data-animation-override>

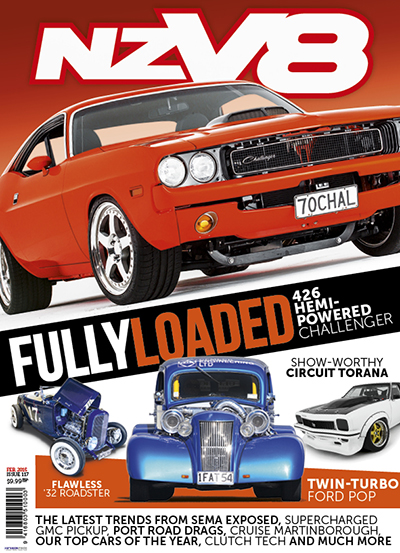

“Fitted with the latest and greatest suspension technology, as well as a 426ci injected Hemi, is this Dodge Challenger the ultimate open-road touring machine?”

“I saw it pulling out of the street, just as I arrived,” says Phil Kenny of the Dodge he had his heart set on buying some nine years ago. After a four-hour or so drive, sitting with a wad of cash in his pocket, he was understandably a bit pissed off that the seller had let the car go before he even got a chance to take a look.

Seeing his dismay, the seller did come up with an alternative — although it wasn’t another ’70 Dodge Charger, but a ’70 Challenger. While it wasn’t the car he’d dreamed of owning, Phil thought that, since he’d driven so far, he may as well at least have a look. What he found was a car that was, while dead stock, in surprisingly good nick, complete with 360 and automatic transmission. Being permanently busy with work obligations, Phil decided that, as he’d made the time and effort to get there, and had the time to check the car out, it was better to bite the bullet and buy it than go home empty-handed.

For the next few months, Phil drove the car around, much to the delight of his son Benn, who was the one who had pushed him to buy a muscle car in the first place. As much as he tried to enjoy it, though, the relationship between Phil and the car was somewhat strained — while he loved the character and the look of it, the old-car gremlins that came with it were not his thing. Being far more accustomed to high-end, late-model vehicles, he found that the more he drove it, the less he liked it, and the more he was torn about what to do.

Again through the insistence of Benn, Phil decided to strip the car down and rebuild it, as much for a bit of father and son bonding time as anything else. “When we pulled it down, we didn’t know what we were going to do with it; we just decided that either way we’d get it back to bare metal” — and that they did. Once all parts were removed, the car was dropped to Kiwi Metal Polishers in Rotorua, where it was acid dipped to remove any paint and filler, before being etch primed.

The car would remain in that state for a further five years, while Phil figured out what he was doing, and continued with his normal busy life. The more he thought about what to do, the more he decided that the car needed to be brought kicking and screaming into the 2000s.

Coming from an engineering background, Phil wouldn’t find designing and building complex parts a problem, were it not for the time involved in doing so. It was with this in mind that he went searching for a manufacturer of parts that could live up to his high expectations. As he scoured the internet, one name kept on appearing: XV Motorsports (XVM). Better still, XVM didn’t just design and build suspension componentry for E-body Challengers and ’Cudas, but offered the full package to bring the cars into the modern world — just what Phil was after. While XVM openly stated that its packages required more work than many other options available, these were of the highest quality, and that was a compromise Phil was prepared to make to ensure he got the best end result. As a test bed for its products, and to showcase what it could do, XVM actually built a ’70 Challenger and filled it with the best components available.

After reading a few articles on that specific car, Phil knew the answer that he was looking for essentially lay with him building his own replica. After researching exactly what parts he wanted, he wrote a long shopping list and sent an order sent off to XVM. During discussions with the XVM team, talk turned to engines — or, more specifically, to the 6.1-litre injected Hemi in the company’s demo car. The engine was built by Canadian company, Sean Hyland Motorsport, and, rather than mess about trying to find someone else to build his engine, Phil chose to use the same company.

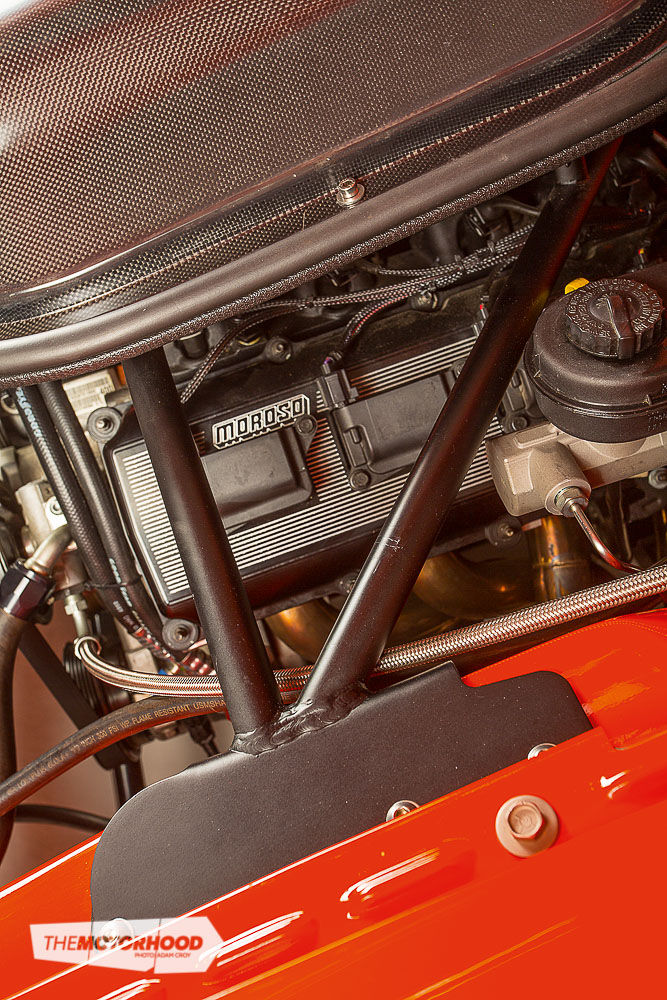

Like that of the demo car, Phil’s motor was a brand-new Hemi, the difference being that his motor was increased in capacity from 6.1 litres to 7 litres (426ci). While the car was never to be a track weapon, the intention was always to build something that could hold its own against most late-model cars on the open road, and every extra bit of power would help. Of course, the exception was that it mustn’t have too aggressive a cam profile, as it must be able to handle daily driving duties with ease. With that in mind, the team at Sean Hyland built the motor with a forged rotating assembly, held together by ARP fasteners, and dropped in one of their medium-spec camshafts. Up top, they fitted an Accufab four-barrel throttle body, which receives fuel from billet rails, and an in-tank fuel pump. Wanting to have something truly his own, Phil changed things when it came to picking an intake set-up, and decided upon a great-looking carbon-fibre shaker scoop, as opposed to the T/A scoop on the demo car.

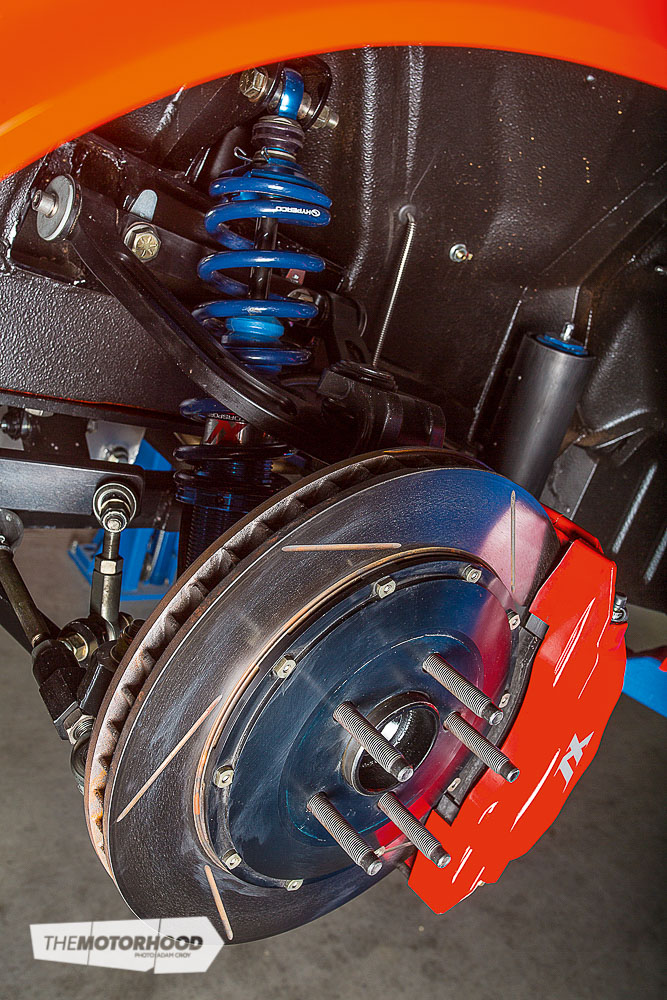

While the engine was a key component of Phil’s shopping list, it was really the supporting parts from XVM that would set the car apart, and would keep Phil busy during the odd spare moment he could muster. Included in the engine was a full replacement aluminium K-member, complete with mounts specifically for the late model Hemi and Tremec TKO five-speed transmission combo. Hanging off that K-member is a suspension set-up that most would consider to be as good as, if not better than, that of most of today’s performance vehicles — the key pieces being 2008 Corvette lower A-arms and uprights along with billet upper A-arms, Moog hubs, and an adjustable sway bar, complete with billet fittings. Providing dampening is a set of XVM’s remote reservoir coilover shocks, which, as you can probably guess, are adjustable in every which way, and perfect for a grand tourer such as this.

One of the other major advantages offered by the XVM front end set-up is rack and pinion power steering, something that couldn’t even be dreamed of back when the car rolled off the production line. While some say that the vagueness of the original steering is just character, Phil wasn’t having a bar of it, and he couldn’t be more positive about the driving experience with the new arrangement.

Of course, it wasn’t just the front end that helped sort that; down the back, the original leaf springs are long gone and in their place is a set of beautiful billet lower arms holding the Dana 60 diff in place. As with the front, a set of remote reservoir shocks is matched with an impressive sway bar system, and every component has undergone hundreds of hours of testing and development to make sure it works in total harmony with the others. As part of the set-up, various bits of welding were required, such as attaching the full chassis connectors, a new lower radiator support tube, crush tubes for various mounting points, and far more.

While it may have taken a bit of time to install, Phil can’t speak highly enough of the product.

In fact, he was so impressed with XVM’s products that even the 18×9.5-inch and 18×10-inch wheels were purchased from the company, as were the six-piston front calipers and four-piston rears. These work in conjunction with a Hydroboost booster and separate Wilwood handbrake caliper to provide fantastic stopping power.

With the driveline aspect of the build sorted, the next step was to sort out the less than ideal factory panel gaps, and straighten out the few imperfections on the 40-year-old body. For this, Phil turned to Simon Tippens at Creative Metalworks. Simon not only perfected the gaps to a state far better than when the car left the factory, but also removed various moulding holes and smoothed out the engine bay.

When it came to paint, people kept suggesting that Phil go to Rodney Holland of Rodney’s Restorations. Known as the fussiest painter around, Rodney ensured that the body was flawless before spraying it inside, outside, and underneath in a modern twist on the well-known “Hemi orange” colour. Rodney was also entrusted with painting various undercarriage and engine bay components in a contrasting black, before delivering the car back to Phil for assembly.

As we know, piecing a car like this back together always takes longer than expected, especially when you’re as fussy as Phil is. It was this quest for the best finish possible that lead him to hand the interior retrim over to Trevor Watts and the team at Auto Interior Specialists. Trevor has worked abroad with the upholsterers for Aston Martin, so he shipped a number of parts off to them with specific instructions. What returned was amazing. The late-model electronically adjustable seats feature amazing stitchwork, while the door skins have layer upon layer of detail unseen anywhere else. The Auto Interior Specialists team covered the dashboard with equal precision before crafting a custom hood lining and fitting plush Mercedes carpet.

Before the interior work could take place, Phil and his wife, Colleen, had covered the whole interior with layers of Dynamat, as well as fitted electric windows, Vintage Air air conditioning, and a full new dash cluster from XVM. The finishing touch to the interior were the billet speaker grilles that Phil CNC’d up himself; they perfectly match the billet shifter selected from the Ringbrothers’ catalogue.

Having access to CNC machines also allowed Phil to create various custom parts for under the hood, including a custom fuse box, and to remachine parts he wasn’t happy with for the billet hinges he’d purchased. This attention to detail sees the build up there with the best of them, both in terms of quality and of the cohesiveness of the whole car.

So now that it’s finished, how does it drive? Phil is delighted. He’s got the classic muscle car look he was after, but with the ride quality, stopping power, and handling of today — not to mention the creature comforts to match. While Phil says that the work involved, the delays incurred, and the hurdles he had to jump have put him off building another car, we’re sure that once he gets a few more miles on the Challenger, he’ll change his tune. Then again, he’s built the Challenger to be everything he wanted, and everything most of us can only dream about, so maybe we’ll let him off for building only one!

1970 Dodge Challenger

- Engine: 426ci Chrysler Hemi, 6.1-litre block, custom XVM manifold, Accufab throttle body, billet fuel rails, FAST ECU, XVM headers, twin 3-inch stainless exhausts, Magnaflow mufflers, custom alloy radiator, twin electric fans

- Driveline: Tremec TK0600 five-speed gearbox, Dana 60 diff, 3.9:1 ratio, aluminium driveshaft

- Suspension: XVM aftermarket K-member, remote reservoir shocks, C6 Corvette lower arms, C6 Corvette uprights, XVM billet top arms, adjustable roll bars, XVM steering rack, billet lower rear arms, adjustable panhard bar, Hyperco springs,

- Brakes: Hydroboost booster, six-piston StopTech front calipers, 350mm front rotors, four-piston StopTech rear calipers, Wilwood handbrake caliper, 325mm rear rotors

- Wheels/Tyres: 18×9.5-inch and 18×10-inch XVM billet wheels, 275/35R18 and 295/35R18 Michelin tyres

- Exterior: Customized Hemi orange PPG paint, painted bumpers, carbon-fibre shaker scoop,

- Interior: XVM gauges, custom console, full leather retrim, Recaro electric seats, Dynamat, Ringbrothers shifter, JVC audio, custom billet speaker grilles, Vintage Air air conditioning

- Performance: 612hp at the flywheel

Driver profile

- Driver: Phil Kenny

- Age: 57

- Occupation: Company director

- Previously owned cars: Porsche 996, Aston Martin

- Dream Car: This one for now

- Why the Challenger? I always wanted a Charger, but missed out on the one I was trying to buy

- Build time: Four years

- Length of ownership: Nine years

- Phil thanks: Rodney Holland at Rodney’s Restorations, Trevor at Auto Interior Specialists, Simon Tippens at Creative Metalworks, Howard from Autotronic Services Ltd, and my son, Benn — if it wasn’t for him, the car wouldn’t have been built

This article was originally published in NZV8 Issue No. 117. You can pick up a print copy or a digital copy of the magazine below: