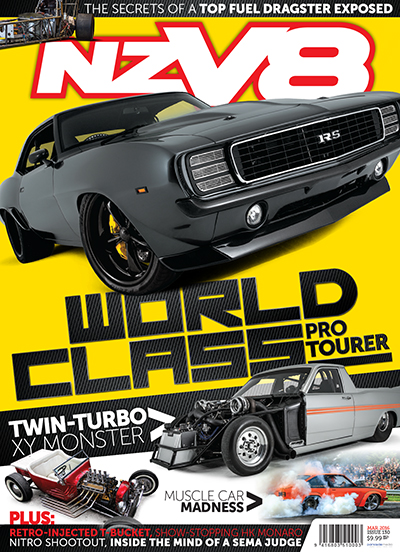

You’ve seen the incredible pro-touring Camaro on the cover of our latest issue — NZV8 Issue No. 30 — but what would the owner build if he could build the car of his wildest dreams?

“If the owner could have any car in the world built, we’d build him an FIA GT3–spec ’69 Camaro,” says IPC’s Nick Williamson matter of factly.

This would essentially be a car much like Ian ‘Inky’ Tulloch’s 2014 SaReNi United Camaro GT3, featured in NZV8 Issue No. 119 and built to compete in local endurance series. As a number of IPC’s other race vehicles are also endurance racers, this type of build would be right up the company’s alley.

In a ’69 Camaro, the most convenient starting point would be a brand-new Dynacorn bodyshell. This utilizes a separate chassis, so an aftermarket Chassisworks-style front clip would likely be the easiest option for improving the front suspension. IPC’s skills extend to the ability to custom engineer and fabricate a cantilever-style suspension system for inboard shocks, with perfect-circuit racing characteristics and geometry.

An independent rear suspension subframe from a late-model Camaro could be grafted into the Dynacorn body, again to provide optimal suspension geometry, as could readily available adjustable components by aftermarket manufacturers. As the car’s track would be increased beyond that of a standard ’69 Camaro, wide-body fenders would be required to contain the Camaro’s footprint.

The Dynacorn body’s doors, fenders, bonnet, bumpers, nose cone, boot, and roof panels could all be used as plugs for lightweight carbon-fibre panels to be made up. The IPC team could even modify the original steel fenders by pumping them out, to use as a plug for wide-body carbon-fibre fenders. At the rear, the quarters could be cut off the body and pumped outwards, allowing for removable wide-body carbon-fibre rear quarters secured by Dzus-style fasteners. Not only would this allow for a wider track to be contained, but it would also allow for easily replaceable panels in the event of damage.

Of course, effective aero would be a huge area of investment, with a low drag coefficient and high downforce required for maximum on-track performance. A flat underfloor would be advantageous, and could be made of either sheet alloy or carbon fibre. It is likely that carbon fibre would be the material of choice when crafting a front splitter, canards, rear diffuser, and spoiler.

For the ultimate in braking performance and weight saving, the Camaro could be engineered to run Brembo GT-R billet brake calipers, with six-piston units up front, and four-pistons at the rear, with two-piece floating discs and race-compound pads. To save on unsprung mass, lightweight alloy wheels would be a necessity, although they’d also need to look the part. OZ Racing Superforgiata CL centre-locking alloys, measuring 19×11 inches all round, should allow for superb handling as well as rapid wheel and tyre changes at the pits if required.

Of course, making it all go would be the fun part, and keeping the spirit of the original IPC Camaro, the engine would have to be LS based. An LS7 crate engine would form a good base engine, and a few performance and reliability enhancements, such as forged, high-compression pistons, a race-profile solid roller camshaft, and beefed-up valvetrain, as well as a multi-stage dry-sump system, should ensure decent power from a reliable engine that wasn’t afraid to rev.

A sequentially-shifted Holinger RD6 six-speed manual transmission would be a pretty easy choice for a transmission that was strong, reliable, fast-shifting, and with a good spread of gear ratios.

That’s a boiled-down account of the most likely way an FIA GT3-spec ’69 Camaro would come about — ignoring the fact that a ’69 Camaro hasn’t actually been GT3 homologated by the FIA. While there’d be a whole lot more to worry about, such as roll caging, fuel system, electronics, and telemetry, it could all be done, and IPC would be the team to do it!

This article was originally published in NZV8 Issue No. 130. You can pick up a print copy or a digital copy of the magazine below: