data-animation-override>

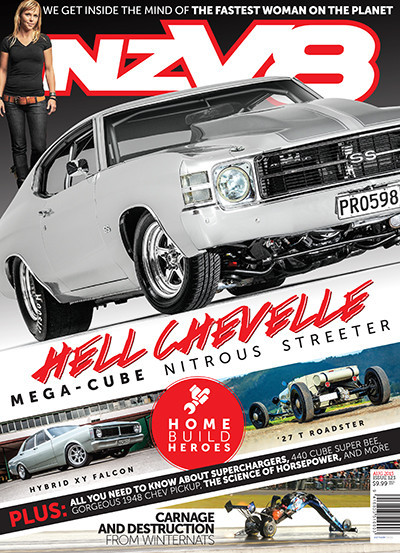

“He ran nine-second quarters in his street car back in the ’90s, so when Mike Bari decided two decades later that he wanted another tough streeter, it was always going to be epic!”

While some people sit reminiscing about the old days or talking up what they’re going to do in the future, Auckland mechanic and owner of Autocare Services Ltd, Mike Bari, is the opposite. Yep, way back in the ’90s his street-legal, and driven, Capri was good for nine-second quarters, making it legitimately one of the toughest street cars in the land at the time. Despite this giving him plenty to be proud of, he’s not one to stand there saying how great he was. Nor will you find him talking up what he’s going to do next, be it in person or on the internet. Instead, you’ll more likely find him researching his next project to the extent he can tackle pretty much any aspect of the whole build himself.

At least that’s how you could have found Mike until he started spending every waking hour on his 1971 Chev Chevelle three and a half years ago. After selling off the Capri at the dawn of the new millennium, he always hankered for another tough streeter, but with business and family commitments to take care of first and foremost, the time was never right. That didn’t mean he was stuck solely with the diesel work van, though, as he did manage to build a seriously tough, yet family friendly, Commodore VK — featured on the cover of NZV8 Issue No. 24 — which he still owns. As tough as the VK may be, it was never going to cut it on the drag strip, and that was never the intention for it, so Mike knew he’d eventually build himself something else.

The ironic thing is that the build of the Chevelle was actually kicked off when Mike found himself without a licence and was stuck catching the train to work for an extended period. This gave him plenty of time to sit and read, and it was here that the blueprint for a tall-deck big block formed in his mind. So keen was he on building something with big cubes that he commenced the build before even thinking about what vehicle the engine would go into. The suggestion from his son Caden to track down his old Capri set off a chain reaction of events that would end up seeing him complete that car, but for a customer rather than for himself.

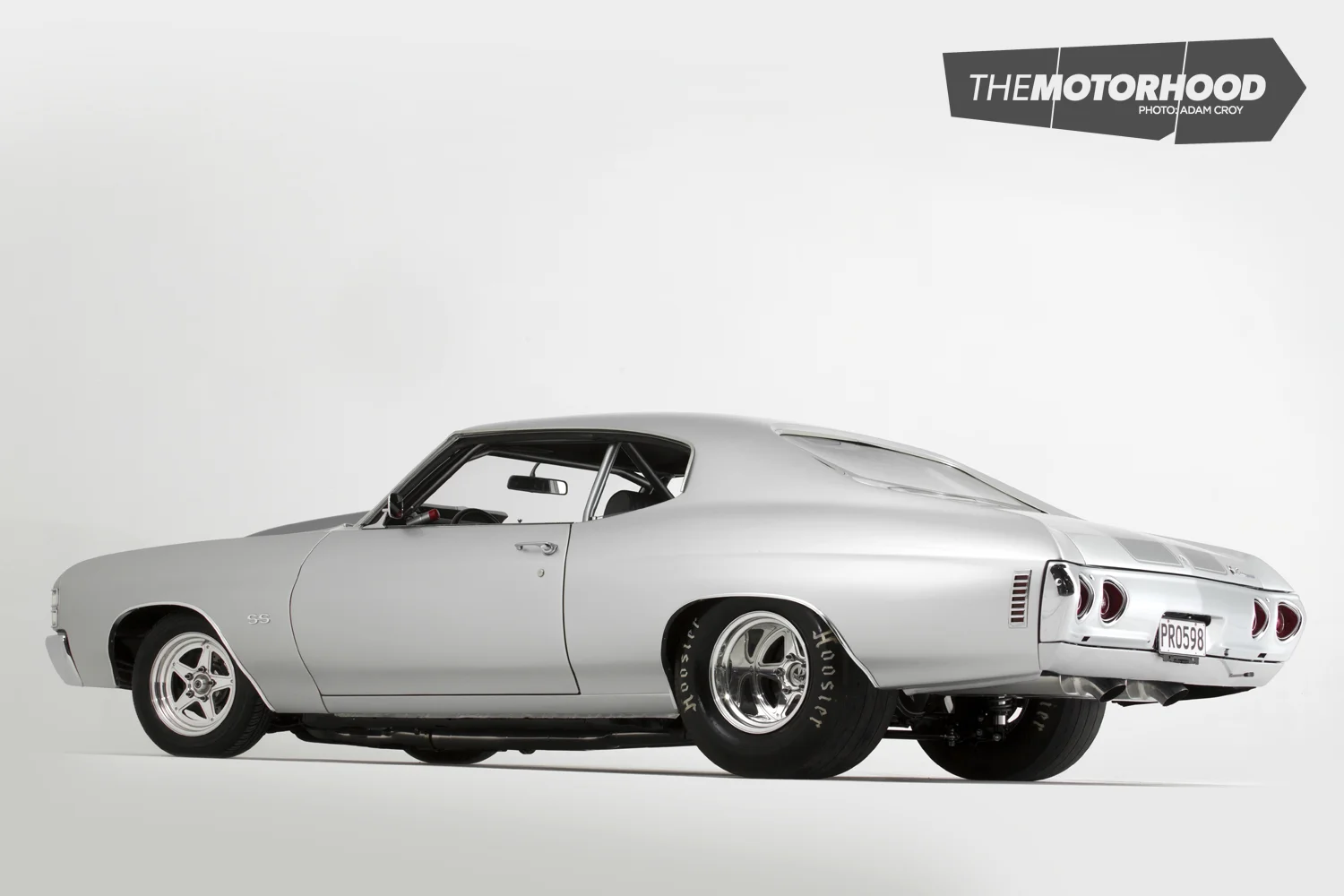

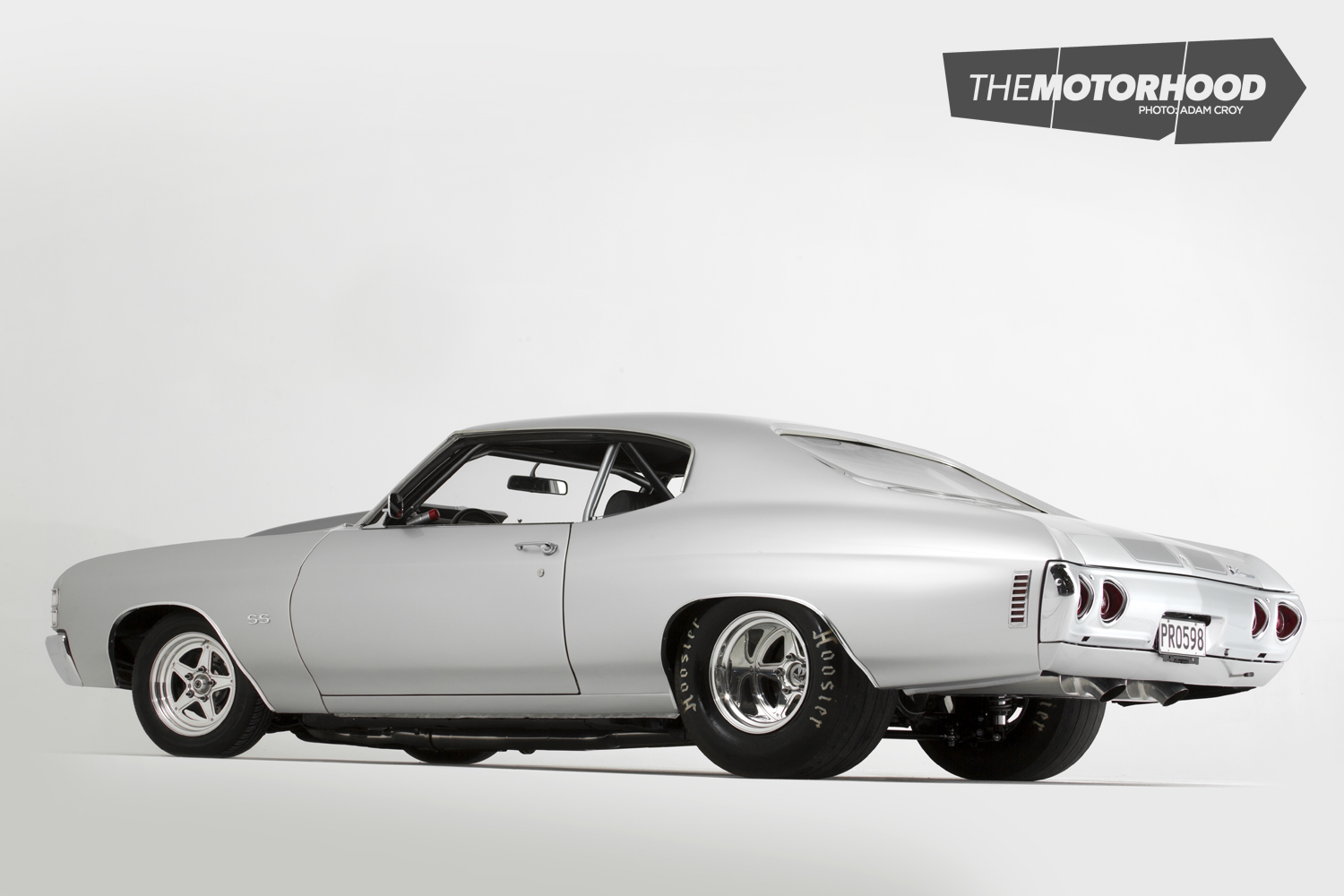

So, it was with the knowledge that the Capri wasn’t up for grabs that Mike turned to a vehicle he’d always wanted to own — a second-generation Chevelle. The appeal was not only the tough looks of these vehicles but also the fact they’re not just another belly button Camaro.

While Mike was chipping away at the engine, he had Chuck’s Restoration Supplies search out a decent body. Being a perfectionist by nature, he knew the only way he’d ever be happy was with a car he’d done himself. Rather than hunt out something with good, but not good enough for him, paint and panel, he requested a rust-free and straight shell he could rebuild to his desired standard. That way, he could entrust the paintwork to his good friend and fellow muscle car fan, Kyle Kitson, and his team at Greenpark Panel & Paint.

The car Chuck’s found fitted the bill exactly — a rust-free but straight ’71 Chevelle, complete with a tired but still drivable small block in it. So drivable was the car that Mike even got it legal and cruised in it for six months before pulling it down to transform it into the quick streeter he’d spent the last decade dreaming of.

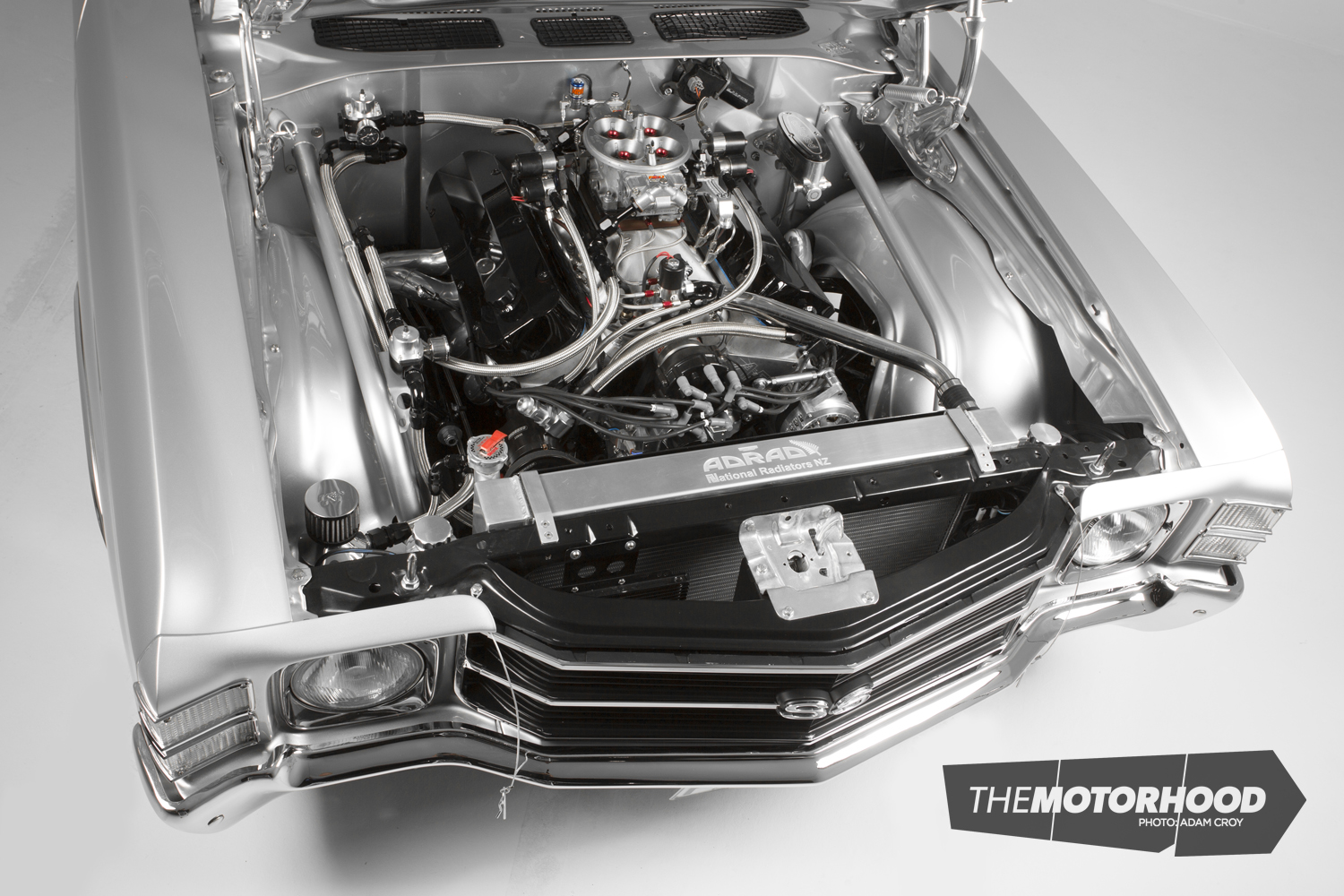

With the car running a full chassis, the body was pulled off, and a few simple changes made to it, such as smoothing the firewall and unwanted engine bay holes. It was then delivered to the team at Greenpark to add the final touches and a gorgeous coat of PPG waterborne silver paint.

Being free of the body allowed Mike to get into the chassis fabrication side of things — and plenty of work was required. The big challenges were not only getting the car to accept larger rear tyres but also adding enough adjustment to ensure those rear tyres hooked up well when they had power applied to them. As the car needed to be truly streetable and look like a genuine muscle car, Mike didn’t want massive tubs, so it was a compromise between looks and traction. For this, he chopped the rear off the chassis and replaced it with a Competition Engineering rear clip and four-bar set-up. This allowed the 15×12-inch Centerline Qualifier rims he’d already purchased and wrapped in 29×14.5×15 Hoosier Quick Time Pro tyres to fit under the rear guards — or at least they would once the body and chassis were reunited.

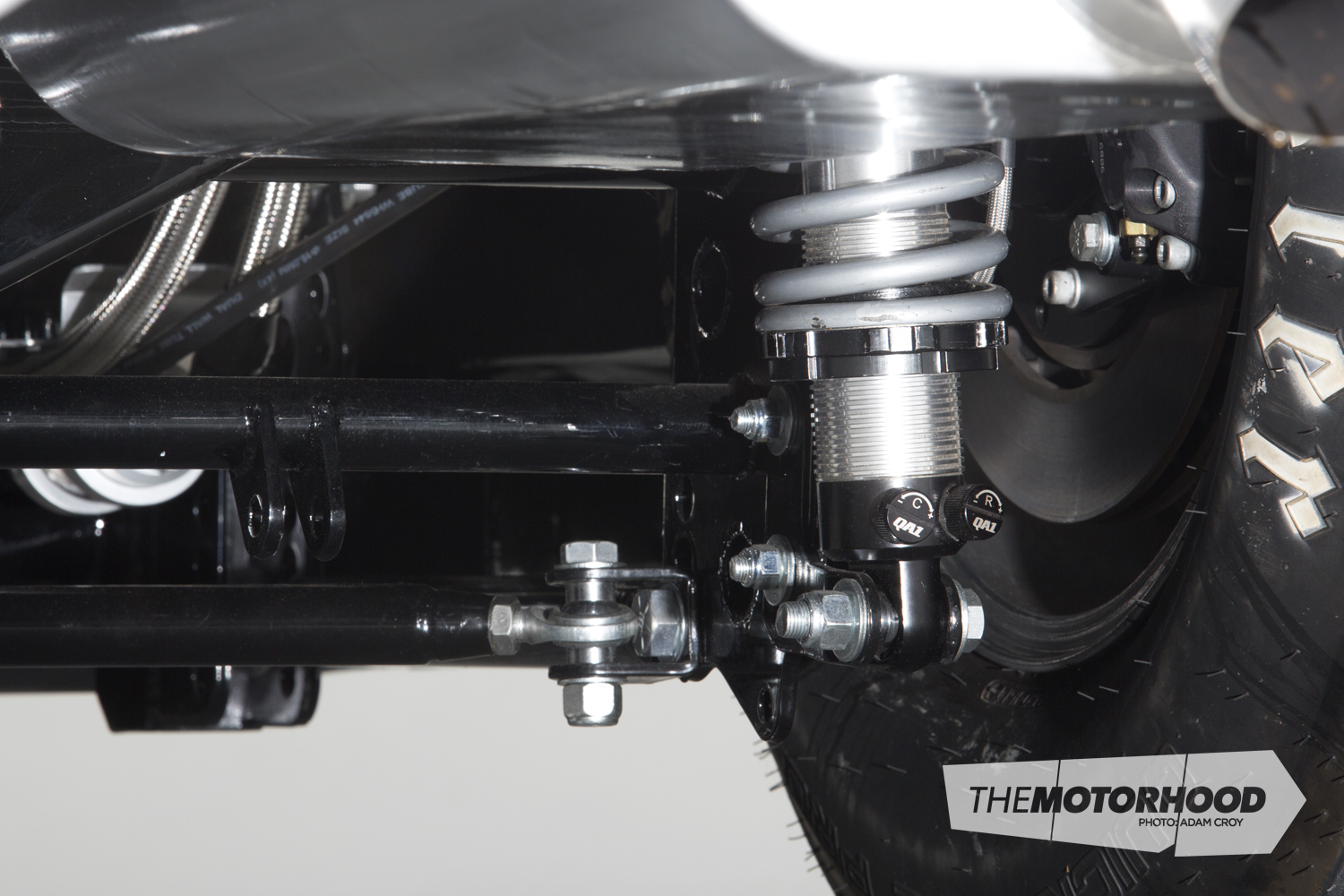

Knowing the car had to be built once and built right, rather than changed over the years, Mike put plenty of work into building the ultimate diff set-up for it. That included scrapping the original 12-bolt altogether and starting from scratch with a custom-length Strange chromoly housing. To this, Mike fitted a Moser head with Detroit Locker centre and 35-spline axles. A pair of adjustable QA1 coilovers now tie it to the diff along with that fully adjustable four-bar set-up mentioned earlier. A custom 3½-inch chromoly driveshaft, complete with billet yokes, is also attached.

The trans is as modified, and bulletproof, as the rear, having had plenty of hours’ attention from Chuck Mann. It now hosts a plethora of billet internals along with a reverse pattern manual valve body and transbrake — just the thing for coping with the punishment it’ll receive on race day.

Despite all this effort going into making sure the chassis was essentially as unbreakable as it could be, Mike still found time to make sure the car would also be nice to drive. After all, despite being built to run quick quarters, it was always set first and foremost to be a street car. This meant the aftermarket disc brake front end that was fitted when the car was purchased was soon sold on, and a set of Wilwood calipers and rotors installed instead. Not content with fitting these to the stock spindles, though, Mike replaced the spindles with aftermarket items mated to tubular A-arms and a Competition Engineering sway bar. Out the back are similar Wilwoods, but it’s the parachute that’ll attach to the mount hidden behind the flip-down numberplate that will have the best chance of slowing the car from the speeds it’s capable of reaching.

For safety’s sake, Mike, with help from C&M Performance’s Carl Jensen, built a roll cage complete with swinging door bars, making it easy for access yet safe enough to run single-digit passes. Wanting the true muscle car look, he never had any intention of fitting race seats, instead choosing Scat low-back leather-clad items. The rest of the interior was trimmed up to match, with plenty of custom panels fabricated and trimmed by Mike himself.

The stock gauges are as long gone as the stock trim, with Auto Meter items now taking pride of place in the modified dash. As cool as those look, it’s the custom mount for the TCI shifter that appeals to us the most. Inspired by race cars, and integrating the parachute lever as well as auxiliary switches, it leaves little illusion about the level of the car’s fabrication, build detail, and intended purpose.

The high level of detail extends into the engine bay, where the mother of all alloy radiators now resides. The triple pass item was built by Adrad to Mike’s own specs, and should be just the thing to keep the car cool no matter the conditions. Hanging off the back of it, within a laser cut shroud, is a pair of electric fans. The fans, along with the rest of the car, were rewired by the team at C&M Performance, who did so without leaving as much as a single strand of wire visible. That’s impressive when you see how much electronics are used on the motor itself.

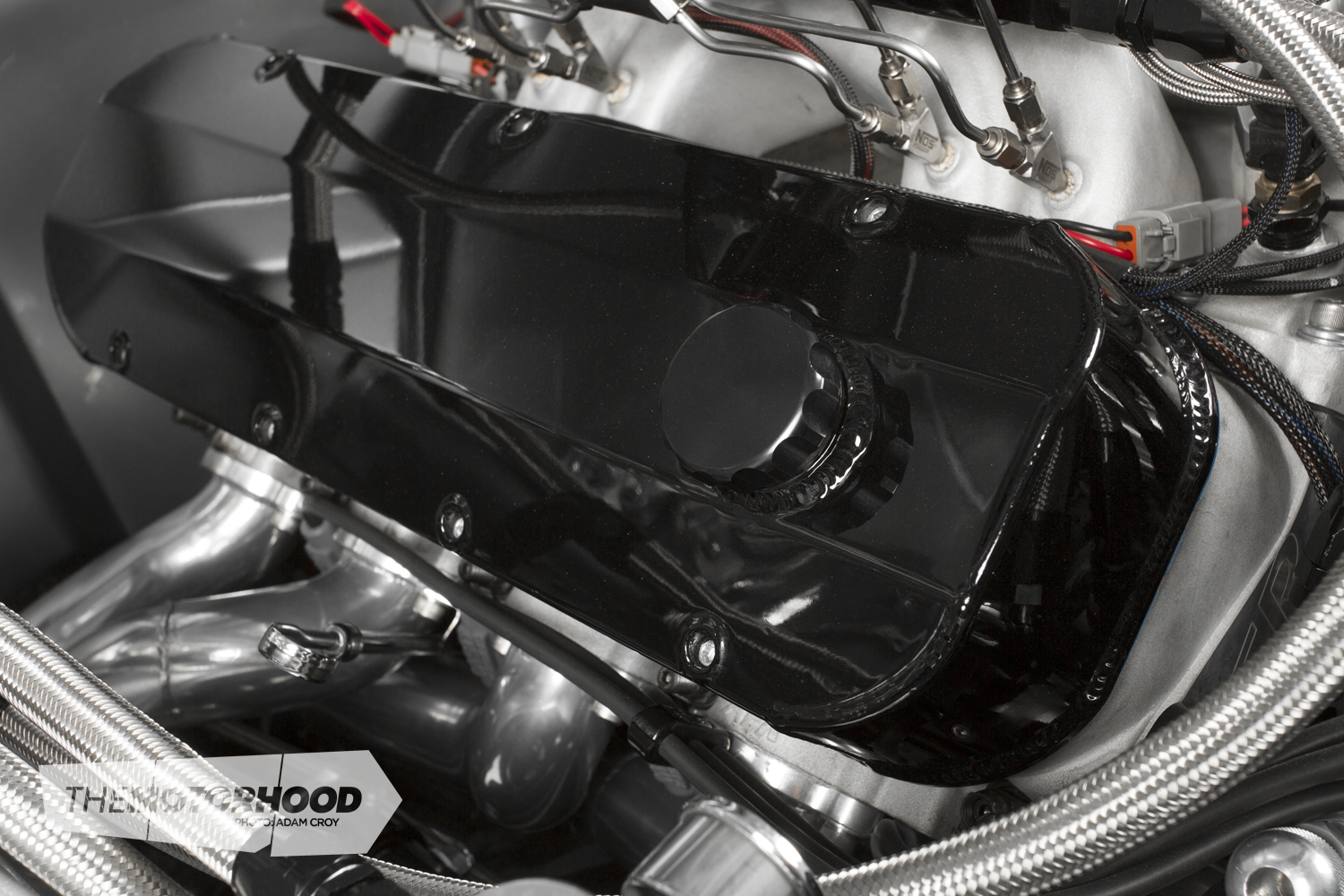

The motor that started this whole thing now displaces a massive 598 cubic inches, and was built by Mike with help from friend Murray Gray of Muzzas Motors. Building it as tough as Mike wanted it to be wasn’t without its complications, the most notable headache being that fitting the Hemi-sized Crower ‘Hippo’ roller lifters required the lifter bores to be machined out. Hemi guru, Mike Gearing, was called upon for this task, while Murray looked after the rest of the machine work.

Mike himself fitted the Eagle stroker crank and 6.7-inch rods along with custom JE pistons. When it came to sorting the heads, he had it kind of easy in a way, being friends with well-known drag racer, and owner of the quickest street car in the country, Reece Fish. When Reece upgraded his engine combo a few years back, Mike was nearby, and quickly purchased what was needed. Included in that were the high-flowing CNC-ported AFR Magnum heads — already fitted with titanium inlet valves and stainless exhaust valves. With Reece’s car putting out in excess of 1500hp when using them, they were certainly up to the task.

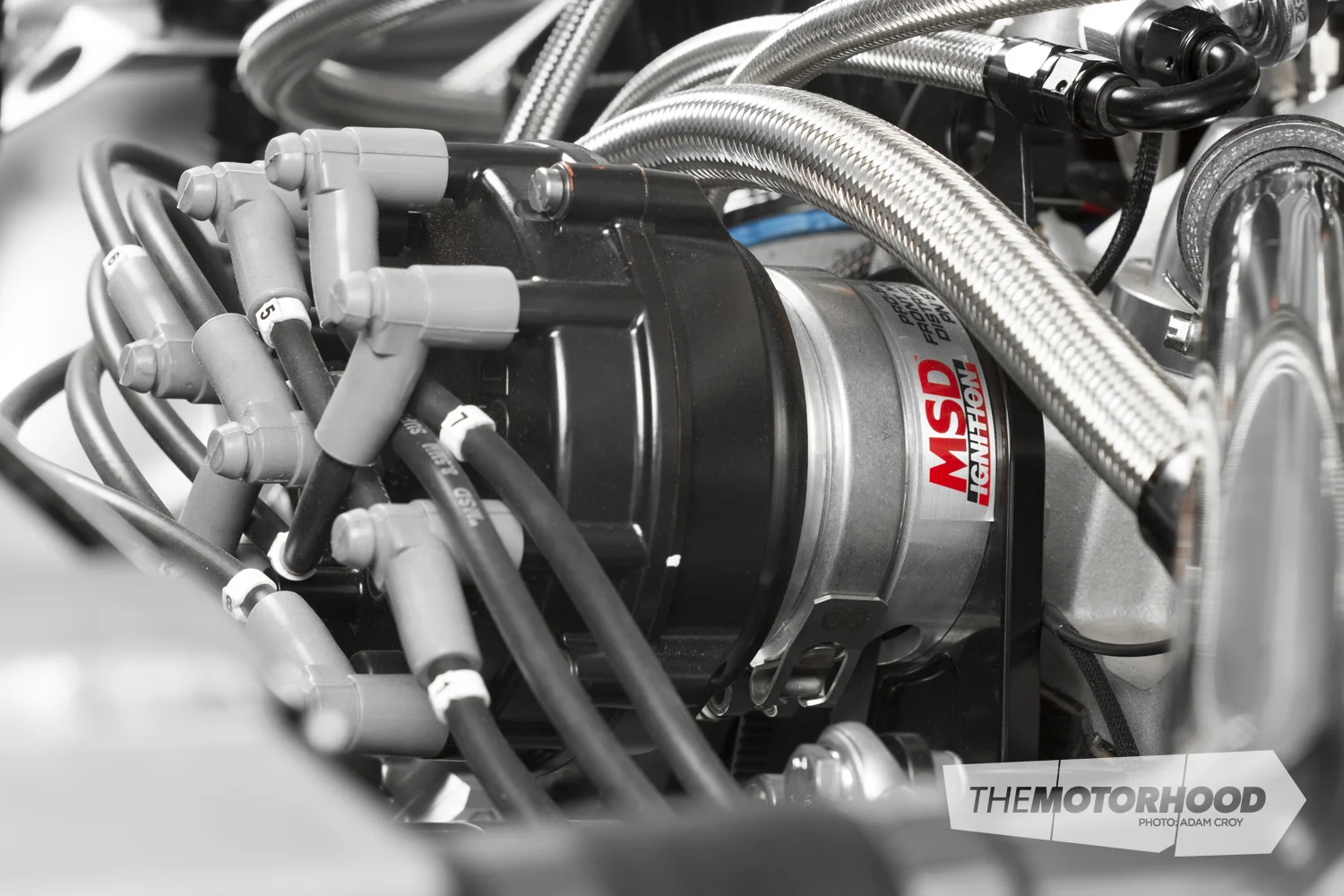

The programmable ignition system was also a Fish cast-off. This did, however, mean that Mike needed to change to a front-drive distributor set-up, and things spiralled a bit further than originally intended. The plus side is that the engine now essentially has the best bits available attached to it, and hopefully they should last the distance.

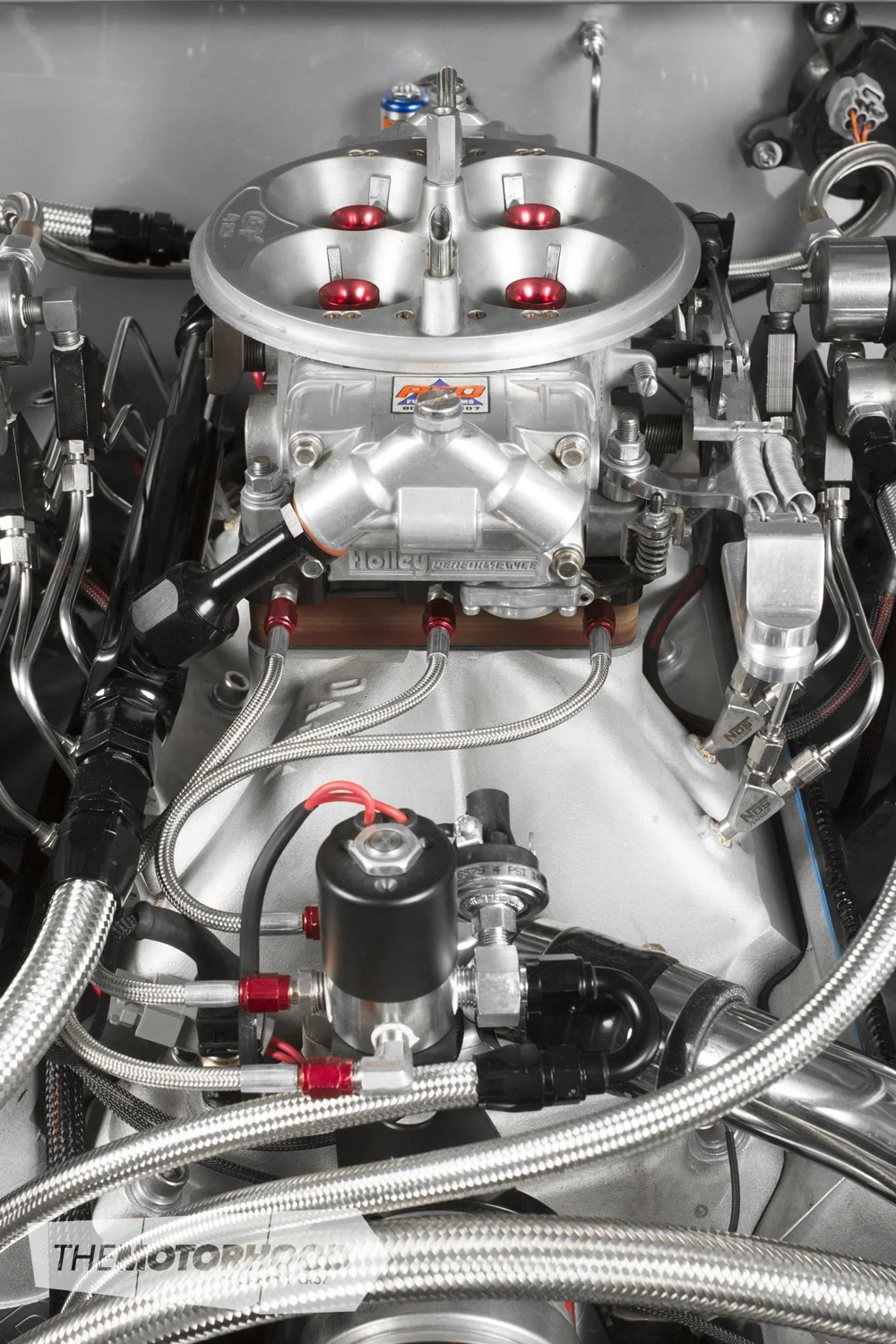

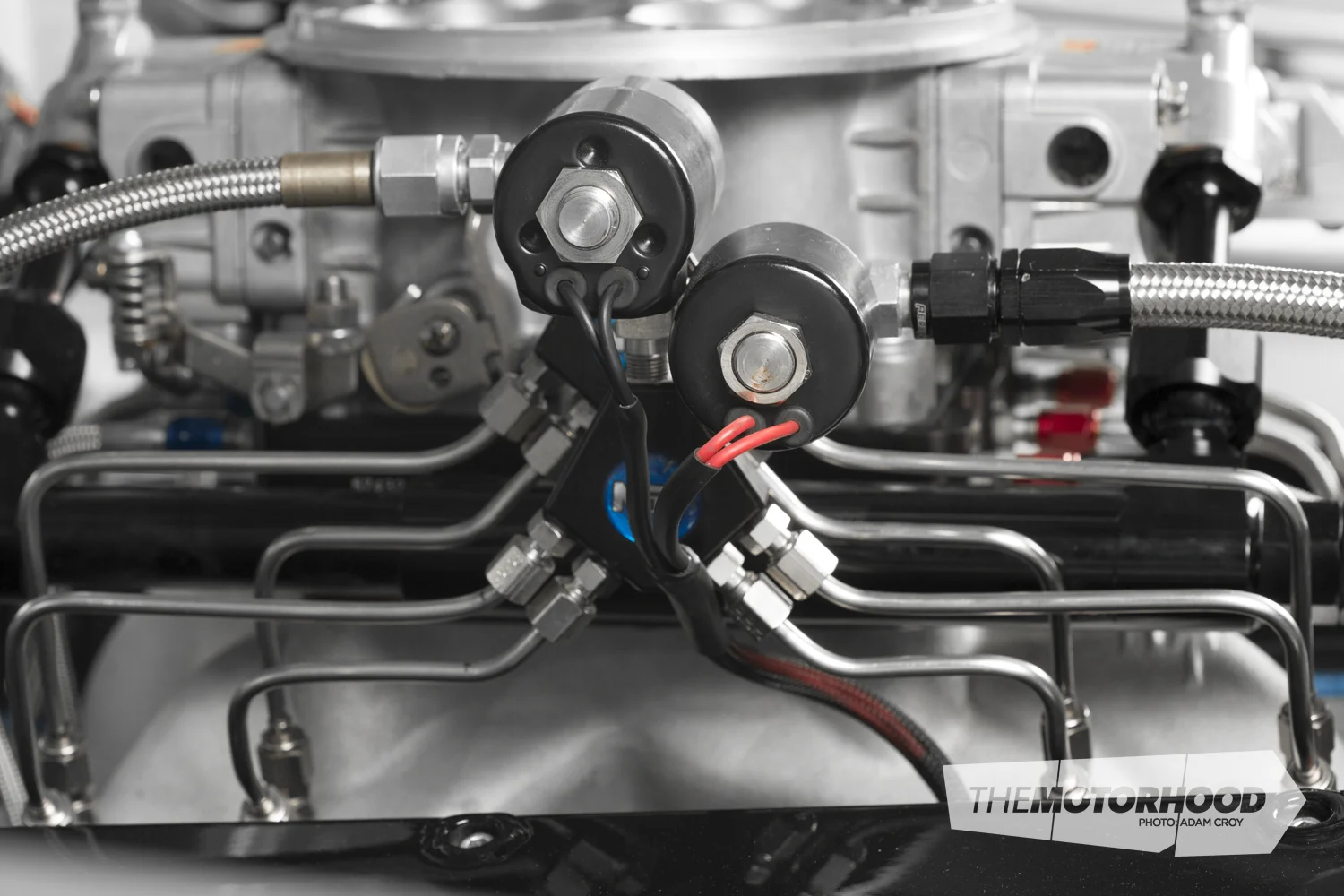

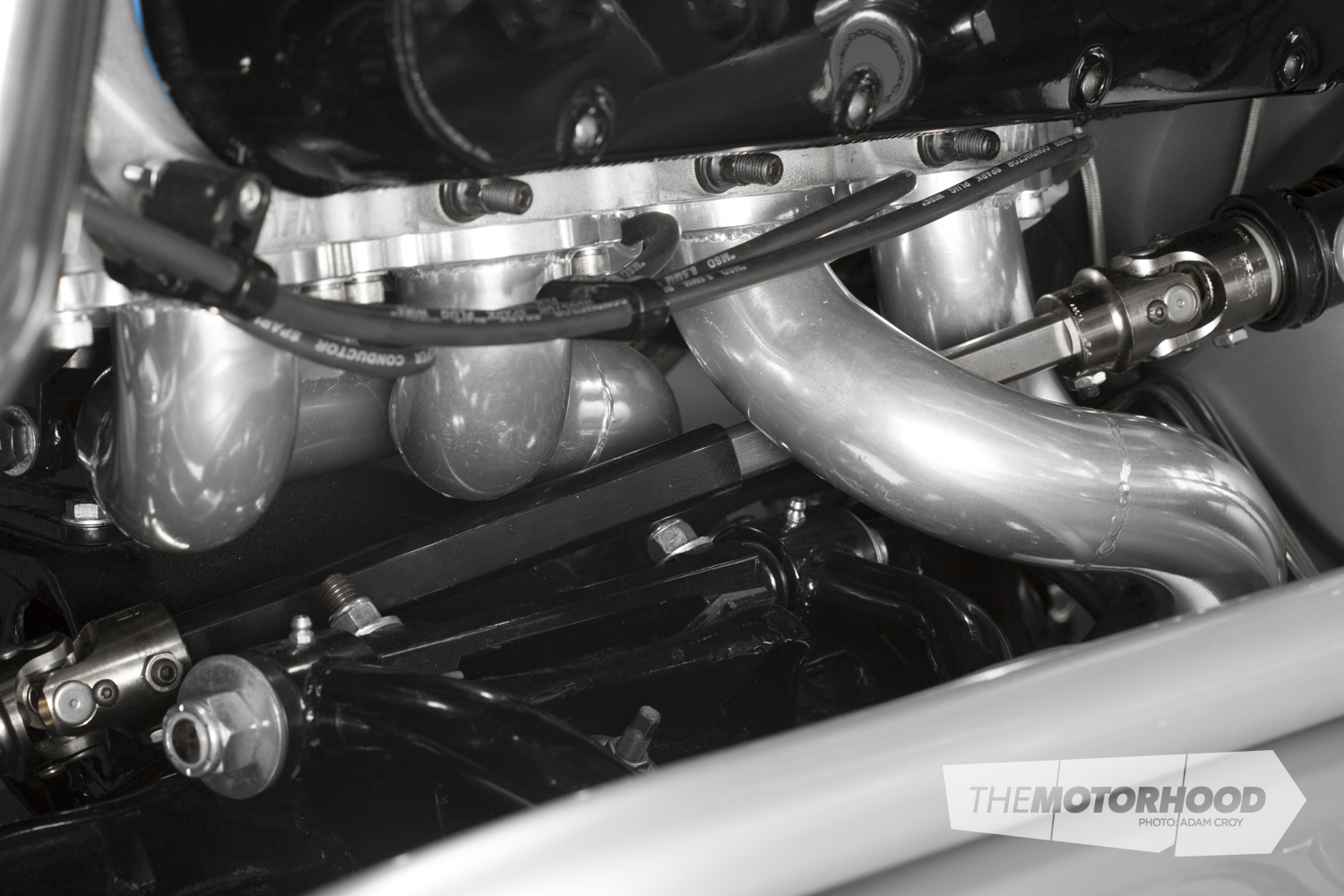

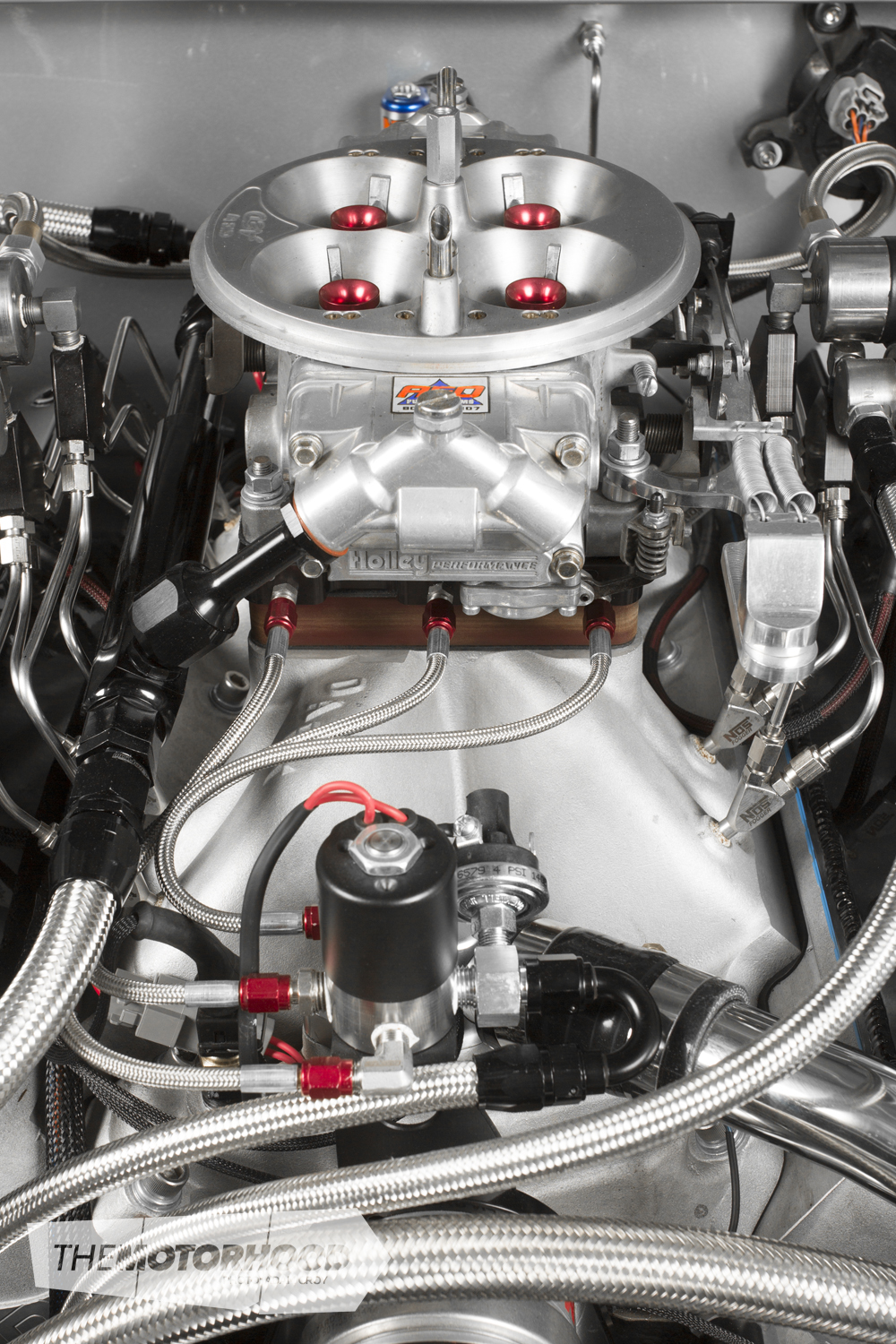

Equally impressive is the intake set-up, which consists of a Dart port-matched inlet manifold fitted with a custom-built 1275cfm AED Dominator carburettor. Of course, to make the type of power Mike was after, and to keep it streetable, it’d need more than just a giant carburettor. With Mike being a long time proponent of nitrous, a multi-stage plate and port set-up also found its way into the mix. Interestingly, the whole lot runs off a single Holley Dominator EFI-style pump, which ups its flow rates electronically when the nitrous gets used. Well, that’s the theory — as yet, the nitrous hasn’t been plumbed in. Instead, Mike’s chosen to get some seat time with the car naturally aspirated before connecting the bottle. It still made a seriously healthy but easy 665hp at the tyres, which is no shortage for most of us mere mortals, especially on pump gas and in full street trim. But when you remember that Mike played with power levels of this type a few decades ago, you’ll soon see why we think it won’t take long for him to get the nitrous itch.

Mike’s not one to talk it up, though. He won’t go telling us it’s going to make a million horsepower and run ludicrously fast passes. Instead, he’d rather let the results speak for themselves. We’re sure we’re not alone in wanting to see those results. Mike’s in no rush, though — after all, “It’s just a street car …”

1971 Chev Chevelle

- Engine: 598ci big block Chev, Dart Big M tall-deck block, Eagle 4340 steel stroker crank, Eagle 6.7-inch rods, JE custom pistons, Crane roller cam, Crower ‘Hippo’ oversized 0.904-inch roller lifters, AFR Magnum Pro CNC ported alloy heads, Victory titanium inlet valves, stainless exhaust valves, Jesel rockers, Jesel cam belt drive, Manton custom pushrods, Dart port-matched inlet manifold, custom 1275cfm AED Dominator carburettor, custom 2¼-inch headers, twin 3½-inch HPC-coated exhaust, MSD ignition, MSD front-mount distributor, Moroso sump, Moroso oil pump, ATI crank damper, Moroso vacuum pump, CSR electric water pump, custom Adrad triple-flow alloy radiator, Holley dominator EFI-style fuel pump, Holley fuel filters, multi-stage nitrous (port and plate)

- Driveline: GM TH400, reverse pattern valve body, billet internals, transbrake, custom billet 3800rpm torque converter, Strange chromoly diff housing, 35-spline axles, Moser diff head, 35-spline Detroit Locker, custom 3½-inch chromoly drive shaft, billet yokes

- Suspension: Tubular A-arms, Competition Engineering four-bar rear, Competition Engineering sway bar, QA1 adjustable coilovers

- Brakes: Wilwood discs and calipers, Wilwood alloy front hubs, Wilwood master cylinder

- Wheels/Tyres: Centerline Qualifier 15×6-inch and 15×12-inch, 195/65R15 Hankook and 29×14.5×15 Hoosier Quick Time Pro tyres

- Exterior: Fibreglass four-inch cowl induction hood, smoothed firewall, raised transmission tunnel, new floor pans, new boot floor, new rear compartment, PPG waterborne paint

- Chassis: Competition Engineering rear rails, widened wheel tubs, chromoly roll cage

- Interior: Scat seats, Grant steering wheel, TCI outlaw shifter, Auto Meter gauges, chromoly roll cage, removable door bars, modified dash, custom shifter mount

- Performance: 665hp at 6000rpm (at the wheels), 98 octane pump gas (without nitrous)

This article was originally published in NZV8 Issue No. 123. You can pick up a print copy or a digital copy of the magazine below: