data-animation-override>

“We’re back with the second instalment in the two part series of the ultimate guide for transmission buyers.”

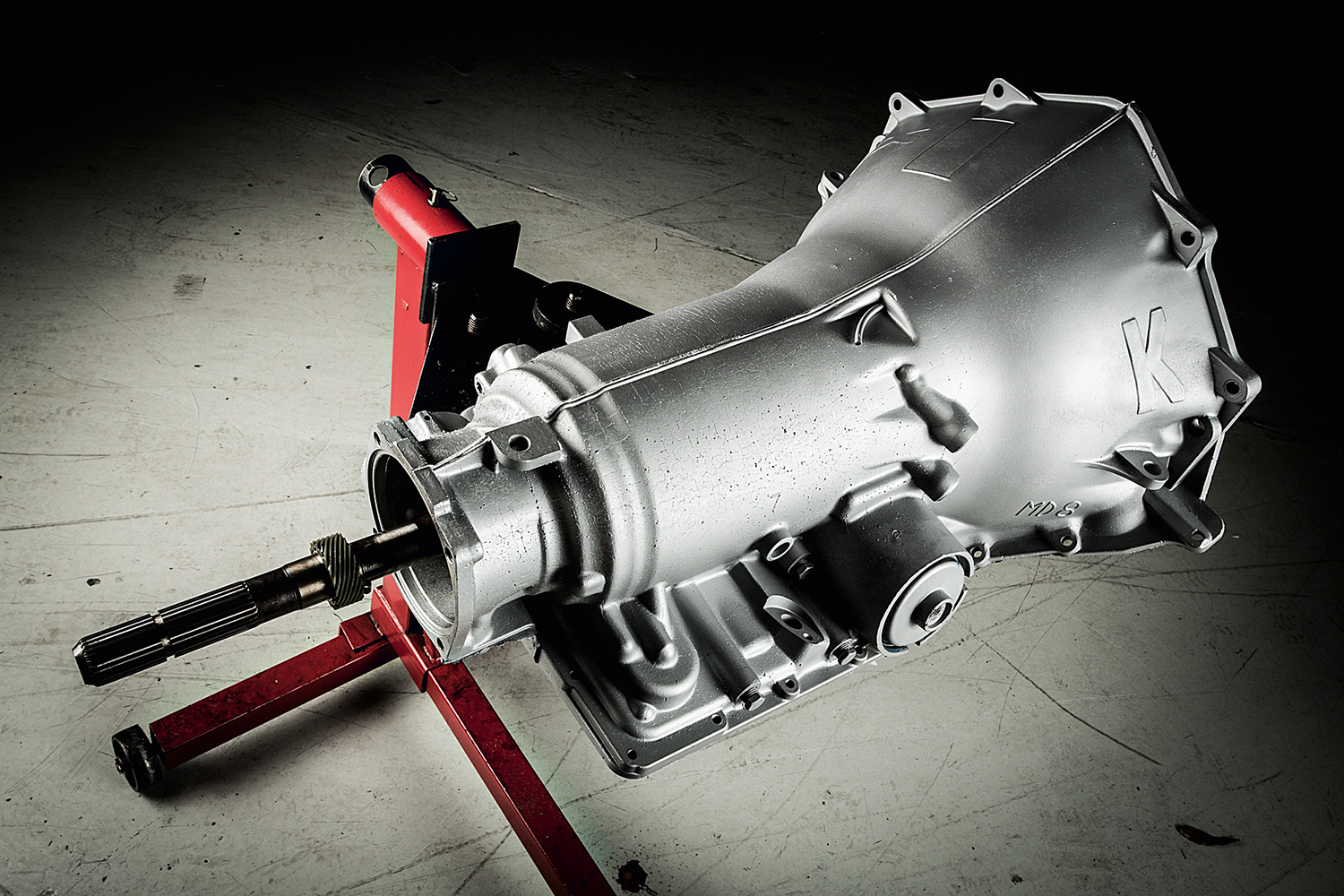

700R4

Although commonly referred to as a 700R4 or 700R, the more correct name would be TH700R4, being that it comes from the Turbo Hydramatic family of GM transmissions. The four-speed 700R4 was introduced for the 1982 model year of Chev vehicles, and renamed 4L60 in 1990 when GM standardized its transmission names. The 60 in the name indicates a mid-strength transmission.

The 700R4 is hydraulically shifted, based on governor pressure and TV cable position, and a range of vehicles was equipped with it up until and including the 1993 Camaro and Corvette — or, more locally, the 1988–2006 Holden Commodores.

Early 700R4s had a 27-spline input shaft, and it was a common failure point. In 1984, the 700R4 designed for use behind Chev small-block engines was upgraded to a 30-spline item, similar to that of the TH400. Between 1984 and 1987, internal components, from the ring gear to the oil pump housing, were also updated. In 1992, electronic controls were added and the 700R4 became the 4L60E.

Expert’s opinion

Ian Hunter from Kaspa Transmissions says:

“Over time, they developed them quite a bit; the best ones are from 1987–on for the reason that they were improved over the years. Earlier ones are OK, but ’87 onwards is the preferred choice. The 700R is not a super-strong trans, and it does tend to burn up inside, so check for any burnt

oil smells.”

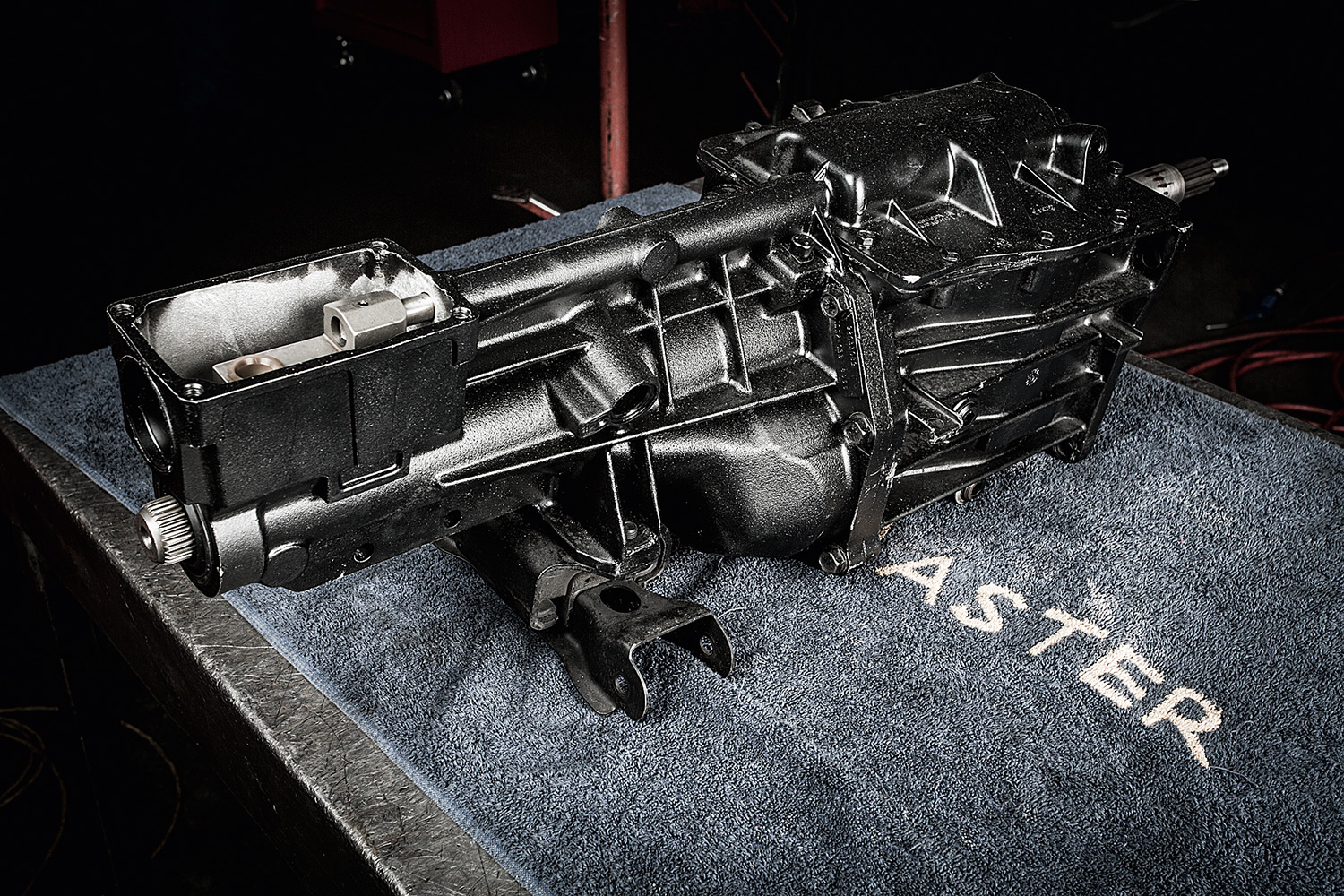

T5

The T5 five-speed manual transmission was produced under the name BorgWarner T5 as well as Tremec T5 in the later years. Fitted to a wide range of vehicles from the early 1980s right through to the six-cylinder Pontiac Firebird of 2002. Countless ratios and options are available, the more desirable T5 being the ‘world class’ as fitted to 1983 to 2002 Camaros and some Fords. VN-VS Commodores were also fitted with the T5, although never the world class spec.

What makes the world class version more desirable is that these have bearings on first, second, and third main shaft gears whereas the non–world class T5 transmissions don’t. In addition, the world class transmissions use tapered roller bearings on the countershaft, whereas non–world class transmissions use flat (cylindrical) roller bearings. The syncros are also quite different, with the world class versions being longer lasting.

Generally the non–world class transmissions are rated for 265ft·lb, whereas the world class ones are rated at 300ft·lb. The best way to identify a world class version, in the absence of any ID tag, is that, when you view the input-shaft end (with bellhousing removed), the cover for the forward countershaft bearing/support is a dead giveaway. On non–world class T5 transmissions, it looks like a frost plug, whereas on the later versions it’s a heavier steel cover (marked ‘Timken’ and with a part number).

All T5 transmissions have die-cast aluminium cases, but mounting features on the cases vary considerably from application to application, as do shifter mechanism and placement, input shaft length, diameter, and number of splines, and overall case length.

Expert’s opinion

Kris Geurts from Motortech Transmissions says: “We do a bit of T5 and T6 stuff, and they’re a pretty good box, they usually just suffer from general wear and tear. Bearings, etc., are really the thing to look out for. There’s not really any way to tell externally how good they are, just drive them and check they feel nice and tight, not sloppy and whiney. Running through the gears without them under load you won’t feel anything, you really need to road test them.

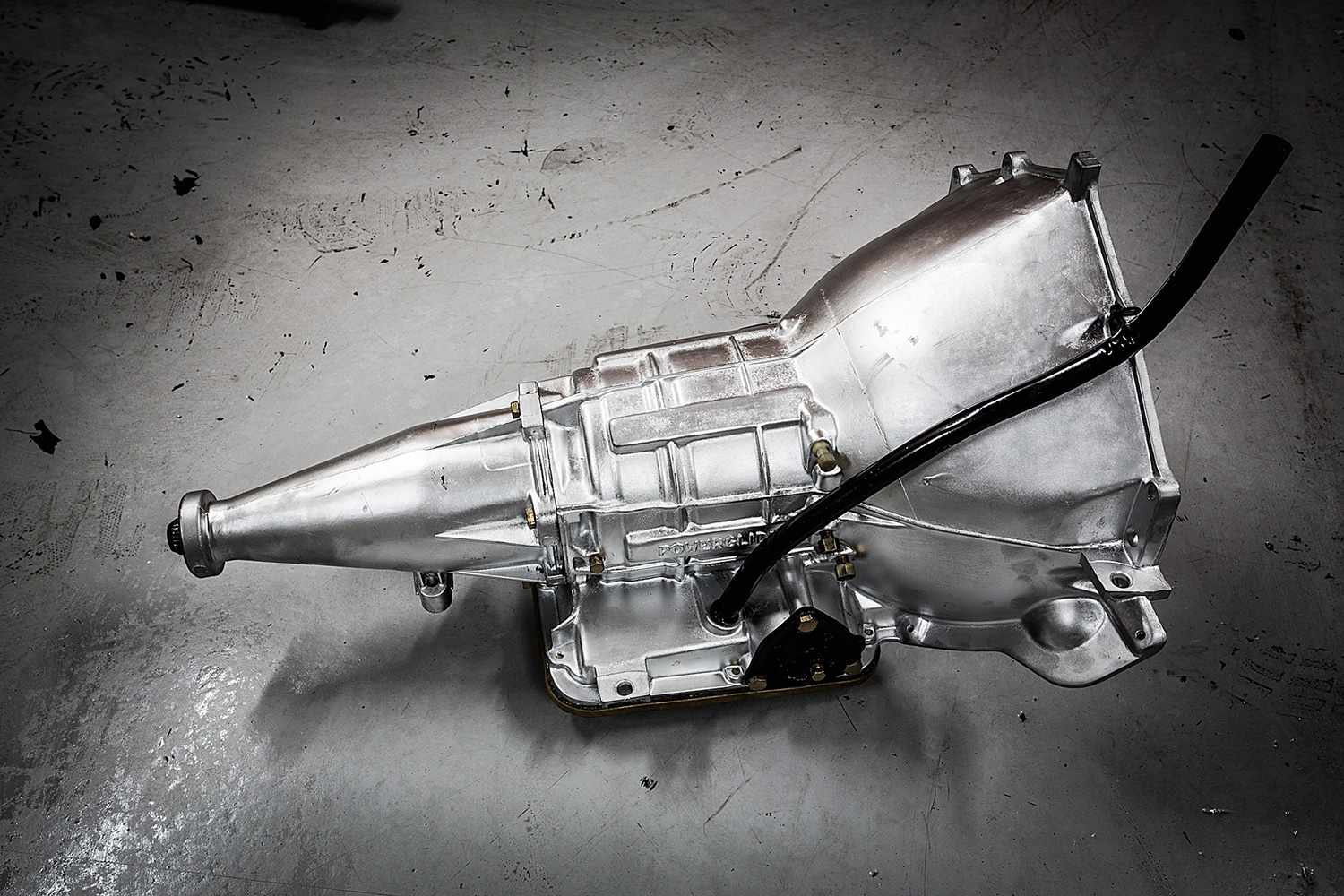

Powerglide

Possibly the most popular transmissions in drag racing, the two-speed Powerglide was designed by GM and went into production from early 1950. Its high strength and simplistic design saw it stay in production until 1973.

Powerglides produced in the first three years didn’t automatically shift between low and high, meaning that many drivers started in low and manually shifted to drive when moving. From 1953 onwards, however, the transmissions work as we now expect transmissions to work, and by the mid 1950s, more than half of all new Chevs were sold with a Powerglide fitted.

Until 1962, all Powerglides were steel cased. However, from 1963 onwards aluminium was used, with a heavy-duty aluminium version being offered for 409ci V8-powered vehicles. The heavy-duty version uses a 1.76:1 reduction planetary gear set, instead of the usual 1.82:1. The 1.76:1 version was fitted to all Powerglides except those used by Holden Australia behind their Australian-built V8 engines. Holdens fitted with Chev V8 engines used the 1.76:1 ratio gear set.

Powerglides can be built to hold a huge amount of torque. Due to their popularity in drag racing, most parts are available

brand new.

One thing to watch out for when buying a Powerglide is that, until 1957, they used the shift sequence of: P-N-D-L-R. That was changed in 1958 to the now-standard P-R-N-D-L sequence.

Many Powerglides share the same length, 27-spline output shaft, and mounts as the TH350, making them easily interchangeable. However, 16-spline output shaft versions cannot be interchanged.

Expert’s opinion

Chuck Mann from Rotorua V8 Performance says: “You really need to drop the pan off them, not that you can see a lot, but you can see what the oil is like and what material is in there. If it’s full of sludge it gives you a sign it’s not looking too good and needs to be pulled down. The high clutch and band are usually the things to go on a Powerglide — if the oil is discoloured, that’s a sign. You can buy all brand-new aftermarket parts for them now, you could build a complete brand-new one with the parts available. The stronger Powerglide to get is the 1.76:1 ratio version, which you can tell externally as it has a 12 7/8-inch input shaft length.”

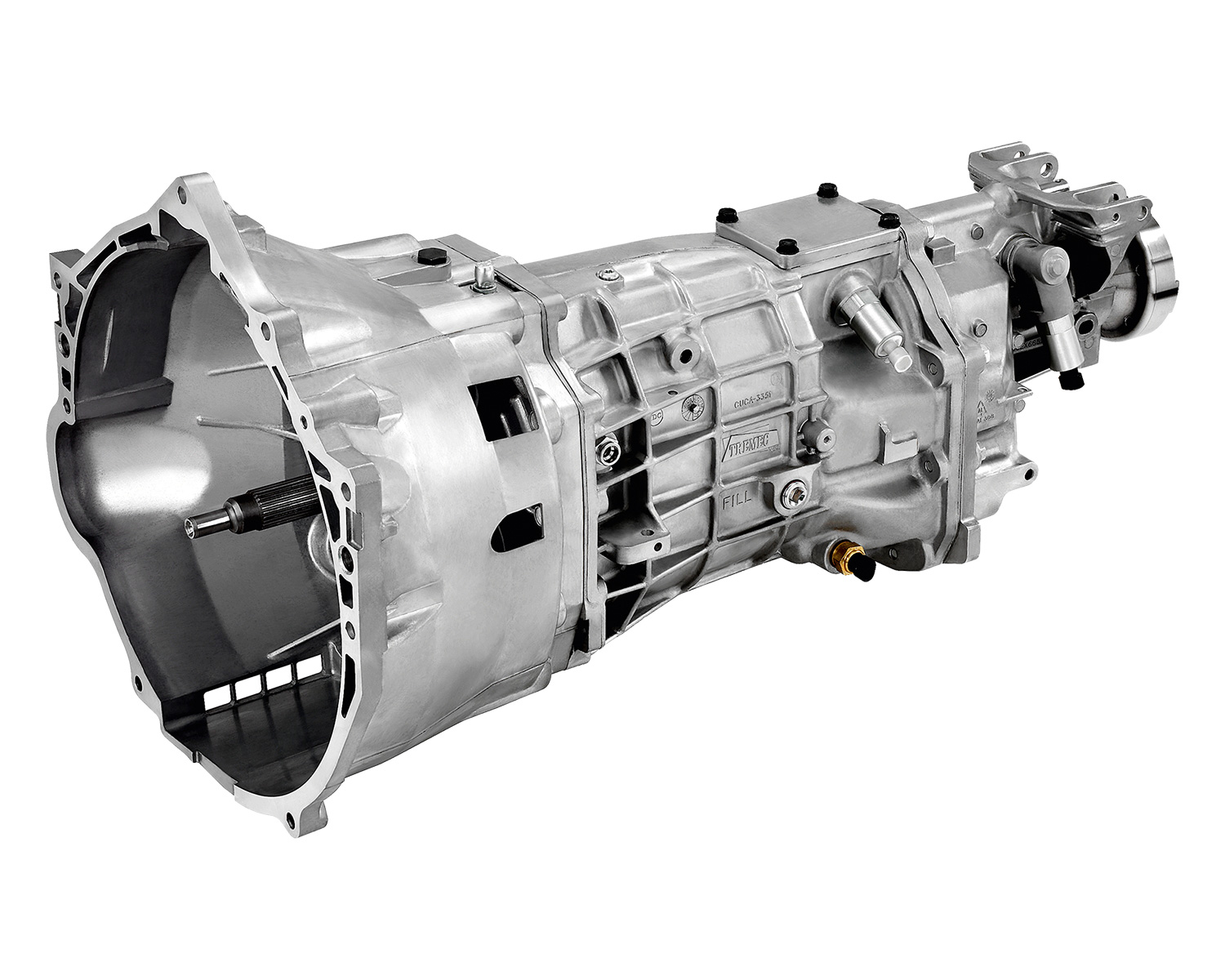

Tremec TR6060

The Tremec TR6060 six-speed manual took over as the stronger and newer replacement for the T56. The TR6060 uses removable wear pads on the shift forks, and an alloy main case, extension housing, and clutch housing. Rated at 600 ft·lb, it’s a seriously strong box — hence it being used in the HSV range from 2008 onwards, 2008 to 2013 Corvettes, the FG Falcon range, and the 2010 onwards high-performance Camaros.

The TR6060 features triple synchromesh on first and second gears, and double synchromesh on all other gears, including reverse, and that offers significantly reduced gear-shift effort and shift travel. The reduced shift travel has made for increased space to allow for the use of larger gears, which are stronger, to deliver improved torque capacity and gearbox durability. A new single-piece counter shaft contributes to the greater torque capacity and durability enhancements.

The broached forward and rearward shift detent grooves help to offer more precise control of shift detents and a positive shift feel. These are a great option for a high-performance build, and one of the best brand-new options in the market.

Expert’s opinion

Chris Hogg from The Gearbox Factory says: “They’re a larger box, so you’ve got to make sure you’ve got plenty of room. They do give you two extra cruising gears, as they’re a six-speed, so good for long journeys, but if you’re mainly driving around town, you’ll be changing gear all the time, and you won’t ever get up into fifth and sixth.