If you’ve been to any car events in the upper North Island over the last few years, there’s a damn good chance that you’ve seen and admired Tania Foster’s amazing ’36 Ford Coupe.

The car, which you can find out more about here was completed just days before her husband Steve, who’s vision it was, passed away. The good thing is, Tania’s been driving the wheels off it ever since, just as Steve would have wanted.

Although the car is in clear-coated bare metal, complete with a few visible weld lines here and there, so much more went into the build than you realize at first glance — even with it in this raw state.

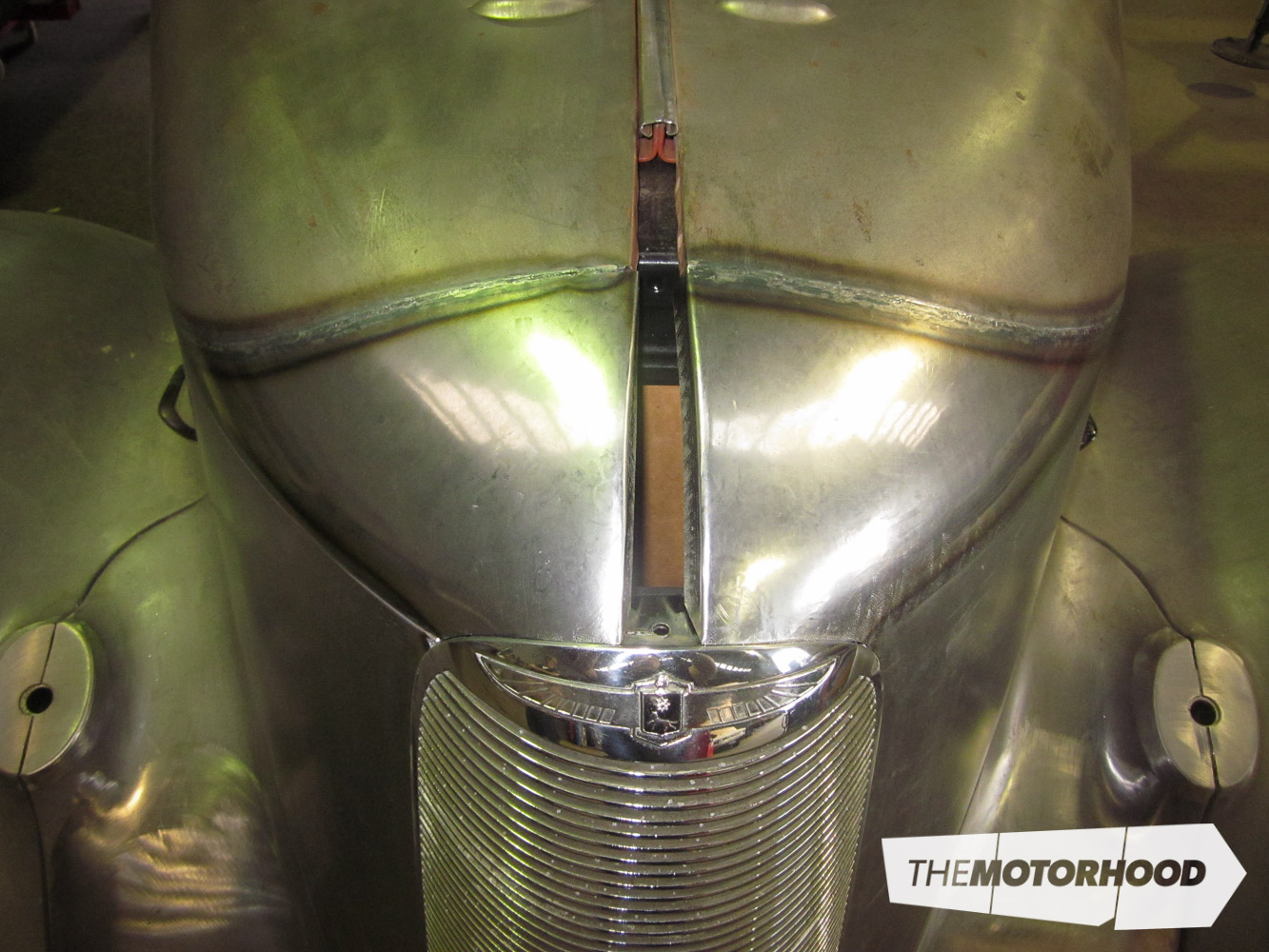

As an example, here’s a pile of the parts that were dropped off to Paul Duff and his talented team at Bodymods, who performed most of the metal work on the vehicle. That grille is off a LaSalle.

Inspiration for the build was taken from the Jack Calori, Jon Fisher and John Mearns (pictured) cars in America, which have had similar treatment.

Not sure what a LaSalle is? Don’t worry, you may not be alone. Here’s a LaSalle similar to the one that donated its grille to the build. Not exactly a common vehicle on the road these days.

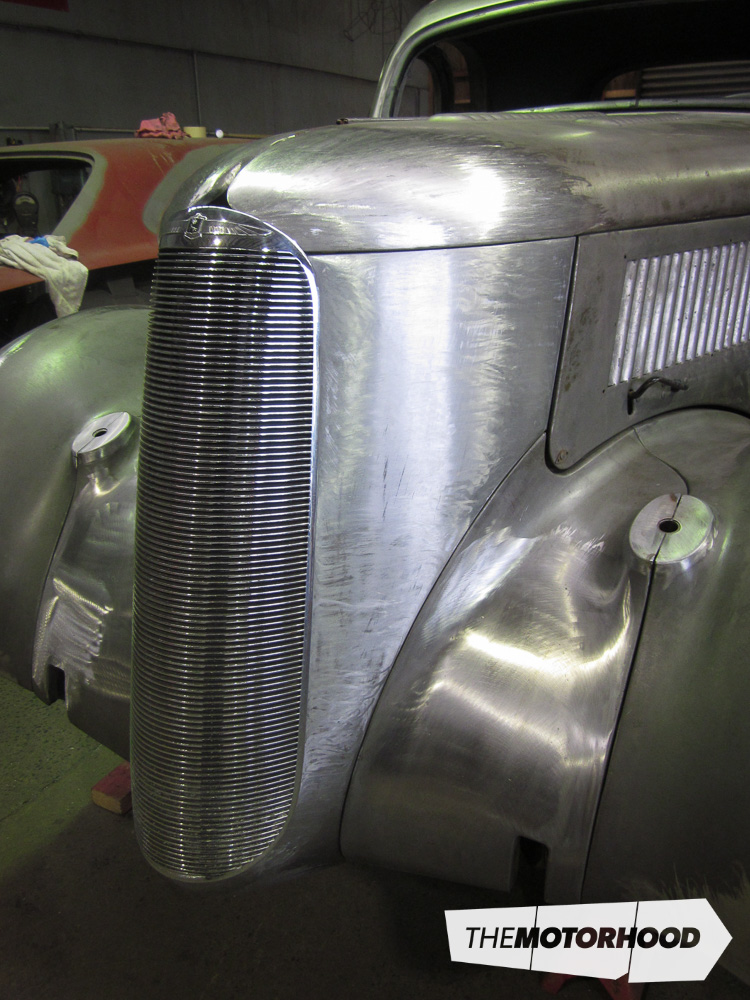

It’s not until you see the car as it was dropped at Bodymods that you realize just how radically different the entire front end is now.

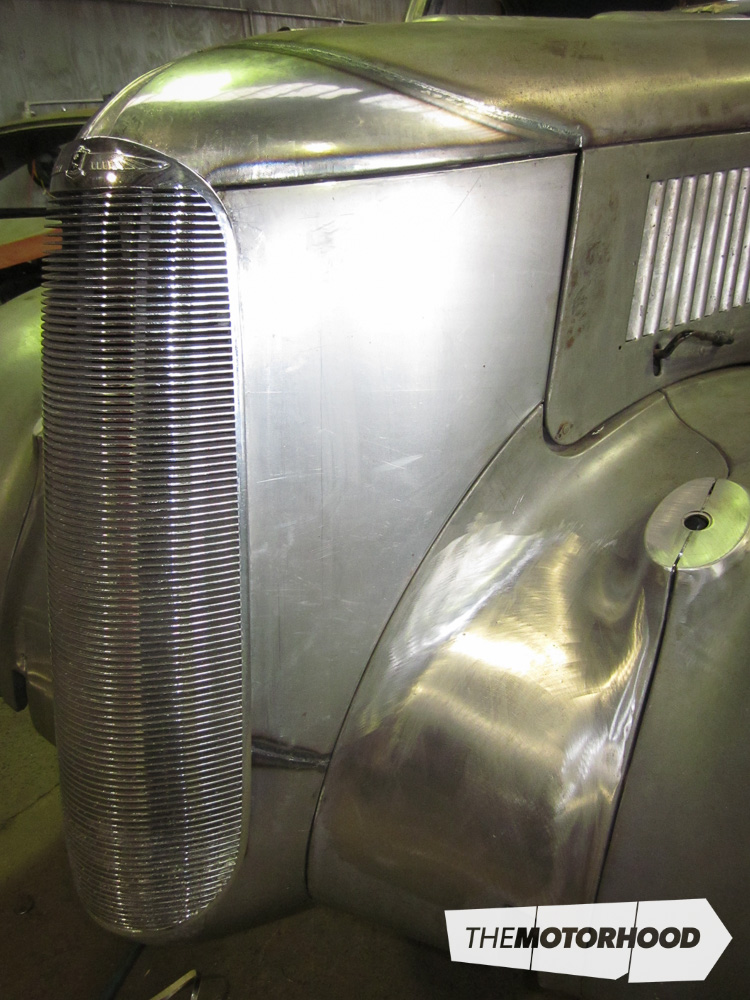

If you’ve ever tried to bend metal, or, for that matter, weld panel steel, you’ll appreciate just how much work’s gone into creating the new front sections of the hood.

That same workmanship extends to the new side pieces, all of which fit perfectly without the need for any body filler.

With the welds ground off, it’s impossible to tell where the new metal starts and the old metal ends.

While the body was in pretty good shape for its age, the rear guards had been damaged at some stage, as you can see here.

The Bodymods team sculpted, rolled, and welded metal to end up with a result as good as new. Can you tell how much has been replaced?

There’s more going on here than what you first notice, but the work has been so well done you’d never know, even though in some instances Steve specifically asked for the weld lines to be left visible.

That whole left-hand side of the trunk is new, including the outer skin.

Didn’t pick that one either, did you?

But here’s what it looked like once the paint came off — hardly something that could be left bare metal.

In a similar fashion, a few patches were required elsewhere, not that you’d notice unless you really went looking.

With a big Hemi up front, the whole firewall was cut out before a new, factory-looking replacement lower-section was constructed.

Here it is, complete with indent for one cylinder head. She’s a tight fit.

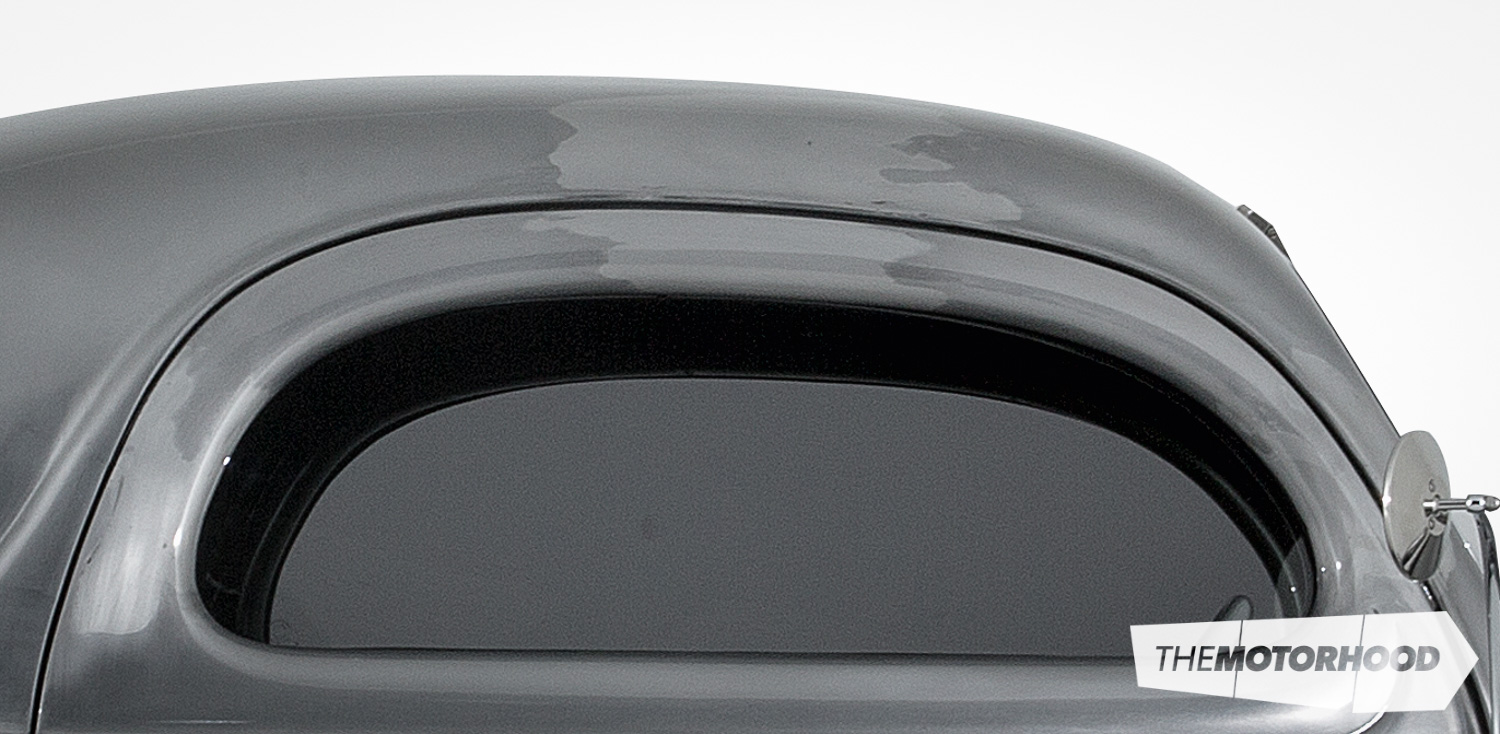

To get the profile as Steve wanted it, the rear wheel arches were reshaped, and the spats also modified, the result is a sleek look, that flows perfectly from the running boards through to the tail.

The finishing touch to the body was working out a few small dents, and, as you can imagine, the only way was by hammer and dolly — no bog or lead filler here.

Speaking of lead, the filler in the roof, which was chopped many years ago, was a point of contention between Bodymods and Steve. The Bodymods guys were keen to remove it and make the work blend into the body. Steve, however, preferred it to remain visible, so that’s how it stayed.

Here’s how the car was handed back to Steve to continue with the build — that’s him on the right and Bodymods’ Paul Duff on the left.

How’s that for an amazing finished job?