A few lads from the land of the long white cloud build the ultimate Mopar to take to the long white dyno!

Words: Todd Wylie Photos: Richard Opie

For many people, 2020 was promising big things! Mandy Sinclair was one such person, having decided that after visiting the salt flats of Bonneville a couple of times, 2020 would be a perfect year to return, via Las Vegas where she and husband Andrew could renew their wedding vows. Andrew, being the loving husband he is, agreed to that idea … as long as the wedding was at the drive-through with a land-speed car on the trailer. Being equally as car mad as him, Mandy agreed, and plans were set in motion for the trip of a lifetime.

Of course, there’s a long back story about why Andrew had his heart set on building a machine that he could hit 200mph in across the Bonneville Salt Flats in that well predates the vow renewal. In fact, the story goes three decades back. Starting his racing career when he was just 17, Andrew has always been fascinated with all forms of motorsport. Pursuing his interest, he ended up reading a book on the achievements of Ab Jenkins, the 24th mayor of Salt Lake City. Ab was also a racer, piloting a car known as the ‘Mormon Meteor’, and was instrumental in setting up land-speed racing in the area and making sure that international drivers knew all about what Bonneville had to offer. Well aware of Ab’s achievements, and the appeal of the salt, when the chance came up to make a trip there with a bunch of fellow Central Muscle Cars racers in 2008, Andrew jumped at the chance. While there is plenty from that tour that will forever stay on tour, we can tell you that the lads had a hell of a time, with highlights that include standing on top of a camper and listening to a 500-cube engine on nitro run down the salt at 7000rpm. Andrew recalls that enlightening experience: “Holy shit, it was the best noise I had ever heard!”

“Anyway, while there,” he continues, “we got drunk — again — and I said to my brother-in-law Paul, ‘Shit, we have to do this’, and we shook on it.”

From the sounds of it, anybody who knows Paul knows that when a deal is done on a handshake, it’s stuck to, a statement that Andrew confirms by saying, “he’s done some pretty wild things on a handshake”.

With an idea in mind, but a global financial crisis and a wrecked circuit race car to deal with, the salt-racing dream was going to have to wait a few years, but the plus side was that this would allow plenty of time for a car to be built slowly and built well instead of rushed for the sake of it — besides, the handshake deal never included a set timeframe.

With a few years to dream up a plan, there was certainly no shortage of ideas bounced around by those in the know, although there was always one thing that was set in stone. That was that the car would be built and managed by Mike ‘Bic’ Anderson at Sonic Race and Machine in Tauranga. Bic’s been an essential part of the Sinclair family’s racing programme for many years now, and, being a lifelong race engineer, including plenty of time working on cars for various premier US racing series, his knowledge and expertise are second to none.

It wasn’t until 2015 when things really kicked into gear, which was a time when Andrew had been spending plenty of time with fellow Australian madman and racer Paul Stubber. Andrew explains: “He invoked the Anzac spirit and said, ‘Shit, why don’t we both get cars, one Aussie, one Kiwi?’ He just happened to have an HQ Monaro, a spare Nascar motor, 12-bolt diff, and a four-speed Tex sitting in the shed, and he was keen to build a rat rod out of all his old shit. By then, I was getting pretty enthusiastic about Hemis, so I thought a New Zealand car with a Hemi was the way, so it had to be a New Zealand–assembled Valiant Charger.”

The logic behind the decision was simple. Most Yanks wouldn’t know what a Valiant Charger was, and, as far as aerodynamics are concerned for old cars, the Charger was ahead of its time. In the early days, the plan was to run it on the salt then bring it home and transform it into a circuit car, but the idea soon morphed into building a much more serious, dedicated land-speed racer, and the car is all the better for it.

“While Bic furiously looked up all sorts of classes, engine combos, etc., I started looking at logistics,” states Andrew.

The two would come together for regular liquid-enhanced planning sessions, and, after around six months, the class and engine size were decided on.

“Hats off to Bic here. There are so many classes available, it can get quite daunting when you are starting from a clean sheet of paper,” states Andrew. “This was when the mechanical injection idea came in, as having a cool car was right up there with having a fast car. Actually, cool was probably more important then, as I had a dream of doing 200mph, joining the 200mph club, and getting a red hat — easy. It was only on a subsequent trip that I read the rules fully and realised I have to beat a record over 200mph, and, by then, we had decided on ‘A’ up to 500 cubic inch — ‘C’ Classic — ‘B’ Blown — ‘F’ Fuel ALT Altered, and the record for this class was 247mph already.” Needless to say, the desire to go fast had become even more important, as it often does.

With a set direction, you’d think it would all be plain sailing, but anyone who’s ever dealt with the Southern California Timing Association’s (SCTA) rule book would soon let you know it’s not quite that simple. “Bic’s had some interesting times trying to decipher the rule book,” Andrew says. Thankfully, Kiwi Steve Davies, who is head scrutineer for SCTA has been on hand to help out.

“They don’t prescribe that much besides safety items. They just let you build it, then encourage other competitors to protest you if they think it’s outside of the rules — very different to how we do it,” Andrew laughs.

When it came time to piecing together the monster Hemi, the guys had initially intended to get the engine built overseas — that was until they came across Warren and Dean Landon of Landon Motorsport. Discussing the build requirements with them, it was clear that they were more than capable of building a kickass combo that would create the power required.

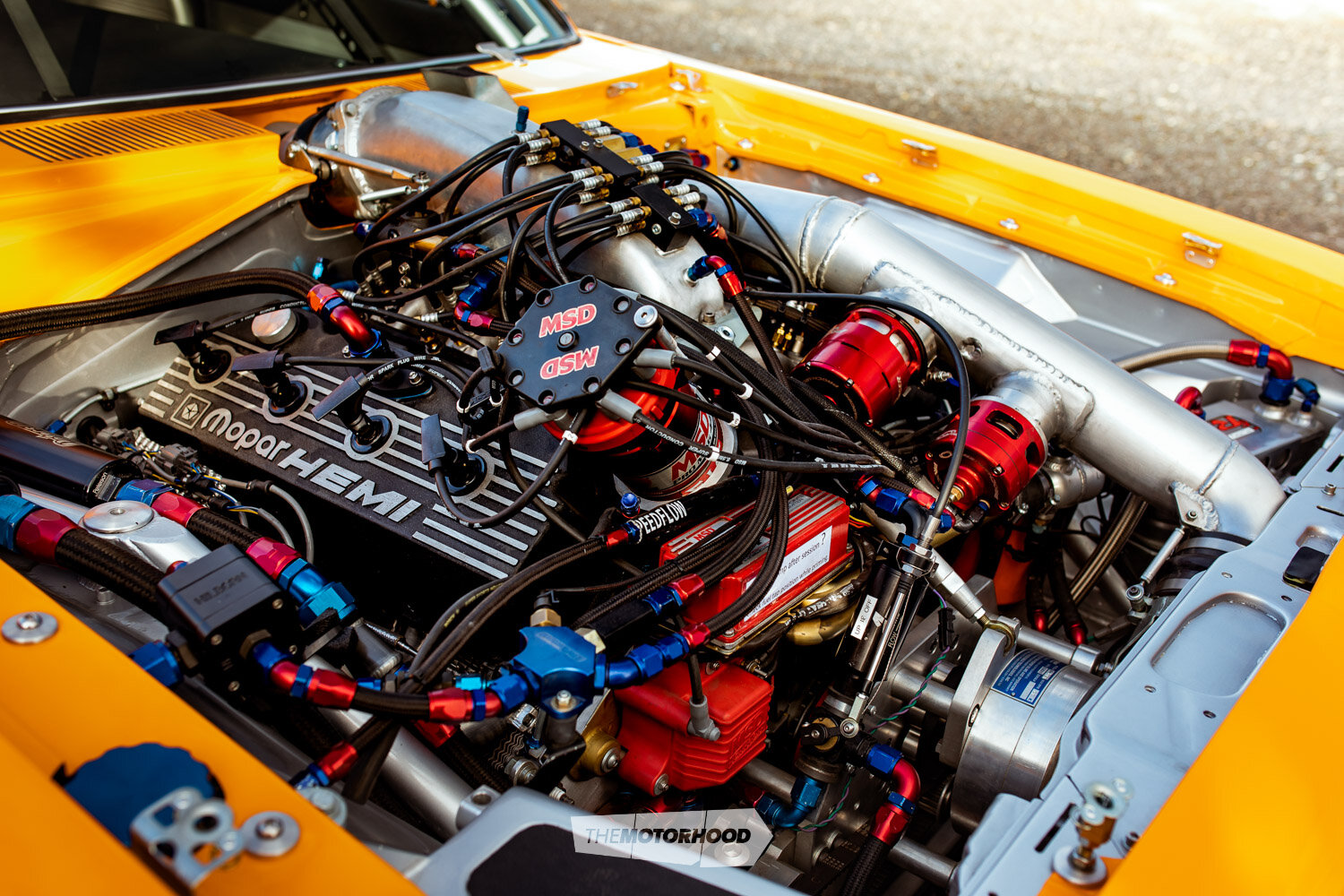

“I have been really impressed with their effort both in thinking/designing and also their work effort to stick to timeframes when we are building such a custom engine with no real book to go by,” Andrew mentioned to NZV8, back when the engine was still being built. To come in under the 500ci class limit, the Landon Motorsport guys filled the Keith Black Gen II Hemi block with CP pistons, Crower rods, and a Windberg crank to displace a total of 495ci.

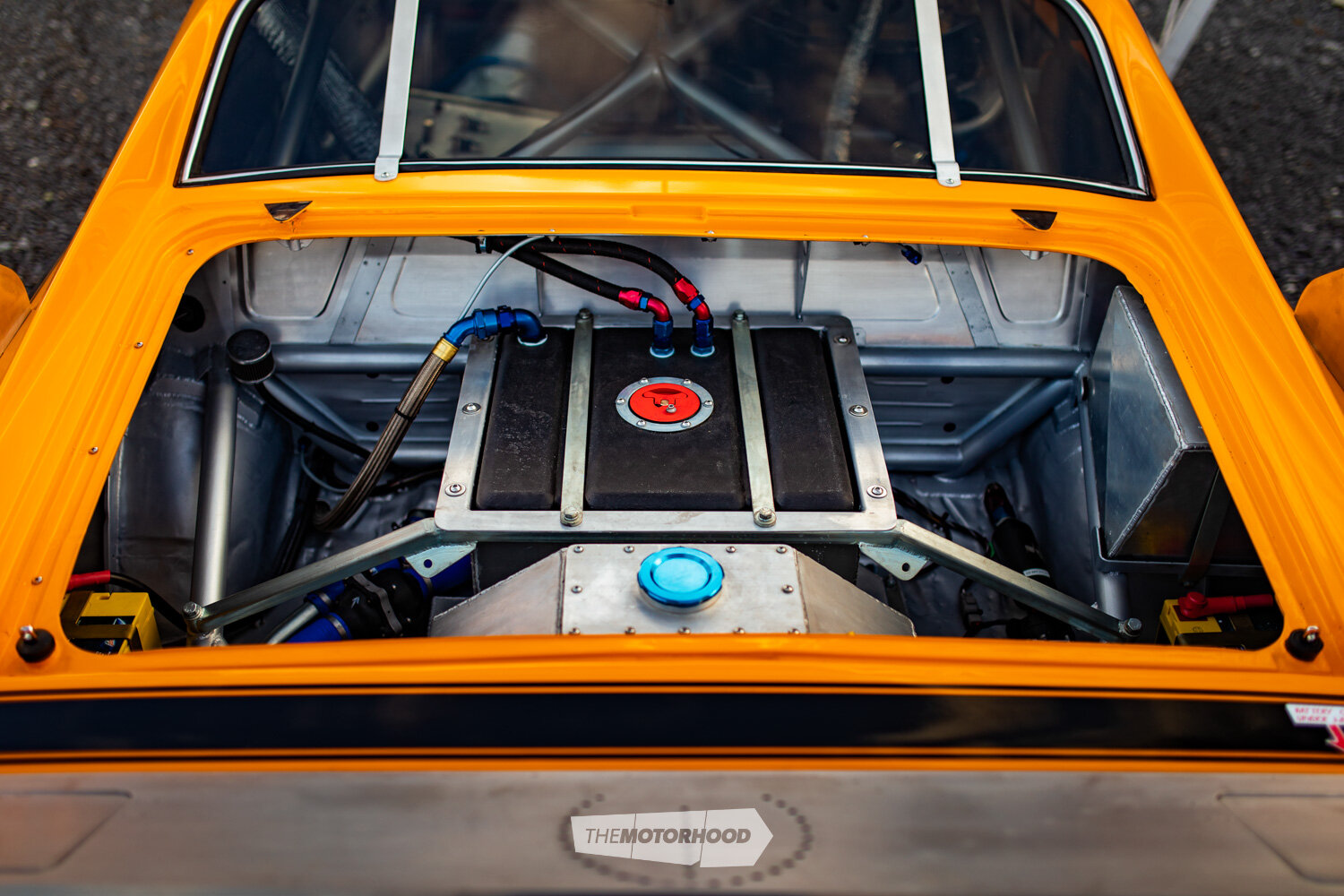

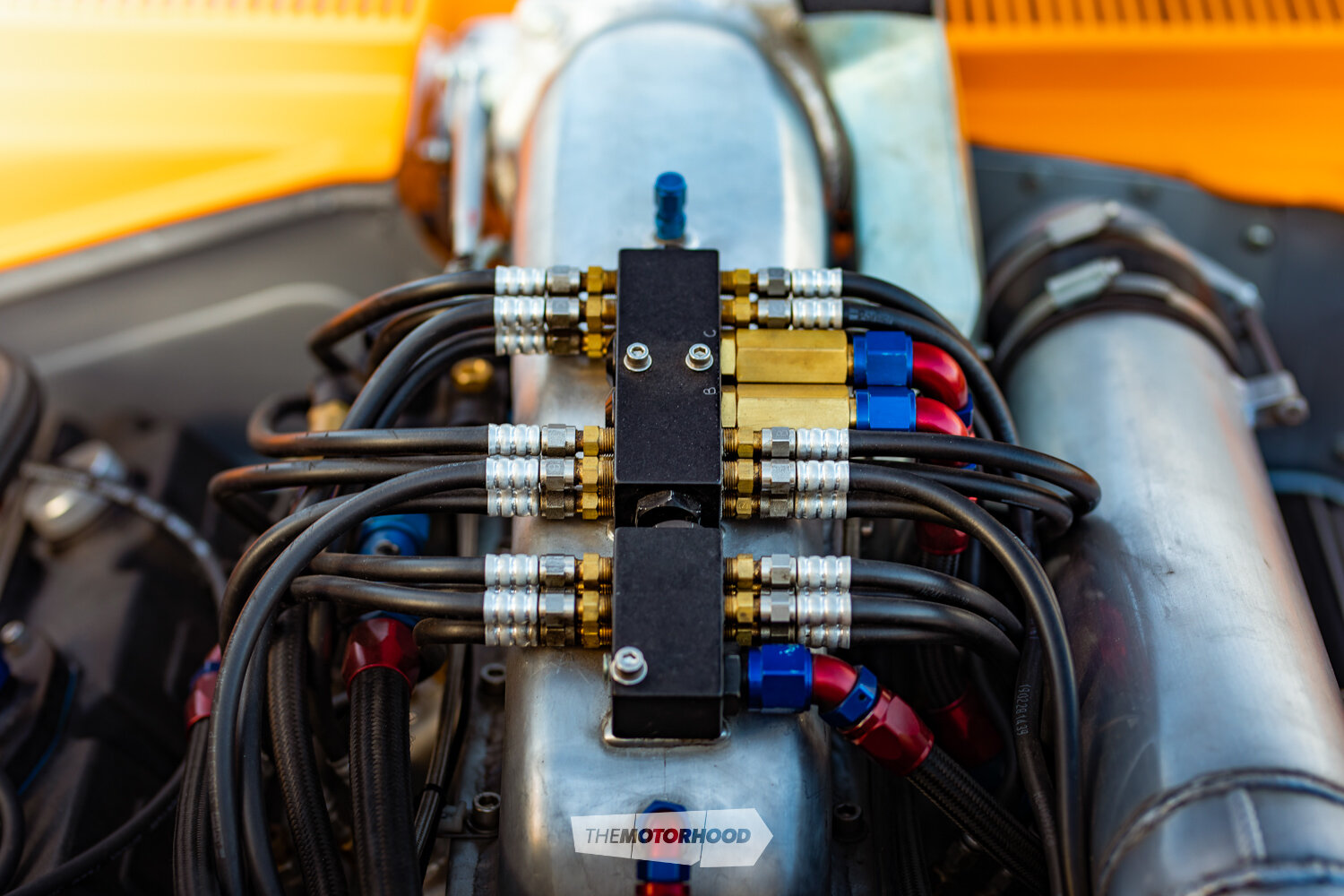

As you’d expect from a combo designed to run at high rpm for extended periods, there are plenty of internal secrets. The not-so-secret parts include the modified wet heads, now packing T&D rocker gear along with custom valves, and these are attached to the block via Cometic gaskets. A Jesel belt drive hangs off the front and takes care of providing methanol to a Kinsler mechanical fuel-injection system. That system uses no fewer than three nozzles per cylinder to pump the copious quantities of fuel from a custom front tank, which is fed by an even more impressive custom rear tank. To ignite that liquid is an MSD Pro Mag 44 ignition system, which is usually found on high-end drag cars. The reason for such an impressive fuel and ignition system should be screamingly obvious, and that is the giant F-1X-12 ProCharger swinging off the front of the motor. The ProCharger utilises a F3 gearbox and Supercharger Store drive system to run directly off the front of the crank.

The big difference between this and a drag-specific set-up is that, since the car will be fighting high ambient air temperatures as well as even higher intake temperatures, a custom Shearer Fabrications intercooler system has been added. The chilled air flows from the intercooler through to a five-inch Accufab throttle body mounted to the custom intake manifold that Bic created. The exhaust gasses created from this monster combination are expelled through a short set of zoomie headers. While the zoomies are primarily for the power advantage they offer, we can’t help but suspect that maybe Andrew is pretty keen on the noise the car will make through them too!

Keen eyes may have noticed the MoTeC sensors all over the car — around 25 in total. They’re not there for EFI but to allow for comprehensive data logging; as, let’s face it, if you’re packing up a race car and sending it to the far side of the world for a few days of racing, you want to make sure that you give yourself every possible chance of success.

Those sensors measure everything from ride heights to suspension travel, all temps and pressures, wheel speeds, and O2 levels. As Bic wisely states, “After the first few salt runs, you need all the data you can gather to make the smartest decisions going forward.”

During the build process, the guys took the unpainted and incomplete car for a few test hits on the airstrip at Tokoroa. Keeping in mind that Andrew has driven more than his fair share of quick street cars and race cars, it’s impressive when he came out of the test runs with a ‘holy shit’ look plastered on his face.

“I’ve never driven anything with that much root before … 700-odd horsepower in a track car is sure a whole lot different,” he says. “This thing is wild. It scared the shit out of me on the first run, but after a number of runs I was keen to have more space and be able to stretch its legs.”

Following this, he’s been trying relentlessly to get the chance to run the car at Ohakea, but has had no success with the powers that be as yet.

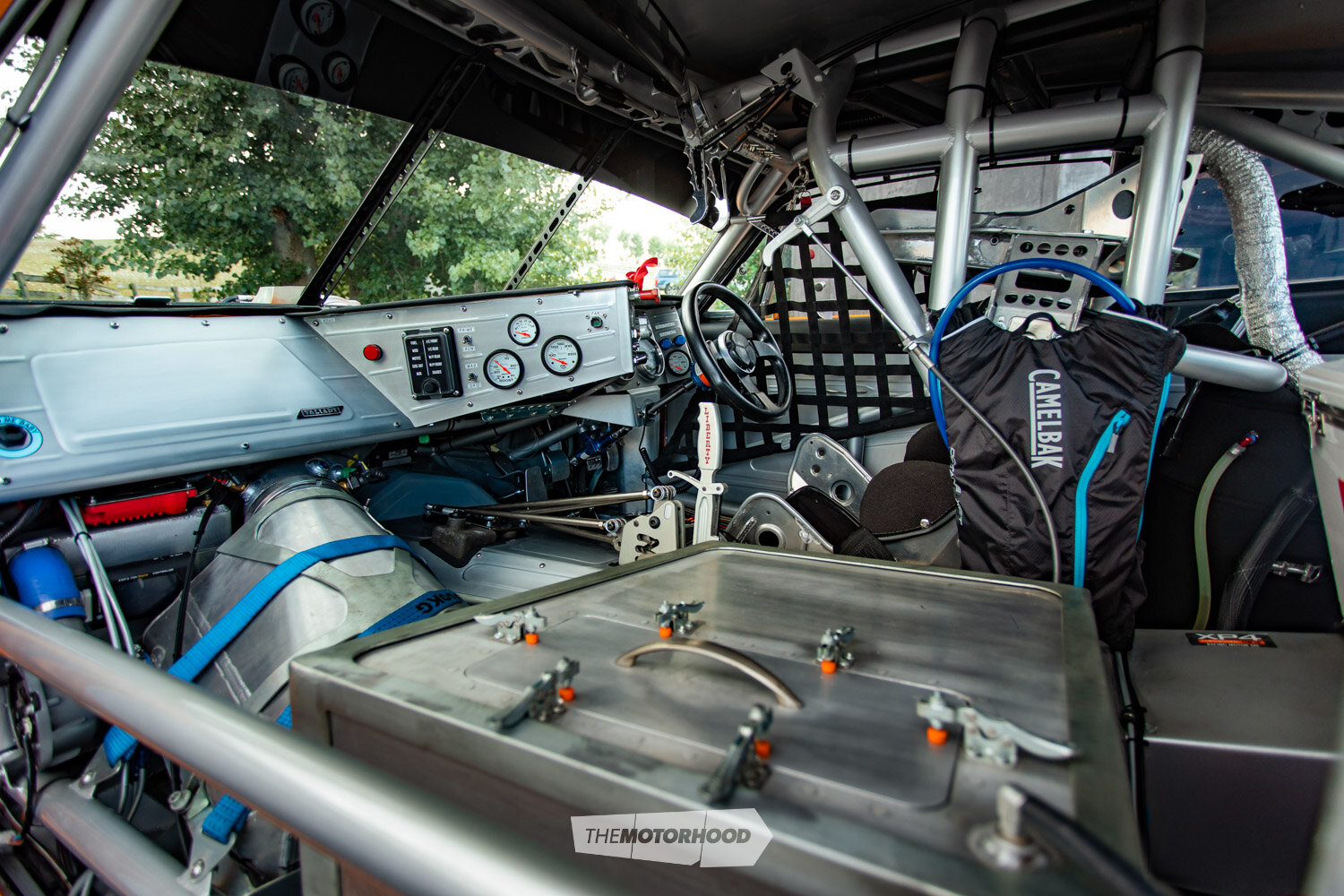

If the team doesn’t get that chance, it may not be till they head overseas that Andrew will be able to run the Liberty Extreme five-speed transmission through all its gears. At least, however, the Crower Prosportsman twin-disc clutch, Jerry Bickel driveshaft, and Winters Extremeliner rear end are all working perfectly. While you’d probably think that a land-speed car may not need much suspension — as, in theory, it should be racing on an incredibly flat surface — salt conditions vary wildly from year to year. As such, the team didn’t want to arrive and not be able to run due to a rough track, as plenty of cars have encountered in the past, so Bic used nothing but the best Penske coilovers in the car. These are working with custom A-arms up front and a three-link rear end, along with a custom front roll bar. Naturally, those front A-arms aren’t attached to a traditional Charger front end but instead to a custom space-frame chassis that has been constructed utilising the original front chassis rails. With overall weight not being a huge issue, the chassis could be built for maximum driver safety as well as positioning all components exactly where Bic wanted them for serviceability and weight distribution.

To fit the big Hemi, transmission, and to allow for the cage to be built, much of the original firewall was removed; Bic estimates that there’s about one square foot of the original left. The same goes with the car’s floorpan, which has had various areas chopped out and replaced to allow for items such as the quick-change rear diff and raised driveshaft tunnel. The hours of fabrication extend into all the engine ancillaries, which include no less than 10 custom built tanks and numerous coolers for various different fluids. While the electrical side of things was taken care of by Matt at Sparked Electrical, the complex plumbing on the car was all done by Bic, and there’s plenty of it. The completed engine bay definitely falls into the category of function over form. Mind you, with a big-arse Hemi and front-driven ProCharger, there’s not many engine bays that look tougher, either!

Likewise, the interior is all business, with a Kirkey seat, a Liberty shifter, and a custom steering wheel being the main features, along with an old-school analogue dash in keeping with the era of the car, and AutoMeter gauges to keep an eye on the Hemi’s vital stats. The custom pedal box is in charge of Wilwood six-pot calipers at the front and four-pots at the rear, which clamp custom rotors up front and Wilwood items out the back. While they’re overkill in theory, as twin parachutes should take care of slowing the car down on the salt, knowing that any testing would need to be done with shorter run offs, the comprehensive brake system was also a good investment in driver (and car) safety.

The custom front air dam, rear spoiler, and roof rails are the only body mods allowed to fit within the CBFALT class, so once the car was tested, it was stripped completely, put back on the rotisserie, and sent off to Craig and the boys at Greerton Panel and Paint to have the panels straightened and coated in Spies Hecker McLaren Papaya paint.

Just as we go to print, the completed car is being revealed to Andrew’s friends and supporters for the first time. Many of these people, around 50 in fact, were also scheduled to be attending the car’s initial debut at Bonneville in late 2020. While Mandy may like to think they were going just for the drive-through wedding, we suspect that the allure of hearing a 500ci Hemi scream its heart out across the salt flats of Bonneville may have a large part to do with it too.

Having attended Bonneville in 2017, 2018, and 2019, many American locals that the couple have become friends with along the way were looking forward to seeing the New Zealand–built creation as well. Obviously, that now has to wait till the madness of Covid clears, as only then will the car be strapped into the custom modified shipping container that will become the team’s home away from home. The container is complete with essentials such as a kitchen and rooftop viewing deck, along with a full workshop facility. Once on the salt, the crew will consist of a mix of Kiwis including Bic, Brent ‘Flash’ Gordon (Bic’s second in command), Wayne Patten, and Peter Barker. Pete’s role as chief cook — not to mention truck driver and unofficial photographer — makes him a very popular member of the group. American data guru Randy Gibson, who Bic worked with while living in the States, will join the fray too, giving them even more expertise — not that they are lacking in that department.

Depending on how Covid continues to affect the world, plan B is to head to Lake Gardiner in South Australia. Logistically, it’s much tougher than Bonneville, with absolutely nothing for a couple of hundred kilometres around the race venue, meaning that they must be completely self-sufficient. Until the world is opened up to international travel again, the team are all dressed up with no place to go. A run down the airstrip at Ohakea would still be nice if it can be arranged, as really, with a car of this calibre, there’s nowhere else locally to safely unleash its full potential. Mind you, the dream of hitting 200mph has been in the works for many years now, and Andrew and Mandy have already been married for 30 years, so what’s a few more years to wait?

This article originally appeared in NZV8 issue No. 190