data-animation-override>

“Just like his real-life Chevelle, Steve Haddock’s concept is now show pony — it’s made to drive!”

Steve Haddock is a man who likes to use his cars, but that can’t stop them from looking the business. That much is evident in his ’68 Chevelle you’ve read about earlier in this issue, and it’s a theme he’s carried over into his Concept Corner idea, with this super-slick ’56 Nomad.

“I’d start with a ’56 Chev Nomad, and give it a two-inch roof chop” Steve explains. “To clean up the exterior, I’d shave the door handles, and finish it in candy red and silver-grey paint, with colour-coated chrome.”

It’s definitely a good start, but Steve’s far from finished …

“Underneath, it’d get a Roadster Shop Fast Track chassis, with narrowed rear frame rails for a Strange nine-inch rear and four-link rear suspension. I’d also have Wilwood brakes fitted at each corner, with a line-lock installed, and operating on a Hydroboost system,” he adds. Just as his Chevelle was built to be a proper driver, so is this concept Nomad. Of course, wheels make or break the car — as they say — and just as Steve took care of business under his Chevelle, he’s got that sorted here too.

“I’d like a set of Boyd Coddington HR99 Pro Touring wheels with a charcoal centre, 18-inch fronts and 20-inch rears, wrapped in Michelin rubber,” explaining the narrowed rear chassis section. And Steve’s going to need all that rubber because he’d be running one hell of a powerplant — the 502 he’s currently running ain’t much compared to it!

“The engine would be a Procharged 572ci big block, with a 4L80E transmission and Compushift II controller.

“Inside, I’d have electric front bucket seats with a custom centre console, and full leather upholstery, with LED lighting and a custom sound system. The rear seats would also fold down, to allow a bed in the rear — better add tinted windows, too!

“This thing will go like hell, and look low and cool,” Steve says, “It will be a comfortable and stable ride. Skids will definitely be on!”

LVVTA’s view

Justin from LVVTA says, “You’d be a brave soul to take on a roof chop on a car as rare as a ’56 Nomad, but if done right, could really look the part without offending the purists too badly. With any roof chop, remember that the glazing needs to meet applicable glazing requirements; some of the glass may need to be custom made or cut from the original glass — if so, make sure the manufacturers markings are retained on the glass, or that any new glass is correctly marked by a local auto glass specialist.

“There’s a section in chapter 15 of the Hobby Car Technical Manual (HCTM) that has full details of all approved glazing, and the various markings needed for compliance. Shaved door handles are no problem provided some basic requirements are met — this info can be found in the ‘Door Opening Requirements’ section of Chapter 13 in the HCTM, and includes common-sense rules, such as requiring a hidden door release to be shielded so that it can’t be unintentionally activated by road debris, and that a remote controlled opener can’t activate the door release when the vehicle is in motion.

“Fitting a mass-produced replacement chassis such as the Roadster Shop unit can be an excellent way to improve and modernize a ’50s car with upgraded suspension, steering, braking, as well as providing greater torsional rigidity; an important factor when you’re tipping massive gobs of HP and torque through the driveline such as with this blown 572 cube monster. As this is already a separate body/chassis car it’s pretty straightforward, just make sure the chassis is specifically designed and sold for the specific type of car it’s going into. The replacement chassis will also need to meet all of the applicable LVV requirements that any custom chassis is required to meet — in the past we’ve seen aftermarket American-built frames that don’t meet some of our local chassis construction requirements, and have needed some modification to be made to crossmember attachments, and in some cases the addition of fish-plates at major joins in the chassis. It might be a good idea to order an unpainted chassis, unless you’re absolutely sure that it’s going to comply. It’s also common for such a chassis to have a custom IFS — don’t forget that this will need an ‘IFS Approval’ through the Technical Advisory Committee (TAC). For details on this process check out the Design Approval section under the ‘Approvals’ tab at our website; lvvta.org.nz.

“With the planned power-plant, the brakes will really need to be on the money to pass the LVV five-cycle fade-resistance brake test. The Hydro-boost braking systems (a brake booster that uses hydraulic fluid from the vehicle’s power steering pump rather than engine vacuum) are common on American GM pickups and vans, and work very well. The big advantages here are in saving a bunch of space under the hood, not requiring additional vacuum pumps, and providing more brake system line pressure than conventional vacuum boosted systems, meaning that less pedal effort is required. You’ll need to make sure that all of the hydraulic pressure hoses are properly rated for the fluid type and pressure, and that all of the related parts (power steering pump, master cylinder, hydraulic hoses, push-rod, brake pedal ratio and brake bias) are compatible and properly set up.

“The vehicle’s interior mods are all fairly straightforward too; electric seats and other interior equipment can all be approved so long as the applicable requirements from the ‘Seats, Seatbelts & Anchorages’ section and ‘Interior Equipment’ sections are met. This sounds like it’ll be a stunning car if it becomes a reality, but I wouldn’t throw away the motel accommodation guide just yet – the low roofline coupled with narrow rear wheel well spacing might make it a bit cramped to get a good night’s sleep!”

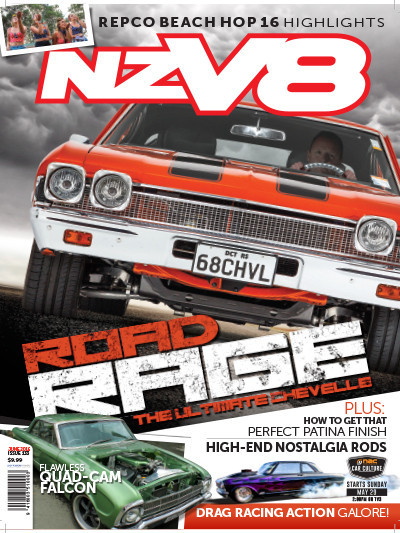

This article originally appeared in NZV8 Issue No. 133. You can pick up a print copy or a digital copy of the magazine below: