data-animation-override>

“It’s been a long time coming, but the Possum Bourne Motorsport–built Subaru BRZ owned by Gary Morgan is ready for the world stage”

You might have noticed that in New Zealand, we are producing much more than oval-ball throwing behemoths who ingest 15‒20 Weetbix in one seating and become instant legends on the 6 o’clock news. There are other avenues than the rugby field for the fan of speed and might, and Gary Morgan is one great example.

A late bloomer — Morgan was 20 when he purchased his first loud, fast machine — it didn’t take him long until he found himself completing his first three-hour endurance race at Manfeild in a road-legal, somewhat race-prepped Subaru Legacy RS. A special bond was formed between Morgan and his Subaru, and a further bond between Morgan and endurance racing itself, creating a connection to the sport and sparking the creation of another kind of behemoth — a world-class, Possum Bourne Motorsport–prepared 2012 Subaru BRZ endurance racer.

Since relocating to the Sunshine Coast in 2005, Morgan has contested several Targa and circuit events, cementing his passion for the sport behind the wheel of a clustered-star badged all-wheel drive, as he explained, “I bought a Legacy RSR that was one of the original five-rally cars brought to Australia for the 1991 Rally Australia. Thanks to my wife, B1 — as she calls it — is still around and has competed from Tasmania to Queensland and has spent recent years doing Targa NZ with some great success — and some crashes; one made Plays of the Week in New Zealand in 2008.”

Morgan sought, though, a platform that combined the endurance and Targa-style elements together and his search landed him a phone call from Possum Bourne Motorsport, claiming they had just the car, Morgan explains, “I received a call from PBMS offering me the opportunity to buy a BRZ as a base car. My son convinced me I should — however, the plan at this stage was to build a Targa car.”

Money was duly exchanged, and plans were hatched between Morgan and PBMS to replicate a previous build they had completed for Subaru Australia, who also required a Targa specific BRZ. The only addition Morgan wanted was the use of a supercharger for a bit of extra might over the factory 149kW— and things naturally snowballed. “Over time, as the roll cage went in and some other items, we had ongoing discussions, and I decided I wanted to build a full-blown endurance car with everything we could possibly do to it. Firstly, keeping an eye on the FIA GT4 rules and secondly, making it eligible for all the iconic races around the world including Bathurst, Sepang, Nurburgring, and Daytona,” Morgan explained.

With a clear and streamlined build plan in place, the team at PBMS set to work on the different aspects of the build. Bryan Hayton, owner of PBMS, had already blown our minds with his talents with the hand-built carbon fibre items on the Vantage Motorsport Subaru WRC car, recently featured in NZPC Issue 222 — and the BRZ is no different.

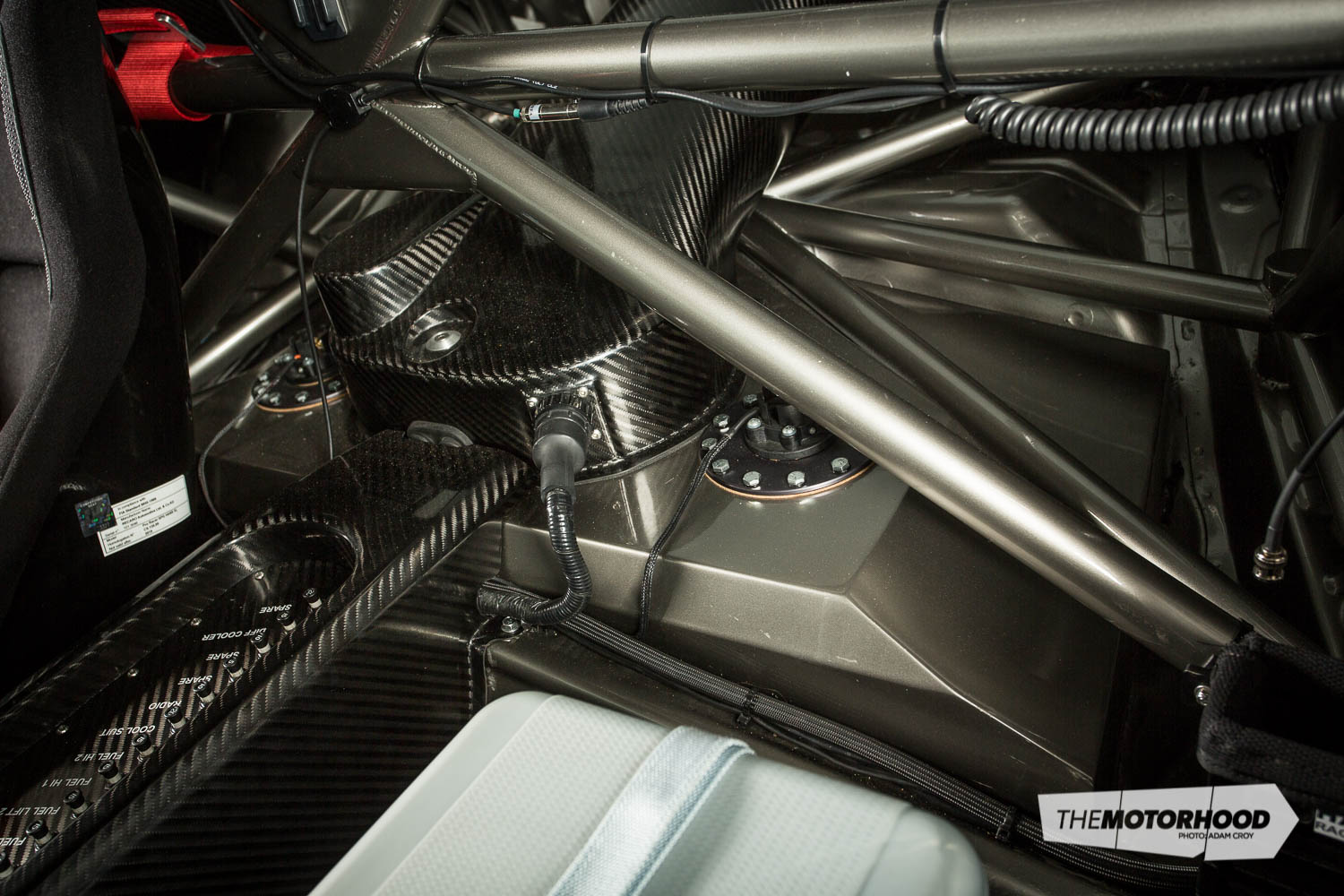

There’s carbon everywhere; if it can be replaced with carbon fibre to save weight, it has been. The roof, with custom air vent, roll cage panels, interior panels, fuel-filler duct, engine cover, boot tray, door cards, parcel tray, centre console, and several other carbon components were whipped up in-house by Hayton in the rock-solid yet lightweight weave. But wait, there’s more — more carbon fibre. The more you look, the more you pick up less-obvious carbon items, such as the trim around the air-jack attachment and side mirrors.

The Fuel Safe quick-fuel filler point is housed in a one-off carbon boot tray that looks like an early ’00s subwoofer compartment. As the E85 is pumped into the fuel flaps, it flows down a fuel neck housed in a carbon fibre duct — one of the most impressive pieces in the vehicle. It’s poetic. The journey continues down into the 120-litre Fuel Safe fuel bag, cased in a custom aluminium housing capable of supporting the increased fuel load. There are two reasons a 120-litre fuel tank is required for this build, the first being the obvious; it’s a fossil fuel–inhaling endurance vehicle; the second comes thanks to a snarling, fire-spitting, chirping, supercharged FA20.

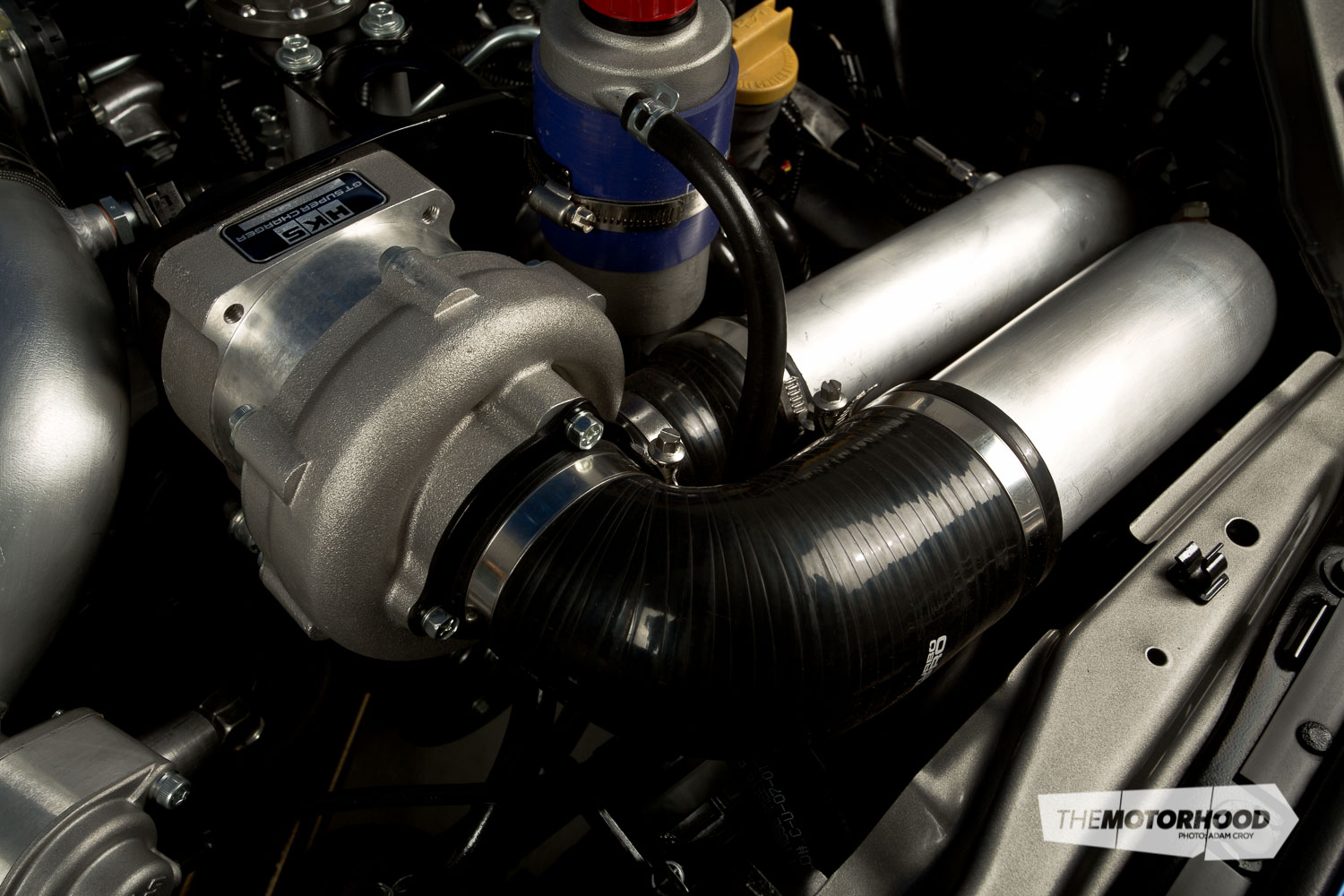

PBMS are used to building reliable, monster EJ20s instead of the later model FA20 found factory in the BRZ, but their expertise is blue-ribbon. The nature of endurance racing exacts harsh forces on vehicle components due to the heat generated over the prolonged period of racing, and when the decision had to be made between supercharging or turbocharging the FA20, it was simple. Supercharging the FA20 would produce much lower engine-bay temperatures for the same given power, and the throttle response a unit such as the chosen HKS centrifugal kit offered was unsurpassed.

Out of the box, the HKS supercharger runs a lowly 7psi of boost, but PBMS have increased the boost pressure with a new pulley and have moved the physical location of the charger with a custom mount to allow for a better-flowing intercooler pipe arrangement. But the kit disliked the extra 18psi that was now being pushed through it, once run up on the dyno. The HKS intercooler experienced intake temps post-cooler of around 100 degrees, which on the dyno caused some drama. Timing was pulled back with the MoTeC M130 to reduce detonation and power was much lower than what they initially thought possible with this set-up. Coupled with this, another problem found on the first dyno outing was the primary header-pipe diameters were far too small, along with the rest of the exhaust system.

As a resolution a much larger front-mounted intercooler, custom enlarged CNC-bent headers, and a three-inch exhaust system were fitted and the team spun her up again. This time, post-cooler intake temps were around 20 degrees and the increase in exhaust diameter sealed massive gains in power. Timing and ignition maps were pushed to the extreme with the E85 fuel, and 306kW (410hp) at the wheels materialized at last.

These numbers are not possible with the factory internals, but PBMS covered this off with JE forged pistons made to PBMS spec, and Pure Performance Motorsport con rods. They also made sure the head got a porting to make use of the added boost pressure, and added Kelford Cams valve springs for reliability. The shakedown was complete.

With the engine now on best behaviour, Morgan is ready to contest New Zealand’s best, meanest and monstrous, as he tells us, “The plan now is to test its reliability over the winter months at the North Island and South Island endurance races culminating at the Highlands 101 in October. Assuming the budget can be found for the programme and the testing goes well, then the Bathurst 12 Hour in 2015 is the goal.”

Morgan will pilot the BRZ in both New Zealand and Australia. To help out, he has chosen young talent Mark Gibson, who has a background racing both Suzuki Swifts, and V8 Supertourers. “We hit it off immediately and I asked him to drive at the first race meeting at Hampton Downs. Mark very quickly got inside the top 10 in the first race against Porsches, a Nissan Skyline R35 GT-R (featured in NZ Performance Car Issue No. 218), and a couple of Audi R8s GT3s. He is, and will remain the main driver, as he loves the car and fits well with the team,” Morgan concluded.

The livery will change once a sponsor is secured, but if you do catch Morgan and the team at a local circuit, make sure to say hello and you might get a closer look at this wild kiwi-built monster before it ships out to take on the world.

Tuning menu

2012 Subaru BRZ (ZC6)

Engine

- Model: Subaru FA20, 2000cc four-cylinder

- Block: Forged JE pistons, Pure Performance Motorsport con rods

- Head: Kelford Cams valve springs, ported and polished

- Intake: Three-inch cold air intake, PBMS intercooler piping, Simota air filter

- Supercharger: HKS centrifugal supercharger, PBMS supercharger mounting plate

- BOV: HKS

- Fuel: PBMS designed fuel cell, 120-litre Fuel Safe bag tank, four low-pressure lift pumps, two Deatschwerks fuel pumps, Tomei fuel-pressure regulator, custom fuel rails, Injector Dynamics ID1000 injectors, Fuel Safe quick fuel system

- Ignition: Factory

- Exhaust: PBMS CNC-bent three-inch stainless steel exhaust system, AdrenalinR mufflers, PBMS CNC-bent 4-1 extractors

- Cooling: 600x300x100mm intercooler, PBMS alloy radiator, Setrab oil cooler

- ECU: MoTec M130 plug and play unit, MoTec LTC (Lambda to CAN module), MoTeC GPS

- Other: MoTeC controlled launch control and traction control, hidden oil catch can, PBMS carbon-fibre engine cover

Driveline

- Gearbox: Holinger SG3-SS six-speed sequential

- Clutch: Exedy twin-plate

- Flywheel: Exedy

- Diff: PBMS spec diff, Cusco LSD, GReddy extended housing

- Other: Driveshaft Shop 600hp axles

Support

- Struts: MCA custom built

- Springs: MCA

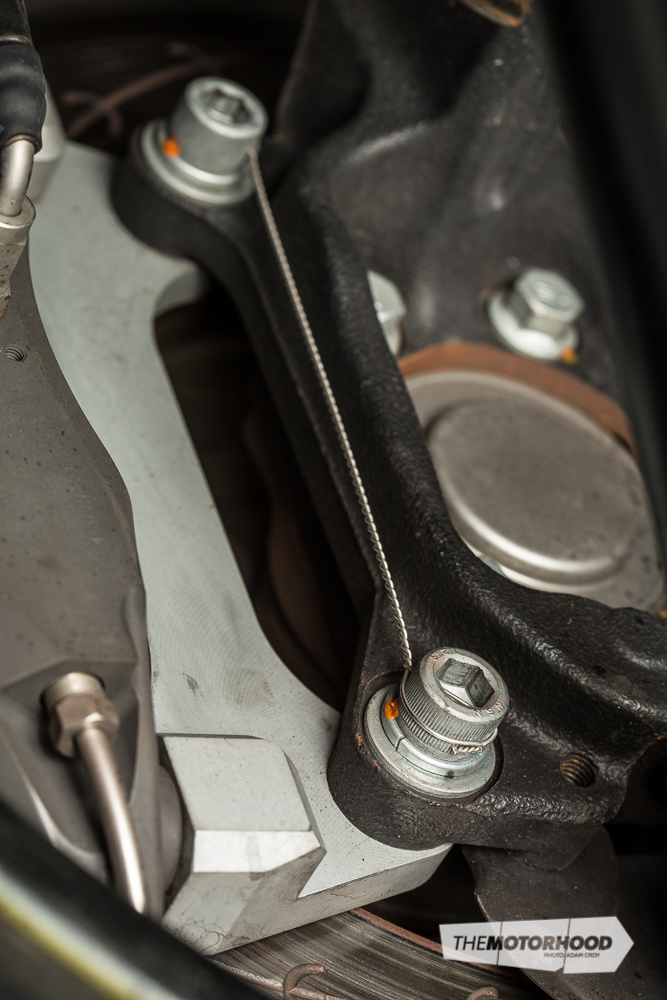

- Brakes: Endless RF650 brake fluid, PBMS braided brake lines, AP handbrake, AP floor-mounted pedal box (F) Endless MONO4 calipers, 345x32mm two piece rotors, Endless MA45B endurance pads (R) Endless MONO4 calipers, 332x28mm two-piece rotors, Endless MA45B endurance pads

- Other: AP Racing air jacks; Whiteline sway bars, bushes and ball joints; PBMS chromoly adjustable bottom arms

Shoes

- Wheels: 18×8.5-inch Work Emotion CR Kai wheels

- Tyres: 245/545-18 Pirelli P-Zero

Exterior

- Paint: Subaru World Rally blue Glasurit paint by Mills Collision Repair

- Enhancements: PBMS carbon fibre roof, PBMS carbon wing mirrors, carbon fibre wing, PBMS carbon fibre front guard garnish

Interior

- SEATS: Recaro

- Steering wheel: Sparco

- Instrumentation: MoTeC C185 Data logger dash

- Other: Suede-trimmed dashboard, PBMS carbon fibre centre console, PBMS carbon fibre MoTeC dash surround, PBMS carbon fibre foot tray, PBMS carbon fibre door cards, PBMS carbon fibre roof vent, PBMS carbon fibre fuel filler duct, PBMS carbon fibre parcel tray

Performance

Power: 306kW (410hp) at the wheels on 25psi with E85

Driver profile

- Driver/owner: Gary Morgan

- Age: 52

- Location: Sunshine Coast, Australia

- Build time: 18 months

- Length of ownership: two years

- Thanks: my wife Marisa and family for their support; Possum Bourne Motorsport; Ultra Paints for supplying Glasurit; High Performance Lubricants for supplying Motul; Andre and Ben at High Performance Academy; Prosport Auto; Michelin; MIS Insurance; MCA Suspension

Serious quantities of fuel are needed for endurance racing, especially when you’re running E85. As a general rule, 30 per cent more fuel is needed to produce the same power with E85 fuel, so PBMS pulled out the factory-capacity fuel tank and fabricated a 120-litre tank to house the plastic Fuel Safe bag

The original exhaust system PBMS had built for the BRZ was around 2.5-inches, all the way through, but as they found out on the dyno, the exhaust system and headers were proving to be a major restriction. The exhaust system was pulled off, replaced with a custom three-inch setup with no mufflers and the header primaries were replaced with larger diameter CNC-bent stainless. This created a major increase in power on the dyno — however the BRZ was now far too loud. Two AdrenalinR mufflers had to be installed in the system to quieten things down

To maintain total reliability, the factory gearbox was replaced with a Holinger unit, with a swag of supporting mods, including an Exedy twin-plate clutch and flywheel and Driveshaft Shop 600hp axles. The diff got similar attention, with a Cusco LSD unit and extended GReddy oil housing

PBMS got serious with the brake setup on the BRZ to ensure that hours into an endurance race there would be no issues. At front, 345x32mm two-piece rotors were installed, and 332x28mm items were installed down the back. To keep the car balanced, Endless MONO4 calipers have been used front and rear with Endless MA45B brake pads, which are Endurance specific. To finish things off, stainless steel braided lines have been used for their consistent pedal feel and an AP floor-mounted pedal box was installed

This article was originally published in NZ Performance Car Issue No. 225. You can pick up a print copy or a digital copy of the magazine below: