data-animation-override>

“What do you get when you cross a mechanic, two engineers, and an old Ford F100? Some pure automotive gold, of course!”

While the first 1956 Ford F100 Ian “Tug” O’Brien built had to be regretfully put up for sale when his sons, Jarrod “Honk” and Richie, were little, Tug’s burning desire to get another one got progressively stronger over the years. As the boys got older, they, too, became more and more interested in cars; in particular, just like their Dad, 1956 Ford F100s found a soft spot in their hearts.

It was with this joint passion in mind that, around 11 years ago, Tug made the decision that now was the time to purchase one. With both boys by then engineers by trade, it was not only a great opportunity for them to be able to hone and show off their skills, but also for Tug to get the truck he’d always wanted — not to mention that, for the boys, it was also a good excuse to spend a bit of time doing cool shit with Dad in the shed.

A suitable starting point was found in Hastings, and the deal was done, but when the O’Briens got the truck home and were able to have a more thorough look, they quickly discovered that things were far from ideal and this would be no quick rebuild. Upon closer inspection, they found that the cab’s pillars were rotten, the floor was buggered, and the right side of the roof was gone. Things didn’t look any better when they got everything back from the sandblaster, either, as the blasting had revealed even more rust. After much head scratching and a few “What the hell have we done?” questions, the decision was made to forge ahead and turn their pile of rust into something special, no matter how long it took.

The fibreglass front end that the truck came with was soon given the flick and the hunt was on for real steel body parts. Thanks to Mid Fifty F-100 Parts in Arizona, sourcing all the patch panels they needed to replace the important missing or rusty body bits was a breeze. A fibreglass wellside and a set of running boards were also purchased and waited patiently in the corner of the shed until the boys were ready for them.

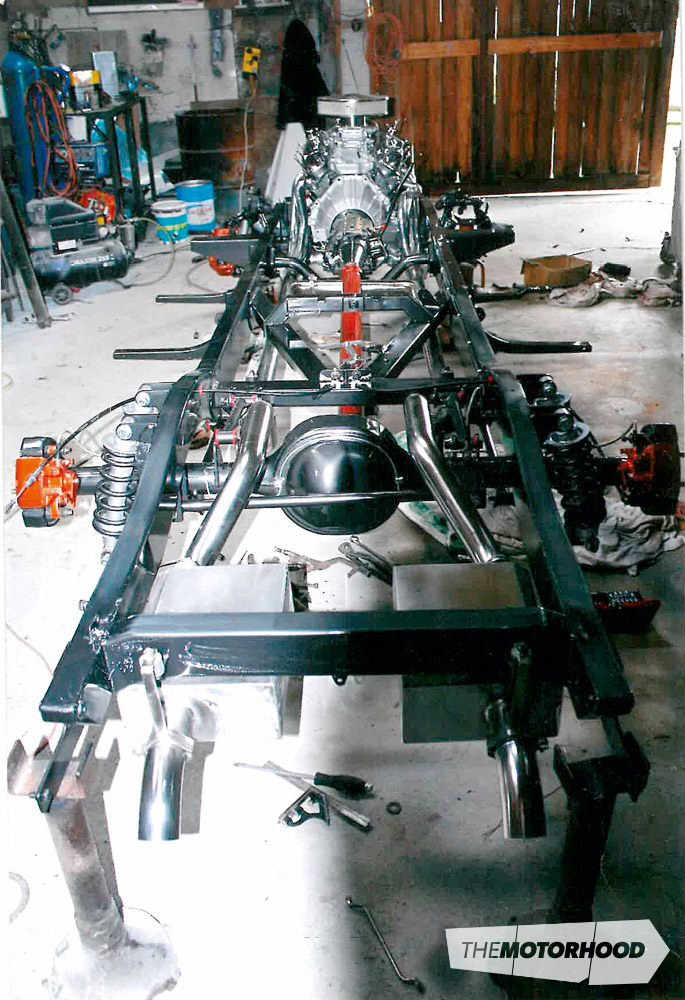

The chassis that the rusty cab was sitting on was discarded, as the boys had decided they would fabricate their own. A sheet of 4mm plate was chopped up by RCR Energy in Dannevirke, and chucked into shed that the truck now called home. Old it may be, but the shed out the back of the family home has played an integral part in the truck’s life. There’s no pristine clean work surfaces here, though; hell, there isn’t even any power! Tug, Honk, and Richie fully intended to get it hooked up but never got round to it. Instead, they rely for their electricity on a 30-metre extension cord hanging out the window of the closest bedroom.

The state of the floor made chassis building interesting, to say the least. It was only after the chassis was completed that Tug finally decided to sort it out. How they managed to get a chassis anywhere near true on a floor that was found to be over a foot out of level is anyone’s guess!

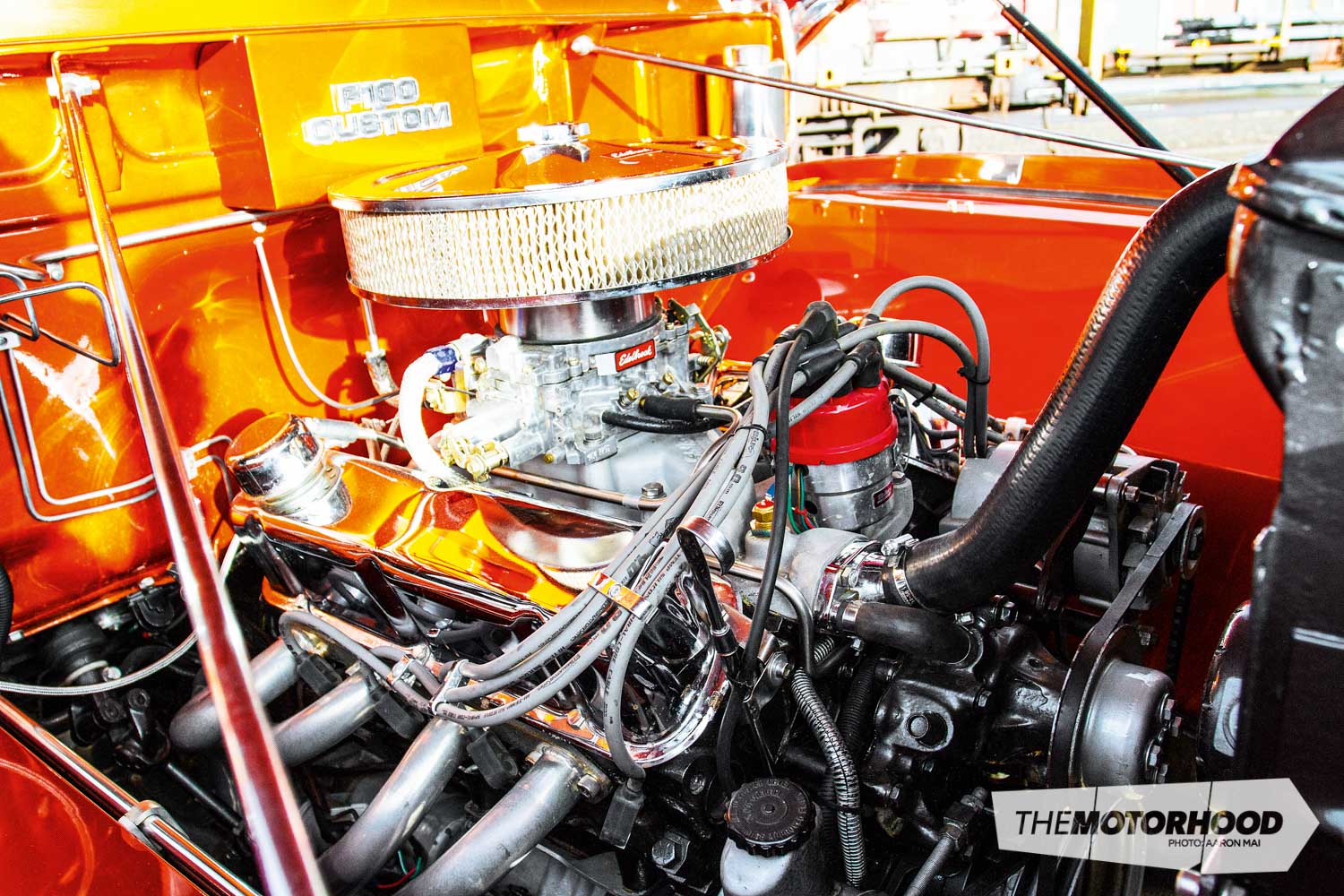

While the boys were busy stitching the chassis together, Tug was sorting out the engine, which was based around an old 302 unearthed from deep in the bowels of the shed; it had once been the propulsion for a Mustang. The thing was so old that when Tug pulled it down the pistons were so seized in place that he couldn’t even get them out of the block. Not being one to give up easily, and also being someone who enjoys a good challenge, Tug used an old tyre bead breaker to “gently persuade” the pistons back out into the Hawke’s Bay sunshine.

The block was then bored 30 thou and filled with a set of flat-top pistons. A stage two cam and lifters were also thrown in for good measure. The stock heads only needed a clean-up. An Edelbrock Performer manifold was screwed in place, along with a matching 500cfm Edelbrock carb.

When it came time to fire the new heartbeat into life for the very first time, Tug called on one of his many other skills: 40 years of experience as a volunteer fireman. Should anything go awry, having the third officer on hand to douse any errant flames could only be a good thing, right — especially when it was he who caused the flames in the first place! After a healthy dose of fuel was poured down the throat of the carb, the engine was cranked over. The freshly built 302 belched a healthy back fire, igniting the fuel that hadn’t been poured in. Thinking quickly, and not wanting everything in the shed to go up in smoke, Tug chucked the flaming container of fuel out the nearest open door — all over his son-in-law, Jamie, who had just walked in for a visit! With his leg on fire and Tug in hot pursuit, Jamie was trying his best to run away from the inferno licking its way further up his leg! Jamie was eventually tackled to the ground and the fire on his leg was quickly extinguished. The guys look back on the incident now and all have a bit of a laugh, Honk saying, “That’s what happens to Holden supporters when they come into a Ford shed!”

Now that the engine was firmly sitting between the all-new Honk and Richie (Does that make it Honkie?) built chassis, the rest of the driveline and rolling stock could be attached. A Jag front end had been sourced, completely rebuilt, and bolted on to the front. At the other end was nine inches of Ford’s finest. This was attached to the chassis with a custom four-link that the boys whipped up. Joining the “brother-in-law burner” to the nine-inch is a C4 trans that Lincoln Automatics in Palmy worked their magic on, freshening it up and fitting a shift kit into the process.

Keeping everything up off the ground is a set of shiny new shoes — Chip Foose Nitrous IIs measuring 18×8 inches and 18×10 inches and shrouded in Hankook rubber.

Having such a high-quality chassis sitting underneath a body of lesser quality would have been sacrilege. Thankfully, just as much care and attention were given to the body. The boys had stitched in all the new panels, fitted a big back window, and removed the drip mouldings, giving the truck a fresh, smooth, new look. The doors have had their corners rounded, and all exterior vents have now vanished from the old girl’s flanks.

The fibreglass wellside is now three inches wider than stock and also tips upwards on request. In an effort to keep the tilt mechanism clean and simple, the team robbed a Johnson outboard motor of its rams and power pack. Now, when the boys raise and lower the rear of the truck, everyone looks around for the boat that is trying to put its motor into the water in the middle of the car park.

Tug and the boys would specially like to thank Martin Domper for doing such a great job with the final panel prep and painting. “She ain’t no spray-booth paint job,” says Honk. “If you look hard enough, you can spot the odd sandfly hitch-hiker.” Yep, she was also painted in the family shed — not that you’d ever think that at first glance.

Things are just as tidy inside as they are on the outside. Kerry’s Upholstery Specialists in Levin re-covered the Falcon bench seat, a Dakota Digital cluster was jammed into the dashboard, and power windows now let the hot air out and the cool air in. A decent Sony audio install finishes the package off nicely.

After 11 years on and off, Tug, Honk, and Richie were finally able to drive their truck out of the shed, completed. They would like to thank everyone involved for their help in turning their dreams into reality. Without the extension cord hanging out the window, snaking its way into the ratty old shed, and, of course, Mum’s coffee and cheese on toast, they would probably still be at it! Instead, they’ve got a vehicle that’s not only golden in colour but also golden in build quality, with some golden memories to match.

1956 Ford F100

- Engine: 302ci Ford Windsor, 0.030-inch overbore, flat-top pistons, stage 2 cam and lifters, ported heads, Edelbrock Performer manifold, 500cfm Edelbrock carb, stock fuel pump, Mallory electronic ignition, custom 2½-inch stainless exhaust, HPC-coated custom headers, hand-built stainless steel mufflers, aftermarket transmission cooler

- Driveline: Ford C4 transmission, shift kit, Ford nine-inch diff

- Suspension: Modified Jaguar XJ6 front end, four-link rear, Nolathane bushes, rear coilovers

- Brakes: EA Falcon booster, custom pedal box, Jaguar XJ6 front brakes, EA Falcon rear brakes

- Wheels/Tyres: 18×8-inch and 18×10-inch Foose Nitrous II rims, 245/45R18 and 285/50R18 Hankook tyres

- Exterior: Drip moulding removed, rounded door corners, all vents removed, one piece power windows, custom wellside, custom hard top, custom tailgate, widened rear guards, Ford Sunburst paint

- Chassis: Full custom chassis

- Interior: Falcon bench seat, Flaming River tilt column, Lokar shifter, Dakota digital gauges, custom door trims, digital dash, power windows, Sony audio

- Performance: Untested

This article was originally published in a previous issue of NZV8. Pick up a copy of the edition here: