data-animation-override>

“Kiwis are known for their can-do attitude, and this has seen many of them land in interesting places. We recently caught up with a few of those Kiwis making a name for themselves abroad”

Robin Silk (Photos: Pete Chapouris — So-Cal Speed Shop)

From: Paraparaumu

Now: Pomona, California

If you’re a hot rod fabricator, and good at it, one of the ways you might fulfil your wildest ambitions would be to work at So-Cal (short for ‘Southern California’) Speed Shop in Pomona, Los Angeles. It’s one of the most prestigious hot rod shops in America — and, therefore, the world — and probably unparalleled in terms of history and culture, as it dates all the way back to 1946.

So, you’d think that Robin Silk — having worked there for 13 years now — must have worked hard at getting a foot in the door of the place. Funny thing is, when you ask ‘Silky’ about how he came to work for So-Cal, he’ll tell you that at first he didn’t even want to.

It came about as a result of another Kiwi, Steve Davies (originally from Napier and featured in last issue’s ‘Kiwis Abroad’ feature), who had been working at So-Cal when the company picked up a prestigious contract to build some cars for GM in 2002. They needed another clever fabricator, so Steve talked So-Cal owner Pete Chapouris into speaking with Robin. Robin, however, wasn’t looking for a full-time job at So-Cal, or anywhere in the US, for that matter, because, although he’d been in the US for a year by then, he’d originally only gone there for a few weeks to buy parts and was getting ready to head home.

Robin had made the trip to the US in 2001 to buy some parts for the Top Doorslammer race car that he had begun building here in New Zealand. When he arrived, he hooked up with fellow Kiwi Grant Downing, who, at that time, was running his business in LA building race cars. Grant needed another clever pair of hands and convinced Robin to help him for a few months doing general fabrication and engineering (mostly on door cars). A few months quickly turned into a year.

One of Grant’s biggest customers was NHRA Top Fuel Funny Car star Del Worsham, and, in 2002, Worsham ended up buying Grant’s business. Grant was retained to continue looking after the building of the Worsham team’s cars, while Robin ended up being talked into staying on by Del to look after his ‘Blue Max’ nostalgia nitro funny car. At the same time, Grant was going through the process of getting his own fuel funny car built, sorted, and licenced, and Robin was there helping him throughout the process. Robin remained as a key member of the crew for a number of years, looking after the bottom end of the nitro engine. “I was the smallest one there, so I got the bottom end. Dirty, f***ing horrible job!” he reflects.

Luckily, Robin had had a 12-month visa, but that was coming to an end, and, besides, he’d had enough of being in the US and was ready to go home. This was exactly when he got the phone call from Pete Chapouris of So-Cal Speed Shop asking him if they could meet up for a chat. GM had decided it wanted to build some cars for Bonneville as part of a marketing programme to showcase their new Ecotec engines, and Pete and the So-Cal team had scored the contract to build them. Problem was, apart from Kiwi Steve, Pete didn’t have any guys there with any real experience in building race cars. “The interview was pretty bloody casual,” says Silky. “Pete said ‘Can you do this?’ and I said ‘Yeah, I reckon I can do that alright’, and [then] I was working there!” Silky started and was put straight to work the next Monday. Shortly after Robin started, Kiwi Steve left So-Cal to start his own business, and Robin found himself dropped in the deep end but swimming like the champion that he is.

Robin’s first jobs at So-Cal were building the two belly tank cars for GM. The first was a concept car that was driveable but never raced, and it currently sits on display at GM headquarters in Detroit. The second one was the real deal, and the complete chassis and all of the engineering were done by Silky. The build featured some clever stuff, including a Hewland Engineering gearbox on the back of the Ecotec engine and long front suspension A-arms, all much like a Formula Ford–style race car. This car set a speed record at “about 210mph or something like that, I think — I can’t really remember” says Silky. That lack of recall of the detail-side of things is typical of Silky — he’s always been too busy diving headlong into the next challenge to spare any time to savour the successes of the past.

From there, he built the GM HHR panel van, which was also raced successfully. It didn’t break a record, because after running a phenomenal, and potentially record-setting, one-way pass of 250mph, the car barrel rolled during its back-up run and was extensively damaged.

Robin says the best car he’s been involved with at So-Cal is the famous ‘Speedster’ hot rod. It was largely constructed by a guy in Indianapolis over a 15-year period, then So-Cal — with Silky looking after all of the chassis work and engineering — spent two years finishing it. The stunning car deservedly won the prestigious America’s Most Beautiful Roadster Award in 2013, and you can sense an uncharacteristic touch of pride when Robin talks about it. This writer has known Robin well for over 30 years, and he’s one of the most unassuming and humble guys you’ll ever meet; being around hot rodding royalty through So-Cal hasn’t affected him or changed him one little bit. I know blokes who think they’re a bit special because they met Billy Gibbons of ZZ Top fame once — well, Robin has worked on lots of Billy’s cars, and sits around and shoots the shit with him at lunchtimes, treating and thinking of him no differently to how he would you or me.

The job at So-Cal that Robin took on in 2002 when he was ready to come home to New Zealand is still his job today, although the lure of Kiwiland has resulted in some restructuring in his life. After schooling his and wife Vicki’s children in the US, the family had had enough of the place by 2010 and headed home. By then, however, Robin had become an integral part of So-Cal. He obtained a green card with the help of Pete Chapouris, and a deal was struck once again with Pete that has enabled Robin, ever since, to spend seven months of each year — at three to four months at a time while cleverly missing New Zealand winters — working at So-Cal, and then fill in the rest of the year here running his home-based business on the Kapiti Coast building engines and doing hot rod and race car work. It’s a real balancing act, trying to keep So-Cal, his family, and himself happy. Of that knife-edged act, Robin says incredulously, “and I’m still married, believe it or not! How the f**k do you work that one out?!”

“Everyone says I’m lucky doing all that stuff, but after a while it’s just another job,” he says. “You do that shit all day, and then your own race car at night — bloody hell … you know?” We do know, because we also know that a normal working week for Robin Silk, human dynamo, is between 50 and 60 hours long at So-Cal, then he does outside jobs at nights for various privileged people, and then, after that, he tries to make some progress on that Top Doorslammer race car that he went over there to buy parts for 14 adventure-filled years ago.

When Pete Chapouris was in New Zealand a couple of years back, the subject of Silky inevitably came up during our conversation, and Pete’s enthusiasm for him — in terms of his being a genius fabricator and just an incredibly decent guy — knew no bounds: “Oh Silky, he’s just unreal, man. What a guy. What a neat guy, and what a clever guy!” High praise, and right on the money.

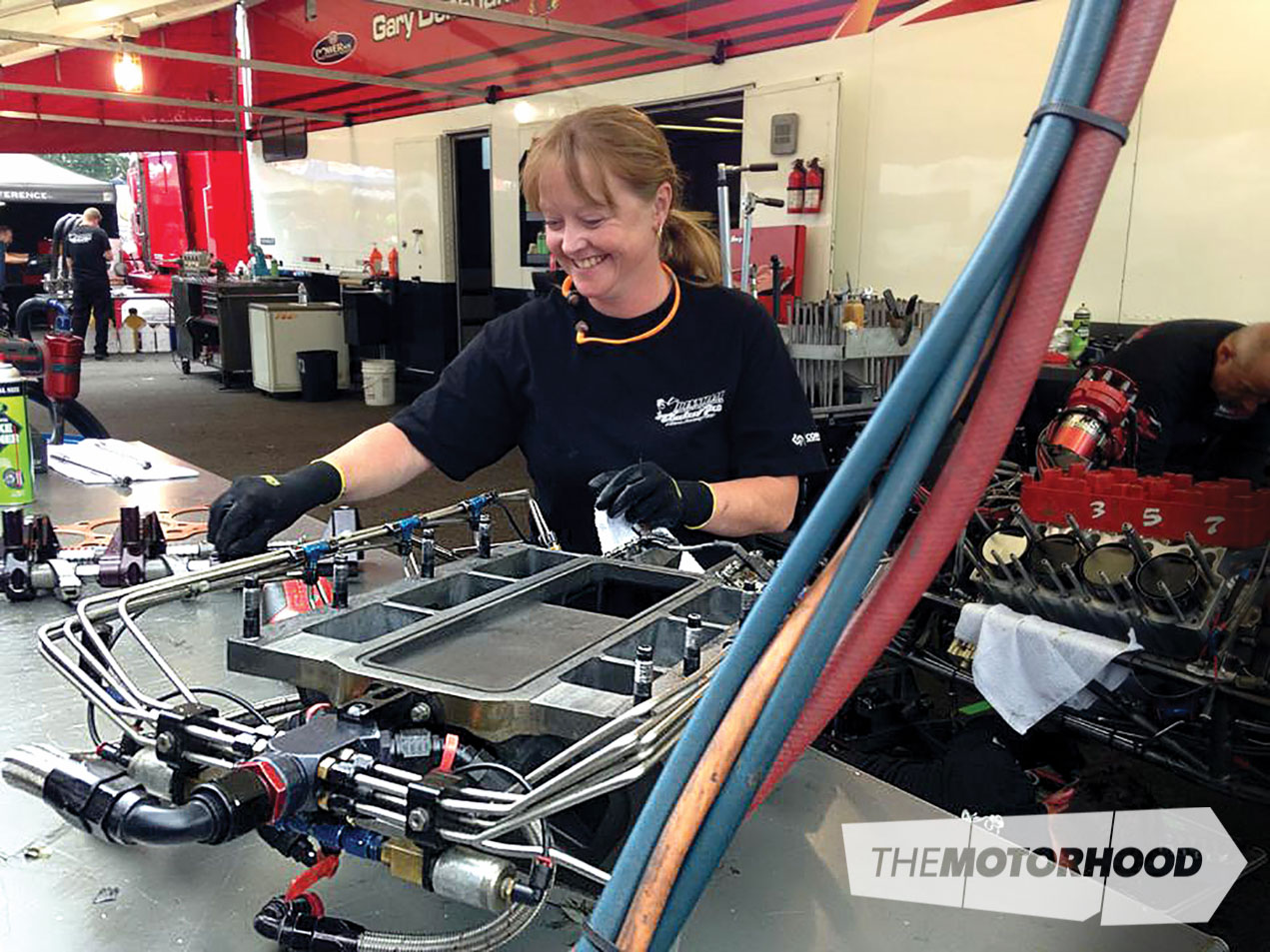

Mellisa Boytim (Photos: Frank Ranney)

From: North Shore, Auckland

Now: Issaquah, Washington

It wasn’t until Auckland born and bred Mellisa Boytim (née Downing) was standing behind a launching nitro funny car that she knew she needed to be involved in the sport. Those few seconds of earth-shaking, eye-watering action changed the course of her life forever.

That first nitro experience happened on a holiday to America to catch up with her brother, Grant Downing (see Kiwis Abroad Part II, NZV8 Issue No. 125). For the following year or so, every few months, Grant would post her vouchers for an American takeaway joint and tell her she needed to move over. Eventually, she bit the bullet and made the move stateside in 2002.

This was at the same time that Grant was preparing his own nitro funny car, and having been so blown away by her first nitro experience, Mellisa wanted to be a part of it. The only crew position left at that time, though, was that of ‘clutch guy’, and, despite having no previous mechanical experience, she took it.

Grant taught her the basics, and she worked hard almost every night to refine the process. It was when Ed Boytim, who worked for Del Worsham, took her under his wing that she learnt all the tips and tricks to become a top-level clutch guy. The next time the car came out, Grant was blown away about just how fast she was.

Ed and Mellisa mustn’t just have been discussing clutch-pulling techniques during those training sessions, as the pair ended up married, and, although that’s now over, they remain great friends to this day.

After doing the clutch for Grant part time for a few years while working an IT support day job, she and Ed got a call one night saying that Gary Densham was looking for a truck driver and a clutch person. Being that Ed could drive the trucks and Mellisa could do the clutch, they were the perfect pair for the job. For the next five years, they worked full time for the team until sponsorship started to dry up due to the Global Financial Crisis.

During those years, she learnt all the other crew positions required in Nitro Funny Car, and can now pull heads and service rods and pistons as well as any other NHRA crew member. The one job she’s not keen on is that of doing the bottom end, saying her [small] stature works against her for that position.

While working full time as an NHRA crew member, she and Ed essentially lived on the road for most of the year, travelling round to round. She states that Densham is the best boss you could ever ask for, and that’s the reason she decided to stay with him and the team.

Interestingly, after spending so much time working on some of the fastest drag cars in the world, she’s never driven down the drag strip or had any intention to, preferring instead to stick to the mechanical side of things. Likewise, she’s never owned any street cars of mention, getting her horsepower fix on the drag strip.

When she first started crewing, she was one of just two female crew members within NHRA Top Fuel ranks, meaning that she had to prove herself to the doubters. Thankfully, she was surrounded by the best crew and chose to focus on the job at hand and prove to any doubters that she had what it took through hard work and determination.

Mellisa has returned to New Zealand for holidays since, coming over to help out Willy White with his nitro funny car when he first competed it here. While she loves New Zealand and misses it, America is now her home, and she has no intention of moving back, due to the opportunities the US offers.

While she’s working as an office manager these days, she still crews for various teams when required, and if the opportunity arose to go full time again, she says it’d be hard for her to turn it down. Anyone who’s ever been near a nitro car when it’s launching will understand exactly why.

Chris Morris

From: Stokes Valley, Lower Hutt

Now: Melbourne, Australia

If you’ve been following our Kiwis Abroad feature over the last few issues, you may have noticed a recurring theme — all those featured created their success through their own merits, regardless of where they came from. Whether you’re from a small town or the big smoke, it’s your level of commitment that determines how far you’ll go, and Chris Morris should be a key example of that. Raised in Stokes Valley in Lower Hutt, Chris’s future in the wheel and tyre industry would be foreshadowed by his local employment as a young man between 1989 and 1993 — initially working repairing punctures at a local petrol station, he moved on to bigger and better things, working as a tyre fitter at Hadley Tyres in Lower Hutt.

Chris’s ambition wouldn’t be confined to the lower North Island for long, though, as he moved to Australia with his then-girlfriend — and now-wife — in 1993. Settling in Brisbane, it didn’t take long for Chris to get sucked back into that circular world he was so used to, as he found employment at a local tyre shop. “I started working there as a tyre fitter, then moved up to become foreman, then assistant manager, and, finally, shop manager,” Chris says of his climb up the ranks of the wheel and tyre world. This role was soon given up to become a salesperson for YHI, one of the world’s largest wheel and tyre distributors.

As a YHI salesperson based in Brisbane, an opportunity saw Chris uproot and shift to Melbourne, and, as luck would have it, it was in Melbourne that he came across a tyre shop business on the market. Not only was it right up Chris’s alley, but the price was right, so the business was purchased. Owning a business in the wheel and tyre industry finally gave Chris the ability to do the kind of wheel and tyre work he wanted — “I’ve always had a passion for custom wheels, especially billet,” he says, “but, at the time, there weren’t many options available in Australia.”

An opportunity to check out Intro Wheels in California was taken, and Chris flew over, returning as an Australian distributor for the custom-wheel brand. His Showwheels company was started in 2003, distributing high-end custom wheels. In 2006, Showwheels purchased their first CNC machine, and Chris started Showwheels’ own KWC Forged brand of wheels. The CNC machine allowed Showwheels to machine wheels to customer preferences for centre bore, PCD, and offset, bringing an even greater degree of customization to the Australian wheel market. “We’d get wheel ‘blanks’ from the manufacturer, such as Intro, and machine the ‘semi-custom’ wheels to the customer’s specifications,” Chris tells us. “We’d later get the ability to fully machine billet wheels in-house. It takes, on average, around eight to 10 weeks per set — that’s from receiving the order to making delivery.”

Hardly any time had passed before Chris branched out into the US, starting Showwheels USA in 2008. The company’s US branch saw a considerable degree of success, manufacturing high-quality wheels and supplying 20 different countries. However, with a family back home in Australia, Chris sold Showwheels USA earlier this year, in January 2015: “I was spending half my time in Australia, and half in the States, with a wife and kids back home. I wouldn’t say it’s easy street, but I’m definitely enjoying being able to take it a bit easier now.”

From a humble lad growing up in a town on the outskirts of the capital to a key player in the custom-wheel scene both Down Under and in the US, Chris Morris is living proof that the world is as small as you make it. We congratulate Chris on his success and look forward to seeing even bigger and better things coming from the custom-wheel market in our little corner of the globe.

Chris Slee (Photos: Wes Duenkel Motorsport Photography)

From: North Shore, Auckland

Now: Franklin, Tennessee

Like most of us, Chris Slee’s love of cars started at an early age. By the time he turned 18, he’d had a Buick featured in a local magazine, and, now some years later, he’s lost count of how many modified cars he’s had over the years.

His early years saw him work in a collision-repair shop, where he learnt the art of metal forming and repairing panels the old way. From here, he moved away from the workshop and into a business selling parts and accessories, although he was busy building race cars for himself on the side, mostly of Japanese origin.

In 2008, Chris and his family took part in the US green-card lottery, and were the lucky recipients of one, so decided to make the move abroad.

Having visited America a few times previously, they decided to settle in Texas before making the move to Franklin, Tennessee, three-and-a-half years ago now.

While living in Texas, Chris worked for a few different automotive-related businesses, the most notable of which was a Mustang specialist that loved the metalwork skills he had to offer and would have loved him to continue on there. However, the move to Tennessee came about when his wife, who works in the medical sector, was offered a great opportunity, one too good to be turned down. The shift also allowed Chris to pursue his dream of working for himself building cars. His business, Kiwi Classics and Customs, has been going strong ever since, and now employs two other staff members.

Starting a new business in a new town without any connections can be hard slog, so Chris knew the way to get himself on the map was to build up a car of his own to showcase his talents. With no specific love of any particular brand, he had a quick look on Craigslist and came across a six-cylinder Mustang that was just five minutes away, with an asking price of US$1K. He took the car and spent hour upon hour on it, creating a one-off 750hp wide-bodied masterpiece that has since gone on to be displayed at the Specialty Equipment Market Association (SEMA) Show and appeared all over the internet.

While the car has certainly helped to put Kiwi Classics and Customs on the map, Chris himself has also received plenty of recognition. Little did he know when he first moved to Franklin that the production company behind the TV show Search and Restore (which has a similar concept to the show Overhaulin’ but a four-week build time instead of one week) is also based there. This has seen him appear on multiple episodes working his magic.

With his work on his own Mustang and the publicity that car has received, he’s become known as a bit of a Mustang guy, but that’s not all he’s open to working on or what he solely specialises in. When we spoke to him, he’d just finished a Dodge Challenger restoration, and was deep into a ’65 Mustang build. His speciality is custom metalwork, but he can turn his hand to anything mechanical as well, making Kiwi Classics and Customs a one-stop-shop that can do anything, although he’s not a fan of fibreglass.

Now that it’s three-and-a-half years since the business began, Chris says he’s living the dream. It’s not Groundhog Day, as every day is different, and he never knows what it’ll bring. That said, he did mention there’s a few things about New Zealand that he misses, such as the build quality of the cars here. Interestingly, though, despite New Zealand having such a good reputation for building high-quality cars, being a Kiwi didn’t really open any doors for him; instead, it took the completion of his own car to showcase his skills and get his name out there.

With a few more big projects already lined up, we’re sure it won’t be the last time we hear the name ‘Chris Slee’.

This article was originally published in NZV8 Issue No. 126. You can pick up a print copy or a digital copy of the magazine below: