data-animation-override>

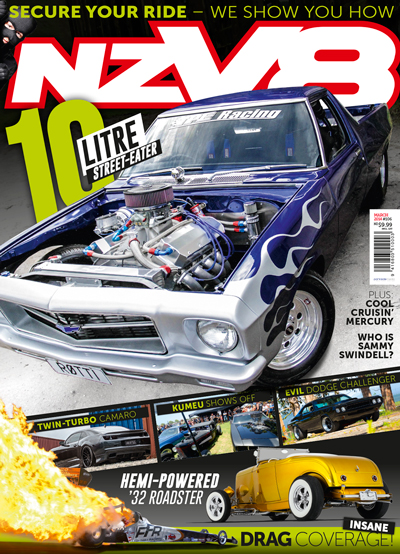

“With an almighty 621ci big block Chev under the bonnet, Glenn Brewer’s brutal Holden HQ has got more than enough bite to back up its bark”

The old saying goes, “there’s no replacement for cubic displacement”, and over the years, Glenn’s ute has had its fair share of V8s under the hood, each one a little larger than the last. A few years ago, he decided to get a bit more serious and give the old girl a full-and-final rebuild. With that well-known saying repeating over and over inside his head, only the biggest and baddest V8 of them all would do, and the one he managed to get his hands on displaced a colossal 621ci!

When Glenn was the tender age of 17, he bought the then–red-and-canopied, 308-powered ute off local Wanganui icon Dave Rowan, one half of the Rowan/Rivers pairing of River Rat drag-racing fame. Over the next 20-odd years, the 308 died and was replaced by a 396 with a healthy 150hp shot of nitrous thrown in for good measure. When he got bored with this, it was ripped out and flicked off to another Wanganui local, Aaron Jackson, who transplanted it into his Torana, ‘COPB8’ (featured in NZV8 Issue No. 104). Engine number three displaced 402 cubes and had a galloping herd of “250 nitrous-oxide–juiced-up ponies” jammed into it. That satisfied Glenn’s hunger for power up until about three years ago, which was when things started to get way out of hand …

Dave Tunnel and his dad, Paul, run Thermal Performance Engineering (TPE) in the River City. Dave’s dad has known Glenn for many years, so it was to Dave and Paul that Glenn turned for help when it came time to create his monster.

With a blank sheet of paper and a pen on the table, the first on the long list of things to do that eventuated was the engine. Glenn wanted one thing and one thing only: “big cubes”. With what else Glenn had in mind, this meant two things: it wasn’t going to happen overnight, and it wasn’t going to come cheap.

That’s where one of his other passions joined the fray. Glenn breeds Rottweilers, and he stresses that his creation is a rolling tribute to each and every one of them. If it wasn’t for the many litters produced over the years, he says, the ute would still be a pipe dream rattling round in his head. That also explains the plate proudly attached on the front and the back, ‘ROTTI’, a fitting tribute to his four-legged friends.

Dave recalls fondly the day he received a phone call from Glenn, who told him, “I’ve found a motor.” He’d heard through the grapevine that New Zealand jet boat marathoner Darren Lawn had removed the engine from his boat. It had only done an estimated 20 hours’ work but had never run right. It was still in pieces, so was in a state perfect for them to be able to see exactly what was on offer. A hasty road trip north was organized; they both liked what they saw; Glenn made Darren an offer; and then, in no short order, Glenn was the proud owner of the House of Horsepower, World Products, all-aluminium Merlin X block–based, 621-cube behemoth that the rest of the ute is now bolted to.

Now, Dave and his dad are a couple of clever bastards when it comes to building horsepower. The internal combustion engine has a hot cycle and a cold cycle — intake = cold; exhaust = hot. Without revealing too many of their craft secrets developed over the years through countless hours of testing and trial and error, essentially what they do is separate the two cycles by using thermal dams. By ‘thermalling’ an engine, they can isolate the intake and exhausts, thus creating lower cylinder temperatures, meaning a cooler charge and the ability to make more power. Glenn’s engine was a perfect candidate for some more R&D.

Once back in Wanganui, they were able to have a more thorough look at what they’d bought. Long story short, it was little wonder the engine had never run that great, as some of the parts laid out in front of them raised a few eyebrows. This ended up being a blessing in disguise though, as it meant they could gather specific parts to tailor the engine to the needs of Glenn’s insatiable appetite for more power and heavy right foot.

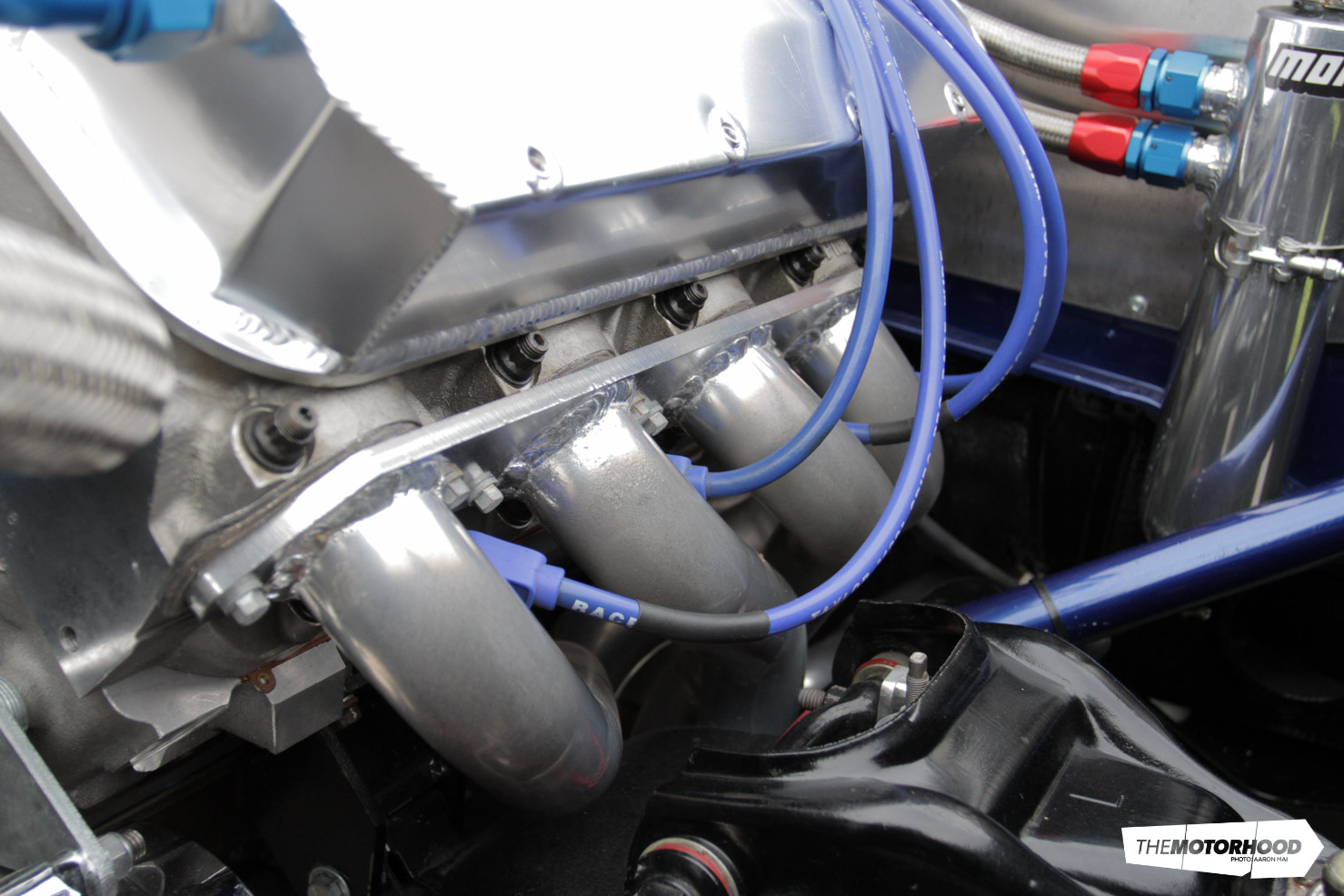

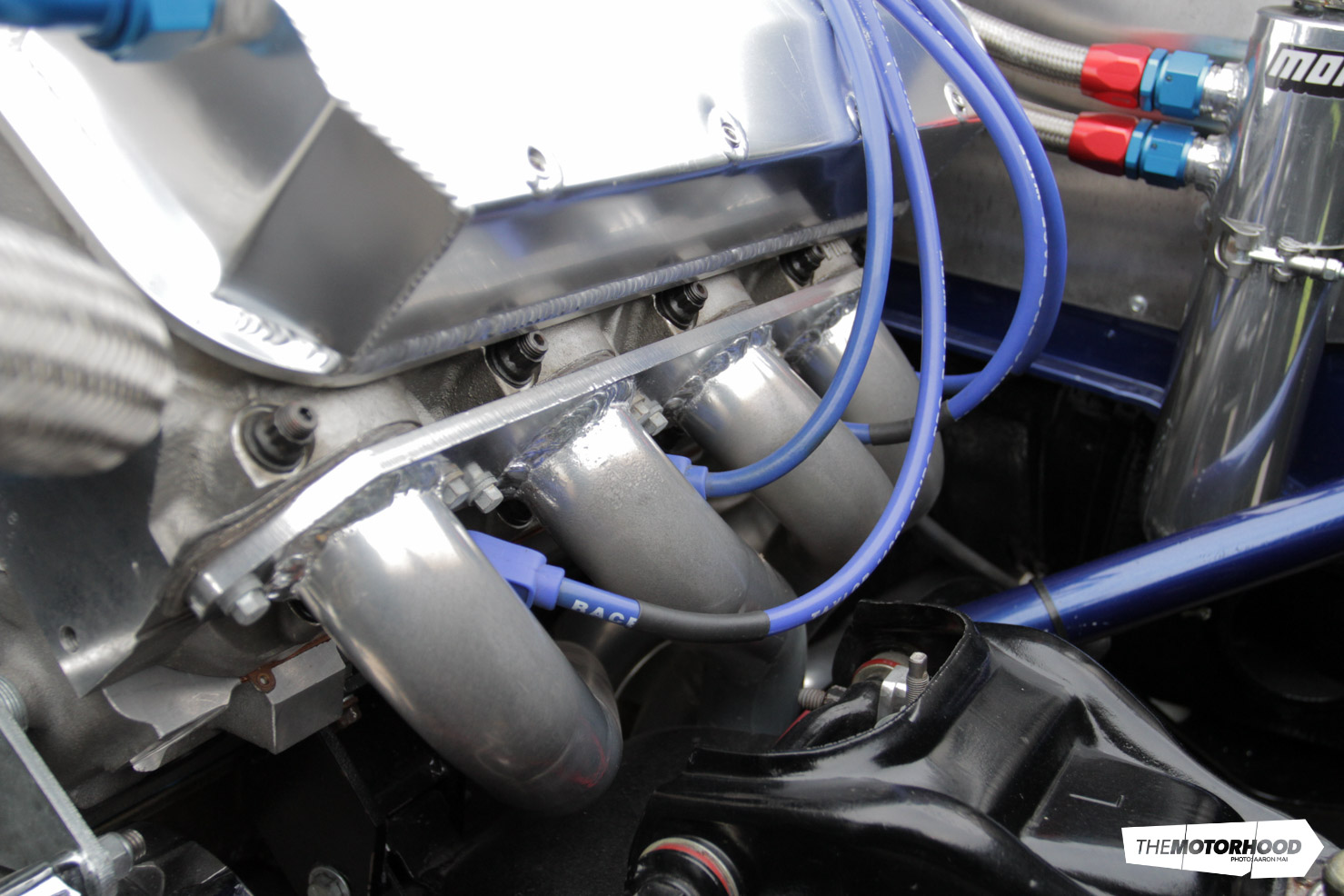

Once the final ARP fastener had been torqued up on the engine, Dave could finally stand back and admire the masterpiece he had assembled over countless hours in his workshop. Located at the bottom of the block is a 4340 crank, and attached to this are eight H-beam rods topped with Wiseco pistons surrounded by Total Seal rings. Dart Pro 1 heads that have received some serious porting, Harland Sharp 1.7:1 rockers, and a Dart stud girdle lurk beneath the shiny aluminium rocker covers. Bolted to the top of the matching World Products Merlin X manifold was initially an 1150cfm carb, but ultimately this proved to be far too small to feed the monster block’s voracious appetite for fuel, and Dave couldn’t tune it to his satisfaction. Thus, this was swapped for an equally monstrous Pro Systems SV1 (single-venturi) carburettor, which Dave says, “drinks a shitload of gas”.

Along with having everything completely blueprinted and balanced — they found the engine to be 19 grams out of balance — Glenn’s engine also received the full TPE thermal treatment.

Now, mounting this impressive engine to something looking less than impressive would be criminal, and, thankfully, Glenn’s vision was far from that. He once again called on Dave and his dad to turn his — and, don’t forget, the dogs’ — dreams into reality. The shell of the old HQ had seen better days, and the old-school tridents the ute had rolled in on were biffed, along with the dated ‘slapper bars’, as they would serve no further purpose.

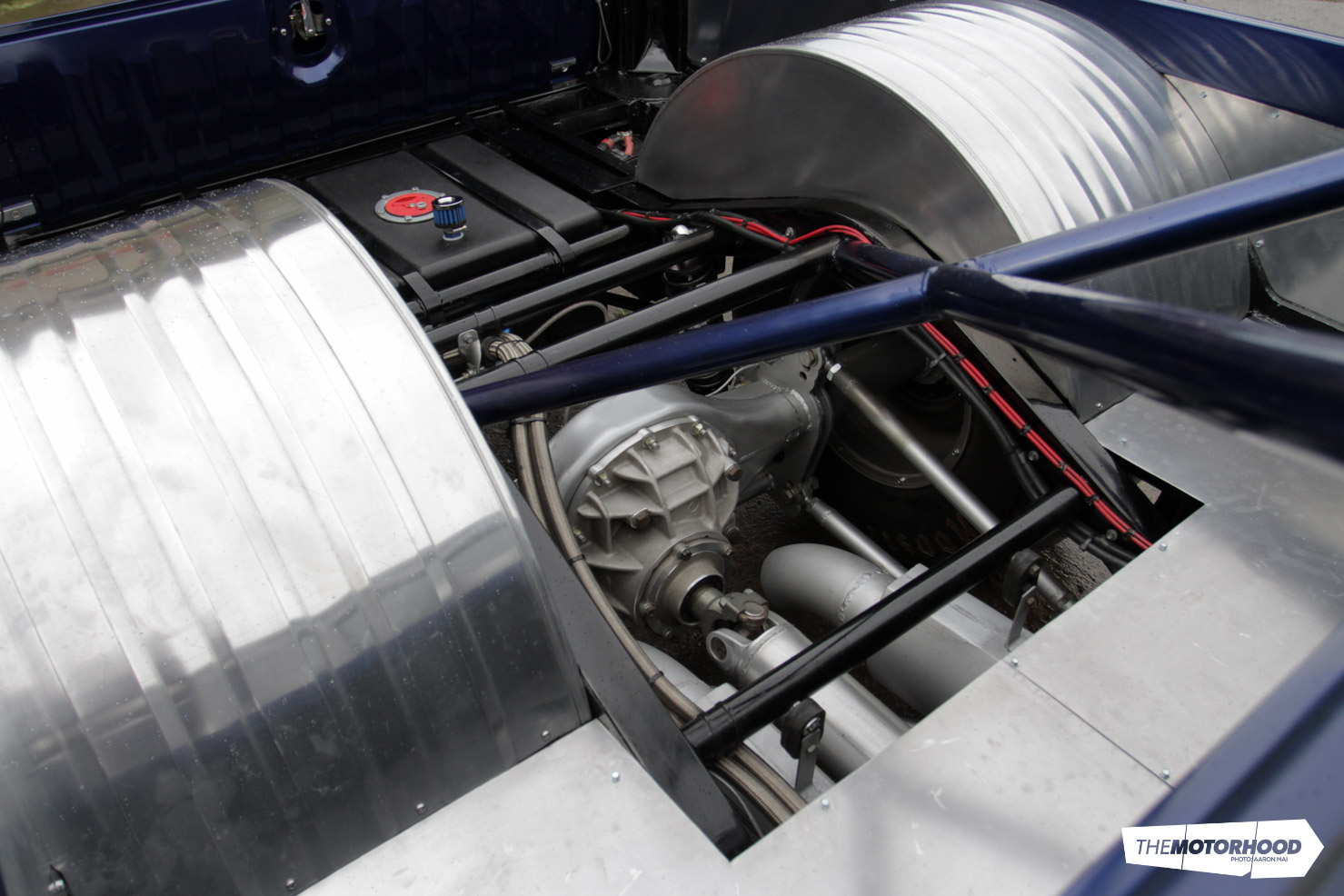

Dave got out the gas and chopped up the floor in preparation for the ginormous tubs necessary to encapsulate the 15×14-inch Weld Draglites wrapped in 31×16.5×15-inch BF Goodriches. Dave had to stretch the rear guards three inches to contain the massive rear rubber. While he was at it, and to help make the space under the bonnet as large as possible, the inner guards have been removed. This, along with the hidden wiring, makes for a very clean-looking engine bay.

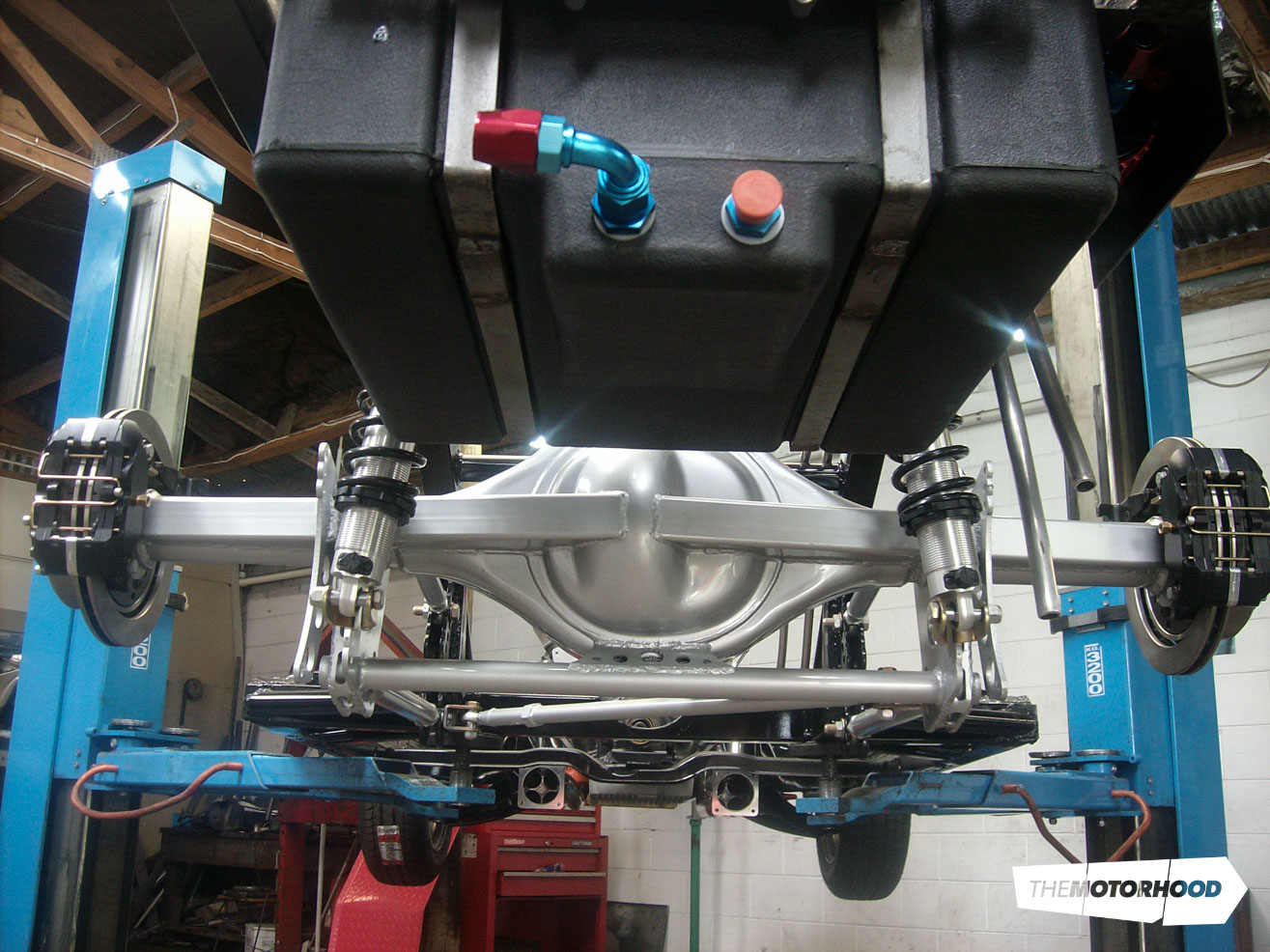

The nine-inch diff is filled with Moser axles turned by an aluminium diff head and a full spool. A custom four-inch driveshaft built in the US connects the Extreme Automatics trans-braked TH400 to the back end, all of which is attached to a Top Gun four-link completing the tough-as-nails driveline.

To help keep a lid on the massive torque curve the engine produces, and to try to stop the body and chassis from twisting themselves into a pretzel, Dave took the liberty of welding up a roll cage to slip into the driver’s compartment. Running the length of the cabin is a raised driveline tunnel to accommodate the massive drive shaft and the car’s low height. Racetech buckets and five-inch RJS Racing Equipment harnesses ensure the driver and passenger stay firmly put. Opposite lock under full power is controlled by a Momo wheel, while a pistol-grip race shifter ensures the reverse-pattern shifts move in the correct order.

Once the exterior panels had been repaired and all rust and noticeable blemishes removed, Dave handed the shell back over to Glenn so he could smooth out anything that he had missed and get everything ready for final paint. This didn’t go entirely to plan, however, as when Glenn had finished prepping the body, it was moved into his shed where it promptly fell off its trolley and slammed onto his driveway, hard. The end result was ripples for Africa; Glenn was left with no other option but to start all over again …

Eventually, after many hours hammering and filing, Glenn was able to apply the custom PPG Pearl Blue and silver flames to the panels. Once these had dried, the whole shell was coated in Total Paint Crystal Clear.

The finished shell was then transported back over the railway lines to Dave’s workshop to be reunited with the waiting chassis and driveline. When the key was finally turned, and Glenn was firmly strapped into the passenger seat, the boys made their maiden journey. When Dave pressed the go pedal for the first time, the question, “What the hell have we built?” was asked. But the answer was simple: “We built your vision, and along with the help of each and every one of your dogs, we also made all your dreams come true.”

1972 Holden HQ Ute

- Engine: 621ci big block Chev, Merlin block, 4340 crankshaft, H-beam rods, Wiseco pistons, Total Seal rings, Comp Cams 750 lift cam, Milodon gear drive, ARP fasteners, Dart Pro 1 ported and blueprinted heads, Dart stud girdle, 1.7:1 Harland Sharp shaft-mount rockers, 1600cfm Pro Systems SV1 Carb, World Products Merlin X intake manifold, Aeromotive A1000 fuel pump, Barry Grant fuel pressure regulator, JAZ fuel cell, MSD distributor, MSD Digital 6 ignition, MSD Blaster 2 coil, 12mm leads, four-inch exhaust, Dynaflow mufflers, Aussie Desert Cooler Burnout King radiator, braided hoses, 16-inch thermo fan, CSR electric water pump

- Driveline: TH400 spragless transmission, 4000rpm stall converter, nine-inch diff,

- Moser axles, full spool, four-inch aluminium drive shaft

- Suspension: 90/10 shocks, custom springs, Whiteline sway bar, four-link rear, Strange adjustable shocks

- Brakes: Wilwood Dynalite four-piston calipers, DBA Gold Series rotors

- Wheels/Tyres: 15×7-inch and 15×14-inch Weld Draglite rims, 31×16.5×15 rear tyres

- Exterior: Tubbed rear, PPG Deltron paint, shaved fuel filler, shaved tonneau cover clips, Hornet scoop, epoxy two-pack primer on bare metal

- Chassis: Custom 3×2-inch back half

- Interior: custom roll cage, Racetech seats, RJS five-point harnesses, MOMO steering wheel, Hurst Pistol Grip Race Shifter, Auto Meter gauges, custom dashboard, raised trans tunnel

- Performance: 9.81 at 128.04mph

This article was originally published in NZV8 Issue No. 106. You can pick up a print copy or a digital copy of the magazine below: