the engine build and shipping programme; Tony Marsh from Marsh Motorsport, for engine-build advice; John Hinton, for the many, many hours of hard work, free advice, time, and laughs; Keith Hunter from Keith Hunter Builders; Dennis Harrington; Bill Douché; Bob Carlyle, for the gearbox build; Rodney Holland from Rodney’s Restorations, for all the chassis and firewall paint and prep work; Tony Conaghan, for a massive wiring recondition, and advice; Colin Brady, for donating the hood; and Kerry Earl for transporter trailer usage; and, last but not least, my wife, Nicole Parker, for her endless encouragement and support. Without her understanding, none of this would have happened.

This article originally featured in NZV8 issue No. 152 — to get your grubby mitts on a print copy, click the cover below