‘Bang for your buck’ is a phrase that gets thrown around frequently in the world of modified cars. Back in the day, it would have entailed slapping some headers and a Holley carb onto your old V8, to get a bit more noise — and hopefully a bit more performance — out of your car. Nowadays, most are content to just take their fuel-injected car down to a tuner, get the ECU re-flashed, and call it a day. As far as we’re concerned, that’s only bang for your buck as far as the time that it’s saved; time is money, after all.

No, if you want real bang-for-your-buck performance, you’re going to have to look at something like Benjamin Peters’ Holden Commodore VT SS. Visually, it doesn’t look like anything more than your usual VT-series Commodore, and when it fires into life, there’s no rumbling fury to indicate anything more than a stock LS1 lives beneath the bonnet.

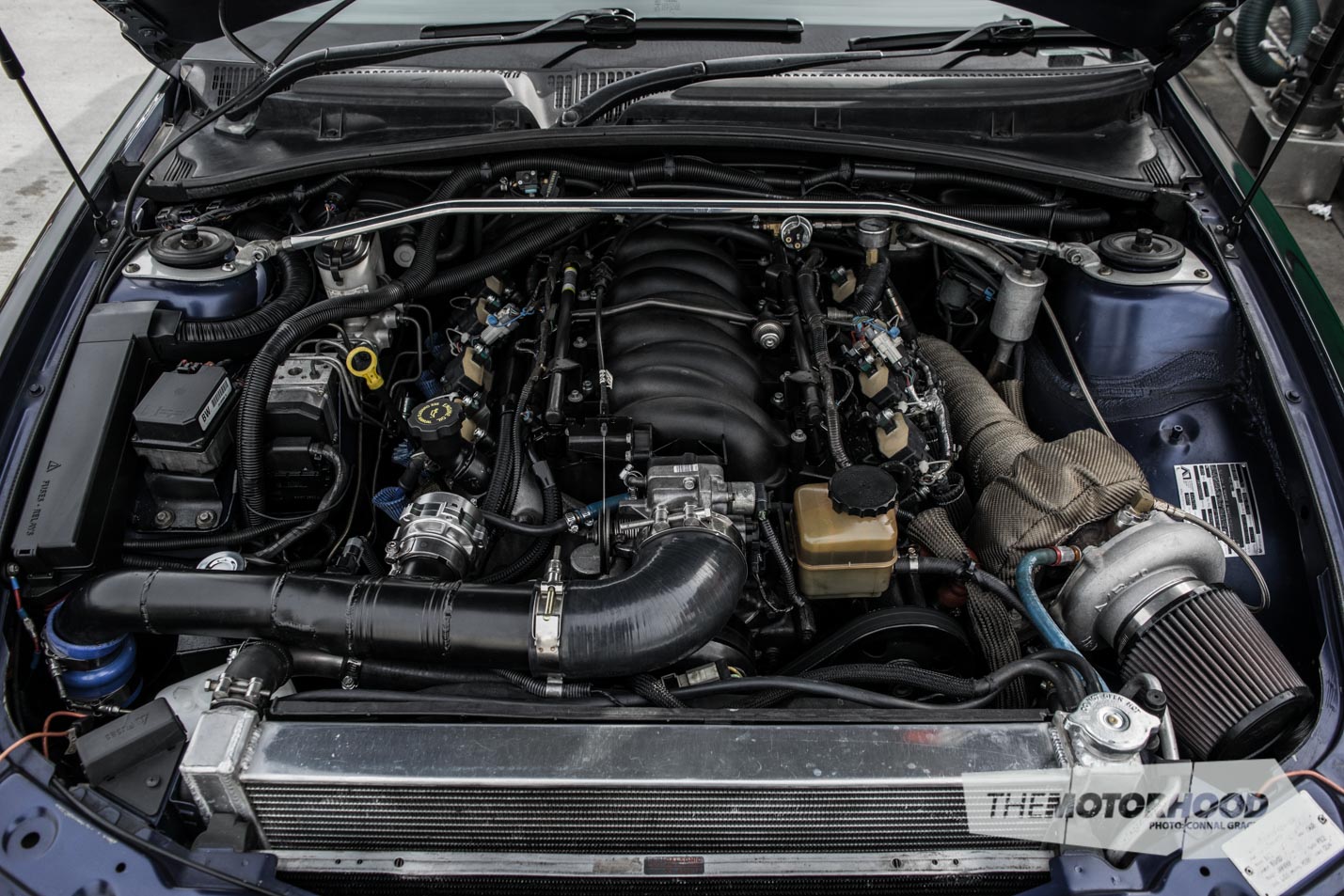

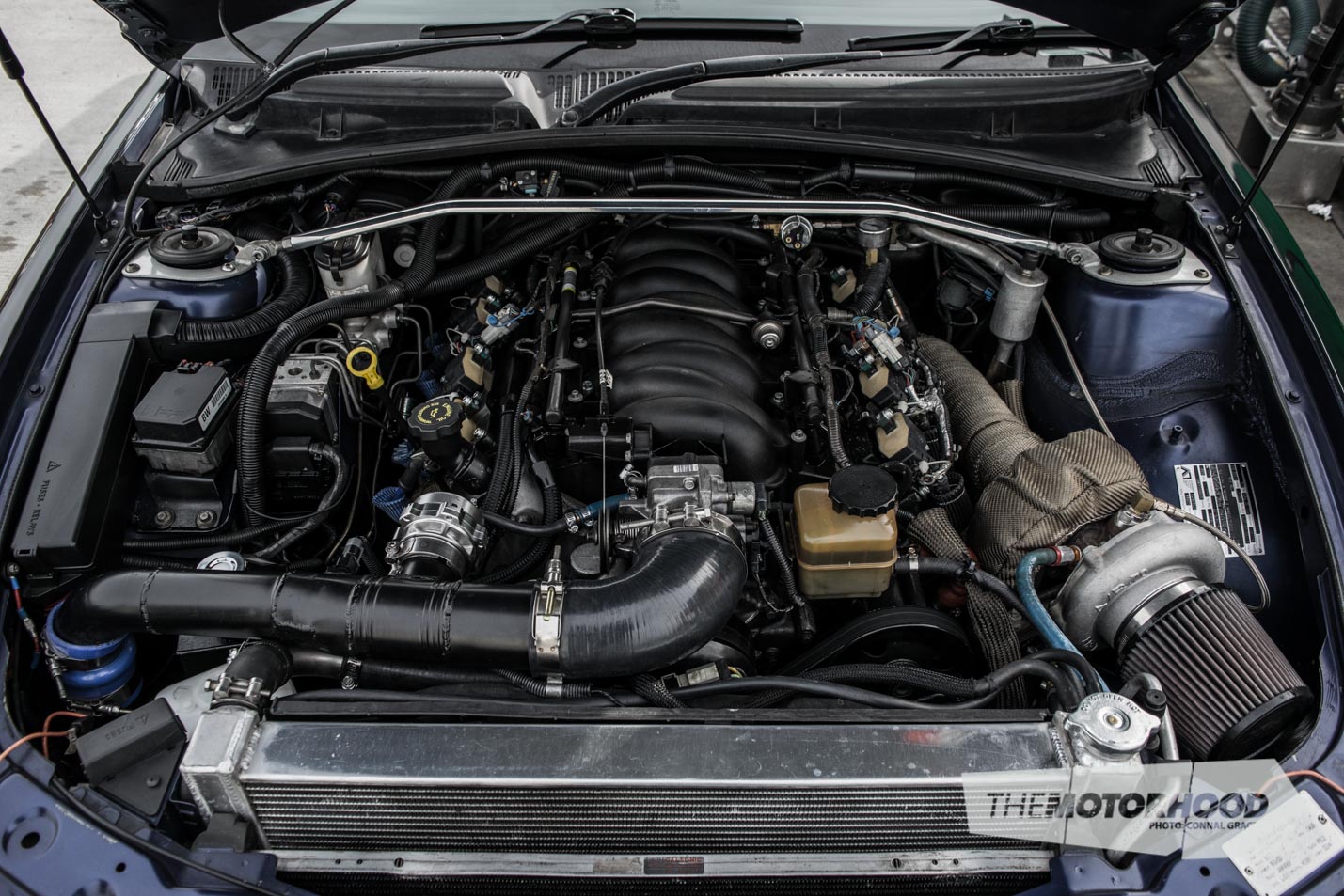

Pop said bonnet, though, and it becomes blatantly obvious that Ben’s Commodore is packing a lot more heat than Holden’s engineers ever planned for. While turbocharged LS-powered Commodores are nothing new, they’re hardly what you’d call dime a dozen, and Ben’s really appeals because he did as much of the build himself, with the aim of keeping costs as low as reasonably possible.

This was achieved not just by doing as much of the work as he could, but by purchasing the most cost-effective parts — within reason — and, most impressively, by completing nearly the entire conversion on a driveway.

For most of 2014, he researched turbo LS motors, building the knowledge he’d need to undertake such a conversion on his own Commodore, which he’s owned since around 2010. From around Christmas 2014, he started buying the parts required — many of which were sourced from eBay — and had the whole lot done by Christmas 2015.

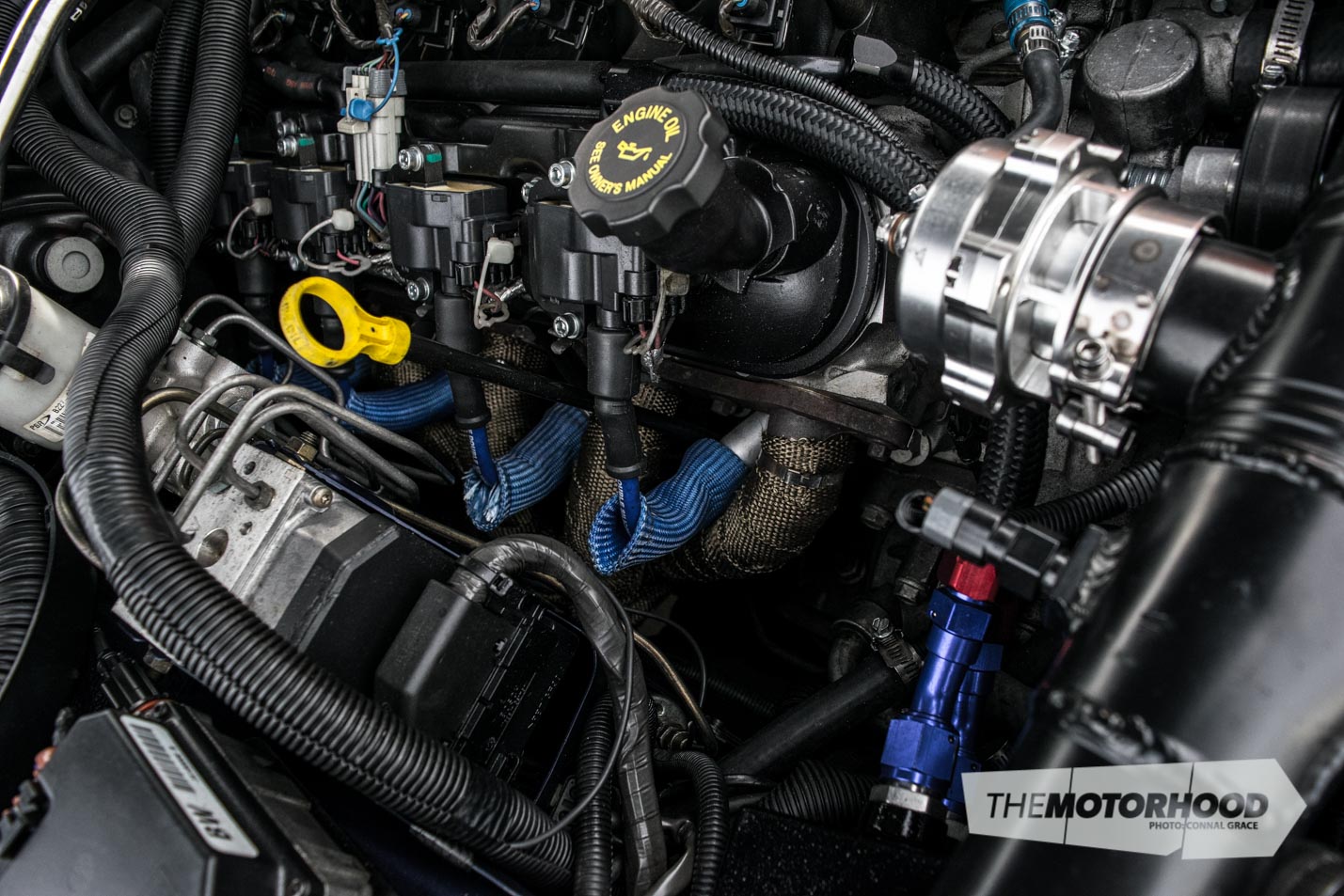

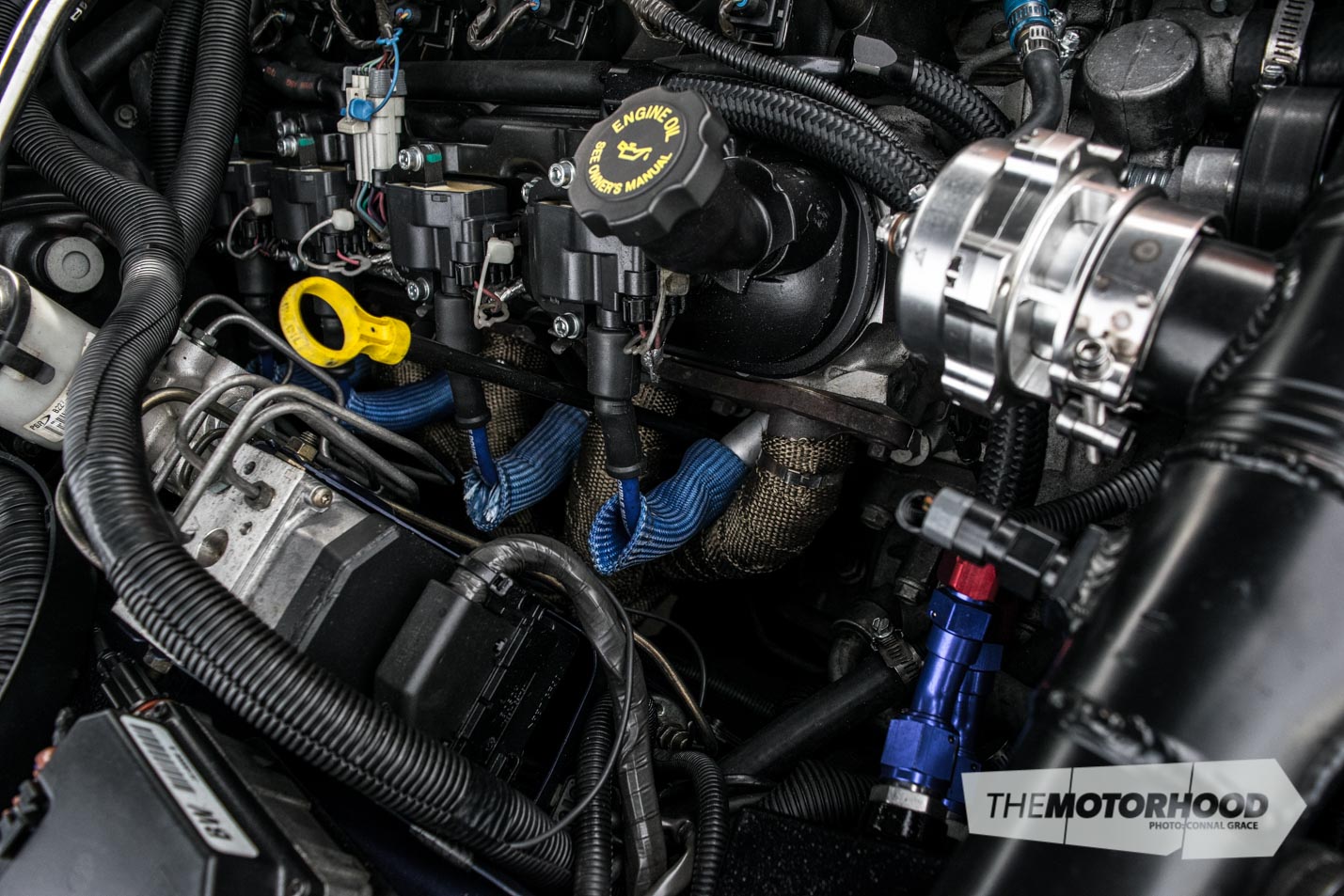

Being budget-conscious, the LS1 is an essentially unopened engine, with 220,000-odd-km on the clock. However, Ben’s research included looking for professionals for help and advice where required, and when Wayne at ProTune Automotive suggested he’d be best to upgrade the valve springs, that’s just what he did. In addition, the injectors have been swapped out for Siemens 60lb/hr units, and the fuel pump has been upgraded to a Walbro replacement to ensure the fuel system can keep up with the turbocharged engine’s appetite.

Cleverly, the turbo conversion retains the driver’s side headers, which loop around to the passenger side underneath the built 4L60E transmission’s bellhousing, rather than trying to fit a crossover pipe in front of the engine. With the help of Kerry at Pit Stop Moselle Avenue, this has been made to work with a passenger-side off-the-shelf turbo manifold, pumping air into a cheap GT3540 turbo.

The turbo breathes out of a three-inch straight-through exhaust, custom-fabricated by Kerry, with one rear resonator. Despite the notable lack of muffling, the system is quiet enough to fly under the radar, unless Ben’s giving it death, which he does quite frequently.

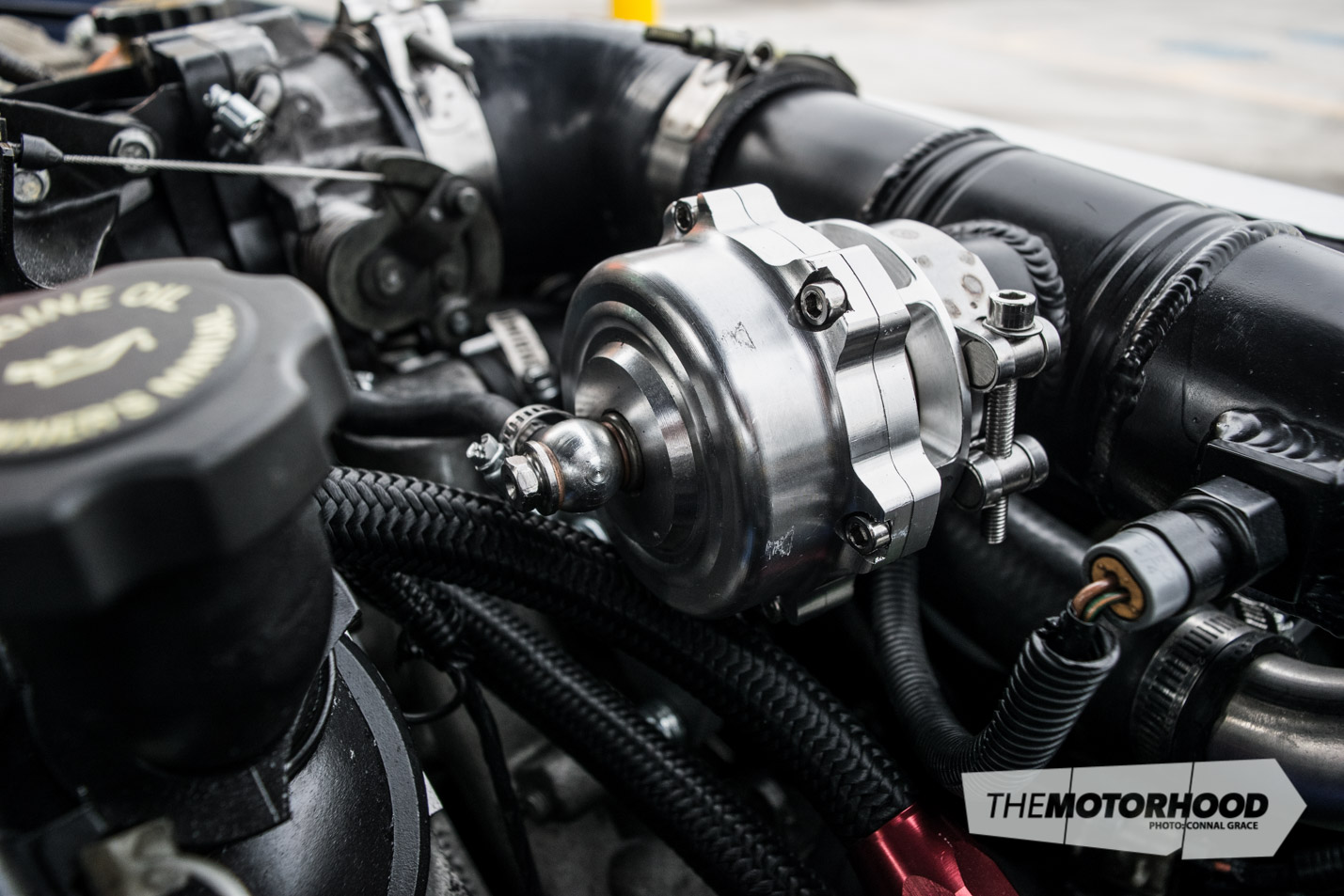

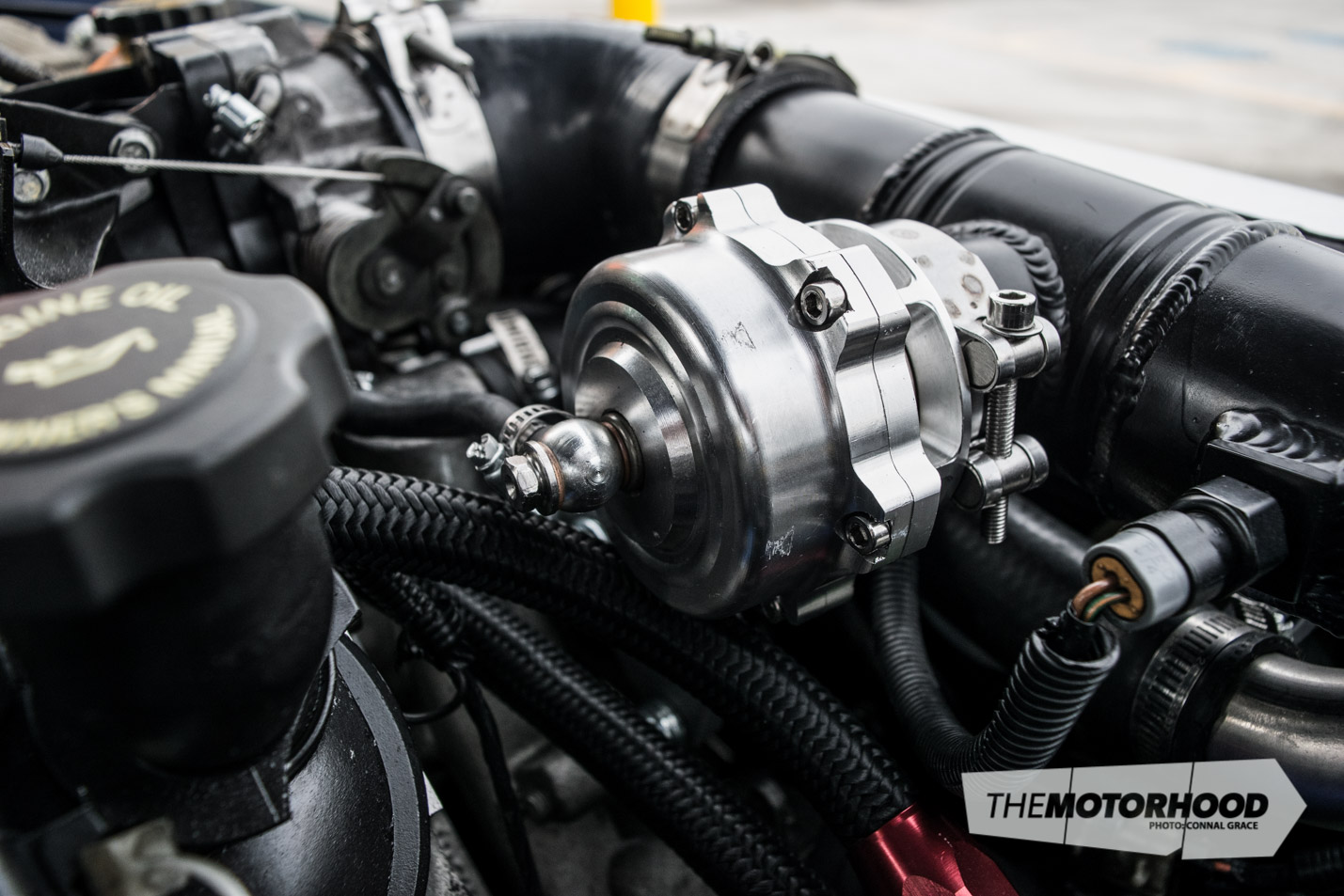

The rest of the package utilizes a 60mm external wastegate, and 50mm blow-off valve (BOV), both of which were also selected for cost efficiency. Wastegate spring pressure is around 4.5psi, meaning normal boost pressure of around 4.5psi.

This is a combo that has proven to be good for 300kW (400hp) at the rear wheels, although Ben’s since added an Innovate SCG-1 boost controller and wide-band oxygen sensor, which includes a boost-control solenoid, allowing Ben to run a higher boost pressure of 7psi — he’s yet to take the Commodore back to ProTune to get it retuned, but is quietly hoping for 500hp.

It’s not just a whole lot of motor and nothing else, though — a chunky strut brace takes up a bit of real estate in the engine bay, giving the big Commodore some much-needed rigidity. With a full set of Nolathane bushes underneath, as well as BC Gold adjustable coilovers, the Commodore sits nicely and can tackle corners like it’s on rails. All Ben really plans to upgrade in the handling department are the rear tyres, as the current 235s turn into smoke too easily.

There are worse problems to have, though, and although Ben says the Commodore is now a little too thirsty for daily drive duties, he’s looking forward to making the most of it at events like the upcoming 2016 Mothers Chrome Expression Session on August 6–7. In hindsight, Ben can’t fathom how he managed to finish it all on the driveway, but he’s understandably glad that he did — it just shows how far a bit of perseverance, Kiwi-style DIY, and some penny-pinching can go.

Even so, Ben couldn’t have finished the job without a bit of help, and he’d like to give a massive thanks to Kerry at Pit Stop Moselle Avenue for his time and help; Wayne at ProTune Automotive, for always making time to help despite how busy he is, and his old man, for freeing up his driveway for the build — even at 1am.