This tough Cortina is proof that with some know-how and hard work, it’s still possible to build a show-stopper on a budget

When Allan Norris debuted his ‘BAD EH’ Holden EH back in 2005, it blew people away. From the tubbed rear end through to the motor that was clean enough to eat off, the undercarriage in which you could see your own reflection, and the flawless leather that adorned the interior, it was a hell of an impressive machine. But there’s no doubt, even for the uninitiated, that it’d take a fairly decent chunk of cash to replicate it. So, when Allan got the itch to build another car, some six-odd years after having the EH on the road, he knew what could potentially happen.

Ironically, it was the mint condition of the EH that was partly behind the drive to build something else — something a bit less precious, a little more relaxing to drive; something to which Allan could throw anyone the keys.

However, working out what could be built on a budget, tick all the boxes, and stand out from the rest took a bit of thinking out — or it would have had Allan’s partner, Stacey, not been a long-term Mk. II Cortina fan.

With the plan to build a low-budget Cortina now agreed on, the search for a suitable donor began, but, despite these cars being among the more common vehicles on the roads back in the ’70s, finding a good one almost proved to be a fruitless task. While happy to deal with worn or missing mechanical parts, both Allan and Stacey really had no patience for dealing with rust and the hurdles it would add.

This meant countless trips up and down the country, including one on Christmas Day to see a car that Allan swore was going to be ‘the one’ — a car that, like the rest, turned out to be a dud. Then it finally happened — Stacey received a panicked phone call one day on the way home, telling her to hurry up, as Allan had found a minter, and they had to go and look at it right away. A two-hour drive through Auckland’s glorious Friday night rush-hour traffic became worthwhile when, indeed, the car turned out to be exactly the mythical, rust-free Cortina that Allan had been searching for.

While happy to deal with worn or missing mechanical parts, both Allan and Stacey really had no patience for dealing with rust

After being push-started down the wrong side of a busy road, the old girl was driven to its new home, where it’d soon undergo its major transformation. After the Cortina had been driven for a few weeks, Allan had a solid plan of what was and wasn’t needed from it. The entire running gear was pulled and put up for sale, from radiator through to exhaust tip. After all, despite the plans being to build the car on a budget, Allan’s never been one to cut corners; the build would be undertaken with just as much care and attention to detail as that of the EH.

Being a welder by trade, Allan wasn’t afraid of getting in and getting his hands dirty, but he wasn’t alone, with Stacey also being hands-on with the build right from the get-go.

While Allan’s first task was to cut out the metal that either wasn’t required or needed to be moved elsewhere, Stacey was given the unenviable task of removing the underseal.

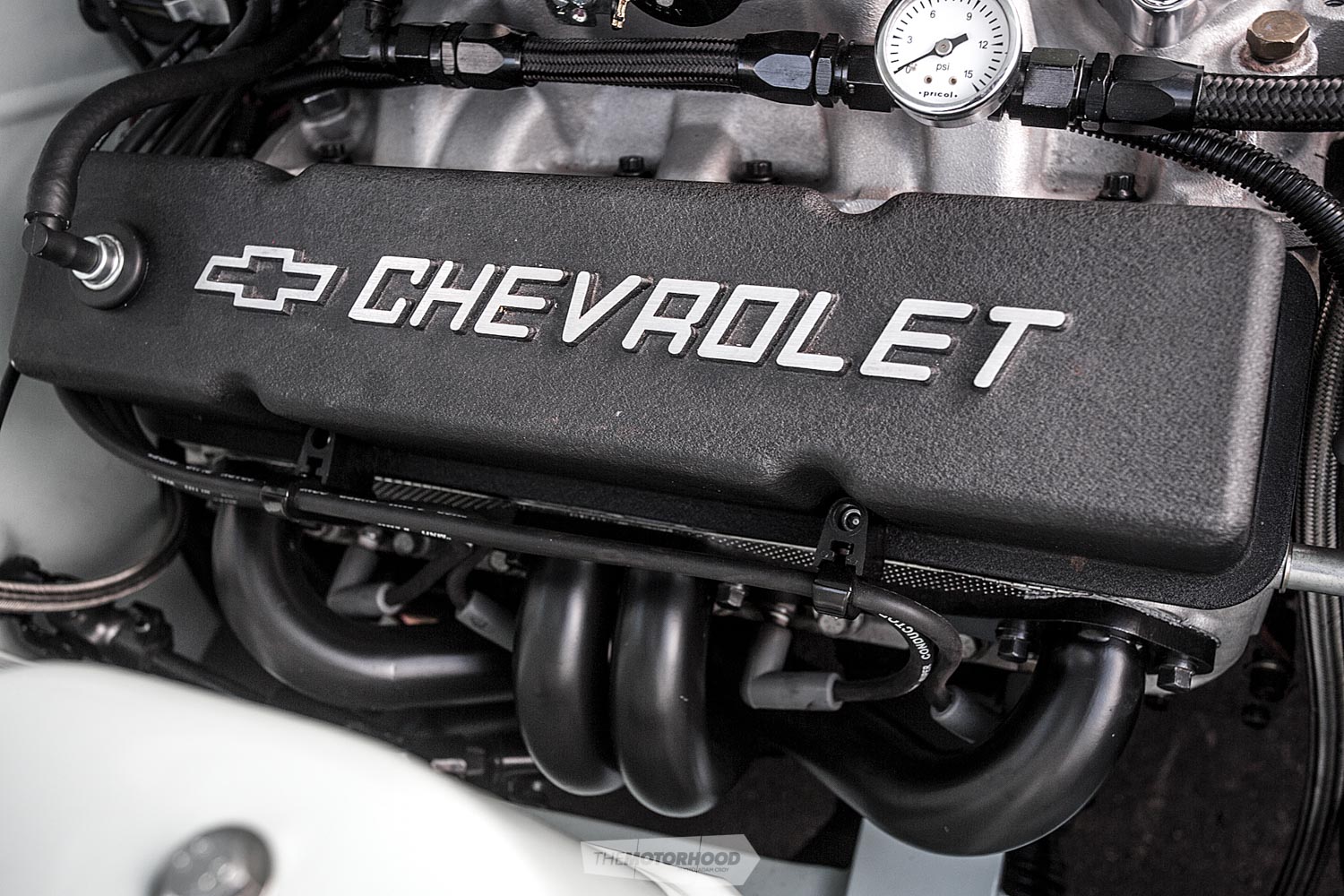

During the midst of this, an old 350 small block Chev was dragged out from under the workbench and delivered to the team at Papakura Engine Specialists, with the simple instruction: build something mild, so the missus can drive it.

“A custom brace was fabricated under the dash for the twin vh44 brake boosters, cleaning up the engine bay.”

While that combo (which would turn out not as mild as intended) was being knocked up, the firewall in the car was pushed rearwards and the transmission tunnel rebuilt in the same manner. Friend Isaac Kearns was called in to help out in this area, cutting, rolling, and swaging up replacement panels, which look as if they’ve been there since the car rolled off the production line back in 1968.

Using the work Terry Bowden performed on the EH as a guide, a set of chassis connectors was created and stitched into place; again, the connectors look as if they came that way from the factory, such is their integration into the vehicle’s structure.

With a clear idea of what the completed engine bay should look like, as well as the knowledge that there would be minimal room when the engine was fitted, a custom brace was fabricated under the dashboard and twin VH44 brake boosters were mounted to it. Not only did this clean up the engine bay, but it would also help to provide braking assistance to the soon-to-be-rapid Cortina.

While Allan was deep into cut-and-weld mode, the dash panel was cut out and replaced with panel steel, which would allow for Auto Meter gauges to be fitted later on, sharing the under-dash real estate with a reverse-mounted brake master cylinder.

Meanwhile, the motor those gauges would be monitoring was coming together nicely at Papakura Engine Specialists, with Keith Black pistons being fitted to the stock rods before reassembly. Edelbrock E Street heads, complete with Crane Cams roller rockers and 2.02-inch inlet and 1.6-inch exhaust valves, were soon attached, and, with the addition of a 750cfm Quick Fuel carb, it wouldn’t be long before the engine could be fired.

The new motor could have been kept below the stock hood, but, to give the car a bit more attitude, Allan hit up Mike Shaw at Mike Shaw Fibreglass for a fibreglass hood and cowl. While Mike didn’t have a Mk. II bonnet in stock, he was more than happy to use Allan’s as a mould from which to make a new one. Allan and friend Les then grafted an off-the-shelf cowl scoop onto it. As part of that same purchase, Allan came away with a fibreglass boot lid — not that the little Cortina really needed to go on a diet, mind you.

“Allan’s research had led him to learn how to integrate a modified and strengthened Ford Escort cross member and steering rack into the car.”

Of course, with Allan being on the anal end of the perfectionist scale, the body took up plenty more of his waking hours before it was considered even close to being ready for paint.

Fortunately, his good friend, talented panel beater Carl ‘Hollywood’ Johnson, was on hand to help with the final touches. When Allan was finally happy with the Cortina’s silky-smooth flanks, friends Allan Farmer and Warrick ‘Wokkie’ Smith came in to help out with the paintwork. After plenty of discussions about exactly what the final colour would be, in the end, the car’s factory colour of Glacier White won out.

On the car’s return from paint, Allan and Stacey got stuck into piecing the car together, taking plenty of time to ensure things were done the right way, rather than the easiest way. Included in this task was de-looming the engine bay. With a host of MSD ignition components being connected at the same time, this was no small job.

Always thinking ahead, Allan’s research had led him to learn how to integrate a modified and strengthened Ford Escort cross member and steering rack into the car. This not only allowed for better steering feel and geometry but also created more room within the engine bay.

Attached to either end of the subframe are adjustable bottom arms, which, in turn, mount to Subaru-sourced coilover shocks and springs. Diffs R Us was called on to help with mating XF Falcon front discs to the Escort stubs, which Allan has paired with VR Commodore calipers. The rear end assembly is a touch simpler, with XR8 discs and calipers on a narrowed XR8 diff working in conjunction with stock leaf springs and tramp bars.

Connecting both ends is a GRP Automatics–built TH350 trans along with a 3000rpm stall converter — this is meant to be a mild-mannered street car, after all.

If you didn’t know much about Cortinas, you could be fooled into thinking the interior of the car had been left stock, but it’s just the attention to detail and clever planning that make it appear that way. The stock seats were sold off with the original running gear and have been replaced with late-model Toyota items, relieved of their headrests before being re-trimmed. The trim work, along with the replacement headlining, was the work of PJ Upholstery.

The finishing touch to the four-year, on–off build was getting the car tuned at C&M Performance, the result being a healthy 282hp at the wheels. When you realize that the car weighs in at just 1140kg with a full tank of gas, that’s plenty of power for plenty of fun.

Sure, the build took a little longer than expected, but, for Allan, building the cars is a part of the fun, and the final result looks as if it should have cost two or three times what it did. The goal was for a clean-looking, quick streeter — and that’s exactly what’s been achieved. It is the perfect tribute to a great mate lost far too soon, whose name now adorns the boot lid. This one’s for you, Jordy, and we’re sure you’d be as proud as Punch to see it!

“The finishing touch to the four-year, on–off build was getting the car tuned at C&M Performance, the result being a healthy 282hp at the wheels”

Allan and Stacey Norris

Car club: Mukka’s Inc

Age: Somewhere between 30 and 50

Occupation: Welder (Allan) / Government agency (Stacey)

Previously owned cars: Big block Holden HZ, ’32 Ford coupe, ’57 Chev, five Holden EHs, ’67 Camaro RS/SS, 351 XR Falcon, Holden HQ, Cortina Mk. V, plus a few more

Dream car: Allan’s got his (EH), and Stacey’s still dreaming of the General Lee

Why the Cortina? We wanted something that wasn’t so common, plus Allan was getting itchy feet to build something

Build time: Three years

Length of ownership: Four years

Allan and Stacey thank: Our girls, Corky and Vada; Isaac Kearns; Carl ‘Hollywood’ Johnson; Bimbo; The Flappers (Jason and Christine); Marianne Te Namu; Allan Farmer; Les ‘Mr Bean’ Ranger; Karl Ristic; Warrick ‘Wokkie’ Smith; Bev, Leoni, and Trish; and the team at C&M Performance

1968 Ford Cortina Mk. II

Engine: 350ci small block Chev, stock crank, stock rods, Keith Black pistons, 10:1 compression, Comp Cams Thumpr camshaft, Edelbrock E Street heads, 2.02-inch inlet valves, 1.6-inch exhaust valves, Crane Cams roller rockers, Edelbrock Performer intake, 750cfm Quick Fuel carburettor, K&N air filter, Holley Blue fuel pump, Holley fuel-pressure regulator, ½-inch fuel line, MSD 6AL ignition, MSD coil, MSD ignition leads, block-hugger headers, three-inch exhaust, Coby muffler, custom radiator, Zirgo 14-inch electric fan

Driveline: GM TH350 transmission, 3000rpm stall converter, Ford XR8 diff, four-spider LSD, 3.36:1 ratio, Falcon driveshaft

Suspension: Modified and reinforced Escort cross member, Escort rack, adjustable bottom arms, Escort stubs, Subaru coilovers, stock rear springs, Gaz adjustable rear shocks, tramp rods

Brakes: Reverse pedal booster, Falcon master cylinder, two VH44 boosters, XF Falcon front discs, VR Commodore calipers, XR8 rear discs and calipers

Wheels/Tyres: 15×5-inch and 15×8-inch Weld Superlite 2 wheels, 175/65R15 and 225/60R15 tyres

Exterior: Fibreglass bonnet, fibreglass boot, fibreglass scoop, Falcon GT-HO bonnet pins, 2K Glacier White paint

Chassis: Plated front rails, custom chassis connectors

Interior: Modified Toyota front seats, Dynamat insulation, SAAS steering wheel, B&M Quicksilver shifter, Auto Meter gauges, custom dash

Performance: 282hp (at the wheels), 312lb·ft at 5000rpm