The Chrysler big block is one of the heavyweights of the hot rodding world, and for good reason. Its design accommodates for massive cubic displacement, and an abundance of off-the-shelf aftermarket parts has made possible all manner of powerful and reliable engine combinations.

But what if you’re not an off-the-shelf kind of person? Cue the dramatic entrance of Tony Baya, long-time hot rod builder and full-time genius — well, that’s a credential we gave him, if he’ll permit it. As the proprietor of Limitless Engineering, Tony looks at everything with an engineer’s inquisitiveness — how does it work, and how can I make it better?

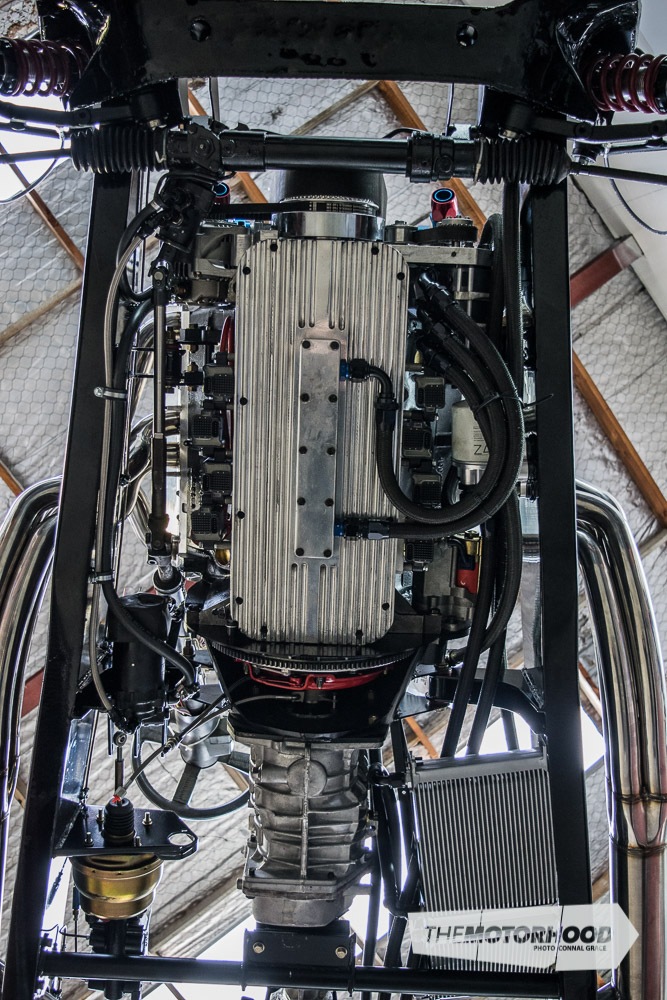

Having done all the usual hot rod builds, his latest has seen him push every conceivable boundary of hot rodding as we know it. While the formula is a standard one — think ’28 Dodge Tudor body, blown Mopar big block, Jaguar rear end — the way he’s gone about it is truly phenomenal. For proof of that, we need not look any further than the power plant.

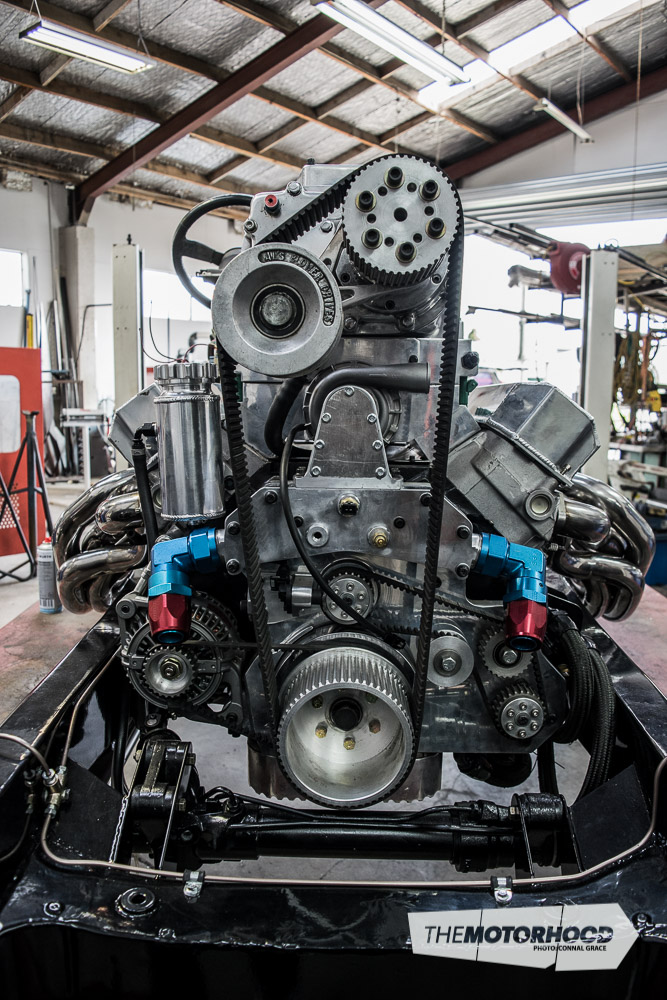

This is a 500ci big block Chrysler, based around an original cast-iron 440 block, but what’s inside is pretty much a given. We want to look at the rest of it.

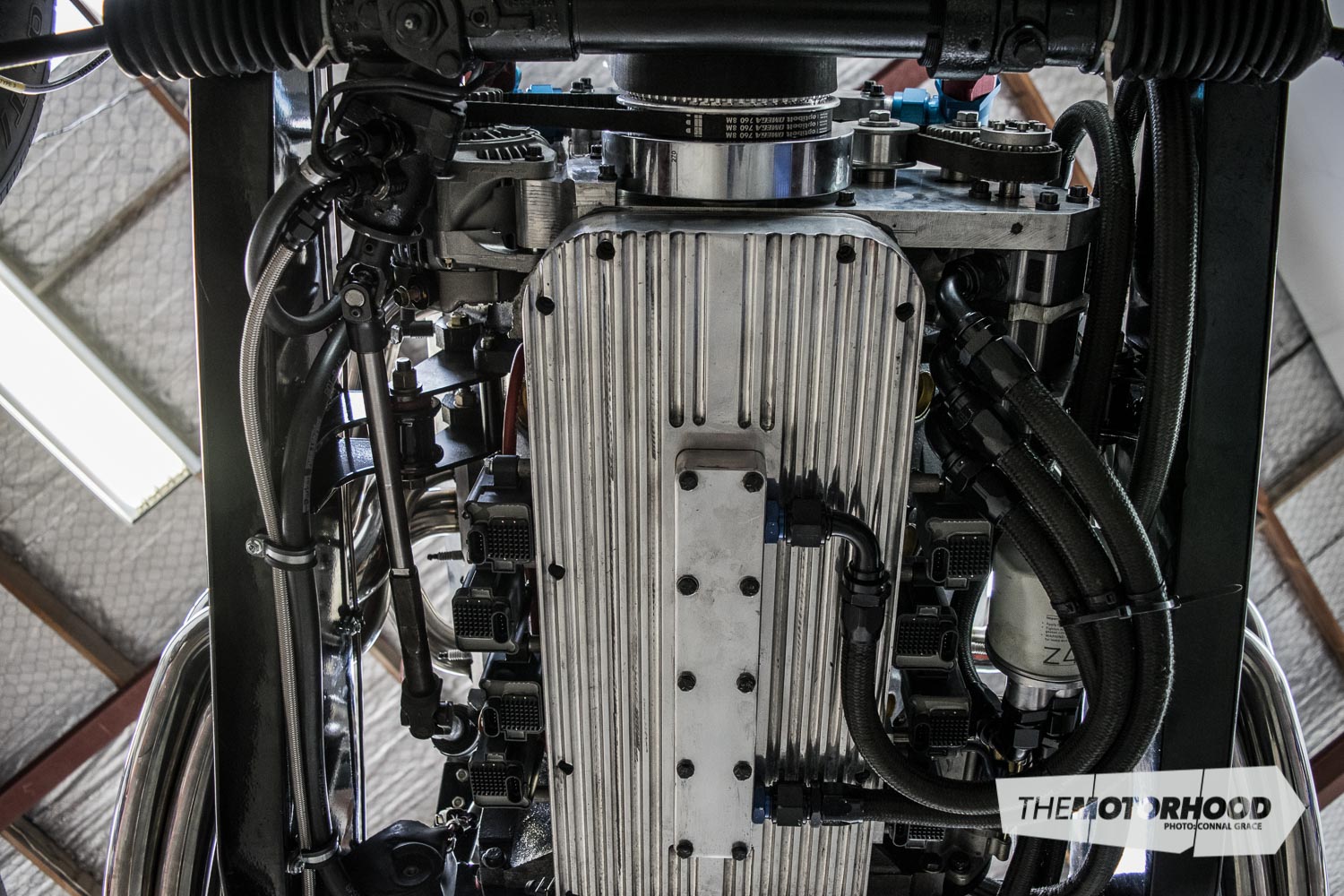

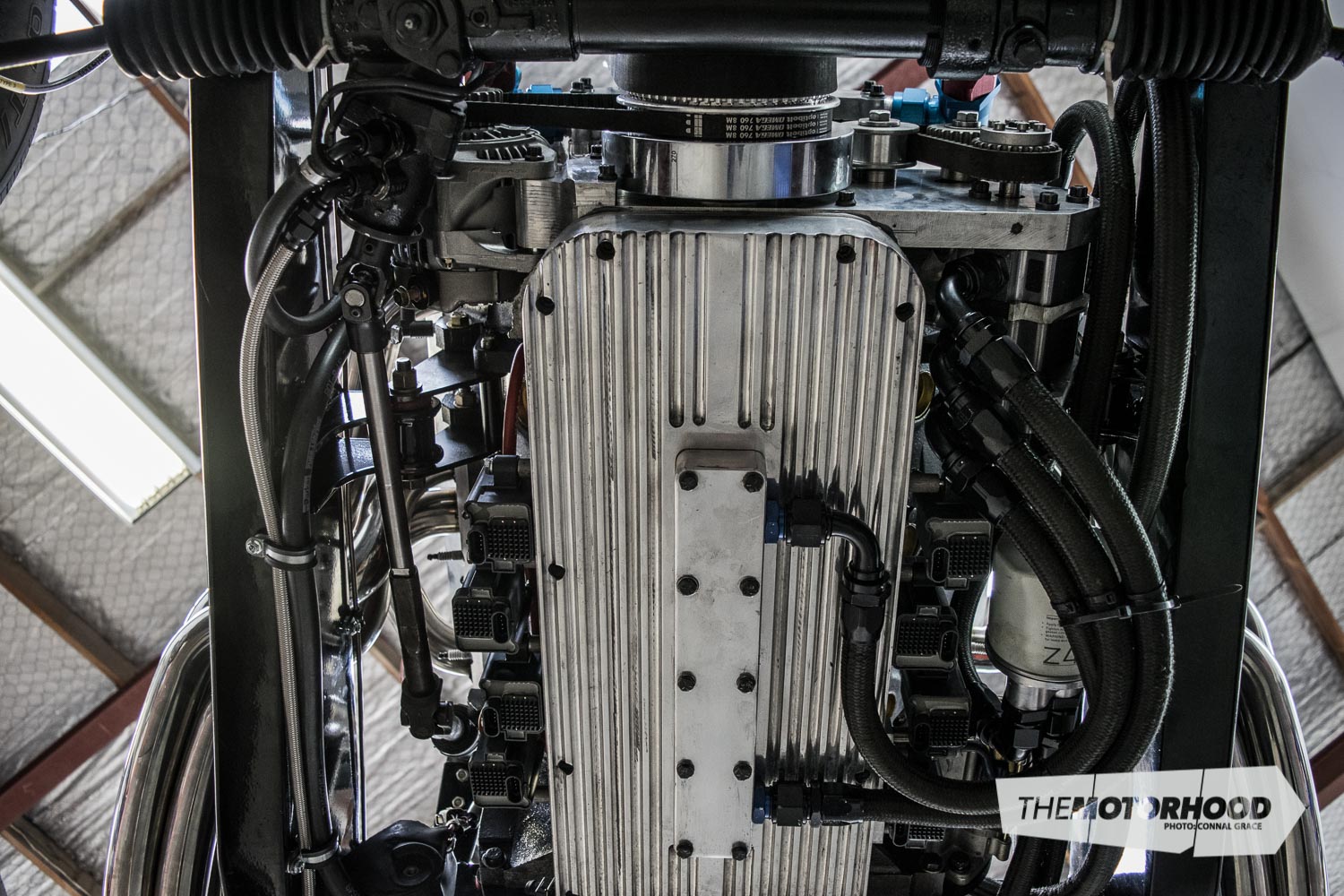

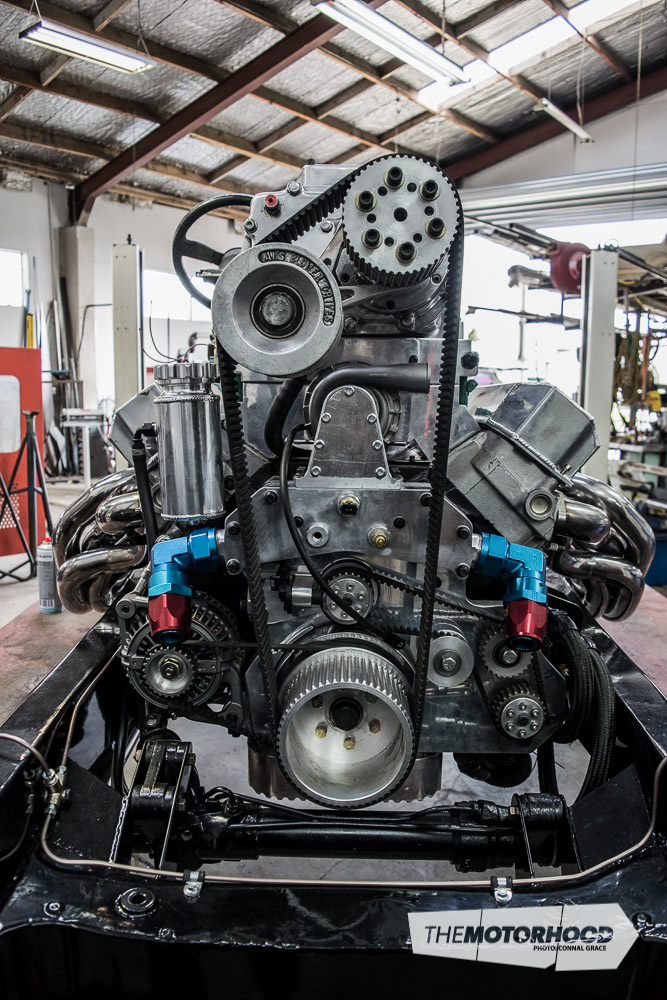

That’s a billet dry-sump pan, painstakingly designed and machined in-house at Limitless engineering. The oil pick-up is another piece of billet goodness, while the pan includes drilled and tapped holes for side-mounted coil packs — necessary due to the confines of the engine bay, and the lack of distributor.

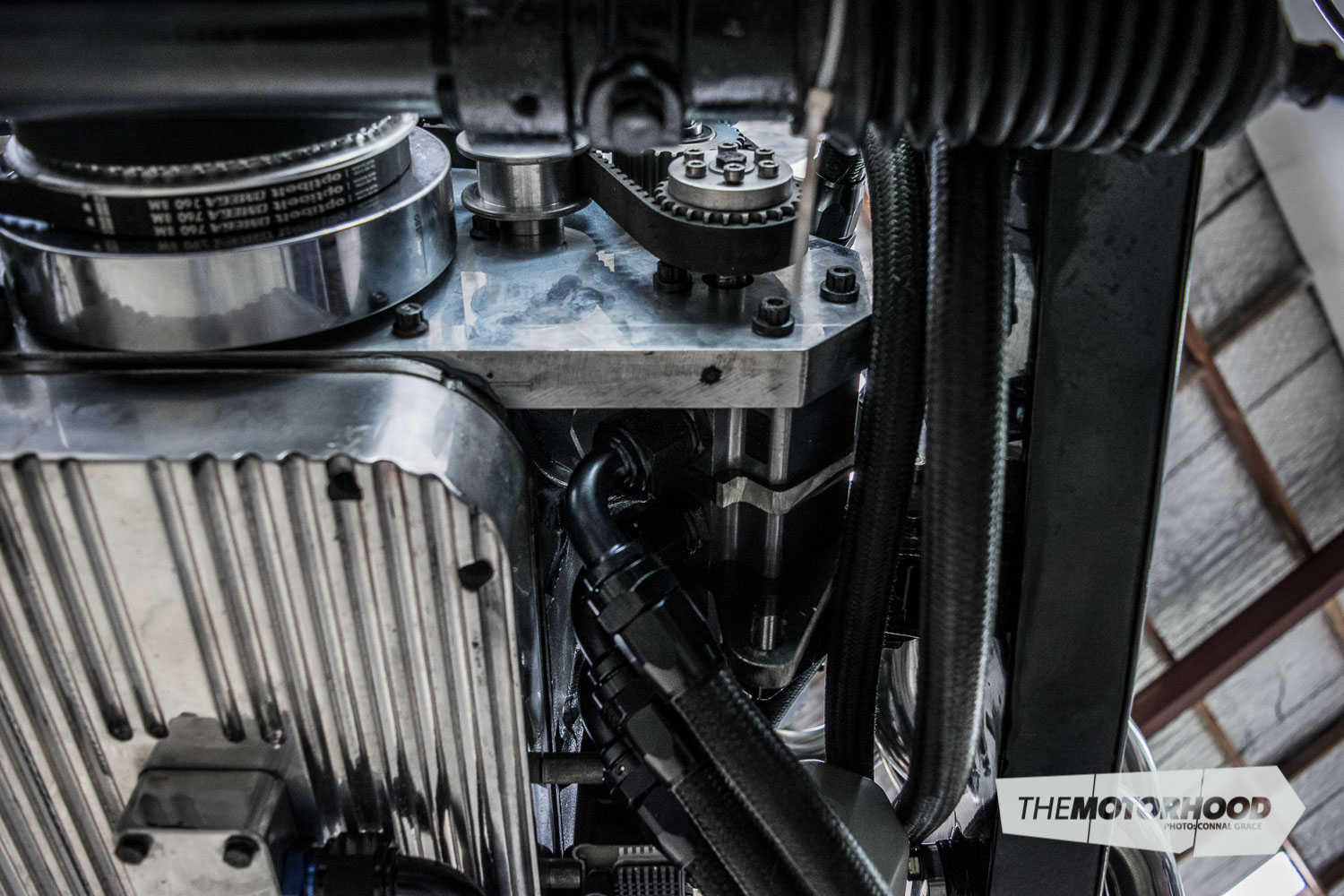

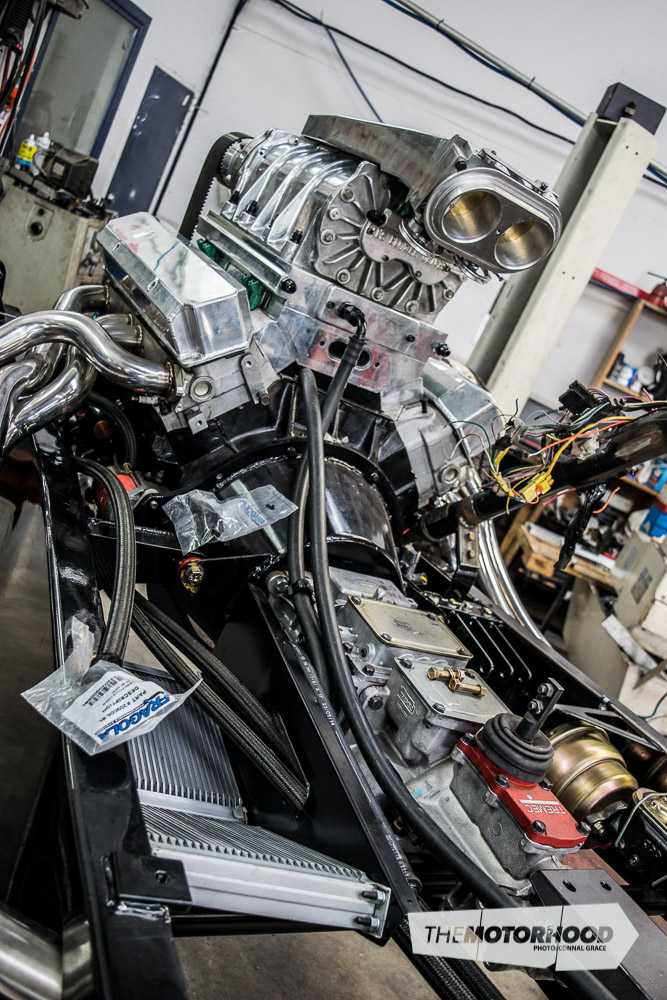

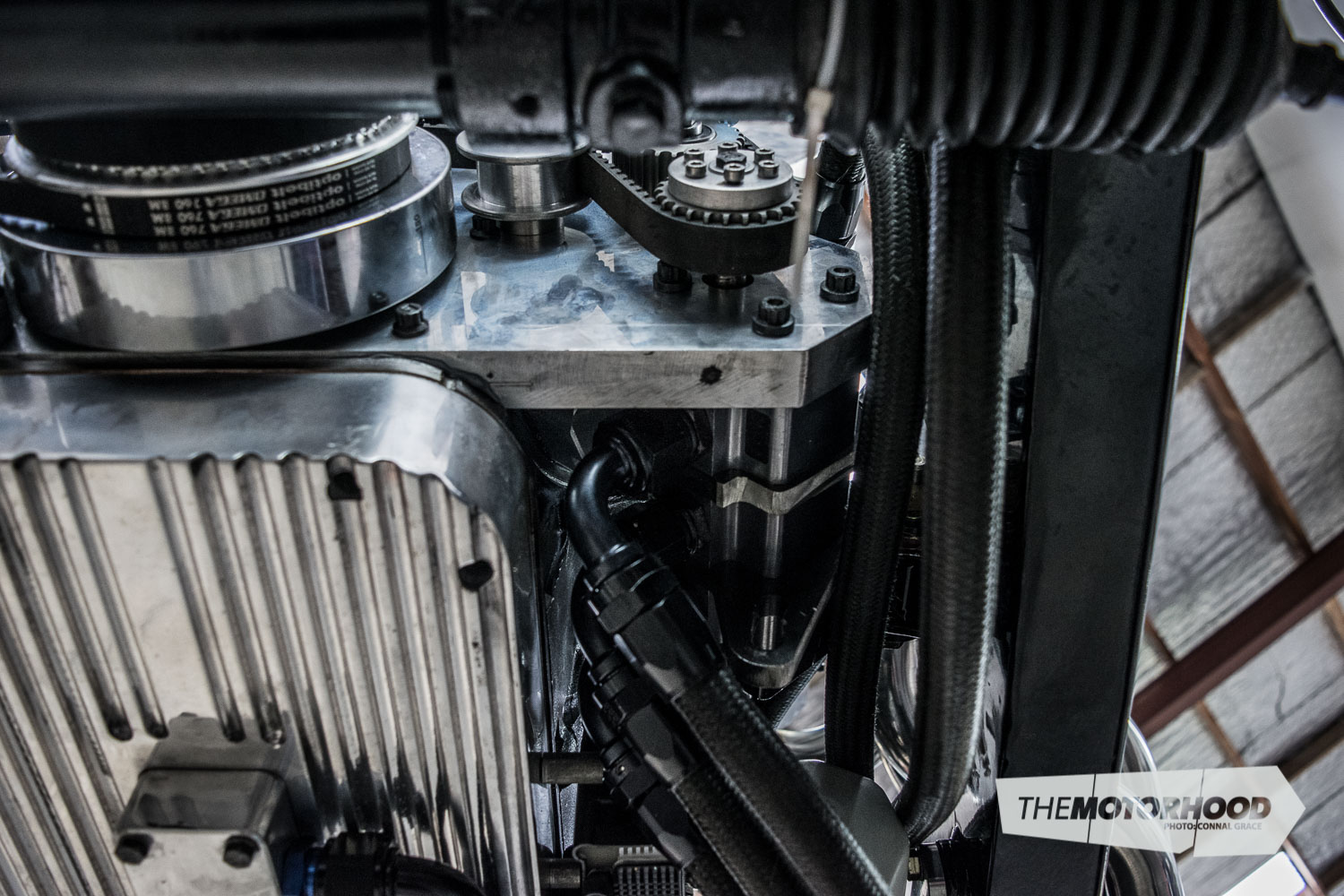

Above this is another piece of custom-machined goodness — a thick slab of alloy mounting plate for the engine ancillaries, chiefly the dry-sump pump and associated idler pulleys.

We can get a better look at it from this angle. Note that the dry-sump pump is cam-driven. This facilitated custom machining of the camshaft, allowing the extension for the front drive gear. While it’s not visible in the photo, the camshaft extension also includes a toothed reluctor wheel for a cam trigger, allowing the individual coil pack ignition system.

Above this is another billet piece, acting as an outlet chamber for the Davies Craig electric water pump. In all honesty, we’re still trying to work out how Tony’s designed this cooling system, but have no doubt that it’ll work perfectly.

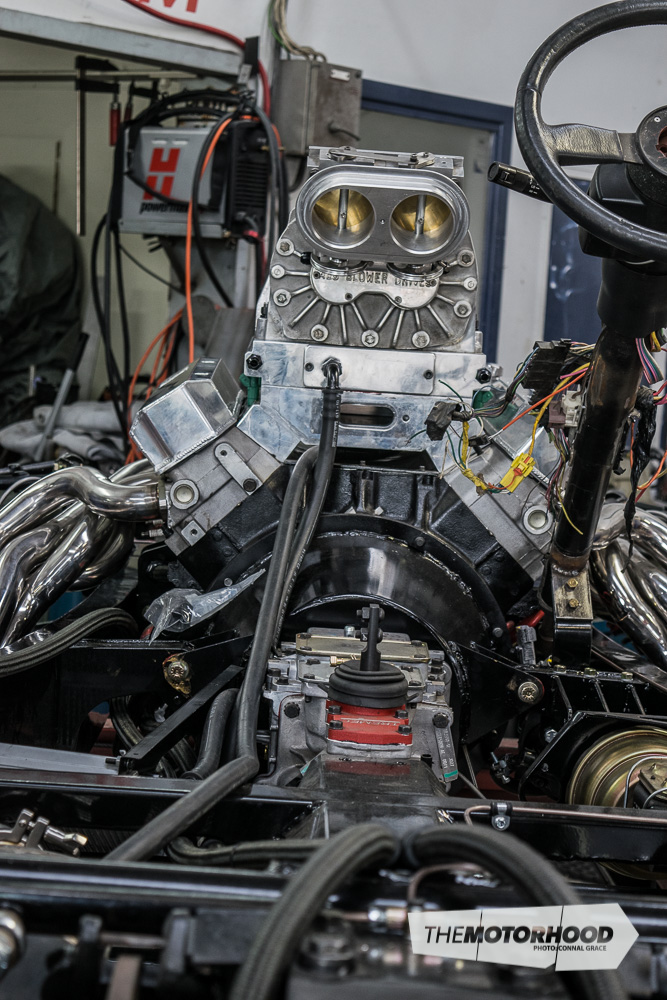

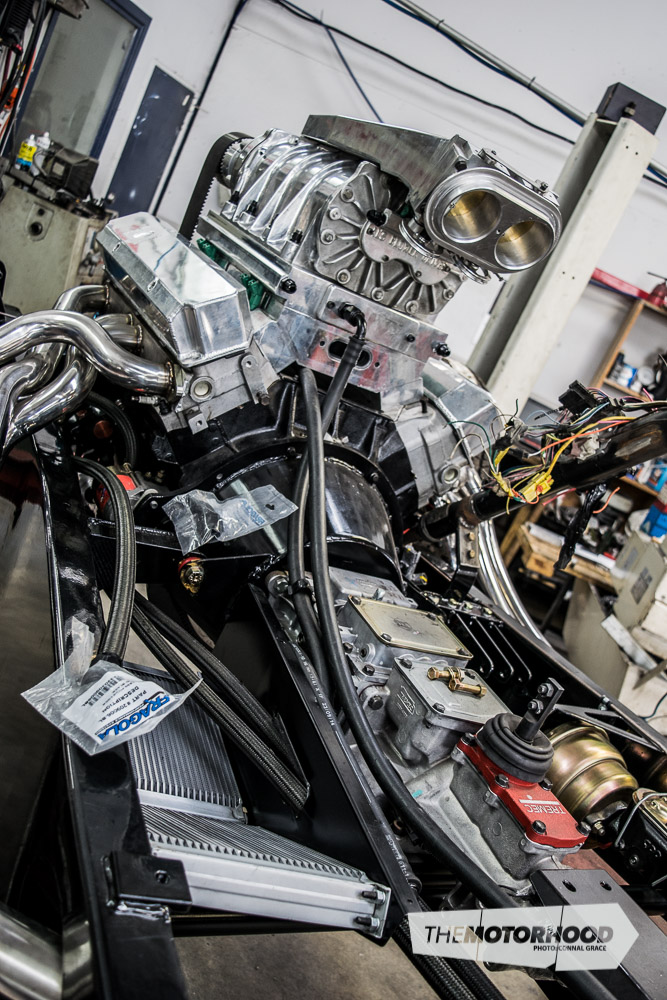

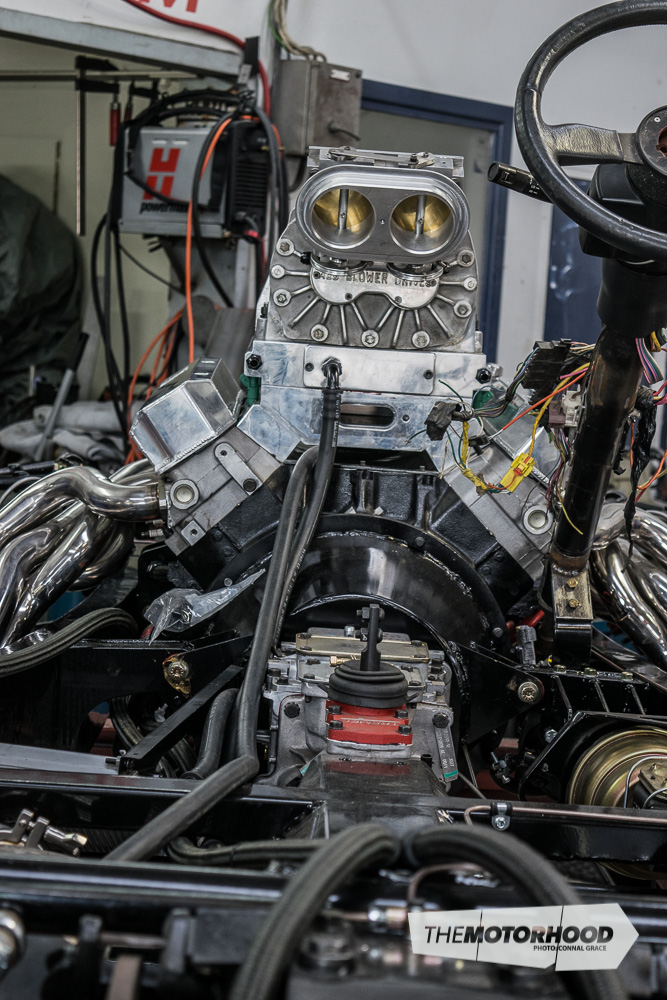

Moving further north gets us closer to the party. Here you can see not only the billet intake manifold, with provision for a pressure-release valve, as well as machined bungs for the fuel injectors. This is where things start to get serious.

Those injectors are there because this supercharged big block will be running electronic fuel injection (EFI). They are fed by a fuel rail that has been designed into the billet water-to-air intercooler sandwiched between the intake manifold and TBS supercharger. And check out that high-pressure hose exiting the rear of the intercooler …

A water feed from the air-to-water heat exchangers — an engineer’s fastidious precaution with regards to both engine cooling and keeping all pistons intact.

But the crown jewel has got to be that intake plenum, yet another piece of CNC-machined excellence. Tony mentioned plans to machine a pair of billet covers to hide the injectors, and with the twin throttle body and air filter hidden within the ’28 Dodge’s cowl panel, the polished tower of power is guaranteed to confuse untold numbers of people. But not you — now you know the ins and outs of what’s going to be one of New Zealand’s most insane vehicle builds.

We’ll have a full feature on Tony’s stunning hot rod in a future issue of NZV8, once it’s finished. But, for now, you’ll have to settle for daydreams about what you’d do if you had unlimited access to the skill and machinery that Tony does.